A Technical Guide to Die Casting Oil Pans for Automotive

TL;DR

Die casting is a high-pressure manufacturing process used to create precise, durable, and complex aluminum oil pans for automotive engines. This method offers significant advantages, including superior heat dissipation compared to steel, excellent strength-to-weight ratio, and the flexibility to integrate complex design features like cooling fins and internal baffling. For engineers and procurement managers, choosing a die-cast aluminum oil pan means investing in enhanced engine performance and longevity.

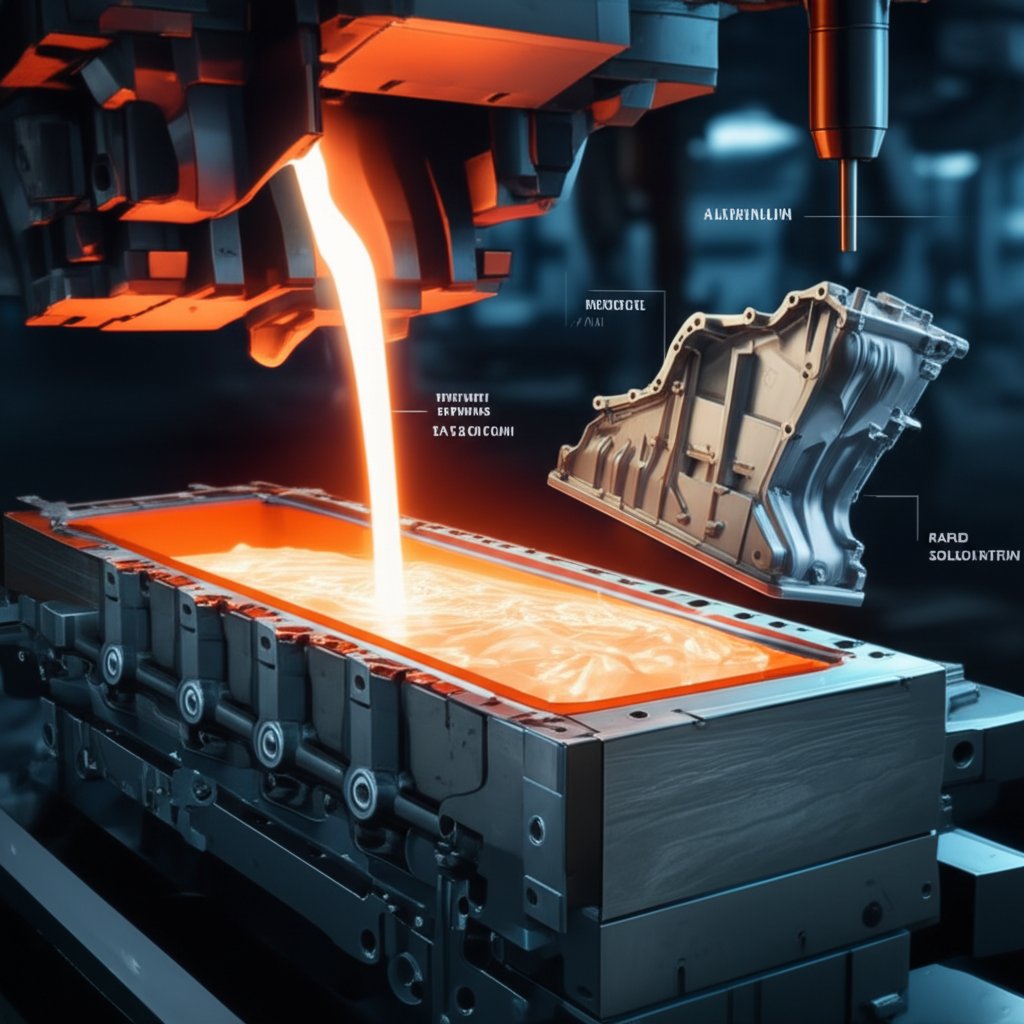

The Die Casting Process for Automotive Oil Pans

The manufacturing of an engine oil pan is a critical process that directly impacts engine reliability and performance. Die casting has emerged as a leading method for producing high-quality aluminum oil pans. The process involves injecting molten aluminum alloy, such as ADC12, into a hardened steel mold—or die—under immense pressure. This high-pressure application ensures the molten metal fills every intricate detail of the mold, resulting in a part with a superior surface finish, tight dimensional tolerances, and consistent quality across high-volume production runs.

The precision of die casting allows for the creation of complex geometries that would be difficult or impossible to achieve with other methods. For example, specific dimensions like 425x342x134mm with wall thicknesses varying from 3mm to 28mm can be consistently produced, as noted by manufacturers like Prodiecasting. This capability enables the integration of features such as cooling fins to improve heat dissipation, streamlined internal pathways for better oil flow, and mounting bosses for filters and sensors, all within a single, unified component.

When selecting a manufacturing process for aluminum oil pans, it's essential to compare the available methods. Each has distinct advantages depending on production volume, budget, and performance requirements. Die casting is often compared with sand casting and gravity die casting.

| Casting Process | Pros | Cons | Best For |

|---|---|---|---|

| High-Pressure Die Casting | High efficiency, superior surface finish, tight tolerances, complex shapes. | High initial tooling cost, potential for porosity if not controlled. | High-volume production of standardized parts requiring precision. |

| Sand Casting | Low tooling cost, design flexibility for large parts, material versatility. | Lower dimensional accuracy, rougher surface finish, slower production. | Prototypes and low-volume orders where initial cost is a primary concern. |

| Gravity Die Casting | Excellent mechanical properties, good surface finish, cost-effective for medium volumes. | Moderate tooling costs, less suited for highly intricate designs. | Medium-volume orders where material strength and quality are critical. |

As detailed by casting experts like Dongrun Casting, the choice heavily depends on the project's scale. While sand casting is suitable for prototyping, high-pressure die casting is the definitive choice for mass production in the automotive industry due to its speed, precision, and repeatability.

Key Advantages of Die-Cast Aluminum Oil Pans

Die-cast aluminum oil pans offer a host of benefits over traditional stamped steel or other cast-iron alternatives, making them a preferred choice for both high-performance and standard automotive applications. These advantages stem from the unique properties of aluminum alloys and the precision of the die casting process. The result is a component that not only holds oil but actively contributes to the engine's overall health and efficiency.

One of the most significant benefits is the inherent strength and vibration-damping characteristics of cast aluminum. One of the most significant benefits is the inherent strength of cast aluminum, which provides a rigid structure that can enhance block stiffness while effectively dampening engine vibrations, leading to smoother operation and reduced mechanical stress. Furthermore, the precision-machined sealing surfaces created through die casting ensure a superior, leak-free seal with the engine block, a common point of failure for stamped steel pans that can warp over time.

The key performance benefits of choosing a die-cast aluminum oil pan include:

- Superior Heat Dissipation: Aluminum is an excellent thermal conductor, allowing it to pull heat away from the engine oil more effectively than steel. Many designs incorporate external fins that increase the surface area, further enhancing this cooling effect and helping to maintain optimal oil temperatures.

- Design Freedom and Complexity: Die casting allows for a "blank sheet of paper" approach to design, free from the constraints of stamping or welding. This enables the creation of pans with increased oil capacity, internal baffles to prevent oil starvation during aggressive maneuvers, and integrated features.

- Lightweight Construction: Aluminum is significantly lighter than steel or iron, contributing to overall vehicle weight reduction. This is a critical factor in modern vehicle design for improving fuel efficiency and performance.

- Improved Oil Flow: The die casting process can produce a smooth interior surface, which improves the flow of oil toward the pickup tube and drain, ensuring consistent lubrication and more complete drainage during oil changes.

- Corrosion Resistance: Aluminum naturally resists rust and corrosion, making die-cast pans highly durable, especially in harsh operating environments or regions where road salt is common.

While die casting is optimal for components like oil pans, other manufacturing techniques are crucial for different automotive parts. For instance, high-strength components subjected to extreme stress, such as connecting rods or suspension parts, often rely on forging. Companies specializing in this area, like Shaoyi (Ningbo) Metal Technology, provide precision-engineered automotive forging parts, demonstrating the diverse manufacturing ecosystem that supports the automotive industry. This highlights the importance of selecting the right process for each specific application to ensure safety and performance.

Design, Materials, and Customization Capabilities

The technical specifications of a die-cast oil pan are critical for meeting the demanding requirements of modern engines. The choice of material, design features, and customization options are key considerations for engineers during the development process. The most commonly used material is an aluminum alloy like ADC12, an Al-Si-Cu alloy known for its excellent balance of castability, mechanical strength, and thermal conductivity.

The design flexibility afforded by die casting is a major advantage. Manufacturers can integrate a wide array of features directly into the pan's structure. For instance, finned designs are a popular feature that increases the external surface area, significantly improving the pan's ability to act as a heat sink for the engine oil. Other custom features can include internal baffles or trap doors to control oil slosh during high- G-force maneuvers in performance vehicles, ensuring the oil pickup is never starved of oil. The ability to design pans with flat bottoms also allows for more complete drainage, removing more contaminants during an oil change.

Customization is a core aspect of the B2B relationship between an automotive company and a die casting manufacturer. Suppliers like DSW Diecasting specialize in creating custom die tooling to produce oil pans that meet specific client needs. This collaborative process involves optimizing the part design for manufacturability, ensuring uniform wall thickness to prevent defects, and strategically placing cooling channels and mounting points. The end goal is to produce a bespoke component that integrates seamlessly with the engine architecture, providing optimal performance, reliability, and serviceability.

Frequently Asked Questions

1. Are die-cast pans good or bad?

Die-cast aluminum oil pans are overwhelmingly considered good, particularly for performance and modern automotive applications. Their main advantages include excellent durability from the high-pressure casting process, superior heat dissipation compared to steel, lightweight construction, and the ability to be cast into complex shapes with integrated features. However, they can be more brittle than stamped steel pans and may crack upon severe impact, whereas steel might only dent.

2. What is the best material for an oil pan?

The best material depends on the specific application and priorities. Aluminum, typically die-cast, is ideal for performance applications where lightweighting and efficient heat dissipation are crucial. It offers excellent design flexibility. Steel is valued for its high durability, impact resistance, and lower manufacturing cost, making it a common choice for many standard passenger vehicles. The choice involves a trade-off between performance benefits and ruggedness.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —