A Guide to the Essential Types of Automotive Stamping Dies

TL;DR

Automotive stamping dies are specialized tools essential for cutting and forming sheet metal into precise vehicle components. The primary types are categorized by their operational complexity: single-station dies, like blanking or compound dies, handle one operation per press stroke and are ideal for simpler parts and lower volumes. Multi-station dies, including progressive and transfer dies, perform multiple operations sequentially in a single press, making them highly efficient for complex, high-volume production runs.

Fundamentals: What Is an Automotive Stamping Die?

An automotive stamping die is a precision tool used in the metal forming process to cut, shape, and form sheet metal into specific components for vehicles. Functioning within a high-pressure stamping press, the die acts as a mold that shapes metal into everything from large body panels and doors to smaller, intricate brackets and structural components. This process is the backbone of modern automotive manufacturing, enabling the mass production of identical parts with exceptional accuracy and repeatability.

The mechanics involve placing a sheet of metal between the two halves of the die. The stamping press then applies immense force, causing the metal to conform to the die's shape. This action can either cut the metal or form it into a three-dimensional part. The distinction between these operations is critical; cutting operations include processes like blanking (cutting an exterior shape) and piercing (punching holes), while forming operations include bending, drawing (stretching metal into a cavity), and coining. A single automotive component may require several of these operations to be completed.

The importance of stamping dies in the automotive industry cannot be overstated. They allow manufacturers to produce lightweight yet strong parts at a rapid pace, which is essential for meeting production targets and ensuring vehicle safety and performance. As detailed by manufacturing experts at ALSETTE, each die is engineered to produce a specific part, ensuring that every component meets the strict dimensional tolerances required for seamless vehicle assembly.

The Major Categories: Single-Station vs. Multi-Station Dies

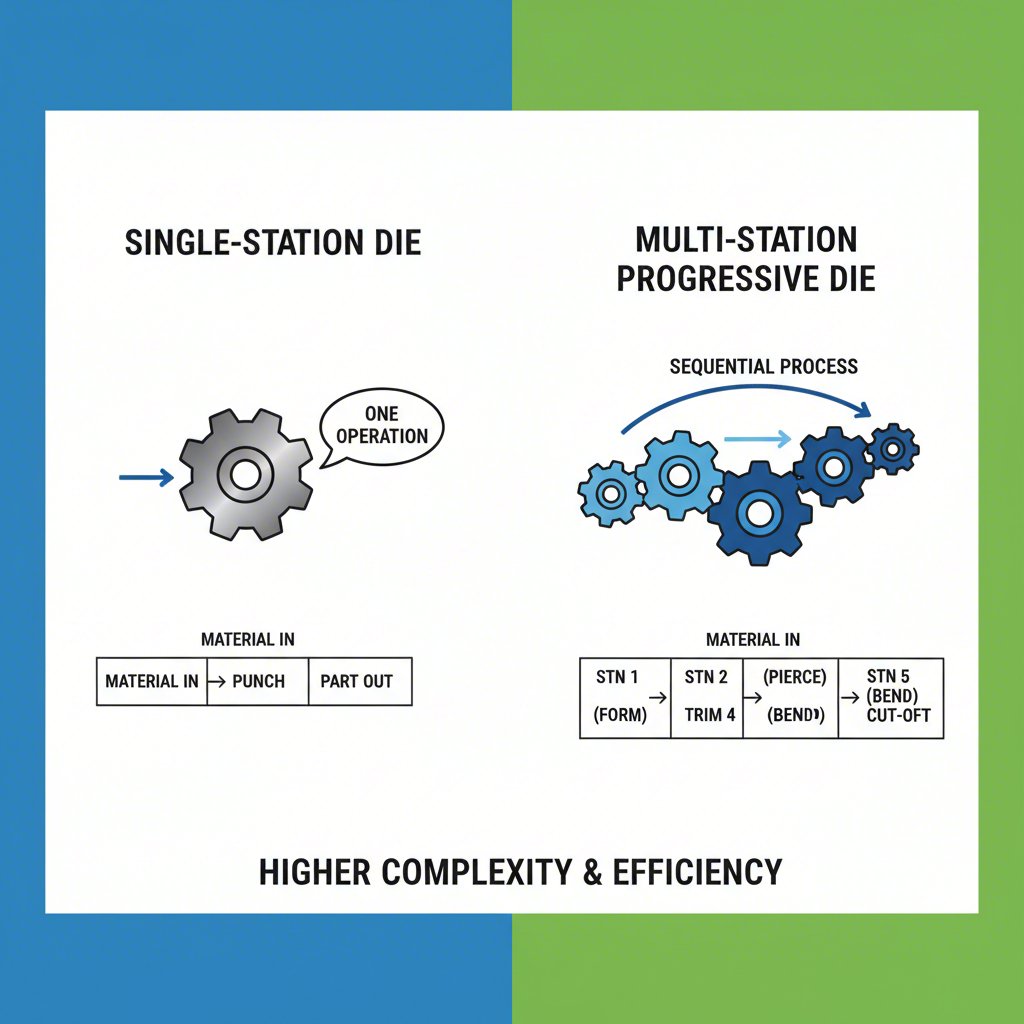

Stamping dies are broadly classified into two main categories based on their operational structure: single-station and multi-station dies. This fundamental distinction dictates the production workflow, efficiency, and suitability for different types of components. Understanding this classification provides a clear framework for comprehending the more specific die types used in manufacturing.

Single-station dies, also known as single-stage dies, perform one specific operation per stroke of the press. For example, one press might be set up with a blanking die to cut the initial shape, and the resulting part would then need to be moved to another press with a piercing die to add holes. This approach is straightforward and generally involves lower initial tooling costs. As a result, single-station dies are typically reserved for simpler components, low-volume production runs, or prototyping where flexibility is more important than speed.

Multi-station dies, in contrast, are designed to perform numerous operations sequentially within a single press. The workpiece moves through a series of stations, with each station executing a different cutting or forming task. This integrated process is highly automated and significantly faster than using multiple single-station setups. As explained by Premier Products of Racine, Inc., this method is the preferred choice for high-volume production of complex parts where efficiency and per-unit cost are primary concerns. The two most prominent types of multi-station dies are progressive and transfer dies.

| Criterion | Single-Station Dies | Multi-Station Dies |

|---|---|---|

| Operation | One operation per press stroke | Multiple sequential operations per press stroke |

| Production Volume | Low to medium | High |

| Part Complexity | Simple | Complex |

| Tooling Cost | Lower | Higher |

| Setup Time | Shorter | Longer and more complex |

In-Depth Look at Multi-Station Dies: Progressive vs. Transfer

Within the multi-station category, progressive and transfer dies represent two advanced but distinct approaches to high-volume manufacturing. The choice between them depends heavily on part size, complexity, and material efficiency goals. Both are capable of producing intricate components, but they achieve this through different material handling methods.

Progressive Dies

In a progressive die, a coil or strip of sheet metal is fed through the press. The strip remains intact as it advances through a series of stations, each performing a specific operation like punching, coining, or bending. The part is gradually formed and is only separated from the metal strip at the final station. This continuous feeding process allows for very high production speeds, making progressive dies ideal for producing large quantities of small-to-medium-sized parts like brackets, clips, and electronic connectors.

Transfer Dies

A transfer die operates differently. The process begins by cutting a blank from the sheet metal. This individual blank is then transferred from one station to the next using a mechanical system, such as robotic arms or grippers. Each station is an independent die performing a single operation. Because the part is not attached to a carrier strip, this method is better suited for larger and more complex components, such as deep-drawn shells, frames, and structural parts. A key advantage highlighted by Larson Tool & Stamping is that transfer dies significantly reduce material waste since no carrier web is needed.

| Criterion | Progressive Die | Transfer Die |

|---|---|---|

| Material Handling | Part remains attached to a metal strip until the final operation. | Individual part (blank) is transferred between stations mechanically. |

| Production Speed | Very high | High, but typically slower than progressive. |

| Part Size Capability | Small to medium | Medium to large and complex |

| Material Waste | Higher (due to carrier strip) | Lower (no carrier strip) |

| Tooling Cost | High | Very high (includes transfer mechanism) |

Exploring Single-Station and Specialized Dies

While multi-station dies are built for volume, a wide array of single-station and specialized dies serve critical functions in both low-volume and high-volume environments. These dies are often focused on performing one or two highly specific tasks with great precision. Understanding these types is essential for a complete picture of stamping operations.

- Blanking Dies: These are among the most fundamental die types. A blanking die is used to cut a specific shape, or a "blank," from a larger sheet of metal. The piece that is cut out is the desired part, and the surrounding material is scrap. This is often the first step in a multi-stage manufacturing process.

- Piercing Dies: The opposite of a blanking die, a piercing die punches holes, slots, or other cutouts into a workpiece. In this case, the material that is punched out is the scrap, while the main sheet is the desired part.

- Compound Dies: An efficient type of single-station die, a compound die performs multiple cutting operations in a single press stroke. For example, it can blank the outer contour of a washer while simultaneously piercing its center hole. This ensures excellent concentricity between the features and is ideal for producing flat parts like gaskets and washers with high precision.

- Combination Dies: Similar to compound dies, combination dies perform more than one operation per stroke. However, they combine a cutting operation with a non-cutting (forming) operation, such as blanking and bending simultaneously.

- Forming & Drawing Dies: These dies shape metal without cutting it. Forming dies are used for bending or shaping parts like brackets, while drawing dies stretch or pull sheet metal into a deep, three-dimensional shape. Drawing is the process used to create components like oil pans and body panels.

- Coining & Embossing Dies: These specialized dies are used to add fine details or patterns to a metal surface. Coining dies apply extreme pressure to make the metal flow into the die's intricate features, creating highly detailed parts. Embossing dies create raised or recessed designs on the sheet metal, often for decorative purposes or to add functional features like grip surfaces, as detailed by DureX Inc.

Critical Selection Criteria: How to Choose the Right Die

Selecting the appropriate stamping die is a critical decision that directly impacts production cost, quality, and efficiency. The choice is not arbitrary but is guided by a set of technical and economic factors. Manufacturers must carefully evaluate their project requirements against the capabilities of each die type to find the optimal solution.

The primary criteria for die selection, as outlined by industry experts like JV Manufacturing Co., are part complexity, production volume, and material properties. Simple, flat parts for a low-volume run can be produced cost-effectively with single-station dies like blanking or compound dies. However, for a complex component with multiple bends and features required in quantities of hundreds of thousands, a progressive die is almost always the necessary choice to achieve the required speed and low per-part cost, despite its high initial investment.

Production volume is often the deciding factor. The high upfront cost of designing and building a progressive or transfer die is justified only when spread across a large number of parts. For smaller batches, the longer cycle times and manual handling associated with single-station dies are more economical. Material properties also play a crucial role. Harder or thicker materials like high-strength steel require more robust and wear-resistant dies, which can influence the design and cost of the tooling.

Navigating these complex decisions often requires deep expertise. For instance, specialized manufacturers like Shaoyi (Ningbo) Metal Technology Co., Ltd. work with automotive clients to design and produce custom stamping dies tailored to specific component requirements, from rapid prototyping to mass production. Ultimately, a thorough analysis of these factors ensures that the chosen die technology aligns with both the engineering specifications and the business goals of the project.

Frequently Asked Questions

1. What are the four main types of metal stamping?

While there are many specific operations, the four most commonly referenced categories of metal stamping are progressive die stamping, transfer die stamping, deep drawn stamping, and multi-slide stamping. Progressive and transfer stamping involve multi-station dies for high-volume production. Deep drawing is a forming process to create deep, hollow parts, and multi-slide stamping uses multiple moving slides to form complex parts from different directions.

2. What are the different forms of die?

In the context of manufacturing, a "die" is a specialized tool used to cut or shape material using a press. The primary forms include cutting dies (like blanking and piercing), which shear the material, and forming dies (like bending, drawing, and coining), which shape the material without cutting it. These can be further categorized into single-station, compound, progressive, and transfer dies based on their operational complexity.

3. How many types of stamping are there?

There are numerous specific types of stamping operations, each designed for a particular function. Key processes include blanking, piercing, bending, drawing, forming, coining, and embossing. These operations can be combined in various ways using different types of dies (simple, compound, progressive, etc.) to create a nearly limitless variety of metal parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —