What Is the True Cost of Die Casting Tooling?

TL;DR

The cost of die casting tooling is a significant one-time investment, ranging from $60,000 to over $500,000 for large, complex, high-production tools. This high upfront expense is necessary because the dies are made from premium, durable tool steel to withstand the extreme pressures and temperatures of the casting process. While the initial investment is substantial, it is offset by a very low per-part cost, making die casting highly economical for mass production.

Understanding the High Cost of Die Casting Tooling

The first thing to understand about the cost of die casting tooling is that it's a major, but necessary, upfront investment. Unlike other manufacturing processes, the die or mold used in casting is subjected to exceptionally severe operating conditions. According to the North American Die Casting Association (NADCA), these dies must endure extreme thermal shock from molten metal and high pressures during injection, which dictates the need for high-quality, expensive materials and precision engineering.

This leads to a wide cost spectrum. For larger, more intricate parts, or multi-cavity molds designed for high-volume production, the price can escalate significantly, running from $60,000 to over $500,000. This tooling cost is typically a one-time expense paid by the customer, who then owns the tool even though it is stored and maintained by the die casting facility.

The justification for this high initial outlay lies in the economics of scale. The durability of the tool allows for the production of tens of thousands, or even hundreds of thousands, of identical parts with high precision and speed. This amortizes the initial tooling cost over the entire production run, resulting in a remarkably low cost per individual part, often making it the most cost-effective method for high-volume manufacturing.

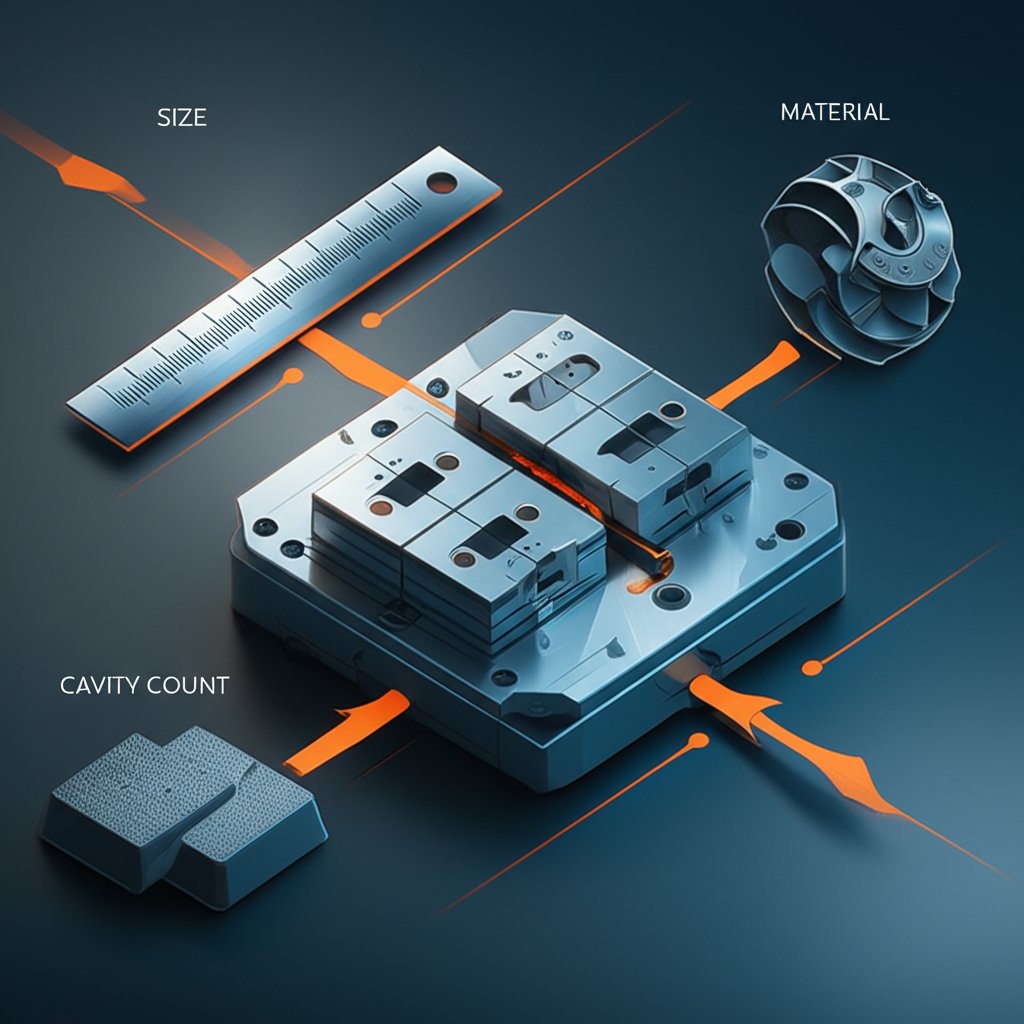

Key Factors Driving Your Tooling Costs

The final price tag on your die casting tooling is not arbitrary; it's a direct result of several interconnected design and production variables. Understanding these factors is crucial for engineers and product designers looking to optimize their parts for manufacturing and manage budgets effectively. Each element contributes to the complexity and robustness required of the mold, which in turn dictates the cost.

The primary drivers of tooling costs can be broken down into the following key areas:

- Part Size and Weight: This is the most straightforward factor. Larger and heavier parts require larger, more massive molds. This increases the amount of expensive tool steel needed and requires larger, more powerful machinery for both mold creation and the casting process itself, directly driving up costs.

- Part Complexity: The geometric complexity of a part is a major cost contributor. Features like deep cavities, sharp corners, minimal draft angles, and especially undercuts that require slides or lifters add significant complexity to the mold's design and construction. Each moving part within the mold increases machining time, assembly labor, and the potential for maintenance.

- Mold Material: Die casting molds are typically made from high-grade tool steel, such as H13, which is engineered to resist thermal fatigue and erosion from molten metal. The specific grade of steel and any required surface treatments or coatings will depend on the alloy being cast (e.g., aluminum vs. zinc) and the expected production volume, all of which influence the material cost.

- Number of Cavities: A mold can be designed with a single cavity to produce one part per cycle or multiple cavities to produce several parts at once. A multi-cavity mold has a much higher upfront cost but dramatically increases production efficiency and lowers the per-part price, making it ideal for very high-volume runs.

- Tolerances and Surface Finish: Parts requiring extremely tight dimensional tolerances or a superior as-cast surface finish demand a more precisely machined and polished mold. This level of precision requires more advanced machining techniques and skilled labor, adding to the overall tooling cost.

How to Estimate Die Casting Costs

Calculating the total cost of a die casting project involves two distinct components: the one-time tooling cost and the ongoing per-part cost. A comprehensive quote from a manufacturer will break down these elements. While online estimators can provide a rough idea, a formal quote based on a detailed design is necessary for accurate budgeting.

According to an analysis by Neway Precision, the mold cost itself is a sum of several parts: design fees, raw material costs for the tool steel, processing and manufacturing costs (like CNC machining and heat treatment), and trial fees. The per-part price is then calculated based on the cost of the metal alloy, the cycle time on the die casting machine, and any necessary secondary operations like trimming, machining, or surface finishing.

To receive an accurate and reliable quote for your project, follow these essential steps:

- Prepare a Detailed 3D CAD File: This is the most critical document. Your 3D model should be finalized and reflect the exact geometry of the part you intend to produce.

- Specify the Material Alloy: Clearly define the alloy you require (e.g., A380 aluminum, Zamak 3 zinc). The choice of material directly impacts both the part cost and the requirements for the tooling.

- Define Production Volume: Provide your estimated annual usage (EAU) or the total expected lifetime volume for the part. This helps the manufacturer determine the most appropriate tooling strategy (e.g., single vs. multi-cavity).

- Outline Finishing and Tolerance Requirements: Specify any critical dimensions, tolerances, and required surface finishes or post-processing steps, such as powder coating or anodizing.

- Request a Formal Quote: Submit your complete technical package to several qualified die casting suppliers to receive a detailed cost breakdown.

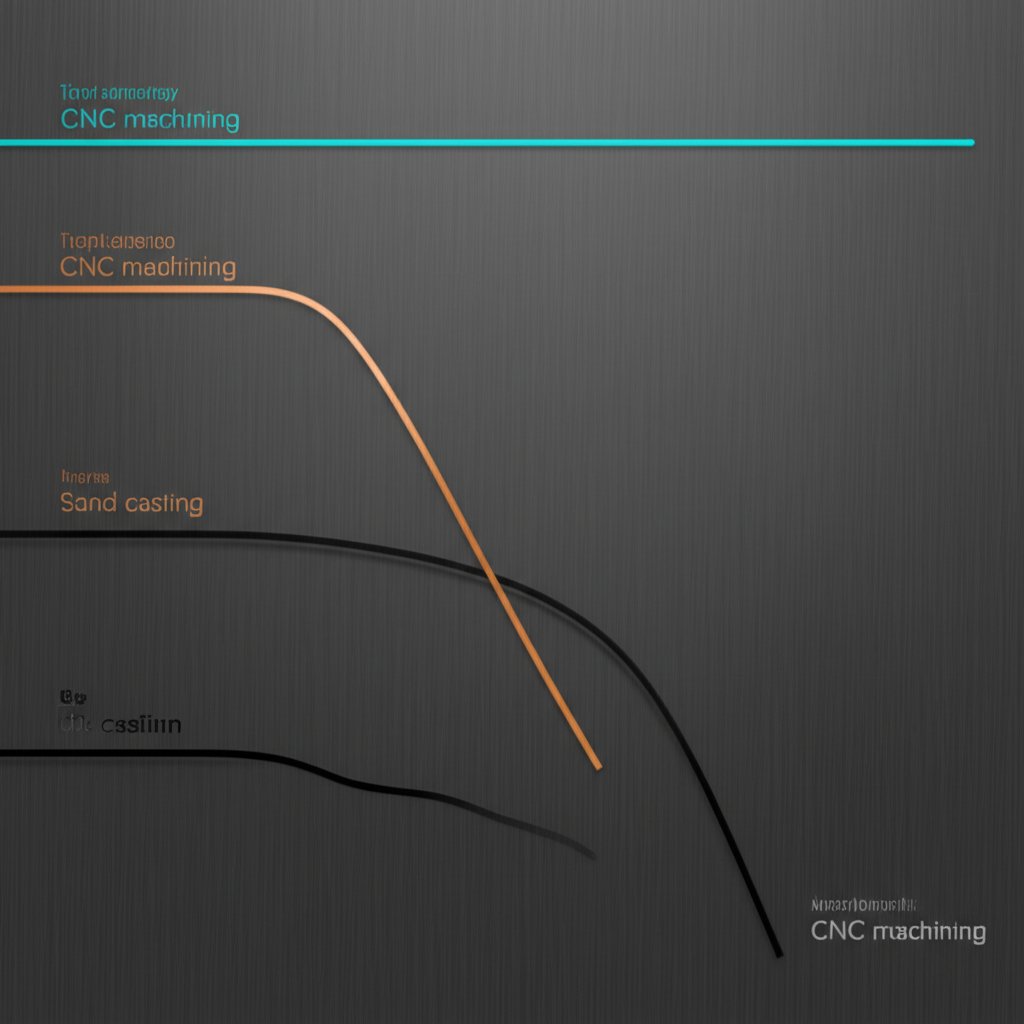

Tooling Cost Comparison: Die Casting vs. Other Processes

Choosing the right manufacturing process depends heavily on balancing tooling costs, per-part prices, and production volume. Die casting is renowned for its efficiency at high volumes, but its high initial tooling cost makes it unsuitable for prototyping or small runs. Understanding how it compares to other common metalworking processes is key to making a cost-effective decision.

While CNC machining involves no specific tooling cost, its per-part price remains high and relatively flat regardless of volume, making it ideal for prototypes and low-quantity production. On the other end of the spectrum, sand casting has a low tooling cost but a higher per-part price than die casting and produces parts with a rougher surface finish. As detailed by manufacturing experts at Batesville Products, the key is to find the break-even point where the high initial investment in die casting tooling is justified by the savings on each part produced.

Here is a general comparison of the tooling costs and ideal applications for each process:

| Process | Typical Tooling Cost | Best for Production Volume | Per-Part Cost (at scale) |

|---|---|---|---|

| Die Casting | $60,000 - $500,000+ | High (10,000+ units) | Very Low |

| Permanent Mold Casting | $10,000 - $90,000 | Moderate (1,000 - 20,000 units) | Low |

| Sand Casting | $6,000 - $20,000 | Low (1 - 5,000 units) | Moderate |

| CNC Machining | $0 | Very Low (1 - 100+ units) | High |

Frequently Asked Questions

1. How much does sand casting tooling cost?

The tooling for sand casting, often called a pattern, is significantly less expensive than die casting tooling. Typical costs range from approximately $6,000 to $20,000, depending on the size and complexity of the part. This lower entry cost makes sand casting a viable option for prototypes and low-volume production runs.

2. Why is die casting so expensive?

The high cost of die casting is primarily due to the tooling. The dies are subjected to extreme heat and pressure and must be constructed from high-quality, hardened tool steel to survive tens of thousands of production cycles. The process of precisely machining, heat-treating, and assembling these durable molds is a complex and costly endeavor that represents a significant upfront investment.

3. Is die casting cheaper than CNC?

It depends entirely on the production volume. For a single prototype or a very small batch of parts, CNC machining is far cheaper because it requires no tooling investment. However, as production volume increases into the thousands, die casting becomes much more cost-effective. The high initial tooling cost is spread across many parts, making the per-part cost significantly lower than the consistent, high per-part cost of CNC machining.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —