Why Hot Forging is Essential for Automotive Transmission Parts

TL;DR

Hot forging is a high-temperature metalworking process used to manufacture exceptionally strong, wear-resistant, and durable automotive transmission parts like gears and shafts. By heating metal above its recrystallization point before shaping it, the process refines the material's internal grain structure. This enhancement is critical for creating components that can reliably withstand the extreme pressure and torque within a vehicle's powertrain.

What Is Hot Forging and Why Is It Essential for Transmission Parts?

Hot forging is a manufacturing process where metal is heated to a temperature above its recrystallization point—typically between 1,500°F and 2,500°F—making it malleable and easier to shape under immense pressure. This shaping is usually done using powerful hammers or presses that force the heated metal into a custom die. Unlike processes that cut or machine material away, forging shapes the entire workpiece, aligning its internal grain structure to the contours of the part. This results in a significant increase in strength, ductility, and fatigue resistance.

For automotive transmission systems, these properties are not just beneficial; they are essential. Transmission components, such as gears, cogs, and driveshafts, are subjected to constant high stress, cyclical loads, and intense friction. If these parts were to fail, the result would be a catastrophic failure of the vehicle's powertrain. Hot forging produces components with a continuous grain flow that follows the shape of the part, eliminating the internal voids and weaknesses often found in casting or machining. This metallurgical soundness ensures the reliability and longevity required for high-performance automotive applications.

Furthermore, hot forging allows for the creation of complex geometries with a high degree of precision. As noted in manufacturing examples from industry leaders like Yamaha Motor, even intricately shaped transmission gears can be forged to near-net shapes. This capability reduces the need for extensive secondary machining, saving time and material costs while producing a component that is inherently stronger than one machined from a solid block of metal.

The Step-by-Step Hot Forging Process for Automotive Components

The hot forging process for a typical automotive part, like a transmission gear, is a multi-stage operation that requires precision control at every step. While specific techniques may vary, the fundamental process follows a clear sequence to transform a raw metal billet into a high-strength component.

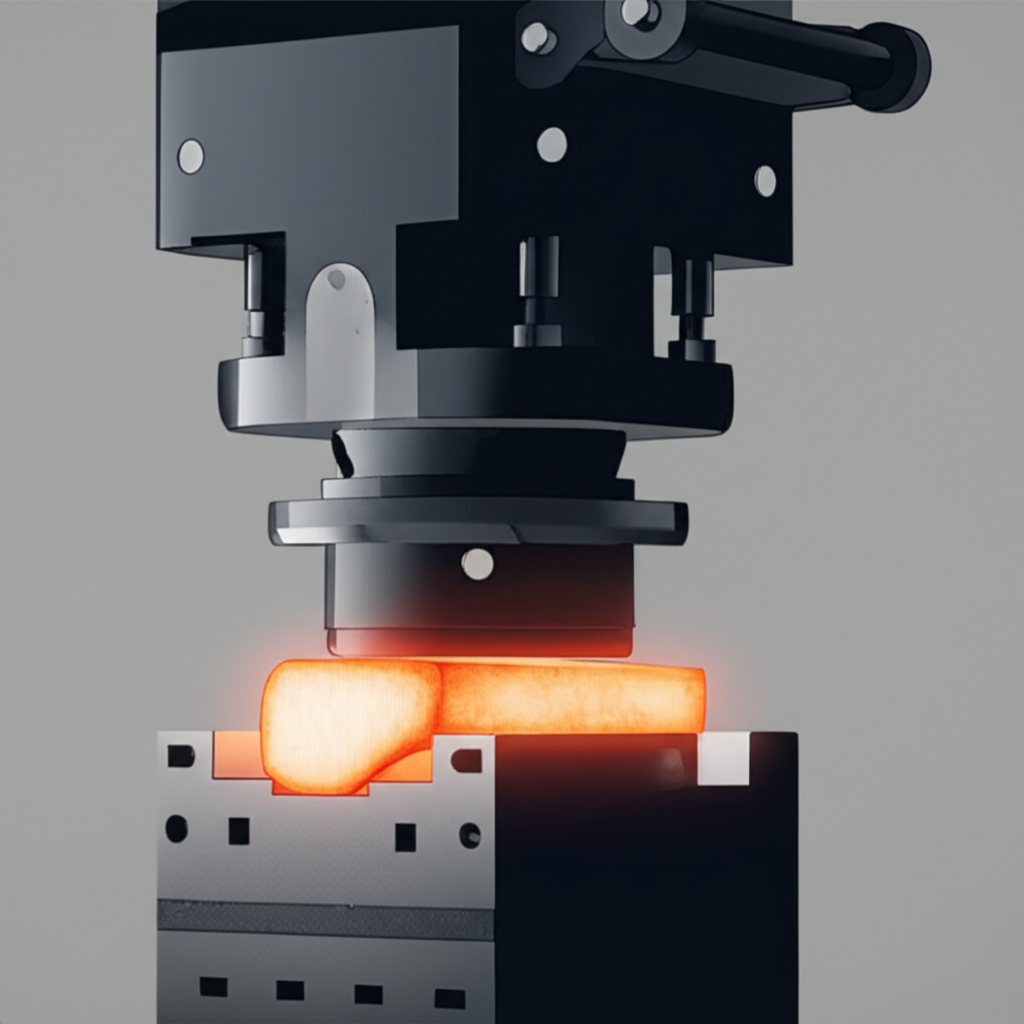

- Billet Heating: The process begins with a raw piece of metal, often steel or a steel alloy, called a billet or ingot. The billet is heated in a furnace to a precise temperature above its recrystallization point but below its melting point. This step is critical, as it makes the metal soft and malleable enough to be shaped without fracturing.

- Forging Operation: Once heated, the glowing billet is quickly transferred to a forging press. For most automotive parts, a method called closed-die or impression-die forging is used. The billet is placed on a lower die, and an upper die attached to a powerful press or hammer strikes it, forcing the metal to flow and fill the die cavities. This may require multiple strikes to achieve the final, complex shape.

- Trimming: During the forging process, some excess material known as 'flash' may squeeze out between the die halves. After the part is formed, it moves to a trimming station where this flash is cut away. The trimmed flash is often recycled, making the process relatively material-efficient.

- Cooling and Finishing: After trimming, the forged part is cooled in a controlled manner to achieve the desired metallurgical properties. Following cooling, many transmission parts undergo finishing processes to meet exact specifications. This often includes heat treatments like carburizing and quenching to increase surface hardness and wear resistance, as well as final machining to achieve tight tolerances.

Executing this process with the precision required for automotive standards demands significant expertise and specialized equipment. For robust and reliable automotive components, many manufacturers partner with specialized firms. For instance, providers of custom forging services from Shaoyi Metal Technology demonstrate this integrated approach by offering everything from in-house die manufacturing to full-scale mass production, ensuring parts meet strict IATF16949 automotive quality standards.

Key Advantages of Hot Forged Transmission Parts

Opting for hot forging in the production of transmission components provides a range of technical and performance advantages that are difficult to achieve with other manufacturing methods. These benefits are central to the safety, reliability, and efficiency of modern vehicles.

- Superior Strength and Fatigue Resistance: The hot forging process refines the metal's grain structure and eliminates internal defects like porosity, resulting in exceptional tensile strength. This makes forged parts highly resistant to impact, shear stress, and the fatigue caused by millions of cycles of use.

- Enhanced Metallurgical Properties: Heating the metal allows for the consolidation of its internal structure, creating a dense and uniform material. This improves the part's toughness and ductility, meaning it can deform slightly under extreme load without fracturing.

- Flexibility for Complex Designs: Because the metal is highly malleable at forging temperatures, it can be forced into complex and non-symmetrical shapes. This allows engineers to design parts optimized for performance and weight without the constraints of other methods, as detailed by industrial application guides.

- Cost-Effectiveness at Scale: While the initial tooling (dies) can be expensive, hot forging is a highly efficient and repeatable process for high-volume production runs. The speed of production and reduced material waste make the cost-per-part highly competitive for automotive manufacturing.

- Structural Integrity and Reliability: Unlike welded or joined components, a forged part is a single, continuous piece of metal. This monolithic structure eliminates weak points, ensuring predictable and reliable performance under the demanding conditions of a vehicle's transmission system.

Hot Forging vs. Cold Forging: A Technical Comparison

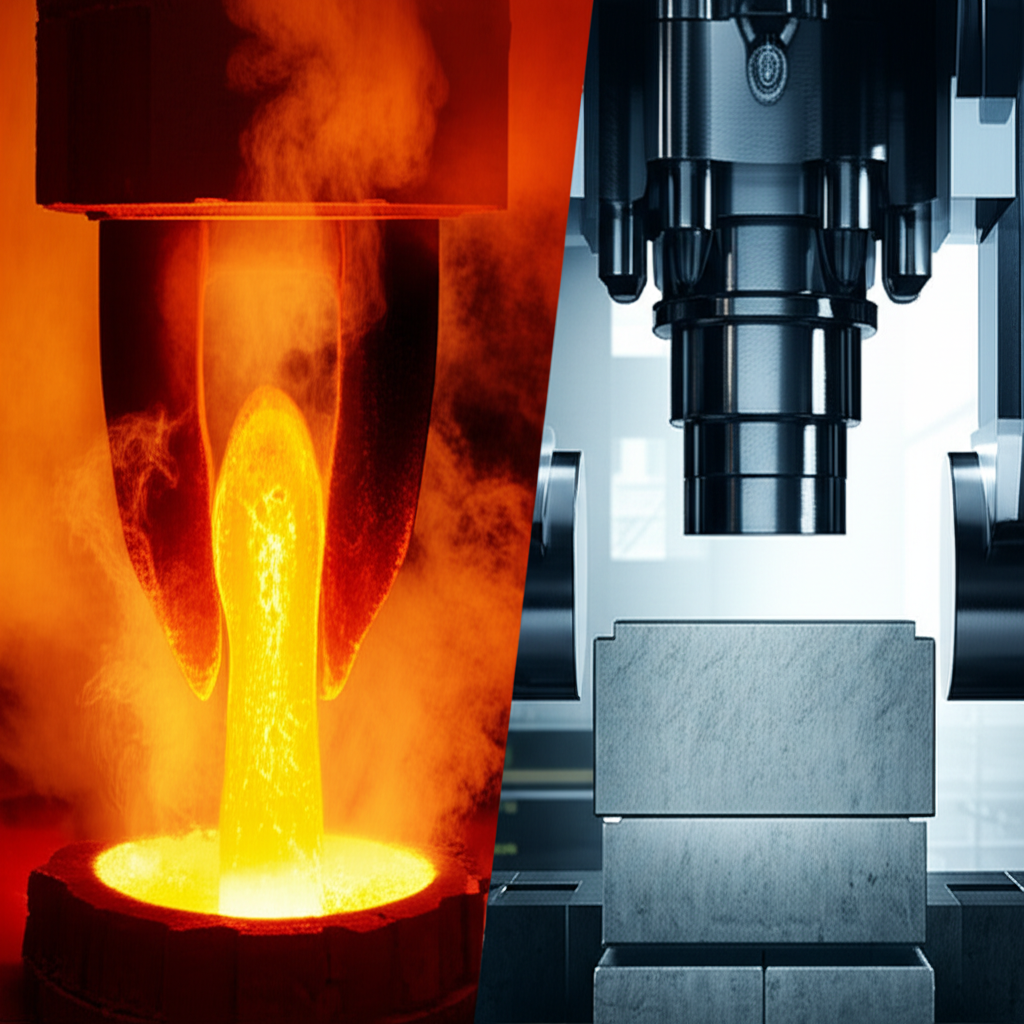

While hot forging is a dominant process, cold forging—shaping metal at or near room temperature—is also used in automotive manufacturing. The choice between them depends on the specific requirements of the component. The primary difference, as explained in detailed comparisons from sources like Fictiv, lies in the trade-offs between strength, precision, and formability.

Here is a technical comparison of the two methods:

| Attribute | Hot Forging | Cold Forging |

|---|---|---|

| Process Temperature | Above the metal's recrystallization point (e.g., up to 2200°F for steel) | At or near room temperature |

| Material Strength | Excellent strength and high ductility due to refined grain structure | Increased hardness and tensile strength due to work hardening, but with lower ductility |

| Dimensional Precision | Good precision, but thermal contraction can lead to wider tolerances | Excellent precision and tight tolerances, often requiring less secondary machining |

| Surface Finish | Surface can have scale or oxidation from high heat, requiring cleaning | Smooth and clean surface finish, as there is no heat-induced scale |

| Ideal Applications | Complex shapes, large components, and parts requiring maximum toughness and ductility (e.g., connecting rods, transmission gears) | Simpler shapes requiring high precision and smooth finish (e.g., fasteners, certain smaller gears, shafts) |

In summary, hot forging is the preferred method for critical, high-stress transmission parts where complex geometry and maximum toughness are the primary requirements. The process's ability to create strong, ductile components is paramount for parts that must endure the powertrain's harsh environment. Cold forging excels in producing smaller, simpler parts with superior dimensional accuracy and surface finish, making it suitable for other components within the automotive ecosystem, as noted by manufacturing resources like Zetwerk.

Forging the Future of Automotive Reliability

Hot forging is more than just a method for shaping metal; it is a foundational process that underpins the reliability and performance of modern vehicles. By transforming raw metal into components with superior strength and resilience, it directly contributes to the safety and longevity of automotive transmission systems. The ability to produce complex, high-stress parts like gears and shafts with exceptional structural integrity ensures that powertrains can handle increasing demands for power and efficiency. As automotive technology continues to advance, the fundamental advantages of hot forging—strength, durability, and reliability—will remain indispensable in manufacturing the critical components that keep the world moving.

Frequently Asked Questions

1. Are transmission gears forged?

Yes, transmission gears are very commonly forged. Both hot and cold forging methods are used to produce gears for automotive and truck transmissions. Forging is preferred because it creates a grain structure that provides the high strength and durability needed to handle the immense torque and forces within a transmission system.

2. What does hot forging do?

Hot forging is a process that heats a metal workpiece to a high temperature, making it malleable. It then uses compressive force from a press or hammer to shape the metal into a desired form. This process refines the metal's internal grain structure, which significantly enhances its strength, toughness, and ductility, making it ideal for high-stress applications.

3. What are the 4 types of forging processes?

While there are many variations, four common types of industrial forging processes are impression die forging (also known as closed-die forging), open-die forging, cold forging, and seamless rolled ring forging. Each method is suited for different part sizes, shapes, and production volumes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —