Key Tool Steel Grades for Automotive Die Performance

TL;DR

Selecting the right tool steel grades for automotive dies requires a careful balance between wear resistance and toughness to ensure tool longevity and part quality. The most commonly used grades include D-Type steels like D2 for high wear resistance in cutting and forming operations, S-Type steels such as S7 for superior shock resistance in high-impact stamping, and A-Type steels like A2, which offer a versatile combination of both properties. The choice ultimately depends on the specific application, from stamping high-strength steel to forming intricate components.

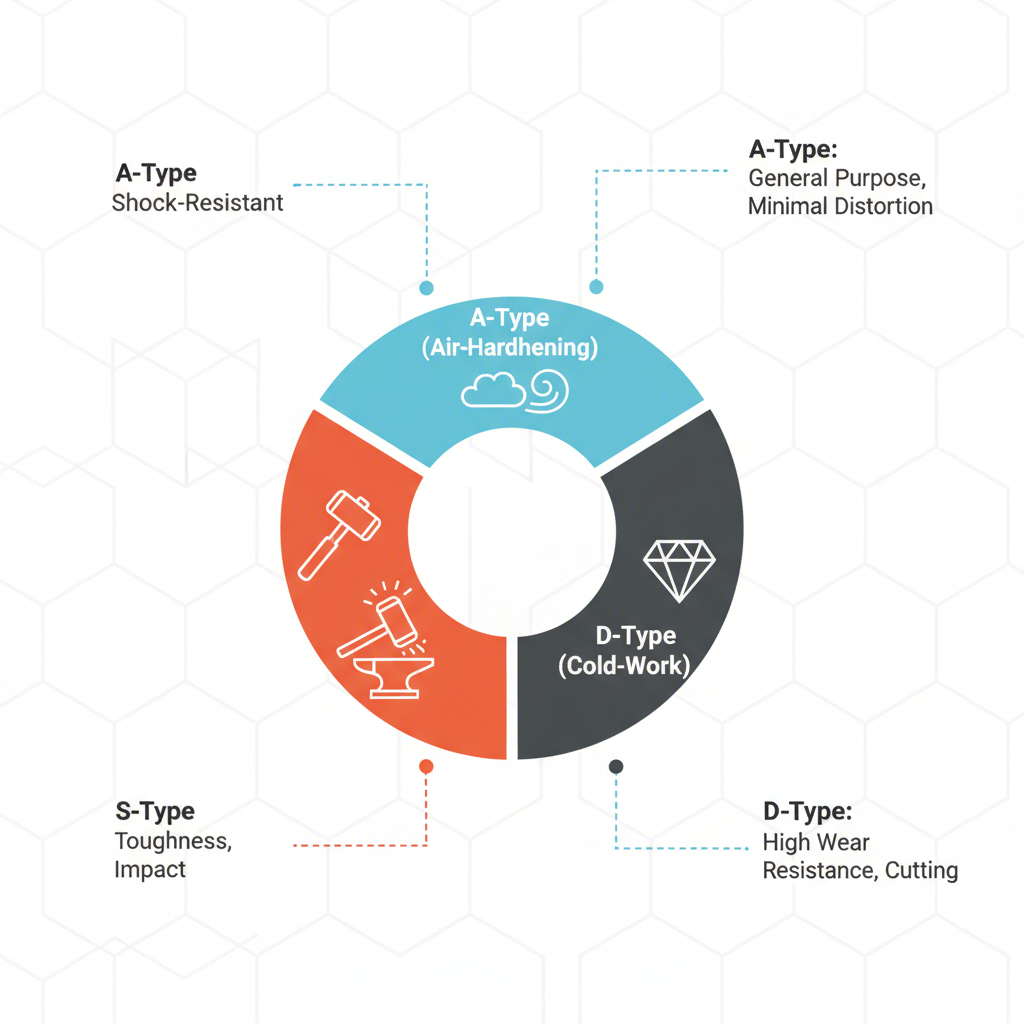

Understanding Tool Steel Classification Systems

Tool steel is a specialized category of carbon and alloy steels engineered to manufacture tools, dies, and molds. Its exceptional hardness, wear resistance, and ability to retain its shape at elevated temperatures make it indispensable in demanding industrial environments. To standardize these materials, the American Iron and Steel Institute (AISI) established a classification system that groups tool steels based on their hardening method, composition, and application. Understanding this system is the first step in selecting the appropriate material for automotive dies.

The classification uses a letter-number designation to identify each grade. The letter indicates the steel's primary characteristic or hardening method, providing a clear framework for engineers and toolmakers. For instance, 'A' stands for Air-Hardening, while 'W' signifies Water-Hardening. This system simplifies the selection process by categorizing steels with similar performance profiles.

While there are several categories, a few are particularly relevant to die manufacturing. These include the water-hardening (W), oil-hardening (O), air-hardening (A), high carbon-high chromium (D), and shock-resisting (S) types. Each group offers a unique combination of properties tailored for specific tasks, from cutting and blanking to forming and stamping. A detailed breakdown of the most common classifications can be found in resources from leading suppliers like SSAB.

| Classification Type | Full Name / Primary Characteristic | Key Feature | Common Automotive Application |

|---|---|---|---|

| A-Type | Air-Hardening Medium Alloy | Excellent dimensional stability after heat treatment. | Forming dies, blanking dies. |

| D-Type | High Carbon, High Chromium | Exceptional wear and abrasion resistance. | Cutting dies, stamping tools for high-volume production. |

| S-Type | Shock-Resisting | High toughness and impact resistance. | Punches, chisels, heavy-duty stamping dies. |

| H-Type | Hot-Working | Retains hardness at high temperatures. | Forging dies, die casting molds. |

Critical Properties of Tool Steel for Automotive Dies

The performance of an automotive die is directly tied to the mechanical properties of its tool steel. Selecting the optimal grade involves navigating a series of trade-offs to match the material's characteristics with the demands of the application. The two most critical properties in this balance are wear resistance and toughness.

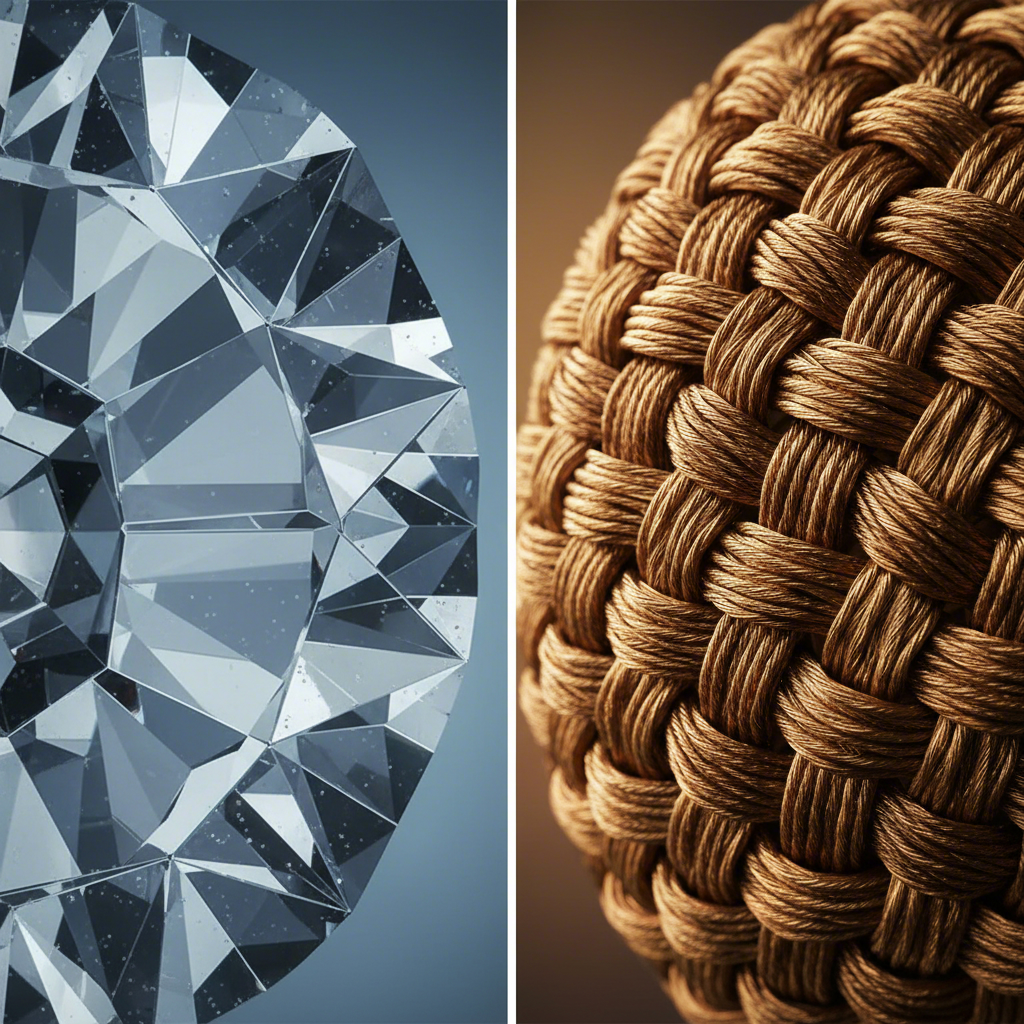

Wear resistance is the steel's ability to withstand abrasion and erosion caused by sheet metal flowing over its surface during stamping or forming. Steels with high wear resistance, such as D-type grades, contain hard carbides in their microstructure that prevent the tool surface from degrading quickly. This property is paramount for high-volume production runs and when working with abrasive materials like Advanced High-Strength Steels (AHSS), which are increasingly common in modern vehicle bodies.

Toughness, conversely, is the material's ability to absorb energy and resist chipping, cracking, or catastrophic failure under sudden impact or high stress. Shock-resisting S-type steels are engineered for maximum toughness. This property is crucial in applications involving heavy impacts, such as blanking thick materials or in dies with sharp corners that are prone to fracture. As detailed by industry experts at Pennsylvania Steel, high-impact applications require steels designed to absorb shock without fracturing.

The fundamental challenge in tool steel selection is that wear resistance and toughness are often mutually exclusive. Increasing a steel's hardness to improve wear resistance typically makes it more brittle, reducing its toughness. This trade-off is evident when comparing grades like D2 and S7. D2 offers superior wear resistance but is less tough, making it suitable for cutting dies. S7 provides exceptional toughness at the expense of wear resistance, making it ideal for punches and shock applications. The goal is to find the right balance for the specific die component to maximize its service life.

Deep Dive: Top Tool Steel Grades for Automotive Dies

In the automotive industry, a few 'workhorse' grades of tool steel have become standards due to their reliable performance across a range of applications. These materials provide a spectrum of properties that allow toolmakers to optimize performance for everything from simple brackets to complex structural components. Understanding their individual strengths is key to successful die design and manufacturing.

For complex projects, partnering with a specialist can be invaluable. For example, manufacturers like Shaoyi (Ningbo) Metal Technology Co., Ltd. possess deep expertise in custom automotive stamping dies, leveraging advanced simulations and material knowledge to select the optimal tool steel grades for precision, efficiency, and longevity in high-volume production environments.

Below is a detailed comparison of the most common grades used in automotive tooling, with insights drawn from various tooling specialists.

| Grade | Key Properties | Common Hardness (HRC) | Typical Automotive Application |

|---|---|---|---|

| D2 | High wear resistance, good hardness, fair toughness. | 58-62 HRC | Cutting edges, forming dies, stamping tools for high-wear parts. |

| A2 | Good balance of wear resistance and toughness, excellent dimensional stability. | 57-62 HRC | Blanking dies, forming dies, punches, general purpose tooling. |

| S7 | Excellent toughness and shock resistance, good machinability. | 56-60 HRC | Heavy-duty punches, chisels, shear blades, high-impact stamping. |

| H13 | Excellent red hardness, high toughness, good heat resistance. | 45-52 HRC | Hot forging dies, die casting molds, extrusion dies. |

| P20 | Good machinability, good polishability, typically supplied pre-hardened. | 28-32 HRC | Plastic injection molds, holders for die components. |

As noted by SteelPRO Group, selecting the correct grade is crucial for optimal performance. For cold work applications like stamping, D2 and A2 are top contenders. D2 is preferred when wear is the primary concern, while A2 offers a more balanced profile with better toughness and superior dimensional stability during heat treatment. S7 is the go-to choice when the primary risk is tool chipping or cracking from impact. H13 is a hot-work steel, essential for processes like forging where the tool is in prolonged contact with hot metal. P20, a plastic mold steel, is often used in automotive tooling for holders and support structures due to its ease of machining.

Advanced and Specialty Steels in Modern Automotive Tooling

As vehicle designs evolve to incorporate stronger and lighter materials, the demands placed on automotive dies have intensified. The widespread use of Advanced High-Strength Steels (AHSS) requires tooling materials that go beyond the capabilities of conventional grades. In response, specialty and advanced tool steels, such as those made through powder metallurgy (P/M), have become increasingly important.

Powdered metal (P/M) tool steels are manufactured by atomizing molten steel into a fine powder, which is then consolidated under high pressure and temperature. This process creates a material with a much finer and more uniform microstructure compared to conventionally produced steels. The primary advantage is a more even distribution of carbides, which eliminates the large, segregated carbides that can act as stress points in grades like D2. The result is a steel with superior toughness, wear resistance, and grindability.

The uniform structure of P/M steels also makes them highly suitable for advanced surface coatings, as they provide a stable substrate. For the most demanding automotive applications, such as stamping ultra-high-strength steel components, P/M steels offer a significant increase in tool life and performance, justifying their higher initial cost. As explained by tooling experts, this advanced manufacturing process yields materials with exceptional uniformity and reduced risk of cracking. A comprehensive list of tool steel types and their manufacturing processes can be found at resources like Special Tool & Engineering.

Frequently Asked Questions

1. What tool steel is used for die casting?

For die casting, hot-work tool steels are required due to the extreme temperatures involved. The most common grade used is H13. It is designed to retain its hardness and strength when in prolonged contact with molten metals like aluminum and zinc, offering excellent resistance to thermal fatigue and cracking.

2. Is D2 or S7 better?

Neither D2 nor S7 is universally 'better'; their suitability depends entirely on the application. D2 offers excellent wear resistance and is ideal for cutting and forming dies where abrasion is the main concern. S7 provides superior toughness and shock resistance, making it the better choice for applications with high impact, such as heavy-duty punches or shear blades, where the primary risk is chipping or cracking.

3. What is the difference between P20 and D2 tool steel?

The primary difference lies in their properties and intended use. D2 is a high-carbon, high-chromium cold-work tool steel known for its high hardness and excellent wear resistance, making it suitable for cutting tools and forming dies. P20 is a lower-carbon plastic mold steel, typically supplied in a pre-hardened condition. It is valued for its good machinability and polishability, making it ideal for manufacturing plastic injection molds and die holders, but not for cutting applications.

4. What grade of steel is used in car bodies?

Car bodies are constructed from a variety of steel grades, not tool steel. Modern vehicles primarily use different forms of sheet steel, including mild steels, High-Strength Low-Alloy (HSLA) steels, and increasingly, Advanced High-Strength Steels (AHSS) like dual-phase (DP) and transformation-induced plasticity (TRIP) steels. These materials are chosen for their formability and ability to absorb crash energy while minimizing vehicle weight.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —