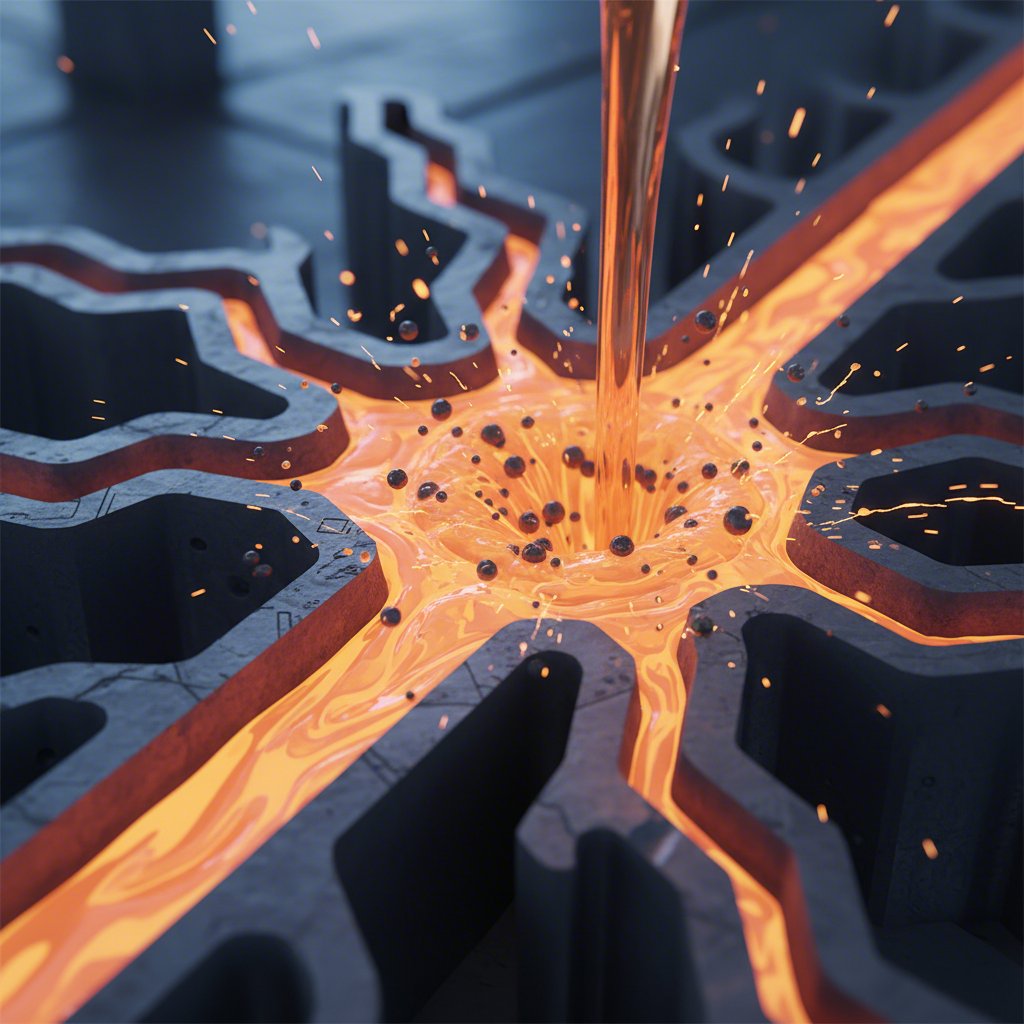

A Practical Guide to Troubleshooting Die Casting Defects

TL;DR

Troubleshooting die casting defects involves identifying imperfections like porosity, cracks, flow marks, and flash, which stem from issues in mold design, process parameters, or material quality. The core of solving these problems lies in a systematic approach to optimizing variables such as injection speed, material and mold temperatures, and ensuring the integrity of the die itself. A clear understanding of the root causes is the first step toward producing high-quality, defect-free parts.

Understanding the Root Causes of Die Casting Defects

Effectively troubleshooting die casting defects begins with a solid understanding of their origins. Most imperfections can be traced back to one of three primary categories: die and mold issues, process parameter inconsistencies, or material quality problems. These factors are often interconnected, where an issue in one area can exacerbate a problem in another. A methodical diagnosis is key to implementing the right solution and preventing recurrence.

Die and mold issues are a significant source of defects. A poorly designed mold with inadequate venting can trap gases, leading to porosity. Similarly, wear and tear on the mold, such as erosion or misalignment of the two halves, can cause flash or mismatched parts. The thermal management of the die is also critical; a die that is too cold can cause flow marks or cold shuts, while localized overheating can lead to soldering, where the molten alloy fuses to the die surface. Preventing these issues starts at the design phase. Partnering with an experienced manufacturer that uses advanced CAE simulations and maintains high tooling standards, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., is crucial for creating robust molds that minimize defect potential from the outset.

Process parameters—the specific settings of the die casting machine—must be precisely controlled. Variables like injection speed, pressure, and cooling rates have a direct impact on the final part's quality. For instance, an excessively high injection speed can create turbulence in the molten metal flow, trapping air and causing gas porosity. Conversely, insufficient pressure may lead to incomplete filling of the mold, known as a short fill. The timing of the cycle, including the solidification and cooling phases, must be optimized to prevent defects like cracks or warping caused by internal stresses.

Finally, the quality of the raw material is fundamental. The molten metal alloy must be clean, at the correct temperature, and properly degassed. Impurities or inclusions in the alloy, such as oxides or slag, can create weak points within the casting, leading to structural failures. The chemical composition itself is vital; for example, low iron content in an aluminum alloy can increase the risk of soldering. Maintaining strict control over alloy purity and temperature ensures the material behaves predictably during the casting process.

| Primary Cause Category | Specific Issue | Potential Resulting Defect(s) |

|---|---|---|

| Die/Mold Issues | Low die temperature | Flow Marks, Cold Shut |

| Process Parameter Issues | High injection speed | Gas Porosity, Flash |

| Material Issues | Impurities in alloy | Inclusions, Cracks |

Troubleshooting Common Surface Defects

Surface defects are often the most immediately apparent flaws in a die-cast part, affecting both its appearance and, in some cases, its functionality. Common issues include gas porosity, blisters, flow marks, and cracks. Each has distinct causes and requires a targeted troubleshooting approach to resolve. Understanding these visual cues is the first step in diagnosing the underlying process problem.

Gas Porosity and Blisters are closely related defects caused by trapped gas within the metal. Gas porosity appears as small, often round voids on or just below the surface. Blisters are raised bubbles on the surface, formed when trapped gas expands and deforms the thin outer skin of the casting, especially during heat treatment or ejection from the mold. The primary cause is air entrapment during the turbulent filling of the mold or gas released from the mold release agent.

- Verify Material Quality: Ensure the alloy is clean, dry, and properly degassed before use.

- Optimize Injection Parameters: Reduce the injection speed to create a more laminar flow and minimize turbulence.

- Improve Venting: Check that mold vents and overflow channels are clean and adequately sized to allow air to escape the cavity. Using a vacuum molding system is a highly effective solution.

- Control Lubricants: Use a high-quality mold release agent and apply it sparingly to avoid excess gas generation.

Flow Marks and Cracks are related to thermal management and stress. Flow marks (or cold shuts) are streaks, lines, or patterns on the surface that trace the path of the solidifying metal. They occur when the molten metal cools too quickly upon contacting the die surface, preventing separate streams from fusing completely. Cracks are fractures that can be caused by thermal stress from rapid or uneven cooling, or by mechanical stress during ejection.

- Adjust Temperatures: Increase the temperature of the die and the molten metal to improve fluidity and prevent premature solidification.

- Optimize Gating: Redesign the gate position and size to ensure the mold fills quickly and uniformly, minimizing the distance the metal has to travel.

- Enhance Thermal Management: Ensure the die's cooling system is functioning correctly to avoid uneven thermal gradients that create stress.

- Review Part Geometry: Minimize abrupt changes in wall thickness and add generous fillets to reduce stress concentration points where cracks often originate.

| Surface Defect | Primary Cause | Key Solution |

|---|---|---|

| Gas Porosity / Blisters | Trapped gas from turbulent flow or lubricants | Optimize injection speed and improve mold venting |

| Flow Marks / Cold Shut | Low die/metal temperature causing premature solidification | Increase die and metal temperatures; adjust gating |

| Cracks | Uneven cooling or mechanical stress | Improve thermal management and part geometry |

Solving Internal and Structural Defects

While surface defects are visually problematic, internal defects can compromise the structural integrity of a component, leading to catastrophic failure in the field. Key internal defects include shrinkage porosity and inclusions, while another key defect, soldering, affects the surface. These flaws are often hidden from view and require careful process control and material management to prevent.

Shrinkage Porosity appears as jagged, angular voids or cavities within the casting, typically in thicker sections. It occurs when molten metal shrinks during solidification, and there is not enough liquid metal to fill the void left behind. This is often a result of poor part design, such as non-uniform wall thicknesses, or inadequate feeding from the gating system. To prevent shrinkage porosity, it's essential to design parts with uniform sections where possible. For more insights on defect prevention, Dynacast offers a detailed guide on the topic. Effective thermal management and properly sized gates and risers are also crucial to ensure proper feeding during solidification.

Soldering is a defect where the molten alloy chemically welds itself to the surface of the die. This damages both the part upon ejection and the die itself, leading to costly downtime and repairs. Soldering often appears as a rough patch or line on the casting. It is typically caused by localized high temperatures, erosion of the die surface, or improper alloy composition, particularly low iron levels in aluminum alloys. Preventative measures include:

- Ensuring proper die cooling to avoid hotspots.

- Controlling alloy chemistry, especially maintaining iron content between 0.8% and 1.1% for certain alloys.

- Using a high-quality die release agent to create a protective barrier.

- Polishing the die cavity to remove any roughness that could act as an anchor point for soldering.

Inclusions are foreign particles trapped within the metal matrix. These can be metallic (e.g., slag) or non-metallic (e.g., sand from the mold, oxides, or bits of refractory material). Inclusions create stress concentration points that significantly weaken the part and can initiate cracks under load. The primary sources are impure alloys, inadequate cleaning of the molten metal, or debris in the die cavity. According to a comprehensive list by Dolin Casting, strict cleanliness is paramount. This includes using clean ingots, thoroughly skimming slag from the melt, cleaning ladles and tools, and ensuring the die cavity is free of debris before each shot.

Correcting Dimensional and Geometric Defects

Dimensional and geometric defects relate to the final shape and accuracy of the casting, directly impacting its ability to fit and function in an assembly. Common issues in this category include flash, warping, and mismatch. These defects often point to problems with the die casting machine, the die itself, or thermal stresses during cooling. Correcting them is essential for maintaining production efficiency and reducing post-processing costs.

Flash is a thin, unwanted sheet of metal that forms on the parting line of a casting or around ejector pins. It occurs when molten metal escapes from the die cavity under high pressure. The most common causes are insufficient clamping force from the machine, worn or damaged parting line surfaces on the die, or excessive injection pressure. A detailed explanation from Rapid Axis highlights that die wear is a major contributor. Troubleshooting this issue requires a systematic check:

- Verify Clamping Force: Ensure the machine's tonnage is sufficient to hold the die halves tightly closed against injection pressure.

- Inspect the Die: Check the parting line for debris, wear, or damage. Regular die maintenance is crucial.

- Optimize Process Parameters: Reduce injection speed or pressure to a level that fills the part without forcing metal out of the cavity.

Warping or Deformation occurs when a casting distorts from its intended shape during or after solidification. This is typically caused by uneven cooling, which creates internal stresses that pull and twist the part. Thin-walled sections cool and shrink faster than thick sections, leading to this stress. Other causes include improper ejection that mechanically bends the still-hot part. To solve warping, focus on achieving uniform cooling by adjusting die cooling channels and ensuring the part design minimizes large variations in wall thickness. Adjusting ejection pin placement for a balanced force can also prevent deformation.

Mismatch is a defect where the two halves of the casting do not align correctly, resulting in a step or shift along the parting line. This is almost always a mechanical issue related to the die or the machine. Worn or broken alignment pins in the die, loose components in the die casting machine, or improper die setup can all lead to mismatch. The solution involves a thorough inspection and maintenance of both the die and the machine to ensure precise and repeatable alignment between the two die halves for every cycle.

Frequently Asked Questions About Die Casting Defects

1. What are the most common defects in die casting?

The most common die casting defects can be grouped into three categories. Surface defects include porosity, blisters, flow marks, and cracks. Internal or structural defects include shrinkage porosity and inclusions. Dimensional defects include flash, warping, and mismatch. Each type has distinct causes related to process, material, or die design.

2. How are casting defects typically identified?

Many defects, such as flash, flow marks, cracks, and warping, can be identified through careful visual inspection. For internal defects like porosity or inclusions, non-destructive testing methods are required. These can include X-ray inspection to see inside the part or ultrasonic testing to detect hidden flaws.

3. What is the key to preventing casting defects?

The key to prevention is a holistic approach focusing on three areas. First is robust tool design, ensuring proper gating, venting, and thermal management. Second is strict process control, which involves optimizing injection speed, pressure, and temperatures. Third is high-quality material management, using clean, properly treated alloys and maintaining a clean production environment.

4. What are the main categories of failures related to castings?

Failures related to castings are typically caused by defects that compromise the part's integrity. These can be categorized as surface imperfections that affect coatings or aesthetics, structural flaws like porosity and cracks that reduce mechanical strength and can lead to fracture, and dimensional inaccuracies like warping or mismatch that prevent proper assembly and function.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —