Understanding Unit Die Systems in Die Casting

TL;DR

Unit die systems in die casting represent a highly efficient and cost-effective tooling strategy. They consist of a standardized main die frame, often called a unit holder, that remains in the casting machine, and smaller, interchangeable cavity inserts that are specific to each part. This modular approach is ideal for producing small to medium-sized parts with simpler geometries in low to medium volumes. The primary benefits are significantly reduced tooling costs and faster setup times compared to developing a complete, custom die for every component.

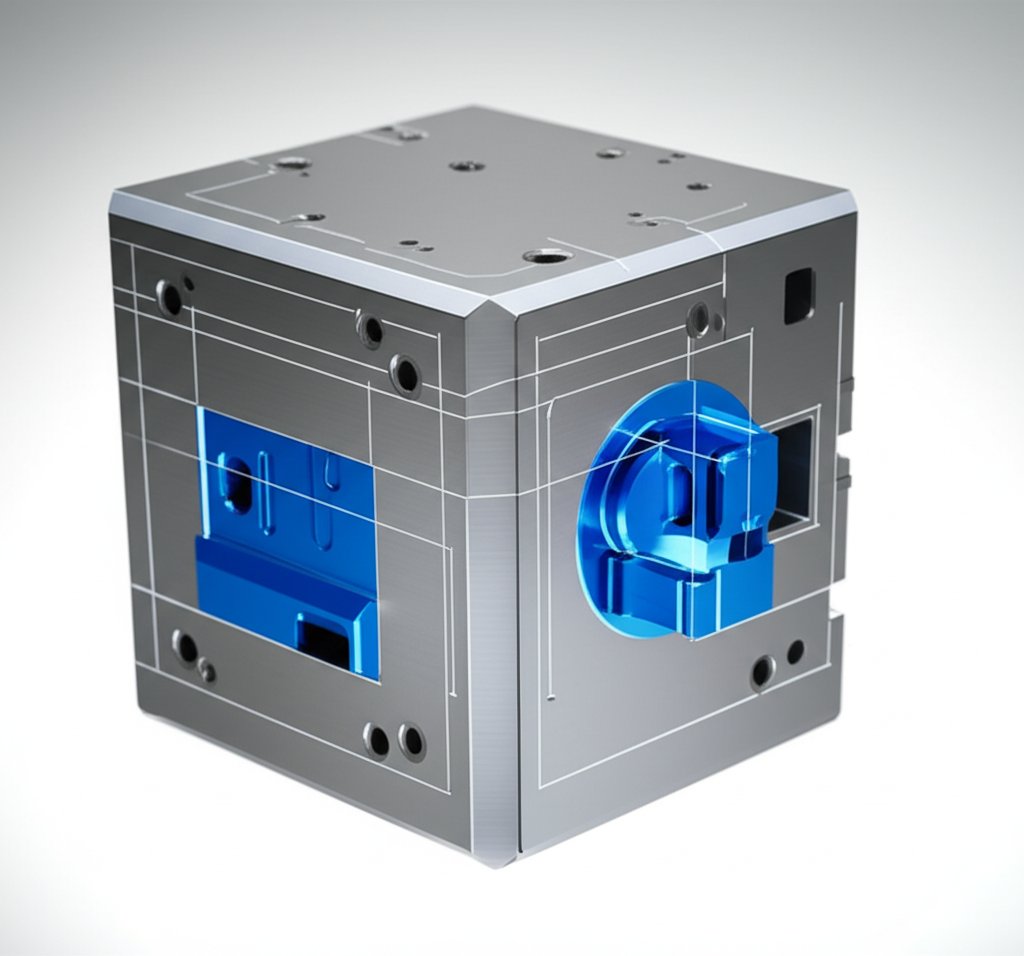

What Is a Unit Die System in Die Casting?

A unit die system is a specialized type of production tooling used in high-pressure die casting. The core concept revolves around a master unit holder or frame owned by the die caster, which is designed to accept smaller, custom-made die inserts. These inserts, sometimes called cavity blocks or simply unit dies, contain the actual part geometry. While the large, standardized holder remains mounted in the die casting machine, the smaller inserts can be quickly and easily swapped out to produce different parts. This modularity is the system's defining feature.

This approach stands in stark contrast to a traditional or 'complete' die, which is a fully self-contained tool built specifically for a single part or a family of parts. A complete die integrates the cavity, ejector system, cooling lines, and all other components into one dedicated package. While offering maximum control and efficiency for high-volume or complex parts, building a complete die is a significant investment in both time and money. Unit die systems were developed to provide a more economical alternative for specific production scenarios.

The primary advantage of this system is the reduction in tooling investment. Since the customer only needs to purchase the comparatively small cavity insert, the upfront cost can be a fraction of that for a complete die. This makes it an attractive option for startups, projects with limited budgets, or for producing a diverse range of small components without commissioning a dedicated tool for each. The die caster absorbs the cost of the large, universal holder, spreading its expense across multiple customers and projects.

To better understand the distinction, consider the following comparison:

- Complete Die: A fully custom, standalone tool. It is designed and built for a specific part, offering optimal performance for complex geometries and high-volume production. It represents a higher initial investment.

- Unit Die System: A standardized frame (holder) with a custom, replaceable insert (cavity). It is best suited for smaller, less complex parts and lower production volumes, offering significant cost savings and faster changeovers.

This system effectively democratizes access to die casting for components that might otherwise be too costly to produce using this method. By standardizing the most expensive part of the tooling—the holder—die casters can offer a flexible and affordable solution for the right applications.

Core Components and Working Principle

A unit die system functions through the interaction of several key components, each with a specific role. While designs can vary, the fundamental parts work together to create an efficient, interchangeable tooling assembly. The main components include the unit holder, the cavity insert, and the associated systems for ejection and alignment.

The Unit Holder (also known as a holder block or master frame) is the largest and most critical part of the system. Typically owned by the die caster, it is a robust, standardized frame machined from durable steel like 4140. This holder contains the alignment features, such as guide pins and bushings, and often the primary ejector system mechanics. It is designed to fit into a specific casting machine and remains in place during production runs and even during part changeovers.

The Cavity Insert (or unit die) is the customer-owned portion of the tool. This is the custom-machined block that contains the part's negative space, or cavity, along with the necessary runners and venting for molten metal flow. To withstand the thermal and pressure stresses of die casting, these inserts are made from high-quality, heat-treated tool steel, most commonly H-13. According to information from General Die Casters, a few standard unit die sizes include 10”x12”, 12”x14”, and 15”x18”.

Other essential components that complete the system include:

- Ejector Plate and Pins: This system is responsible for pushing the solidified casting out of the cavity insert after each cycle. While the main ejector plate may be part of the holder, the specific pin locations are integrated with the custom cavity insert.

- Guide Pins and Bushings: These ensure precise alignment between the two halves of the die (cover and ejector) as they close, which is critical for producing accurate parts and preventing damage to the tooling.

- Sprue Bushing: This hardened component directs the flow of molten metal from the machine's nozzle into the runner system within the cavity insert.

- Cooling Lines: Channels within the holder and sometimes the insert circulate a fluid (like water or oil) to regulate the die temperature, which is crucial for controlling solidification, cycle time, and part quality.

The working principle is straightforward and efficient. To change from producing one part to another, a technician unclamps the old cavity insert from the unit holder, removes it, and installs the new insert. Because the massive holder block does not need to be removed from the casting machine, this process is significantly faster than swapping out a complete die, which can weigh thousands of pounds. This rapid changeover minimizes machine downtime and makes it economically viable to run smaller batches of different parts.

Key Advantages and Limitations of Unit Dies

Unit die systems offer a compelling set of advantages, but they also come with inherent limitations. Understanding this balance is crucial for designers and engineers to determine if it is the right tooling strategy for their project. The decision primarily hinges on trade-offs between cost, speed, part complexity, and production volume.

The most significant advantage is the drastically reduced tooling cost. As detailed in a guide by A&B Die Casting, a unit die is a lower-cost production tool because the customer only pays for the replaceable cavity unit, not the entire standardized frame. This can lead to significant savings compared to a complete die, making it an excellent choice for projects with tight budgets. Another key benefit is speed, both in tool manufacturing and production setup. Since the holder is pre-existing, only the smaller insert needs to be made, shortening lead times. Furthermore, swapping inserts is much faster than changing a complete die, reducing machine downtime between runs.

However, these benefits come with notable limitations. Unit dies are best suited for smaller, simpler parts. The standardized nature of the holder restricts the available space, limiting part size and the complexity of features. For instance, the use of multiple or complex moving core slides—used to create undercuts or internal features—is often constrained. A comprehensive guide from Chicago White Metal Casting notes that unit dies are most appropriate for less complex designs and lower annual volumes precisely for this reason. They are generally not suitable for large structural components or parts requiring intricate slide actions.

The table below summarizes the key differences between a unit die system and a complete die:

| Factor | Unit Die System | Complete Die |

|---|---|---|

| Tooling Cost | Low to moderate (customer buys insert only) | High (customer buys entire custom tool) |

| Setup Time | Fast (quick insert changes) | Slow (requires removal of the entire die) |

| Part Complexity | Limited (best for simple geometries, minimal slides) | High (can accommodate complex geometries and multiple slides) |

| Production Volume | Ideal for low to medium volumes | Ideal for high volumes |

| Part Size | Limited to small and medium parts | Can accommodate small to very large parts |

Ultimately, choosing a unit die is a strategic decision. For a designer with a small, simple part and a modest production forecast, it offers an accessible entry into the high-quality world of die casting. For a complex, high-volume part, the investment in a complete die is necessary to achieve maximum efficiency and design freedom.

Typical Applications and Industries

Due to their cost-effectiveness and efficiency for smaller components, unit die systems are utilized across a wide array of industries. They are the go-to solution when a project requires the strength and precision of die casting but cannot justify the expense of a full, dedicated tool. The applications typically involve small-to-medium-sized parts with relatively simple geometries that are produced in low to moderate volumes.

The versatility of unit dies makes them suitable for many sectors. For instance, Diecasting-Mould.com highlights their use for producing parts with complex shapes, provided they fit within the constraints of the unit holder. This adaptability has led to their widespread adoption in fields where product life cycles are short or where multiple variations of a small part are needed.

Common industries and specific part examples include:

- Automotive: While large structural components require complete dies, unit dies are perfect for smaller parts like sensor housings, small brackets, connector bodies, and minor engine or transmission components. For more demanding applications requiring superior strength, other manufacturing methods like forging may be used for components that need maximum robustness.

- Electronics: The electronics industry relies on unit dies to produce a variety of components such as small zinc enclosures, heat sinks, connectors, and mounting brackets for computer and phone parts. The precision of die casting is essential for the tight tolerances required in this sector.

- Consumer Goods: Many everyday products contain parts made with unit dies. These include components for kitchen appliances, hardware for furniture and cabinetry (handles, knobs), parts for sporting equipment, and components for toys.

- Industrial Equipment: Unit dies are used to manufacture parts for machinery and tools, such as hydraulic and pneumatic fittings, valve components, and small machine parts where the production volume for any single design does not warrant a complete die.

The key takeaway is that unit die systems provide a flexible manufacturing pathway. They empower companies to approach a die caster with a new part design and potentially fit it into an existing unit holder. This not only saves on initial tooling costs but also leverages the die caster's existing infrastructure, creating a symbiotic relationship that makes high-quality metal part production more accessible for a broader range of applications.

Frequently Asked Questions

1. What is a unit die?

A unit die is a cost-saving die casting tool that consists of a standardized main die frame (or holder) and smaller, replaceable cavity units. These custom inserts are designed to be removed from the main frame without taking the entire holder out of the die casting machine, allowing for faster and more economical production of smaller, simpler parts.

2. What are the two types of die casting machines?

The two main types of die casting machines are hot-chamber machines and cold-chamber machines. Hot-chamber machines are used for alloys with low melting points, like zinc, where the injection mechanism is immersed in the molten metal. Cold-chamber machines are used for alloys with high melting points, such as aluminum, where the molten metal is ladled into a "cold chamber" before being injected into the die.

3. What are the components of die casting?

Die casting involves several key components. The primary components are the die casting machine, the die or mold (which contains the cavity for the part), and the metal alloy being cast. The die itself is made of two halves—a cover die and an ejector die—and includes elements like runners, gates, vents, ejector pins, and often moving slides or cores to create complex features.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —