Stamping Die vs Drawing Die: Essential Process Differences

TL;DR

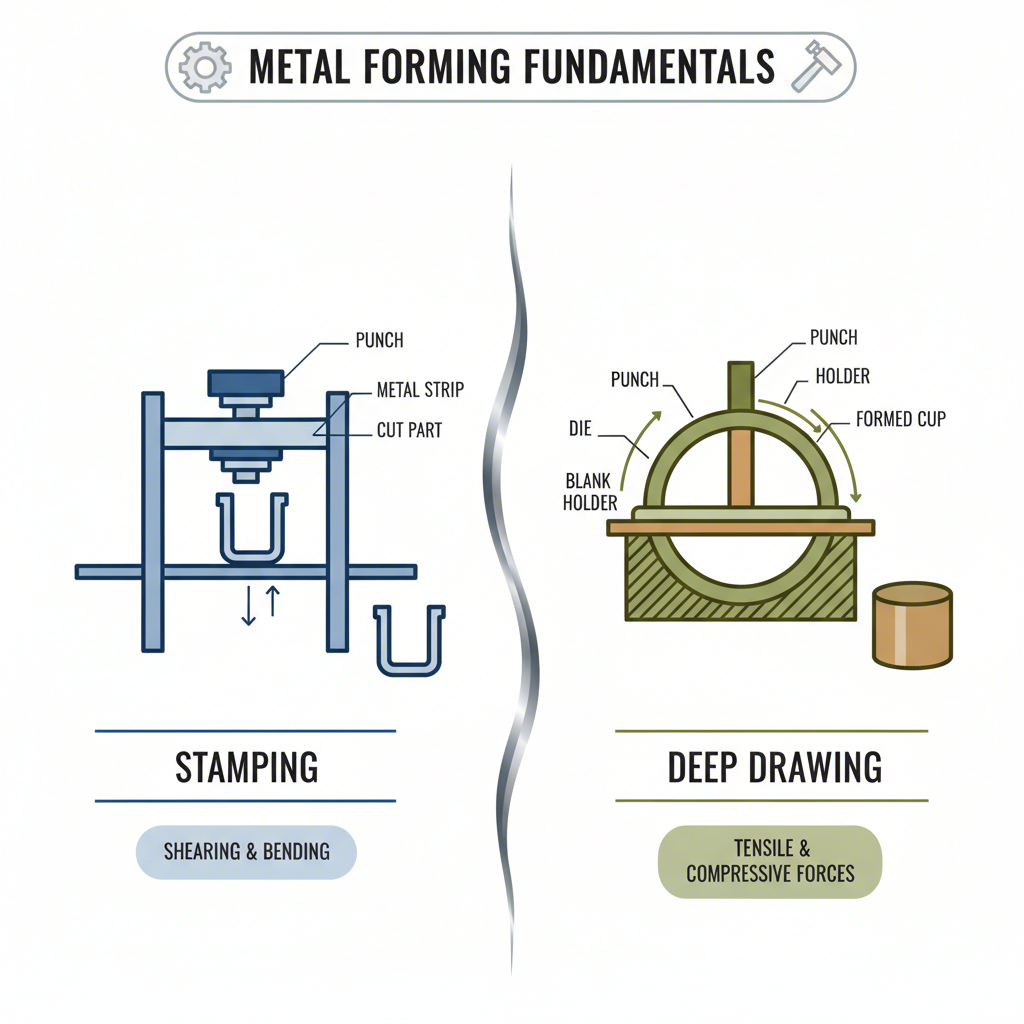

Deep drawing and metal stamping are forming processes that use dies, but they serve fundamentally different purposes. Metal stamping primarily cuts, punches, bends, and forms flat metal sheets into various shapes. In contrast, deep drawing is a specialized process that stretches or 'draws' a metal blank into a die cavity to create deep, seamless, hollow parts like cans or sinks, achieving shapes not possible through standard stamping.

Understanding the Fundamentals: Defining Stamping and Drawing

In metal manufacturing, dies are specialized tools used to cut or shape material using a press. While both stamping and deep drawing rely on dies, the mechanics of how they shape metal are distinct. Understanding these foundational processes is crucial for selecting the correct manufacturing method for a specific component.

Metal stamping is a broad category of cold-forming processes that includes a variety of operations like punching, coining, blanking, and bending. A stamping press with a dedicated die strikes a flat sheet of metal, often from a coil, to cut it or form it into a predetermined shape. This method is exceptionally fast and efficient for producing a high volume of identical parts, such as automotive brackets, electrical contacts, and coins. The focus is on altering the shape of the metal along a single plane or with simple bends, rather than creating significant depth.

Deep drawing, on the other hand, is a more complex process focused on creating depth. It transforms a flat metal blank into a three-dimensional, hollow vessel without seams. A punch pushes the sheet metal through a die, causing the material to flow and stretch into the new shape. To prevent wrinkling and control the material's movement, a blank holder applies pressure to the edges of the sheet. This controlled metal flow is the key distinction from stamping. As noted in an article from The Fabricator, drawing involves the inward movement of the blank's edge, whereas simple stretching does not. This technique is essential for producing parts like kitchen sinks, cookware, and automotive oil pans.

Head-to-Head Comparison: Key Differences Between Stamping and Drawing

While both processes shape metal with dies, their differences in mechanics, application, and outcome are significant. The choice between a stamping die and a drawing die directly impacts the final product's geometry, strength, and precision. A direct comparison highlights the unique characteristics of each method.

The most fundamental difference lies in how the metal is deformed. Stamping often involves shearing (cutting) or simple bending, where the material undergoes localized stress. Deep drawing, however, is a process of tension and compression, where the material is forced to flow and stretch into a new shape. This extensive deformation often results in work hardening, which can make the final part stronger and more durable than a standard stamped component. This increased durability is a key advantage for parts that will be under stress.

| Factor | Metal Stamping | Deep Drawing |

|---|---|---|

| Metal Deformation | Primarily cutting, bending, and forming on a flat plane. Material is sheared or displaced. | Material is stretched and flows into a die cavity under tension, creating depth. |

| Final Product Shape | Varied shapes, often flat or with simple bends (e.g., brackets, clips, panels). | Deep, seamless, hollow, and often cylindrical or box-shaped parts (e.g., cans, pots, sinks). |

| Precision & Finish | Produces parts with high precision and accuracy; finish can vary by process (e.g., cutting, bending). | High dimensional accuracy with a smooth, uniform surface finish. |

| Part Durability | Standard durability based on the base material properties. | Higher durability due to work hardening that occurs as the material is stretched and stressed. |

| Tooling & Costs | Generally lower initial tooling costs, very cost-effective for high-volume production of simple parts. | Higher tooling and setup costs, making it more suitable for high-volume runs of complex parts. |

This distinction in material deformation also affects the precision and finish of the final component. Deep drawing typically produces parts with higher dimensional accuracy and a smoother finish because the material is forced to conform tightly to the die surface under controlled pressure. In contrast, stamped parts can have rougher edges from cutting operations and may be less precise. Furthermore, the ability of deep drawing to maintain a relatively uniform wall thickness is a significant advantage for applications requiring consistent strength and integrity, such as pressurized containers.

Choosing the Right Process: Applications and Considerations

Selecting between metal stamping and deep drawing depends entirely on the specific requirements of the part, including its geometry, material, production volume, and budget. Each process offers distinct advantages tailored to different manufacturing scenarios.

When to Choose Metal Stamping

Metal stamping is the ideal choice for high-volume production of relatively simple, flat, or shallow parts. Its primary advantages are speed and cost-effectiveness. The process is highly automated and can produce thousands of parts per hour, making it perfect for industries that require large quantities of components at a low cost per unit.

- Advantages: High production speed, lower initial tooling costs for simple designs, and versatility across various operations like blanking, bending, and coining.

- Disadvantages: Limited ability to create deep or complex shapes, potentially more material waste, and a rougher finish compared to deep drawing.

- Typical Applications: Automotive brackets and panels, electronic connectors, washers, and industrial hardware.

For industries like automotive manufacturing, where precision and efficiency are paramount, specialized providers are essential. For example, Shaoyi (Ningbo) Metal Technology Co., Ltd. excels in creating custom automotive stamping dies, offering comprehensive solutions from prototyping to mass production for OEMs and Tier 1 suppliers who demand high quality and rapid turnaround.

When to Choose Deep Drawing

Deep drawing is the superior method when the part design requires significant depth, a seamless construction, and high strength. It is particularly well-suited for creating cylindrical or box-shaped items where seams would be a point of failure or are aesthetically undesirable.

- Advantages: Ability to produce strong, seamless parts with complex geometries, excellent for hollow shapes, and enhanced durability due to work hardening.

- Disadvantages: Higher initial tooling and setup costs, slower cycle times than stamping, and limitations on suitable materials (ductile metals are preferred).

- Typical Applications: Cookware (pots and pans), kitchen sinks, automotive oil pans, fire extinguishers, and aerosol cans.

Matching the Process to the Part

Ultimately, the decision between a stamping die and a drawing die is a function of the final part's design intent. Stamping excels at rapidly and economically producing a vast array of components by cutting and forming flat sheet metal. Its strength lies in its speed and versatility for parts without significant depth. Deep drawing, conversely, is the specialized solution for transforming that same flat sheet into a deep, seamless, three-dimensional object through controlled material flow. While more complex and costly upfront, it achieves geometries and structural integrity that stamping cannot. The right choice is always the one that aligns the manufacturing process with the part's required form, function, and performance.

Frequently Asked Questions

1. What is the difference between die stamping and die casting?

Die stamping and die casting are fundamentally different manufacturing processes. Die stamping is a cold-working process that uses a press and die to shape or cut sheet metal. In contrast, die casting is a process where molten metal (like aluminum or zinc) is injected into a mold cavity under high pressure. Stamping works with solid metal sheets, while die casting starts with liquid metal.

2. What is the difference between die cutting and stamping?

Die cutting is a specific type of stamping. While 'stamping' is a broad term that includes bending, forming, and coining, 'die cutting' refers specifically to the process of using a die to shear or cut material into a specific shape. Essentially, die cutting is the blanking or piercing operation within the larger family of metal stamping processes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —