DFM in Automotive: Smarter Die Design for Lower Costs

TL;DR

Design for Manufacturability (DFM) in the automotive industry is a critical engineering methodology for integrating manufacturing process considerations directly into the earliest stages of product design. Specifically for die design, this approach aims to streamline production, reduce complexity, and lower costs. By ensuring a component can be manufactured efficiently at scale from the outset, DFM delivers higher quality, more reliable automotive parts and accelerates time-to-market.

What is DFM (Design for Manufacturability) in the Automotive Industry?

Design for Manufacturability, often abbreviated as DFM, is a proactive engineering practice focused on designing parts, components, and products for ease of manufacturing. In the high-stakes automotive sector, DFM is not just a best practice but a foundational strategy for success. It involves a collaborative effort between designers, engineers, and manufacturing experts to anticipate and mitigate production challenges before they ever arise. The core philosophy is to move beyond creating a design that simply works and instead create one that can be produced efficiently, reliably, and cost-effectively.

This methodology integrates manufacturing knowledge into the design phase, challenging traditional, siloed workflows where a design is “thrown over the wall” to the production team. By considering factors like material properties, tooling capabilities, and assembly processes from day one, automotive companies can prevent costly rework, delays, and quality issues. According to the principles outlined in a comprehensive DFM guide, this early integration is where engineers have the most leverage to influence final production costs and timelines.

For example, in automotive die design, a simple DFM consideration could be adjusting the corner radius of a stamped metal bracket. A design with sharp internal corners might look clean in a CAD model but is difficult and expensive to machine into a die, leading to higher tooling costs and potential stress points in the final part. An engineer applying DFM would specify a rounded corner that is easily achievable with standard cutting tools, thereby reducing machining time, extending tool life, and improving the structural integrity of the component.

The ultimate goal is to eliminate unnecessary complexity. This approach forces teams to question every design decision's impact on the factory floor. As industry leaders like Toyota have emphasized, if a design choice doesn't add value for the customer, it should be simplified or removed to avoid adding complexity to the manufacturing process. This mindset is crucial in an industry facing intense competition and the rapid transition to electric vehicles (EVs), where efficiency and speed are paramount.

Core Principles and Objectives of Automotive DFM

The primary objective of Design for Manufacturability in the automotive industry is to optimize the relationship between design, cost, quality, and time-to-market. By embedding manufacturing logic into the design process, companies can achieve significant competitive advantages. The main goals are to minimize manufacturing costs, enhance product quality and reliability, and shorten the product development lifecycle. These objectives are achieved by adhering to several core principles.

A fundamental principle is design simplification. This involves reducing the total number of parts in a component or assembly, which is one of the quickest ways to cut costs. Fewer parts mean less material, tooling, assembly labor, and inventory management. Another key principle is the standardization of parts, materials, and features. Using common components and widely available materials simplifies the supply chain, reduces costs through volume purchasing, and ensures consistency. For instance, designing multiple components to use the same type of fastener drastically streamlines the assembly line.

Material and process selection is another critical pillar. The chosen material must not only meet the part's functional requirements but also be compatible with the most efficient manufacturing process. For example, a part initially designed for CNC machining might be redesigned for die casting if production volumes are high enough, leading to a lower per-unit cost. As detailed by experts at Boothroyd Dewhurst, Inc., DFM software can help teams model these trade-offs to make data-driven decisions. This includes relaxing tolerances where functionally possible, as unnecessarily tight tolerances can dramatically increase machining time and inspection costs.

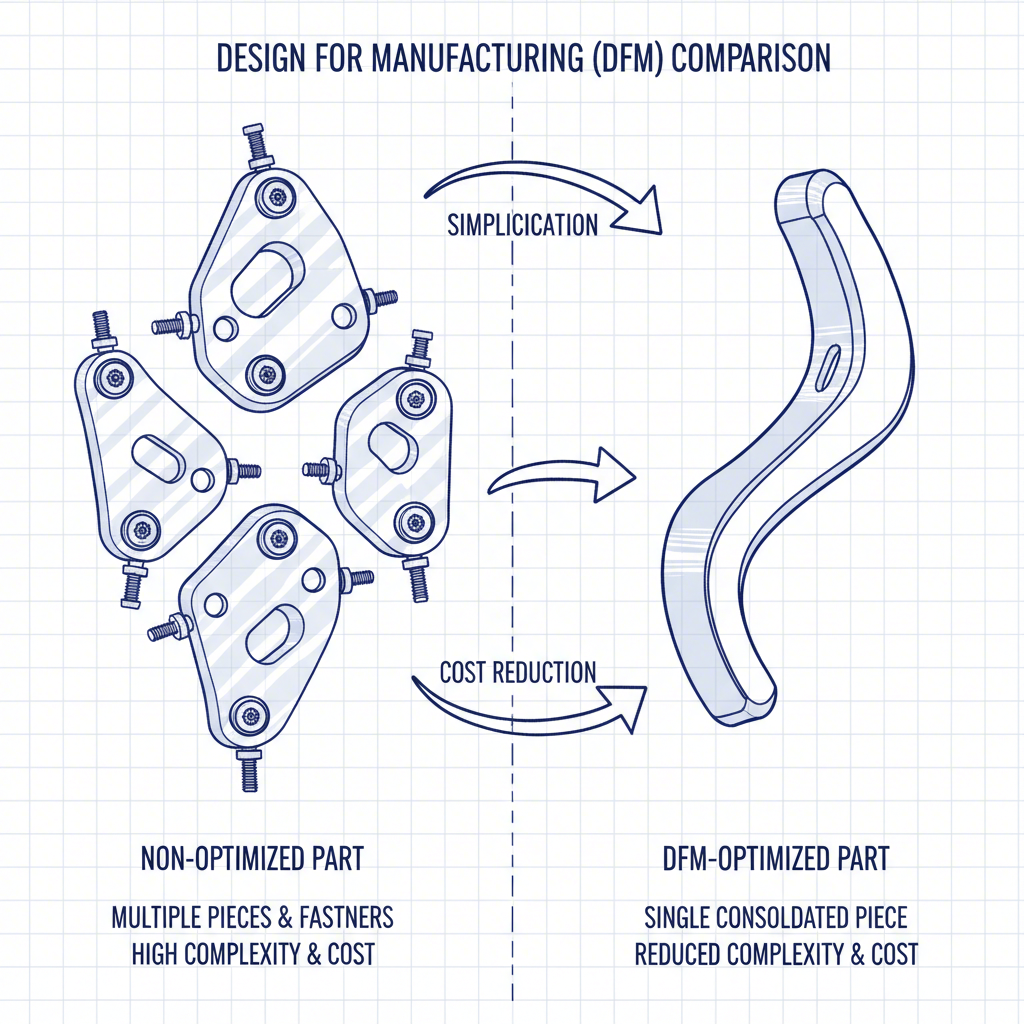

To illustrate the impact of these principles, consider the contrast between a DFM-optimized part and a non-optimized one.

| Metric | Non-Optimized Part | DFM-Optimized Part |

|---|---|---|

| Part Count | Multiple complex components | Single, consolidated component |

| Material | Custom alloy requiring special order | Standard, readily available steel grade |

| Tolerances | Uniformly tight across all features | Tight only on critical mating surfaces |

| Assembly Time | Requires multiple fasteners and manual alignment | Snap-fit design for instant assembly |

| Tooling Cost | High, due to complex geometry and undercuts | Lower, due to simplified design and standard features |

| Production Cost | High | Significantly Reduced |

By applying these core principles, engineering teams can systematically eliminate inefficiencies, reduce waste, and build a more robust and profitable manufacturing operation. The focus shifts from merely solving a design problem to creating a holistic and manufacturable solution.

The DFM Process in Automotive Die Design: A Step-by-Step Approach

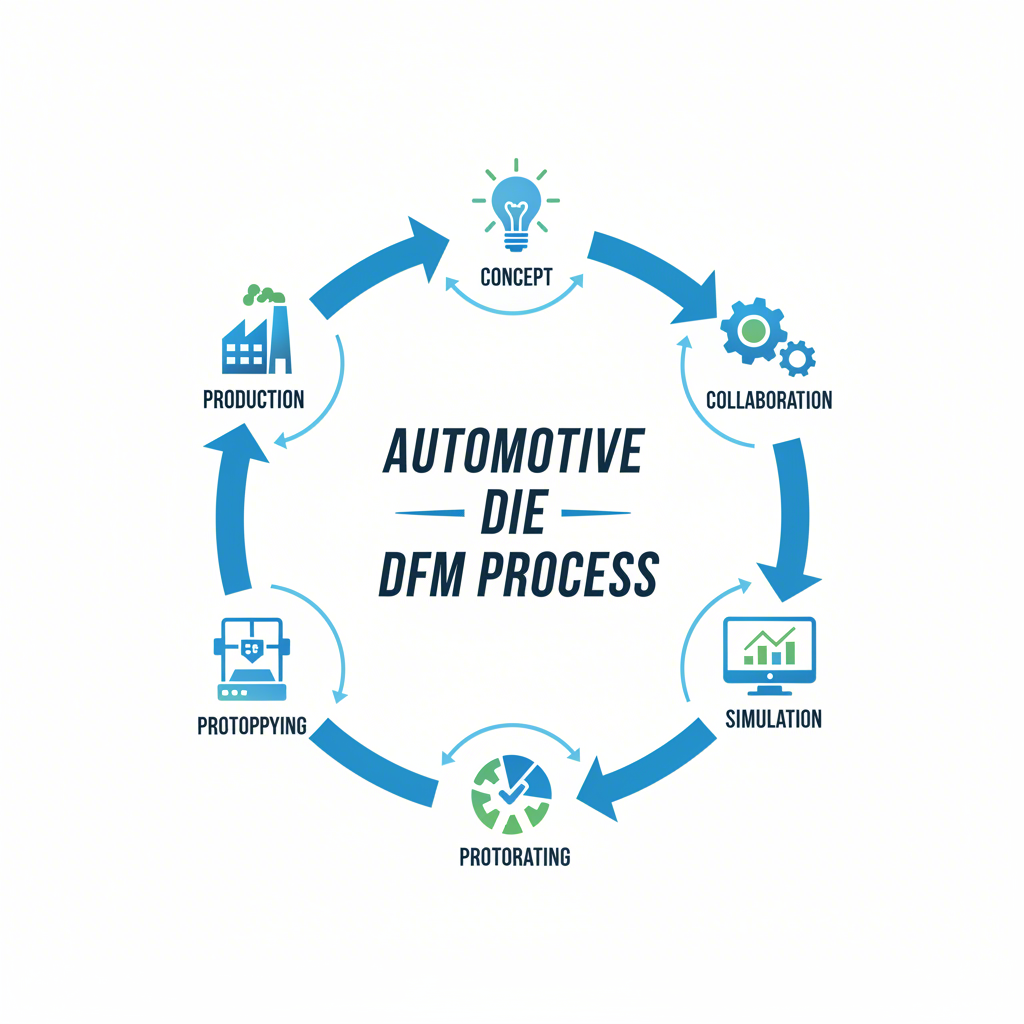

Implementing Design for Manufacturability for automotive die design is not a single event but an iterative process that requires cross-functional collaboration. It involves a systematic approach to analyze, refine, and validate a design to ensure it is fully optimized for production. This structured workflow allows teams to catch potential issues early, when changes are least expensive to make.

The DFM process generally follows several key stages:

- Initial Concept and Feasibility Analysis: This first step involves defining the part's function, performance requirements, and target cost. Engineers evaluate different manufacturing processes (e.g., stamping, casting, forging) to determine the most suitable approach based on production volume, material choice, and geometric complexity.

- Cross-Functional Team Collaboration: DFM is fundamentally a team sport. Design engineers, manufacturing engineers, quality specialists, and even material suppliers must collaborate from the start. This early involvement ensures that diverse expertise is applied to the design, preventing knowledge gaps that can lead to downstream problems. As noted in Automotive Manufacturing Solutions, this “spirit of closeness” between design and production is a key differentiator for leading automakers.

- Material and Process Selection: With a feasible concept, the team selects the specific material and manufacturing process. For die design, this means choosing a grade of steel that balances durability with machinability and ensuring the part geometry is suitable for stamping. For complex projects, partnering with a specialized manufacturer can provide crucial insights. For example, Shaoyi (Ningbo) Metal Technology Co., Ltd. offers expertise in custom automotive stamping dies, using advanced CAE simulations to optimize material flow and prevent defects before any metal is cut.

- Prototyping and Simulation: Before committing to expensive production tooling, teams use simulation software (e.g., Finite Element Analysis) to predict how the material will behave during the manufacturing process. This can identify potential issues like stress concentrations, material thinning, or springback in stamped parts. Physical prototypes are then created to validate the design and test assembly fit and function.

- Feedback and Iteration: The results from simulations and prototypes are fed back to the design team. This stage is a continuous loop of refinement, where the design is adjusted to address any identified issues. The goal is to iterate toward a final design that meets all performance requirements while remaining optimized for manufacturing.

- Final Design for Production: Once all stakeholders are confident in the design's manufacturability, the final specifications and drawings are released for tooling and mass production. Because of the rigorous DFM process, this final design carries a much lower risk of production issues, ensuring a smoother launch.

Real-World Impact: DFM Case Studies in Automotive

The theoretical benefits of DFM become tangible when examining its real-world applications. Across the automotive industry, from small components to large body panels, applying DFM principles has led to significant improvements in cost, quality, and production speed. These case studies demonstrate how a shift in design philosophy translates directly to measurable business outcomes.

One compelling example comes from a manufacturer of locking fuel doors who faced persistent component failure. The original design, made from aluminum, suffered from inconsistent material shrinkage and filling issues during production, leading to unreliable parts. As detailed in a case study by Dynacast, their engineering team was brought in to resolve the issue. The first step was a thorough DFM analysis. Using simulation software, they identified that a different material—a zinc alloy known as Zamak 5—offered superior strength and hardness. More importantly, they redesigned the die casting tool itself, optimizing the gating location and creating a multi-cavity solution to ensure consistent material flow and part integrity. The result was the complete elimination of part failure, a longer tool life, and a lower overall cost per piece for the customer.

Another common application of DFM is in the production of automotive body panels. A traditional approach might involve designing a complex side panel that requires multiple pieces of sheet metal to be stamped separately and then welded together. This multi-step process introduces additional tooling costs, longer cycle times, and potential points of failure at the weld seams. An engineering team applying DFM principles would challenge this approach. They might redesign the panel as a single, deeper-draw stamping. While this requires a more complex and robust initial die, it eliminates entire downstream processes. This consolidation reduces assembly labor, removes the need for welding fixtures, improves the panel's structural integrity, and ultimately lowers the total manufacturing cost per vehicle.

These examples highlight a common thread in successful DFM implementation: moving beyond simply designing a part to designing the entire manufacturing system around it. By considering material science, tooling technology, and assembly logistics during the earliest design stages, automotive companies can solve complex manufacturing challenges, drive innovation, and build a more resilient and efficient production ecosystem.

Driving the Future of Automotive Manufacturing

Design for Manufacturability is more than a cost-cutting tactic; it is a strategic imperative for navigating the future of the automotive industry. As vehicles become more complex with electrification, autonomous systems, and connected technologies, the ability to simplify production becomes a critical competitive advantage. DFM provides the framework for managing this complexity, ensuring that innovative designs are not just conceivable but also producible at scale and at a competitive cost.

The principles of DFM—simplification, standardization, and early collaboration—are timeless, but their application is evolving with technology. The rise of digital tools, such as advanced simulation software and AI-driven analysis, allows engineers to identify and resolve manufacturability issues with greater speed and accuracy than ever before. These technologies enable a more predictive and less reactive approach to product development, shortening design cycles and accelerating time-to-market.

Ultimately, embracing a DFM culture empowers automotive companies to deliver higher-quality products more efficiently. It fosters an environment of continuous improvement where design and manufacturing are not separate functions but integrated partners in innovation. For any automotive manufacturer looking to thrive in an era of rapid transformation, mastering the art and science of Design for Manufacturability is essential for the road ahead.

Frequently Asked Questions About Automotive DFM

1. What is the design for manufacturability DFM process?

The Design for Manufacturability (DFM) process involves designing parts and products with a focus on ease of manufacturing. The goal is to create a better product at a lower cost by simplifying, optimizing, and refining the design. This is typically achieved through cross-functional collaboration between designers, engineers, and manufacturing personnel early in the product development cycle.

2. What is an example of DFM Design for Manufacturing?

A classic example of DFM is designing a product with snap-fit components instead of using screws or other fasteners. This simplifies the assembly process, reduces the number of parts needed, lowers material costs, and decreases assembly time and labor. Another automotive example is modifying a component to be symmetrical, which eliminates the need for separate left- and right-side parts and simplifies inventory and assembly.

3. What is the main objective of Design for Manufacturing DFM in product design?

The primary objective of DFM is to minimize total manufacturing costs while maintaining or improving product quality and ensuring the design meets all functional requirements. Secondary goals include shortening the time-to-market by reducing production delays and streamlining the assembly process.

4. Which design activity is part of the design for manufacturability (DFM) methodology?

A key design activity within the DFM methodology is analyzing and simplifying a part's geometry. This includes actions like using uniform wall thicknesses in molded parts, adding draft angles to facilitate removal from a mold, increasing corner radii to simplify machining, and avoiding features that are mirror images to reduce complexity and tooling costs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —