Vacuum Die Casting for Automotive Parts Explained

TL;DR

The vacuum die casting process is an advanced manufacturing method that uses a vacuum to remove air and other gases from a mold cavity before molten metal is injected. For the automotive industry, this technique is crucial because it significantly minimizes porosity, leading to the production of stronger, denser, and more reliable metal components with superior structural integrity and surface finish.

What is Vacuum Die Casting and Why is it Crucial for Automotive?

Vacuum die casting, also known as gas-free or vacuum-assisted high-pressure die casting, is a sophisticated evolution of the traditional die casting process. The core principle involves injecting molten metal into a reusable steel mold (a die) under high pressure to form complex parts. The defining feature of this method is the integration of a vacuum system, which evacuates nearly all air and trapped gases from the die cavity just before the metal is forced in. This seemingly simple addition fundamentally transforms the quality and capabilities of the casting process. By removing the atmosphere within the mold, the molten metal can flow into every intricate detail of the cavity unimpeded, preventing the formation of bubbles and voids.

In conventional die casting, air trapped within the die can become interspersed in the solidifying metal, creating tiny pockets or pores. This gas porosity is a major defect that can compromise a component's mechanical strength and lead to unpredictable performance failures. The vacuum die casting process directly solves this problem. By creating a near-vacuum environment, there is simply no air to get trapped. The result is a casting that is significantly denser, more uniform, and free from the internal flaws that plague standard castings. This improvement in material integrity is precisely why the technique is so critical for the automotive sector.

The automotive industry operates under immense pressure to produce vehicles that are safer, more fuel-efficient, and longer-lasting. This requires components that are both lightweight and exceptionally strong. Vacuum die casting enables the production of parts that meet these demanding criteria. For example, structural components like chassis nodes, suspension parts, and engine blocks can be cast with thinner walls without sacrificing strength, contributing directly to vehicle weight reduction. Furthermore, the low porosity of these parts means they can be reliably heat-treated to further enhance their mechanical properties or welded during assembly without the risk of defects like blistering, which can occur when trapped gases expand. This makes it indispensable for manufacturing high-performance and safety-critical automotive parts.

- Enhanced Structural Integrity: Minimized porosity leads to components with superior strength and durability.

- Weight Reduction: The process allows for the design of complex, thin-walled parts, reducing overall vehicle weight and improving fuel economy.

- Improved Performance: Parts exhibit consistent and predictable mechanical properties, crucial for safety-critical applications like suspension and engine components.

- Post-Processing Capability: The defect-free nature of the castings makes them suitable for secondary operations like welding and heat treatment.

- Superior Surface Finish: The smooth flow of metal results in a higher quality surface that often requires less finishing work.

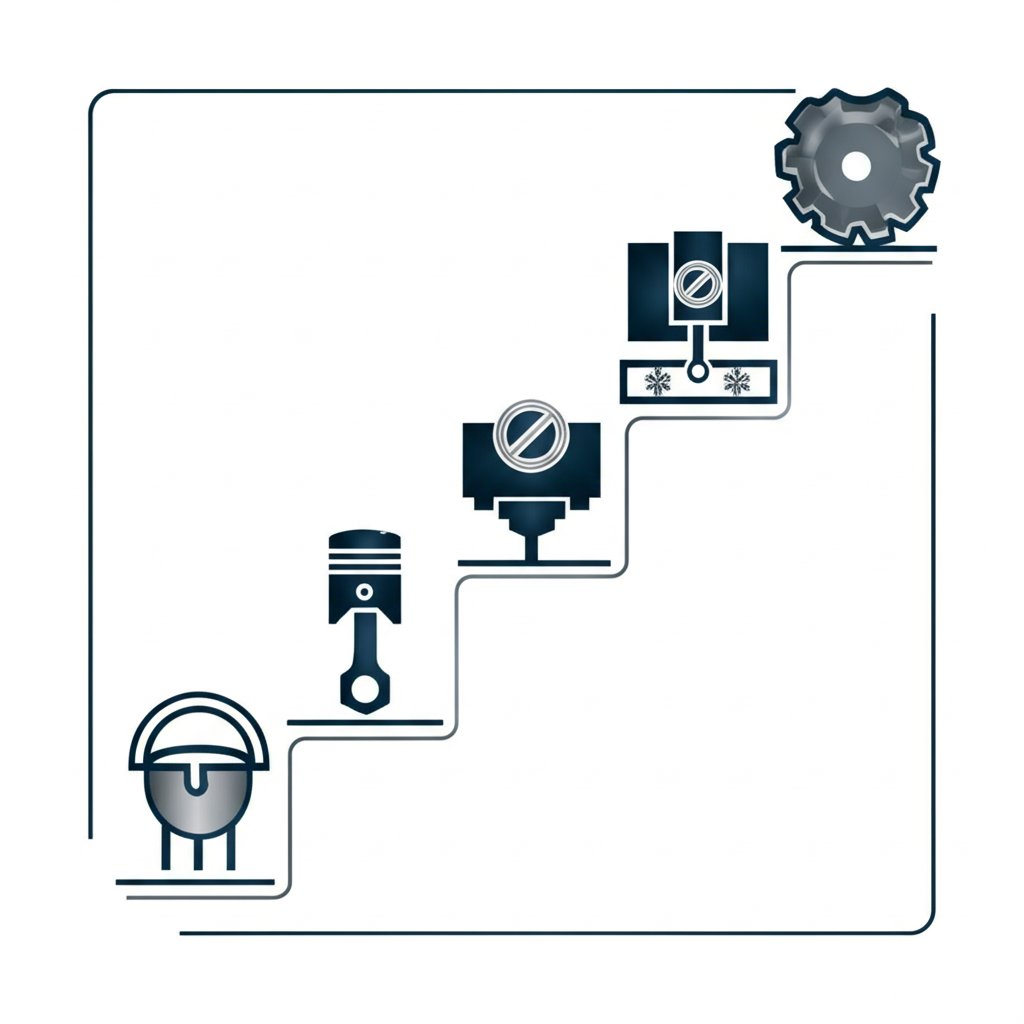

The Step-by-Step Vacuum Die Casting Process

The vacuum die casting process follows a highly structured sequence of operations designed to maximize quality and repeatability. While it shares a foundation with traditional die casting, the integration of the vacuum stage is a critical differentiator that occurs just before metal injection. Each step is meticulously controlled to ensure the final component meets precise engineering specifications.

- Mold Preparation: The process begins with the die itself, which is typically machined from high-grade tool steel to withstand extreme temperatures and pressures. The internal cavity is a negative replica of the desired part. Before casting, the two halves of the die are cleaned, and a release agent is applied to their surfaces. This lubricant ensures that the solidified part can be easily ejected from the mold later without damage.

- Melting the Metal: Concurrently, the selected metal alloy—typically an aluminum, zinc, or magnesium formulation—is heated in a furnace until it reaches a molten state. The temperature must be carefully controlled to ensure the metal has the correct fluidity to completely fill the die cavity during injection.

- Creating a Vacuum: This is the defining step of the process. Once the die is securely closed and clamped, a powerful vacuum pump is activated. This system is connected to the die cavity through valves and channels, and it rapidly removes air and other gases until a specific low-pressure level is achieved. This evacuation must happen quickly, in the moments right before injection.

- Molten Metal Injection: With the die cavity under vacuum, a precisely measured amount of molten metal, known as a "shot," is forced into the die from a shot chamber. This is done under extremely high pressure using a hydraulic ram or plunger. The vacuum in the cavity helps to draw the molten metal forward, ensuring it fills even the most complex and thin sections of the mold smoothly and completely.

- Solidification and Ejection: Once injected, the molten metal rapidly cools and solidifies as its heat is transferred to the steel die, which often has internal cooling channels. After the part has hardened sufficiently, the die halves are opened. An ejector pin mechanism then pushes the finished casting out of the die. The part is then ready for any necessary finishing operations, such as trimming excess material.

Key Advantages for Automotive Components

The adoption of vacuum die casting in automotive manufacturing is driven by a clear set of advantages that directly translate to better vehicle performance, safety, and efficiency. These benefits stem primarily from the near-elimination of gas porosity, which elevates the quality of the final component far beyond what is achievable with conventional methods. This allows engineers to design parts that are lighter, stronger, and more complex.

The most significant benefit is the dramatic enhancement of mechanical properties. With minimal internal voids, vacuum-cast parts exhibit higher tensile strength, ductility, and density. This uniformity allows for more accurate performance predictions and enables the creation of components that can withstand greater stress and fatigue. For the automotive industry, this means producing reliable engine components, transmission cases, and structural parts that form the vehicle's safety cage. This process makes it possible to produce high-quality thin-walled parts with repeatable and expected mechanical properties, a critical factor for mass production.

Another key advantage is the ability to produce parts with intricate geometries and very thin walls. In traditional casting, air pressure can prevent molten metal from filling small or thin sections, leading to defects. The vacuum removes this back pressure, allowing the metal to flow freely into every feature of the die. This capability is essential for modern automotive design, where complex, lightweight components like electronic housings and dashboard frames are common. The resulting parts also have a superior surface finish, reducing the need for costly secondary machining or polishing operations.

| Property | Vacuum Die Casting | Traditional Die Casting |

|---|---|---|

| Gas Porosity | Extremely low to negligible | Moderate to high |

| Tensile Strength | High and consistent | Variable, often lower |

| Pressure Tightness | Excellent, suitable for fluid-carrying parts | Less reliable due to potential leak paths |

| Weldability / Heat Treatable | Yes, without blistering | No, trapped gases cause blistering |

| Thin Wall Capability | Excellent, allows for complex designs | Limited, prone to misruns |

Materials, Machinery, and Technology

The success of the vacuum die casting process relies on a synergistic combination of suitable materials, specialized machinery, and precise control technology. The selection of each element is critical to achieving the desired properties in the final automotive component.

The materials used must possess good fluidity when molten and favorable mechanical properties upon solidification. The most common alloys are non-ferrous due to their melting points and casting characteristics. These include:

- Aluminum Alloys: By far the most popular choice for automotive applications due to their excellent strength-to-weight ratio. Alloys like A380 are widely used for parts such as engine blocks, transmission housings, and structural components.

- Magnesium Alloys: Even lighter than aluminum, magnesium alloys such as AZ91D are used when maximum weight savings is the priority, for example, in steering wheel frames and instrument panels.

- Zinc Alloys: Known for their high ductility, strength, and excellent finishing characteristics, zinc alloys from the Zamak series are often used for smaller, more detailed components like housings and decorative hardware.

The machinery for vacuum die casting is an advanced version of a standard die casting setup. The key components include:

- Die Casting Machine: This can be a hot-chamber or cold-chamber machine, which holds the die, provides the clamping force, and powers the metal injection system.

- The Die/Mold: A two-part steel tool with the part cavity, runners, and gates, plus integrated channels for the vacuum system and for cooling.

- Vacuum System: This is the critical addition. It consists of a high-capacity vacuum pump, storage tank, valves, and control sensors that integrate with the machine's cycle to evacuate the die cavity at the precise moment.

- Melting Furnace: A separate furnace is used to melt the metal ingots and maintain them at the correct casting temperature.

While vacuum die casting is ideal for creating complex, net-shape components, it's important to select the manufacturing process that best suits the specific application's mechanical demands. For components requiring the utmost in strength and fatigue resistance, such as critical suspension or powertrain parts, processes like hot forging are often employed. For instance, specialists in automotive forging parts utilize advanced techniques to produce robust components engineered for high-performance scenarios.

Frequently Asked Questions

1. What is the main difference between vacuum and traditional die casting?

The primary difference is the use of a vacuum system. In vacuum die casting, air and gases are evacuated from the mold cavity before the molten metal is injected. Traditional die casting does not have this step, which often leads to trapped air causing defects like porosity in the final part. This makes vacuum-cast parts denser, stronger, and suitable for heat treatment.

2. What metals are commonly used in vacuum die casting?

The most common metals are non-ferrous alloys known for their excellent casting properties and suitability for automotive applications. These include various aluminum alloys (like A380), magnesium alloys (for lightweighting), and zinc alloys (for high detail and surface finish). Ferrous metals like steel are generally not compatible with the die casting process.

3. Can vacuum die-cast parts be welded?

Yes, one of the key advantages of vacuum die casting is that the resulting parts can be reliably welded. Because the process removes trapped gases, there are no internal pockets of air that would expand and cause blistering or weakness in the weld zone. This is a significant limitation for traditionally die-cast parts and a major benefit for automotive assembly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —