Key Die Set Components for Precision Manufacturing

TL;DR

A die set is the foundational framework of a metal stamping die, comprised of upper and lower plates known as die shoes. These shoes hold and align all other functional components with extreme precision. The most critical parts include guide pins and bushings that ensure alignment, and the working components—such as punches and die buttons—that perform the actual cutting and forming of the material.

The Foundation: Die Sets, Shoes, and Plates

Every stamping die, regardless of its complexity, is built upon a solid foundation. This base consists of the die set, which includes the upper and lower die shoes and various plates. These components serve as the rigid skeleton to which all other working parts are mounted. Their primary function is to maintain a precise relationship between the upper and lower halves of the tool throughout the high-force stamping cycle. Without this stable foundation, achieving part accuracy and consistency would be impossible.

Die shoes are typically machined from substantial plates of steel or aluminum. According to an article in The Fabricator, while steel is common, aluminum is a popular choice because it is lightweight, machines quickly, and offers excellent shock absorption, making it ideal for blanking dies. The plates must be machined—either milled or ground—to be perfectly flat and parallel within extremely tight tolerances. The lower die shoe often features openings to allow slugs and scrap to fall through into the press bed, keeping the work area clear.

The thickness and material of the die set are determined by the forces it must withstand. For instance, a coining die that squeezes metal under immense pressure requires a much thicker and more robust die set than a simple bending die. The overall quality of the die set directly impacts the tool's lifespan, the accuracy of the parts produced, and the maintenance requirements over time. A well-constructed die set is the first step in ensuring a successful stamping operation.

The Precision Alignment System: Guide Pins, Bushings, and Heel Blocks

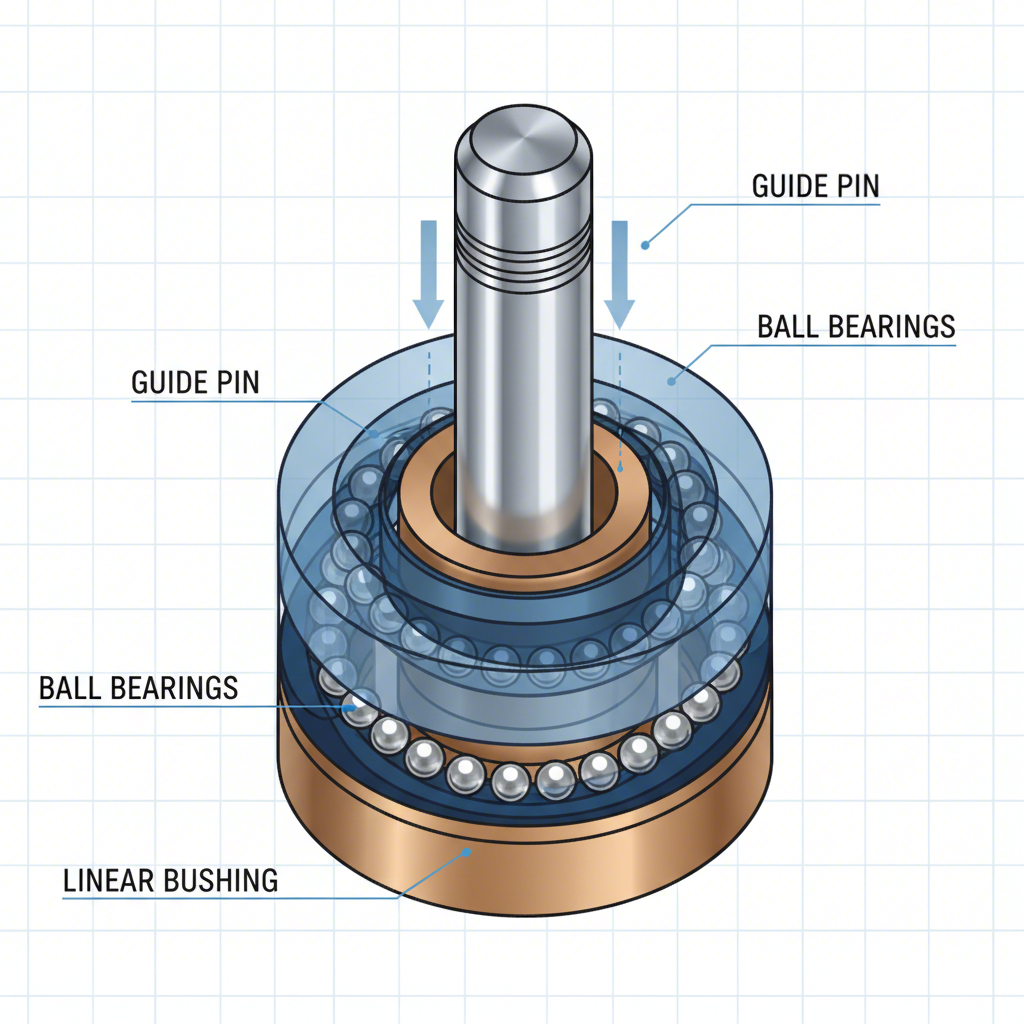

While the die set provides the foundation, the precision alignment system ensures that the upper and lower die shoes operate in perfect unison. This system's primary components are guide pins and bushings. Guide pins, also called guide posts, are hardened, precision-ground shafts mounted to one die shoe that slide into corresponding bushings on the opposing shoe. This engagement guarantees that the working components meet exactly as intended with every stroke of the press, which is critical for maintaining tight tolerances and preventing damage to the tool.

There are two main categories of guide pins and bushings: friction and ball bearing. Friction pins are solid steel pins that slide within a bushing often lined with a wear-resistant material like aluminum-bronze, which may contain graphite plugs for self-lubrication. Ball bearing-style pins, on the other hand, ride on a series of ball bearings housed within a cage, drastically reducing friction. This allows for higher operational speeds without generating excessive heat and makes it easier to separate the die halves for maintenance.

In operations that generate significant side thrust, guide pins alone may not be enough to prevent deflection. This is where heel blocks and heel plates come into play. Heel blocks are robust steel blocks mounted to both die shoes that engage to absorb lateral forces. They often use dissimilar metals for wear plates, such as steel against aluminum-bronze, to prevent galling. By absorbing side thrust, heel blocks protect the guide pins from bending and ensure the alignment of critical cutting and forming components remains perfect.

| Feature | Friction Pins | Ball Bearing Pins |

|---|---|---|

| Mechanism | Solid pin slides inside a bushing | Pin rolls on ball bearings inside a cage |

| Friction Level | Higher | Very Low |

| Speed Capability | Lower speeds | Higher speeds |

| Primary Advantage | Greater resistance to side thrust | High precision, low friction, easy separation |

| Common Application | Dies with significant side forces | High-speed, high-precision progressive dies |

The ‘Working’ Components: Punches, Buttons, and Strippers

The components that perform the actual work of cutting and forming the sheet metal are the punches, die blocks (or buttons), and strippers. The punch is the male component, typically made of hardened tool steel or carbide, that is driven downward to perform an operation. The die button, or die matrix, is the female component located in the lower die shoe. The shape and clearance between the punch and the die button determine the final features of the stamped part, such as the size of a hole or the angle of a bend.

After a punch pierces or forms the material, the material has a tendency to stick to the punch on its return stroke. The stripper's job is to prevent this. A stripper is a pressure-loaded plate that surrounds the punches. As the press ram moves up, the stripper holds the material down against the lower die, allowing the punches to withdraw cleanly. This action is essential for preventing part distortion and enabling high-speed operation. Strippers can be fixed or spring-loaded, with spring-loaded designs providing more controlled pressure.

The design and material selection for these working components are critical for tool life and part quality. As explained by Dynamic Die Supply, punches and die blocks must be made from materials hard enough to withstand repetitive impact and wear. The interaction between these parts, along with pressure pads that hold the workpiece steady, dictates the success of the stamping process. Proper alignment, sharp cutting edges, and effective stripping are all necessary to produce consistent, high-quality parts efficiently.

Component Variations in Progressive vs. Stamping Dies

While all dies share fundamental components, their configuration and complexity vary significantly based on the type of die. The two most common types are single-stage stamping dies and progressive dies. A single-stage die performs one operation per press stroke, such as blanking a part or bending a flange. Its component set is relatively simple, focused on accomplishing that single task. These are often used for lower-volume production or simpler part geometries.

In contrast, a progressive die is a much more complex tool that performs multiple operations simultaneously at different stations. A strip of material is fed through the die, and at each station, a different cutting or forming operation occurs. This allows a complete, complex part to be produced with every single stroke of the press. Consequently, a progressive die contains numerous sets of punches, buttons, and forming tools, all housed within a single, large die set. It also includes additional components like pilot pins to precisely locate the strip at each station and stock lifters to advance the material smoothly.

The design and construction of these complex tools require significant expertise. For industries requiring high-volume, intricate parts, manufacturers of custom automotive stamping dies and similar components often leverage advanced simulations and project management to deliver progressive dies that ensure efficiency and precision. The choice between a single-stage and a progressive die depends on production volume, part complexity, and budget, as the initial cost of a progressive die is much higher, but the per-part cost is significantly lower in mass production.

| Component Aspect | Single-Stage Stamping Die | Progressive Die |

|---|---|---|

| Operations per Stroke | One | Multiple, sequential operations |

| Component Complexity | Low (one set of primary tools) | High (multiple sets of punches, forms, etc.) |

| Material Handling | Manual or simple part feeding | Automatic strip feeding system |

| Unique Components | Basic punches, die blocks | Pilot pins, stock lifters, multiple stations |

| Ideal Production Volume | Low to medium | High to very high |

Frequently Asked Questions About Die Set Components

1. What are the parts of a die called?

The main parts of a stamping die include the die set (upper and lower die shoes), which serves as the foundation. Key functional components are guide pins and bushings for alignment, punches and die buttons (or blocks) for cutting and forming, stripper plates for removing material from punches, and various springs to provide necessary force.

2. What are the components of die casting?

Die casting is a different manufacturing process from stamping and uses different components. A die casting machine uses a mold, or die, typically consisting of two halves: a stationary cover die and a movable ejector die. Inside, it has an ejector pin system to push the solidified part out, a cavity that forms the part's shape, and runners or gates that allow molten metal to flow into the cavity. The alloys used are also different, commonly zinc, aluminum, or magnesium.

3. What is the construction detail of a die set?

The construction of a die set centers on two precision-machined plates: the upper and lower die shoes. These plates are aligned by guide pins and bushings. All other components, such as punch retainers, die blocks, and stripper plates, are securely mounted to these shoes. The entire assembly is designed to be a self-contained tool that can be installed in a press to produce parts accurately and repeatedly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —