A Guide to Forged Engine Component Suppliers

TL;DR

Finding the right forged engine components supplier requires identifying their specialization. Suppliers typically fall into two main categories: large-scale industrial or OEM providers focusing on reliability and volume, or high-performance aftermarket specialists dedicated to racing and power gains. Key players in the industrial sector include thyssenkrupp and Mahle, while performance leaders include Wiseco and Wossner.

What Are Forged Engine Components and Why Choose Them?

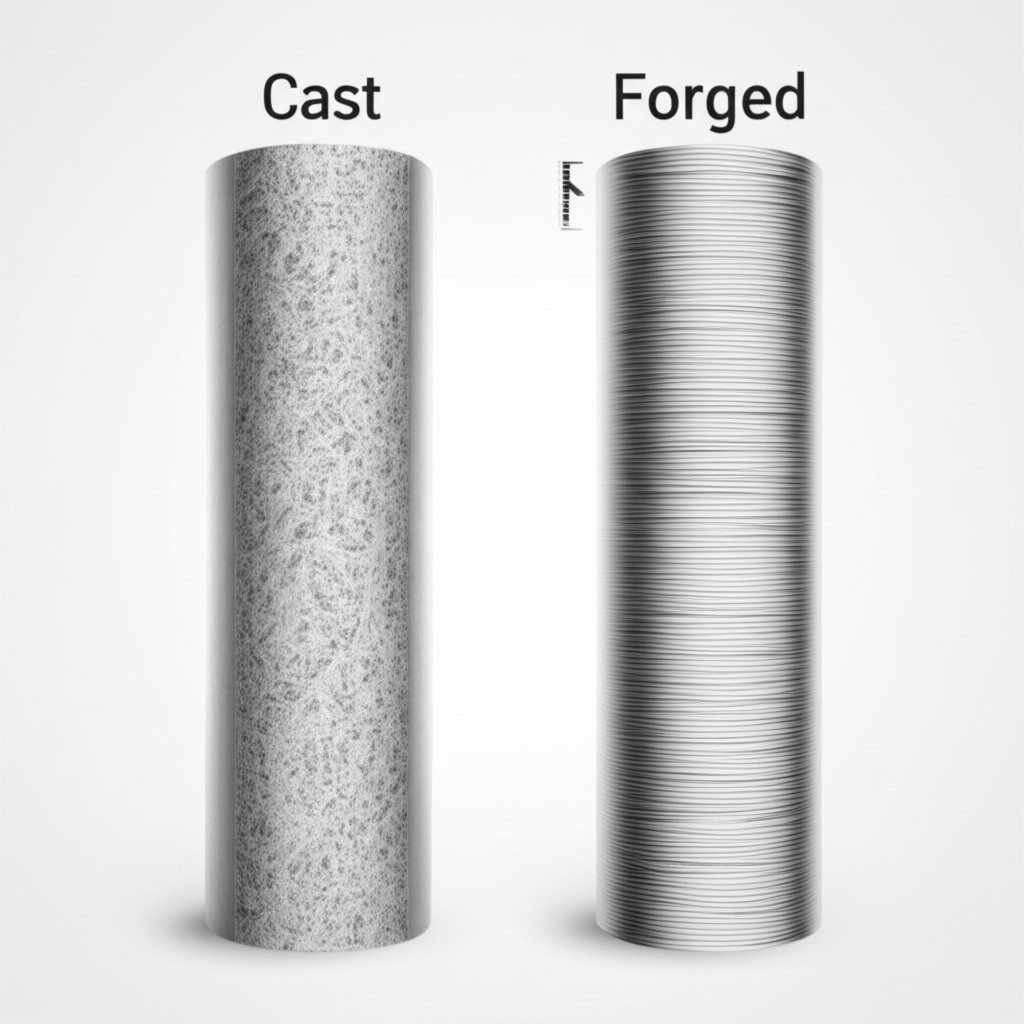

Forged engine components are parts, such as pistons, connecting rods, and crankshafts, that are manufactured through the process of forging. This involves heating a solid billet of metal alloy (like steel or aluminum) to an extreme temperature and then shaping it under immense pressure. This process fundamentally alters the metal's internal grain structure, aligning it to the component's shape. The result is a part with significantly higher density and directional strength compared to a cast component, which is made by pouring molten metal into a mold.

The primary advantage of forging is superior strength and durability. Because the grain structure is refined and continuous, forged parts are highly resistant to impact, shock, and fatigue. This makes them essential for applications where engine failure is not an option. Key benefits include:

- Increased Strength-to-Weight Ratio: Forged components can be designed to be lighter than cast parts without sacrificing strength, which is critical for high-revving performance engines.

- Superior Heat Resistance: The dense molecular structure of a forged part allows it to better withstand the extreme temperatures generated within a high-compression or turbocharged engine.

- Enhanced Durability: Forged internals are less prone to cracking or catastrophic failure under high stress, making them ideal for motorsport, heavy-duty industrial machinery, and aerospace applications.

Choosing forged components is a strategic decision for engine builders and manufacturers aiming to achieve higher power output, greater reliability, and longer service life under demanding conditions. While the manufacturing process is more complex and costly than casting, the performance benefits are indispensable for high-stakes environments.

Key Criteria for Selecting a Forged Component Supplier

Choosing the correct forged engine components supplier is a critical decision that impacts performance, reliability, and cost. Navigating the market requires evaluating potential partners based on a clear set of technical and business criteria. Focusing on these key factors will help you identify a supplier that aligns with your specific engineering and operational needs.

1. Application and Industry Specialization

The first step is to match the supplier's core market to your own. A company like SIFCO Industries, which specializes in flight-critical forged components for the aerospace and defense markets, operates with different processes and certifications than a supplier focused on the automotive aftermarket. Industrial and OEM suppliers prioritize long-term reliability and large production runs, while performance suppliers focus on maximizing power and using exotic materials for racing applications.

2. Material Expertise and Forging Capabilities

Suppliers have different areas of expertise regarding materials and processes. Some excel in forging aluminum alloys for lightweight pistons, while others specialize in high-tensile steel for durable crankshafts and connecting rods. Inquire about their capabilities in open-die forging (for custom, large components) versus closed-die forging (for high-volume, precision parts). A supplier's metallurgical knowledge is crucial for recommending the right alloy for your specific stress and temperature requirements.

3. Quality Systems and Industry Certifications

Certifications are a clear indicator of a supplier's commitment to quality and process control. For automotive applications, IATF 16949 certification is the global standard, ensuring rigorous quality management throughout the supply chain. For businesses needing custom solutions with this level of assurance, a specialized provider can be invaluable. For instance, Shaoyi Metal Technology offers IATF 16949 certified hot forging services for the automotive industry, handling everything from rapid prototyping to mass production.

4. Customization, Engineering, and Support

Your project may require a standard, off-the-shelf part or a fully custom-designed component. Assess a supplier's engineering depth. Companies like Wiseco and Wossner offer extensive catalogs of existing parts but also provide custom piston manufacturing services to meet unique specifications. An ideal partner should be able to collaborate on design, assist with material selection, and provide technical support throughout the product lifecycle.

Leading Suppliers for Industrial, Automotive & OEM Applications

For large-scale industrial, automotive, and Original Equipment Manufacturer (OEM) applications, the focus is on precision, consistency, and the ability to deliver high volumes reliably. These suppliers are foundational partners in global supply chains for everything from passenger cars to heavy machinery and aircraft.

thyssenkrupp Forged Technologies

As a major global player, thyssenkrupp Forged Technologies is a diversified supplier of components and system solutions across the mobility, construction, and resource industries. Their product portfolio is extensive, featuring core engine components like crankshafts and connecting rods, as well as front axles and undercarriage systems. With a vast production network spanning multiple continents, thyssenkrupp is equipped to handle the complex logistical and quality demands of major automotive and industrial clients. Their structured approach to supplier management and engineering competence makes them a go-to for large-scale production partnerships.

SIFCO Industries, Inc.

SIFCO Industries operates in the upper echelon of the forging market, specializing in performance-critical components for the aerospace, energy, and defense sectors. The company supplies flight-critical forged parts and machined assemblies to leading aircraft and engine manufacturers worldwide. Their products can be found on a wide array of commercial, military, and private aircraft. SIFCO's expertise lies in working with advanced alloys and adhering to the exceptionally strict quality and safety standards required for aerospace and defense applications. The company also produces turbine and compressor blades for the energy sector.

Aichi Forge USA, Inc.

Aichi Forge, as noted in search results, is a key supplier of powertrain components, with a particular specialization in crankshafts. They offer comprehensive solutions that cover the entire manufacturing process, from initial design and engineering to the final forging and inspection services. This end-to-end capability allows them to work closely with automotive clients to develop and produce components tailored to specific engine requirements, ensuring both performance and durability for mass production.

Top Suppliers for Performance, Racing & Aftermarket Parts

In the high-performance and racing world, the demands are different. Here, the emphasis is on maximizing power, reducing weight, and withstanding the extreme stresses of motorsport. These suppliers cater to professional race teams, engine builders, and tuning enthusiasts.

Wiseco Performance Products

Wiseco is a dominant name in the high-performance aftermarket, renowned for its industry-leading forged pistons. The company serves a broad range of automotive and powersports applications, including domestic, European, and sport compact vehicles. Wiseco's core business is providing the components necessary for engine rebuilds and achieving ambitious power goals. Their extensive catalog is complemented by custom piston services, allowing builders to create engine internals for virtually any setup, from street performance to professional racing.

Wossner Pistons

With a heritage rooted in racing, Wossner specializes in high-performance forged pistons and connecting rods for both automotive and powersports markets. The company's tagline, "champions choose Wossner," reflects its deep involvement in motorsports. Wossner provides components for a wide array of brands, particularly European and Japanese performance cars, and is a popular choice for enthusiasts seeking superior strength and precision for their engine builds. Their focus on custom orders allows for highly tailored solutions for the most demanding racing applications.

MAPerformance

Modern Automotive Performance (MAPerformance) is a leading retailer and distributor in the aftermarket scene, offering a massive selection of engine internals and assemblies. While they produce their own branded components, their primary role is as a one-stop shop for performance parts from a multitude of top-tier brands, including Wiseco, Wossner, Manley, and JE Pistons. For enthusiasts and builders, MAPerformance provides convenient access to a comprehensive inventory of forged pistons, rods, crankshafts, and fully assembled short blocks for popular platforms like the Mitsubishi Evo and Subaru WRX/STI.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —