Vacuum Assisted Die Casting Design for Flawless Parts

TL;DR

Vacuum assisted die casting design focuses on creating components using a process that removes air and gas from the die cavity with a vacuum before injecting molten metal. This critical step significantly reduces gas porosity, leading to parts that are denser, stronger, and have a superior surface finish. Proper design, including considerations for wall thickness and die sealing, is essential to leverage this process for producing complex, high-performance, and defect-free components.

Fundamentals of Vacuum Assisted Die Casting

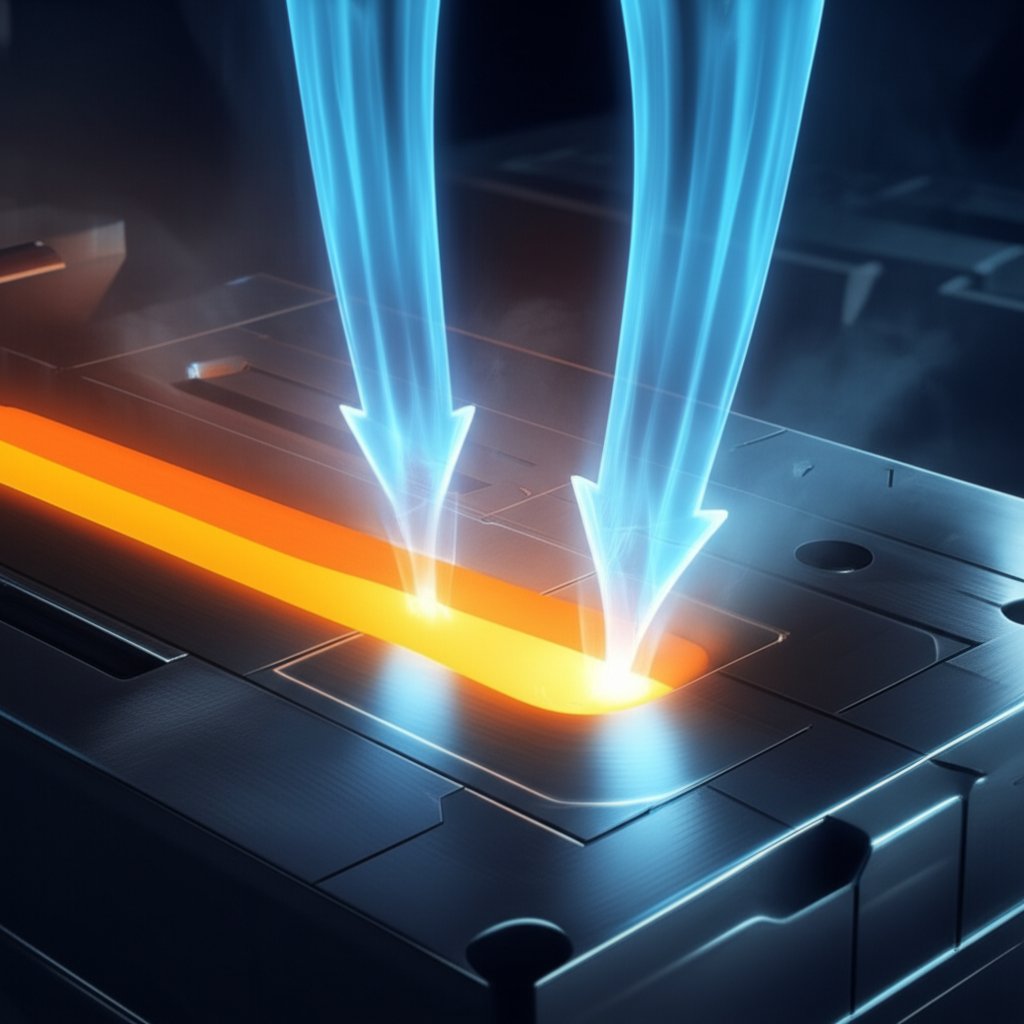

Vacuum assisted die casting, sometimes called gas-free die casting, is an advanced manufacturing process that enhances traditional high-pressure die casting. Its core principle is the systematic removal of air and other trapped gases from the mold cavity and shot sleeve before the molten metal is forced in. By creating a near-vacuum environment, the process addresses one of the most persistent challenges in conventional die casting: gas porosity. This is achieved by connecting a powerful vacuum system to the die, which evacuates the cavity moments before and during the injection of the molten alloy.

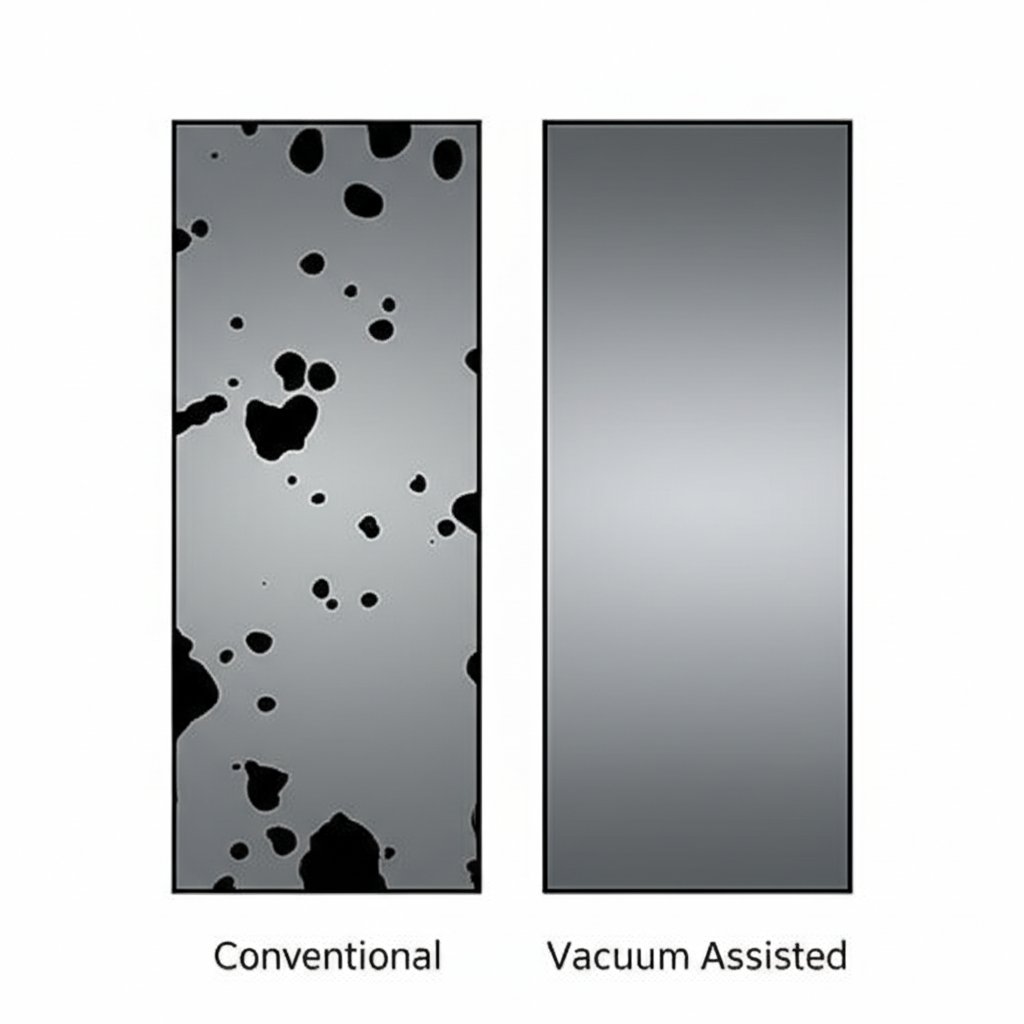

The fundamental problem this technology solves is gas entrapment. In a standard die casting process, the high-velocity injection of molten metal can trap pockets of air inside the die. These trapped gases create voids or pores within the solidified metal, compromising its structural integrity. According to manufacturing experts at Xometry, this porosity can lead to inconsistent mechanical properties and weak spots. The vacuum process mitigates this by removing the air that would otherwise become trapped, allowing the molten metal to fill every detail of the mold without resistance or turbulence.

Compared to conventional die casting, the vacuum-assisted method produces a demonstrably higher quality part. The evacuation of the die not only prevents bubble formation but also helps draw the molten metal into intricate and thin-walled sections of the mold more effectively. This results in components that are denser, stronger, and feature a much cleaner surface finish. As noted by the North American Die Casting Association, while a vacuum system is a powerful supplement, it does not replace the need for sound die casting design practices in engineering the runners, gates, and overflows. The combination of good design and vacuum assistance is what unlocks the highest level of quality.

Core Advantages and Quality Improvements

The primary advantage of employing a vacuum in the die casting process is the dramatic improvement in part quality and integrity. By minimizing gas entrapment, the process yields components with significantly reduced porosity. This leads to castings that are not only denser but also exhibit more consistent and predictable mechanical properties, such as higher tensile strength and elongation. This reliability is critical for components used in demanding applications, including the automotive and aerospace industries.

Another major benefit is the superior surface finish. Defects like blistering and pinholes, which are often caused by expanding trapped gases near the surface, are virtually eliminated. This results in cleaner surfaces straight from the mold, reducing the need for costly and time-consuming secondary finishing operations. As detailed by KenWalt Die Casting, this reduction in defects leads to fewer rejected parts, saving time, labor, and material costs. Furthermore, the uniform filling of the mold under vacuum can extend the lifespan of the tooling by reducing the high internal pressures and wear associated with trapped air.

The quality improvements also open up new manufacturing possibilities. Parts produced via vacuum die casting are suitable for post-processing treatments that are often problematic for conventionally cast parts. Because there is little to no trapped gas to expand and cause defects, these components can be reliably heat-treated, welded, or plated. This capability is essential for structural parts that require enhanced strength or specific surface characteristics.

| Issue in Conventional Casting | Solution with Vacuum Assistance |

|---|---|

| Gas Porosity | Evacuates air from the die, preventing voids and creating denser parts. |

| Surface Blistering | Eliminates trapped subcutaneous gas, resulting in a smooth, defect-free surface. |

| Incomplete Fill (Miss-runs) | Vacuum helps draw metal into thin walls and complex features, ensuring complete mold filling. |

| Inconsistent Strength | Reduces internal defects, leading to more uniform and reliable mechanical properties. |

| Limitations on Heat Treatment | Produces parts with minimal internal gas, allowing for safe heat treatment without blistering. |

The Vacuum-Assisted Process: A Step-by-Step Breakdown

While based on the traditional die casting workflow, the vacuum-assisted process incorporates a critical additional phase. Understanding this sequence is key to appreciating its impact on design and final part quality. The process generally follows these distinct steps:

- Die Preparation and Closing: The two halves of the steel die are first cleaned, lubricated with a release agent, and securely closed. A critical design aspect here is ensuring the die has effective seals to maintain the vacuum once it is applied. Any leaks will compromise the process.

- Vacuum Application: With the die closed, a high-capacity vacuum pump is activated. Valves connected to the die cavity and runner system open, and the pump evacuates the air and any gases from lubricants, creating a low-pressure environment inside the mold. This step must be precisely timed.

- Molten Metal Injection: The desired metal alloy, melted in a furnace, is transferred to the machine's shot chamber. A high-pressure plunger then injects the molten metal into the evacuated die cavity. The vacuum helps to pull the metal smoothly into the mold, ensuring it fills every detail without creating turbulence.

- Solidification and Cooling: Once the cavity is filled, the molten metal begins to cool and solidify, taking the shape of the die. The die is often equipped with internal cooling channels to control the rate of solidification, which is crucial for achieving the desired metallurgical properties.

- Die Opening and Part Ejection: After the casting has solidified, the vacuum is released, and the die halves are opened. Ejector pins then push the finished casting out of the mold. The part is now ready for any necessary secondary operations like trimming, machining, or surface finishing.

This entire cycle is extremely fast, often completed in a matter of seconds to a couple of minutes, making it highly suitable for high-volume production. The integration of the vacuum system adds complexity but is essential for achieving the superior quality this process is known for.

Key Design Principles for Vacuum Die Casting

Effective vacuum assisted die casting design goes beyond just creating a shape; it involves optimizing the part's geometry to fully leverage the benefits of the vacuum environment. While many principles overlap with conventional casting, some are especially critical. To be successful, careful attention to features like wall thickness and draft angles is paramount.

One of the most significant design advantages is the ability to produce parts with thinner walls. Because the vacuum reduces the back-pressure from trapped air, molten metal can flow into and fill much thinner sections than in traditional die casting. A minimum wall thickness of 1mm to 1.5mm is often achievable, though this depends on the part size and material. It's crucial to maintain uniform wall thickness where possible to ensure consistent cooling and prevent defects like warping or sink marks. When thickness variations are necessary, the transitions should be gradual.

Other key design considerations are essential for both part quality and manufacturability:

- Draft Angle: A draft angle, typically at least 1 to 2 degrees, must be incorporated on all walls parallel to the die's direction of pull. This slight taper is crucial for allowing the finished part to be ejected cleanly from the mold without damage or distortion.

- Ribs and Bosses: To add strength to large, flat areas without increasing overall wall thickness, designers should incorporate ribs. The thickness of a rib should generally be less than 60% of the main wall thickness to avoid sink marks. Similarly, bosses (used for mounting or alignment) should follow similar thickness rules.

- Fillets and Radii: Sharp internal corners are a source of stress concentration and can impede metal flow. Generous fillets and radii should be added to all corners to improve the part's structural integrity and facilitate a smoother, more uniform flow of molten metal.

- Die Sealing: From a tooling design perspective, ensuring the die can be hermetically sealed is non-negotiable. This involves precise machining of the die halves and often includes incorporating O-rings or other sealing mechanisms to prevent vacuum loss during the cycle.

By adhering to these principles, designers can create robust, lightweight, and complex components that take full advantage of the vacuum-assisted process, resulting in higher yields and superior performance.

Frequently Asked Questions

1. What is the main difference between vacuum casting and traditional die casting?

The primary difference is the use of a vacuum to evacuate air and gases from the die cavity before molten metal is injected. Traditional die casting injects metal into a die filled with air, which can become trapped and cause porosity. Vacuum die casting removes this air, resulting in denser, stronger parts with fewer defects and a better surface finish.

2. What metals are suitable for vacuum assisted die casting?

The process is most commonly used with non-ferrous alloys that have moderate melting points. This includes a wide range of aluminum alloys (like A380), magnesium alloys (for lightweight structural components), and zinc alloys. Ferrous metals like steel and iron are generally not suitable due to their high melting temperatures, which would damage the die casting tooling.

3. Can vacuum die casting eliminate all porosity?

While vacuum die casting significantly reduces gas porosity to near-zero levels, it may not eliminate all forms of porosity. Shrinkage porosity, for example, can still occur due to the metal's volume reduction as it cools and solidifies. However, proper part and mold design, including optimized gate and runner systems, can help minimize this type of porosity as well.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —