Essential Strategies for Thermal Management in Die Casting Molds

TL;DR

Effective thermal management in die casting molds is a critical engineering discipline that directly governs part quality, production efficiency, and tool longevity. It involves a balanced approach of preheating the mold to an optimal temperature and then precisely controlling cooling during the production cycle. Proper thermal control is the primary defense against common defects like shrinkage, porosity, and cracking, ensuring the consistent output of high-integrity components.

The Critical Role of Thermal Management in Die Casting

In the high-pressure environment of die casting, temperature is not merely a process parameter; it is the cornerstone of quality and repeatability. Thermal management refers to the deliberate control of the mold's temperature before and during the casting cycles. This process ensures that the molten metal flows, fills the cavity, and solidifies under optimal conditions. An improperly managed mold temperature is a leading cause of defects and production inefficiencies, making its control a top priority for process optimization. According to a detailed analysis by Regloplas, a non-optimal die temperature is the greatest primary source of error in the entire process.

The temperature of the mold cavity has a profound impact on the behavior of the molten alloy. If the mold is too cold, the metal can solidify prematurely, leading to incomplete filling of the cavity, cold shuts (where two streams of metal fail to fuse properly), and poor surface finish. Conversely, if the mold is too hot, it can prolong solidification time, leading to shrinkage porosity, dimensional inaccuracies, and increased wear and tear on the tool itself. As experts at CEX Casting note, this delicate balance affects everything from metal fluidity to the final structural density of the part.

Achieving a stable thermal balance within the mold is essential for consistent production. This balance involves removing the exact amount of heat introduced by the molten metal during each cycle. Failure to do so results in thermal fatigue—the repeated expansion and contraction of the mold steel—which leads to microcracks and shortens the tool's service life. Effective thermal management mitigates these risks, leading to a more stable and predictable manufacturing operation.

The benefits of precise thermal control are extensive and impact nearly every aspect of the die casting operation. By maintaining the mold within its ideal operating window, manufacturers can achieve:

- Reduced Defect Rates: Minimizes common issues such as porosity, shrinkage, flow marks, and cracking.

- Improved Part Quality: Ensures superior surface finish, clear contour definition, and consistent dimensional accuracy.

- Longer Mold Lifespan: Prevents thermal shock and fatigue, reducing maintenance costs and downtime.

- Enhanced Productivity: Allows for optimized cycle times and reduces scrap rates, leading to higher overall efficiency.

Core Methods and Technologies for Mold Temperature Control

A comprehensive thermal management strategy employs both heating and cooling techniques to maintain the mold at its target operating temperature. The process begins with preheating the mold to prevent thermal shock from the initial injection of molten metal. This is typically accomplished using electric heating cartridges embedded in the mold or by circulating hot oil or pressurized water through internal channels. Preheating ensures the mold is ready for production and minimizes defects in the first few shots.

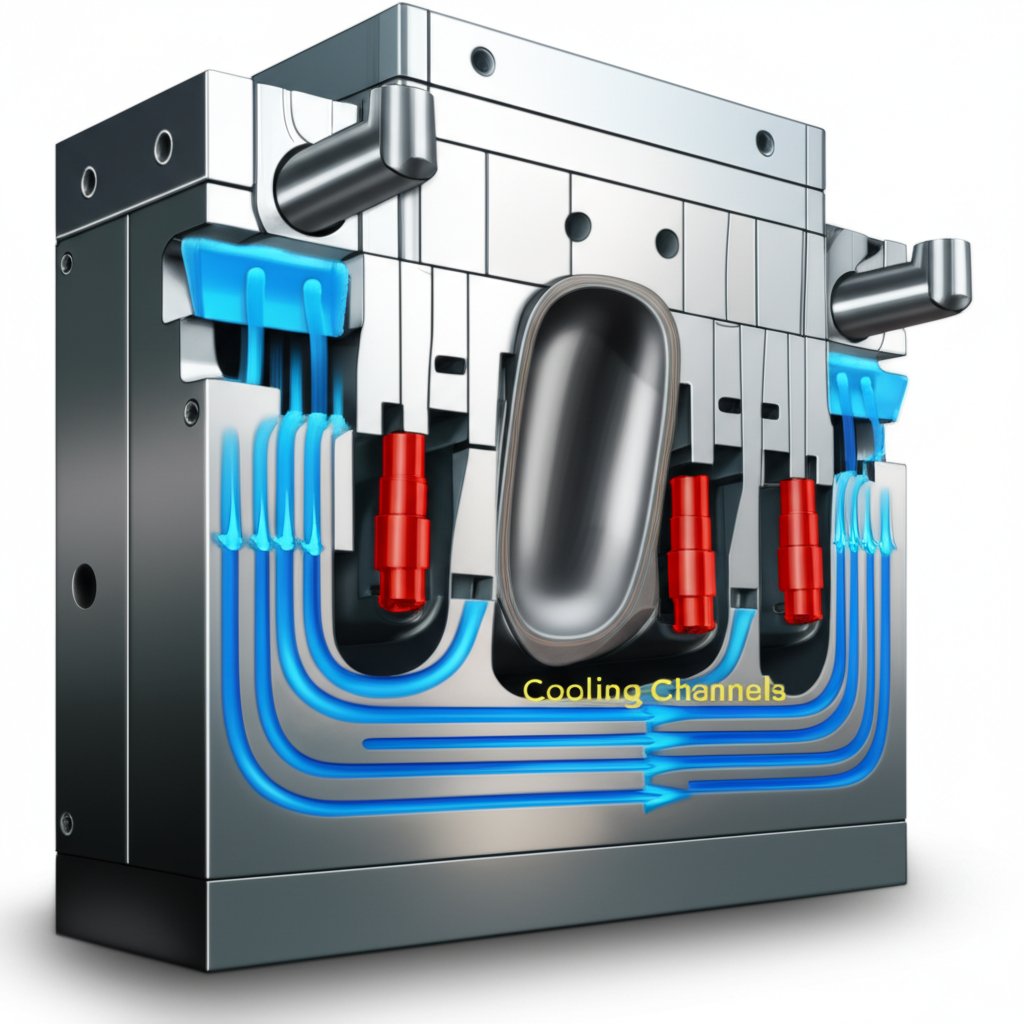

Once production begins, the primary challenge shifts to removing the immense amount of heat transferred from the molten alloy. Cooling systems are integral to this phase and are designed to extract heat efficiently and uniformly. The most common method involves circulating a fluid, such as water or oil, through a network of cooling channels drilled into the mold. Water is highly effective due to its high heat absorption capacity, while oil is used for higher temperature applications to prevent boiling.

In addition to fluid circulation, several other technologies are used to refine thermal control. High-conductivity inserts made from materials like copper alloys can be placed in critical areas to draw heat away from hotspots. Conversely, insulating coatings can be applied to slow down heat transfer in sections that need to remain hotter for longer. For targeted cooling in hard-to-reach areas, devices like bubblers or forced air lines can be employed to provide localized temperature reduction.

The selection of a specific method depends on factors like the casting alloy, the complexity of the part, and the required production rate. Many modern systems integrate these techniques for zoned temperature control, allowing different parts of the mold to be managed independently for maximum precision.

| Method | Description | Primary Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Water/Oil Cooling Channels | A network of channels drilled into the mold through which a temperature-controlled fluid is circulated. | General-purpose bulk heating and cooling of the mold. | Highly effective, allows for zoned control, well-established technology. | Risk of leaks; water can cause limescale buildup, reducing efficiency. |

| High-Conductivity Inserts | Pieces of highly conductive material (e.g., copper alloy) placed into the steel mold. | Targeted heat extraction from localized hot spots. | Excellent for managing heat in thick sections or complex geometries. | Can be costly; requires careful design integration. |

| Mold Coatings | Specialized refractory or lubricating coatings applied to the mold cavity surface. | Insulating specific areas to slow cooling or aiding in part release. | Versatile, can alter solidification patterns without changing mold geometry. | Requires reapplication; can wear off over time. |

| Forced Air / Spot Cooling | Using compressed air or targeted water sprays (bubblers) on specific mold areas. | Cooling cores, pins, or other features where channels are not feasible. | Provides precise, localized cooling. | Less efficient for bulk heat removal compared to liquid cooling. |

Optimization Strategies for Advanced Thermal Performance

As the demand for more complex and lightweight components grows, die casters are moving beyond traditional methods toward advanced strategies that optimize thermal performance with scientific precision. The frontier of thermal management lies in simulation and predictive analysis, which allow engineers to design and validate a mold's thermal behavior before any steel is cut. This proactive approach is fundamental to preventing defects and maximizing efficiency from the outset.

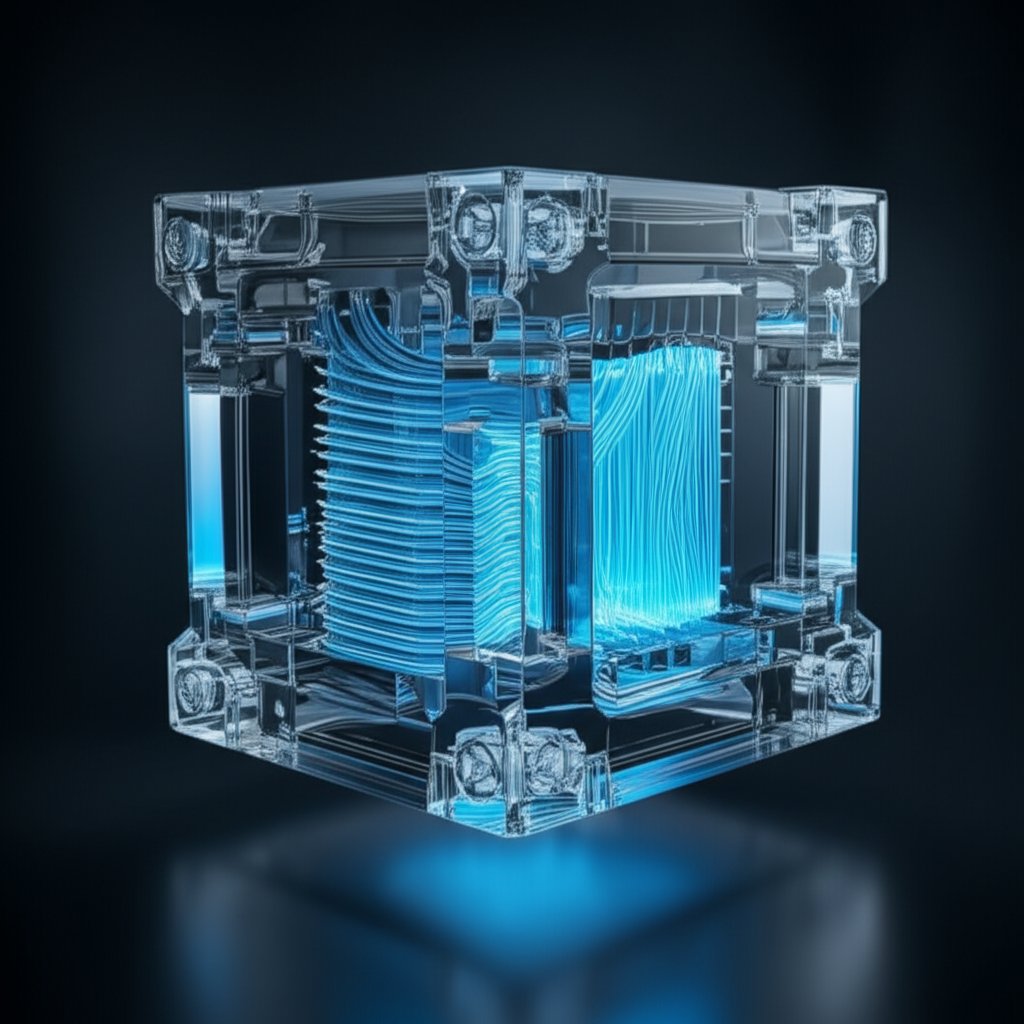

Mold flow analysis is a cornerstone of modern die casting design. This powerful simulation software models how molten metal will flow into, fill, and solidify within the mold cavity. It provides detailed predictions of temperature distribution, identifying potential hot spots and areas prone to defects like porosity. By visualizing the thermal landscape, designers can strategically place cooling channels, inserts, and other control elements to create a balanced thermal profile, ensuring uniform solidification and high part integrity. This level of precision engineering is common in high-performance manufacturing, where material and process control are paramount. For instance, companies specializing in robust components for demanding sectors, such as Shaoyi (Ningbo) Metal Technology in the automotive forging space, rely on meticulous die design and quality control to ensure component integrity.

An even more advanced technique is Topology Optimization. This computational method uses algorithms to generate the most efficient layout of cooling structures within a given design space. As explored in a study published by the National Institutes of Health (NIH), topology optimization can design novel cooling structures that outperform traditional channels, offering superior and more uniform cooling. This can lead to the development of conformal cooling channels that closely follow the contours of the casting, providing highly efficient and targeted heat removal. Often realized through additive manufacturing (3D printing), these optimized designs represent a significant leap forward in mold cooling technology.

Implementing an advanced thermal optimization strategy typically involves the following steps:

- Initial Simulation: Run a mold flow analysis on the initial part and mold design to identify thermal challenges and potential defect areas.

- Design Iteration: Use the simulation results to strategically design the thermal management system, placing cooling channels and other elements to counteract identified hot spots.

- Advanced Optimization (Optional): Employ topology optimization to generate highly efficient, often conformal, cooling channel designs for critical areas.

- Validation: Run further simulations with the optimized thermal system to verify that it achieves the desired temperature profile and resolves the initial issues.

- Prototyping and Testing: Manufacture the mold and conduct trials, using thermal imaging and embedded thermocouples to compare real-world performance against simulation predictions.

Achieving Excellence Through Thermal Precision

Ultimately, mastering thermal management is not just about preventing defects—it's about unlocking the full potential of the die casting process. Precise control over the mold's temperature transforms manufacturing from a reactive to a predictive discipline, enabling the consistent production of complex, high-quality parts with greater efficiency and a longer tool lifespan. From foundational heating and cooling channels to advanced simulation and topology optimization, the available technologies provide a robust toolkit for engineers. By strategically applying these methods, die casters can achieve a stable, repeatable process that meets the increasingly stringent demands of modern industry, ensuring that every part produced is a testament to thermal precision.

Frequently Asked Questions

1. What is the temperature control for die casting?

Temperature control for die casting is the process of preheating a mold to an optimal temperature, typically between 150°C and 250°C, before production and then managing its temperature during the casting cycle. This control is crucial for ensuring proper metal flow, preventing casting defects, improving the surface finish of parts, and extending the life of the mold.

2. What is PDC and GDC?

PDC stands for Pressure Die Casting, and GDC stands for Gravity Die Casting. They are two different methods of casting. In GDC, molten metal is poured into the mold and fills it under the force of gravity. In PDC, the molten metal is injected into the mold under high pressure, which allows for the creation of more intricate parts with thinner walls and better surface finishes.

3. What is the heat treatment of castings?

Heat treatment is a post-casting process used to alter the physical and mechanical properties of a cast part. By subjecting the casting to controlled heating and cooling cycles, its microstructure can be modified to improve properties such as hardness, strength, toughness, and dimensional stability. This is done to meet specific performance requirements for the component's application.

4. How is mold temperature calculated?

Calculating the required mold temperature involves a heat load calculation. This process determines the amount of heat that needs to be removed from the mold to maintain a stable temperature. Key factors in the calculation include the temperature and type of the molten alloy, the weight of the casting, the cycle time, and the physical properties of the mold material. The result helps engineers design an appropriately sized and configured cooling system.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —