Calculating Stamping Tonnage: The Essential Formula

TL;DR

Calculating stamping tonnage requirements is essential for selecting the correct press and ensuring a successful manufacturing process. The fundamental formula is: Tonnage = Perimeter of Cut (in) × Material Thickness (in) × Material Shear Strength (tons/in²). The accuracy of this calculation hinges on using the precise shear strength for your specific material, as this value varies significantly between metals like mild steel, aluminum, and advanced high-strength steels.

The Fundamental Formula for Stamping Tonnage

At the heart of any stamping operation lies a critical calculation to determine the force required to cut or form a part. This force, measured in tons, dictates the size and capacity of the press needed. Using an undersized press can lead to equipment damage and production failures, while an oversized press is inefficient and costly. The most widely accepted formula for calculating the tonnage for blanking and piercing operations is straightforward yet powerful.

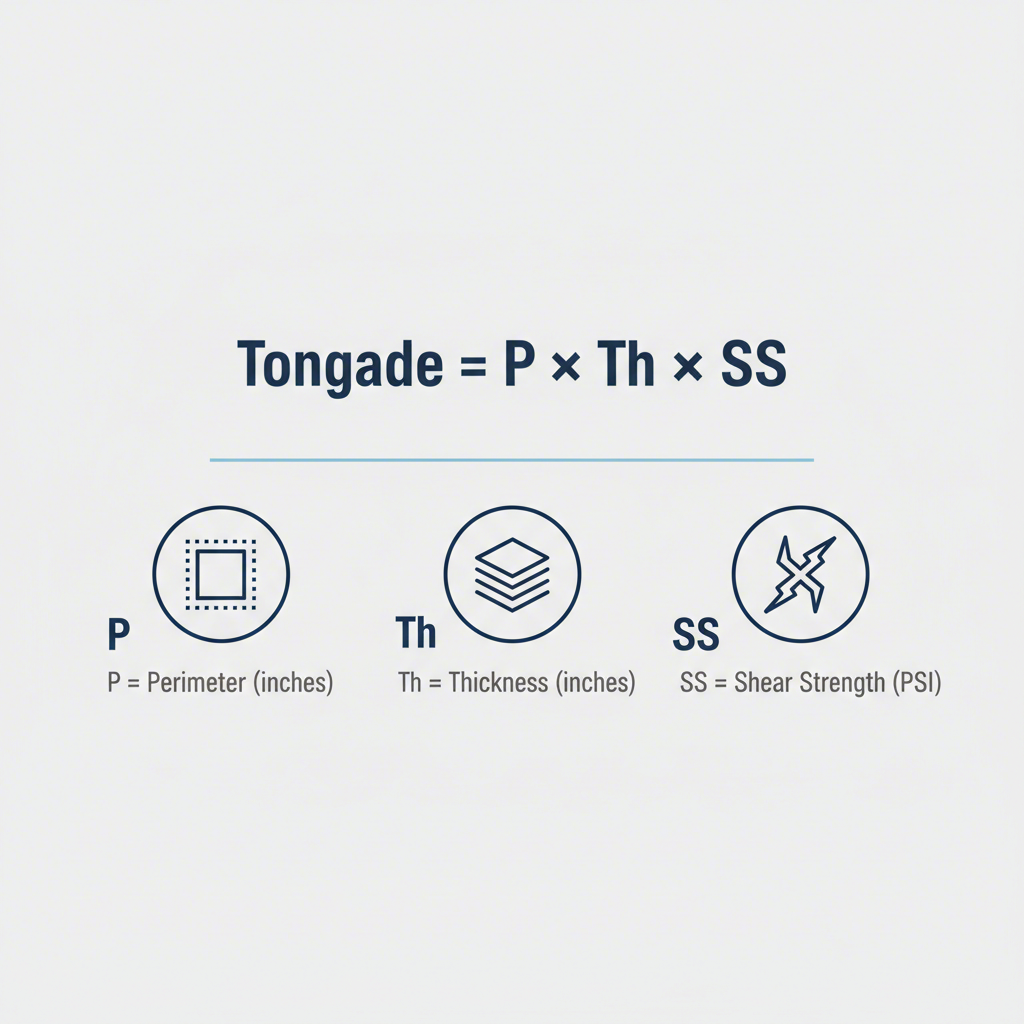

The primary formula is expressed as:

Force (Tons) = P × Th × SS

Each variable in this equation represents a critical aspect of the operation:

- P (Perimeter): This is the total length of the cut being made, measured in inches. For a simple round hole, this is the circumference (π × diameter). For a square or rectangle, it is the sum of all sides.

- Th (Thickness): This is the gauge or thickness of the sheet metal being stamped, measured in inches.

- SS (Shear Strength): This is an intrinsic property of the material that defines its resistance to being sheared, expressed in tons per square inch. This is the most crucial variable for accuracy.

For example, to calculate the tonnage needed to punch a 2-inch diameter hole in a 0.10-inch thick sheet of mild steel, which has a shear strength of approximately 25 tons/in², the calculation would be: Tonnage = (2 in × 3.1416) × 0.10 in × 25 tons/in² = 15.7 tons. It's common practice to add a safety factor of 15-20% to account for variables like tool wear.

To apply this formula to your own project, follow these steps:

- Determine the Perimeter (P): Calculate the total length of all edges being cut in a single press stroke.

- Measure Material Thickness (Th): Use calipers to get an exact measurement of your material's thickness in inches.

- Identify Material Shear Strength (SS): Find the shear strength of your specific material in tons per square inch. This can often be found in material data sheets or engineering handbooks.

- Calculate the Tonnage: Multiply the three values together to find the required force in tons.

- Add a Safety Factor: Increase your calculated tonnage by 15-20% to ensure your press has adequate capacity.

Key Variables Deep Dive: Material Properties and Part Geometry

The accuracy of your tonnage calculation is only as good as the data you use. While perimeter and thickness are straightforward measurements, the material's shear strength is a nuanced variable that has a massive impact on the result. Misunderstanding this property is a common source of error, especially with modern alloys.

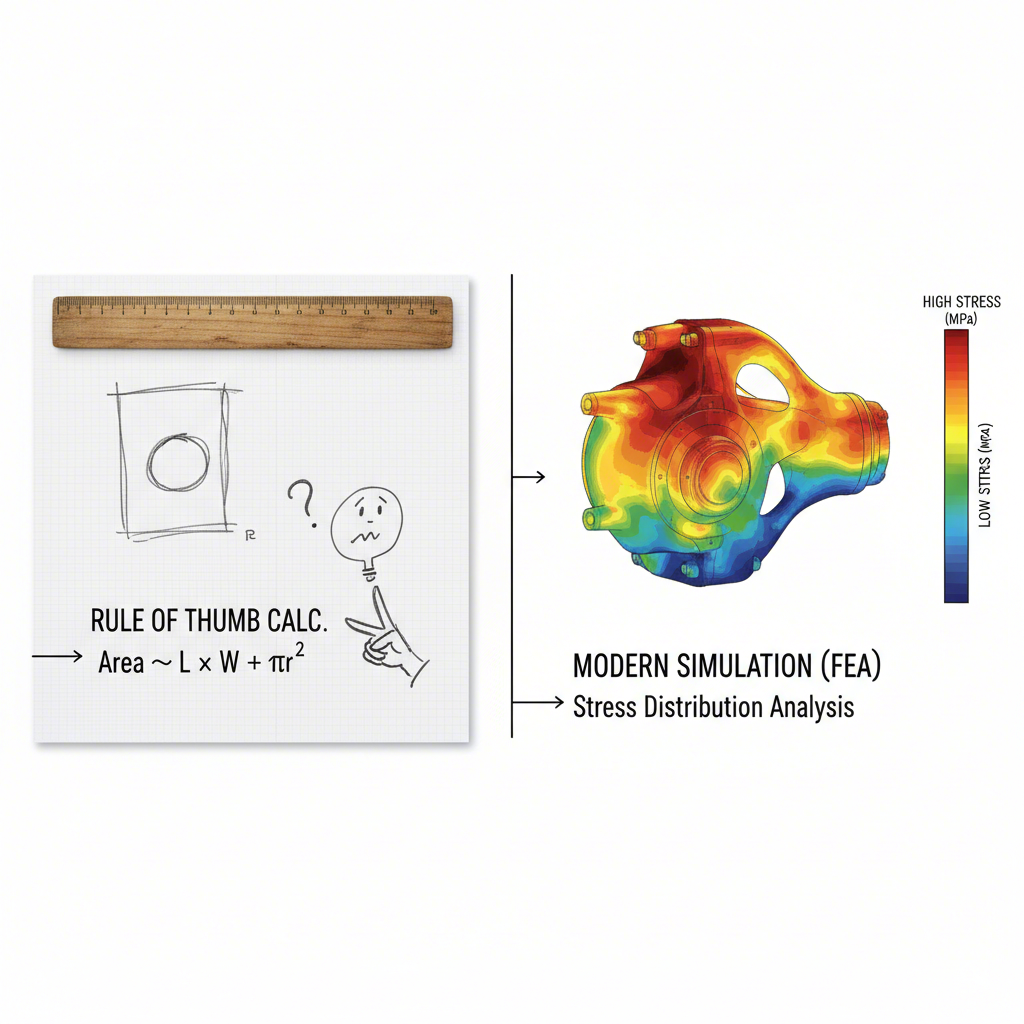

Shear strength is not a universal constant; it varies dramatically from one material to another. For instance, soft aluminum requires far less force to shear than hardened stainless steel. Advanced High-Strength Steels (AHSS), which are increasingly used in the automotive industry for their strength-to-weight ratio, have shear strengths that can be several times higher than that of traditional mild steel. As noted in AHSS Guidelines, conventional rule-of-thumb calculations that worked for mild steel can severely underpredict the tonnage required for these advanced materials, leading to significant problems.

The geometry of the part is equally important. The perimeter must be calculated precisely for the shape being cut. For simple shapes like circles (Circumference = π × diameter) or rectangles (Perimeter = 2 × length + 2 × width), this is simple. For complex, irregular shapes, the perimeter is the sum of all individual straight and curved line segments that are being cut simultaneously.

To illustrate the differences in material properties, here is a table of approximate shear strength values for common metals:

| Material | Shear Strength (Tons/in²) |

|---|---|

| Aluminum (Soft) | ~11 |

| Brass (Half-Hard) | ~20 |

| Mild Steel (HR/CR) | ~25-27 |

| Stainless Steel (Annealed) | ~37 |

| Stainless Steel (Half-Hard) | ~50 |

Note: These are approximate values. Always refer to your material supplier's specification sheet for precise data.

To ensure accuracy in your calculations:

- Verify Material Specs: Never assume the shear strength. Always obtain the correct value for the specific alloy and temper of your material.

- Measure Thickness Accurately: Small variations in material thickness can have a notable effect on the final tonnage, especially with high-strength materials.

- Calculate Perimeter Carefully: For complex parts, break down the geometry into smaller segments to ensure the total cut length is calculated correctly.

Calculations for Different Stamping Operations

While the core principles of calculating force remain the same, the formula must be adapted for different types of stamping operations. The primary distinction lies in what part of the process is consuming energy and how the material is being stressed. Confusing the requirements for blanking, punching, and drawing is a frequent cause of miscalculation.

Punching and Blanking: These are both shearing operations. Punching removes material to create a hole, while blanking cuts out a part's profile from a larger sheet. For both, the standard formula (Tonnage = P × Th × SS) applies directly. The key is to use the perimeter of the feature being cut and the material's shear strength. For example, in punching, 'P' is the circumference of the punch; in blanking, 'P' is the perimeter of the final part.

Drawing: This is a forming operation, not a shearing one. Drawing stretches the sheet metal into a three-dimensional shape, like a cup or shell. The material is put under tension, not shear. Therefore, the calculation must be modified. As explained by The Fabricator, the drawing formula substitutes shear strength (SS) with the material's Ultimate Tensile Strength (UTS). Additionally, the force required by the blank holder or pressure pad must be calculated and added to the total.

Progressive Stamping: In a progressive die, multiple operations (e.g., punching, bending, forming) occur at different stations with each stroke of the press. To calculate the total tonnage, you must calculate the force required for every operation performed simultaneously and then sum them together. This includes piercing, forming, bending, and even the force exerted by spring strippers and nitrogen pressure pads.

Here is a comparison of key considerations for different operations:

| Operation | Key Force Factor | Perimeter (P) Measured | Additional Forces to Consider |

|---|---|---|---|

| Punching | Shear Strength (SS) | Circumference of the punch | Stripper spring pressure |

| Blanking | Shear Strength (SS) | Perimeter of the blanked part | Stripper spring pressure |

| Drawing | Ultimate Tensile Strength (UTS) | Perimeter of the drawn cup/shell | Blank holder / Pad pressure |

To select the correct calculation, use this checklist:

- [ ] Is the operation primarily cutting material? If yes, use the shear strength formula.

- [ ] Is the operation stretching or forming material into a 3D shape? If yes, use the tensile strength formula and add pad pressure.

- [ ] Are multiple operations happening in one press stroke? If yes, calculate the tonnage for each and add them together.

Advanced Considerations and Factors Affecting Tonnage

The basic formula provides a solid estimate, but in a real-world production environment, several other factors can influence the actual tonnage required. Overlooking these details can lead to inaccurate predictions and processing issues. Experienced engineers account for these nuances to refine their calculations and ensure process stability.

One of the most significant factors is the condition of the tooling. The standard formula often compensates for dull tooling by using the full material thickness. However, sharp tools cause the material to fracture after penetrating only a fraction of its thickness (often 20-50%), thus reducing the required force. Conversely, worn or dull tools will require significantly more tonnage. Other factors include the clearance between the punch and die, the material's hardness consistency, and the speed of the press.

Furthermore, there is a critical distinction between tonnage (peak force) and energy. A press might have sufficient tonnage rating, but not enough energy to complete the work, especially for deep-drawing operations that engage the material high up in the press stroke. This can cause the press to stall at the bottom of its stroke. Modern approaches increasingly rely on Finite Element Analysis (FEA) and simulation software to overcome the limitations of hand calculations. As noted by StampingSimulation, these tools can accurately model complex factors like material work-hardening, springback, and binder pressure throughout the entire forming process. For complex components, particularly in the automotive sector, leveraging advanced CAE simulations is no longer a luxury but a necessity. Leading suppliers like Shaoyi (Ningbo) Metal Technology Co., Ltd. utilize these technologies to ensure precision and efficiency in manufacturing automotive stamping dies and components.

For more reliable and safer operations, consider these pro tips:

- Apply a Safety Factor: Always add at least 15-20% to your calculated tonnage to create a buffer for material variations and tool wear.

- Account for All Forces: In complex dies, remember to add the forces from nitrogen springs, pressure pads, and driven cams to your total.

- Consider Tool Sharpness: If you maintain very sharp tooling, you may be able to use a lower tonnage value, but calculating for dull tools provides a safer upper limit.

- Balance the Load: In large presses or progressive dies, ensure the load is balanced across the press bed to prevent tilting and premature wear on both the press and the die.

Frequently Asked Questions

1. How do you calculate tonnage for stamping?

The most common method for calculating tonnage in stamping (specifically for piercing and blanking) is to use the formula: Tonnage = Perimeter of the cut (in inches) × Material Thickness (in inches) × Shear Strength of the material (in tons per square inch). The shear strength value is critical and varies greatly depending on the type of metal being used.

2. How do you calculate tonnage requirement?

To calculate the total tonnage requirement, you must first identify all the work being done in a single press stroke. For a simple blanking operation, you apply the standard formula (Perimeter × Thickness × Shear Strength). For a progressive die with multiple stations, you must calculate the tonnage for each station performing work simultaneously (e.g., piercing, forming, bending) and then add all those values together to get the total required tonnage.

3. How is forging press tonnage calculated?

Calculating tonnage for a forging press is fundamentally different from stamping. Instead of a perimeter-based shearing action, forging involves compressing a volume of material. The formula is more complex and typically relates to the projected area of the forging, the material's flow stress at forging temperature, and a shape complexity factor. It is not interchangeable with stamping tonnage calculations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —