Closed-Loop Casting: The Future of Automotive Aluminum Recycling

TL;DR

Recycling aluminum in automotive die casting is a critical sustainability practice that significantly reduces energy consumption and carbon emissions. The primary goal is to establish closed-loop systems that use 100% recycled materials, a process that slashes energy needs by over 90% compared to producing new aluminum. Innovations in impurity removal and alloy chemistry are overcoming traditional challenges, making it possible to create high-performance automotive parts entirely from scrap.

The Sustainability Imperative: Why Recycled Aluminum is Key for Modern Automaking

In the push toward a greener automotive future, few materials offer the environmental and performance advantages of recycled aluminum. The automotive industry faces immense pressure to reduce emissions, a challenge addressed on two fronts: improving fuel efficiency and decarbonizing the supply chain. Aluminum die castings are central to both efforts. By replacing heavier steel components, lightweight aluminum parts reduce overall vehicle weight, which directly improves fuel economy in traditional vehicles and extends the range of electric vehicles (EVs).

However, the most significant environmental benefit lies in the circular nature of aluminum. Producing primary aluminum from its raw material, bauxite ore, is an extremely energy-intensive process involving mining and electrolysis. In stark contrast, recycling aluminum—creating what is known as secondary aluminum—uses approximately 90-95% less energy. This dramatic energy saving translates directly into a smaller carbon footprint for every component produced. According to industry data from sources like Dynacast, this efficiency is a key reason why 75% of all aluminum ever produced is still in use today.

This commitment to recycling is a cornerstone of the circular economy. Die casting facilities, such as those described by Autocast Inc., often recycle 100% of their internal scrap, from trimmings to parts that don't meet quality standards. By prioritizing secondary aluminum, automakers not only reduce their reliance on virgin materials and the associated environmental damage from mining but also create a more resilient and cost-effective supply chain. This strategic shift is essential for meeting stringent global emissions regulations and consumer demand for more sustainable products.

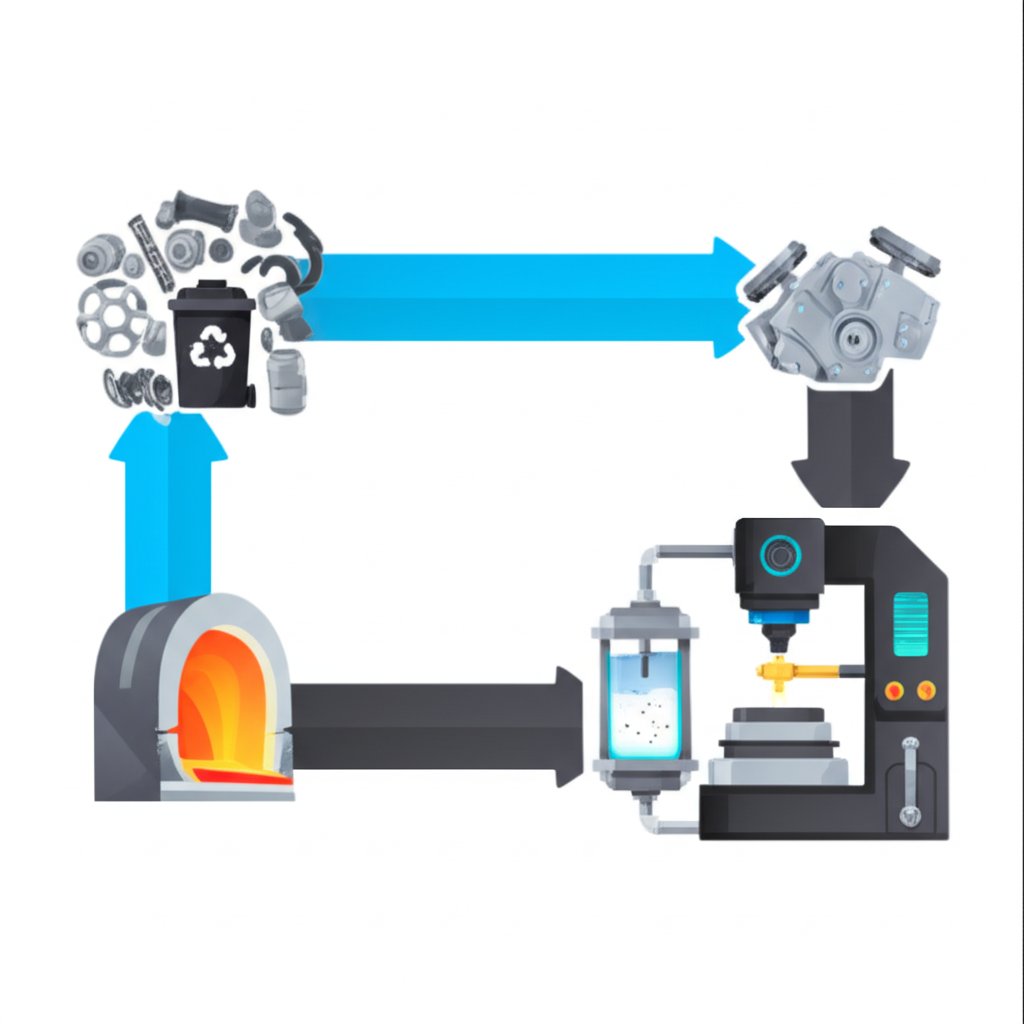

The Recycling Process: From Scrap to High-Performance Die Cast Parts

Transforming aluminum scrap into a high-performance automotive part is a sophisticated process that goes far beyond simple melting and recasting. The journey requires meticulous control at every stage to ensure the final product meets exacting engineering standards. While the specific steps can vary, the process generally follows a clear path from collection to purification.

The typical stages in the aluminum recycling loop include:

- Scrap Collection and Sorting: The process begins with gathering aluminum scrap from various sources, including industrial offcuts from manufacturing (post-industrial scrap) and end-of-life vehicle components (post-consumer scrap). Sorting is a critical first step. Since aluminum is non-magnetic, large magnets are used to remove ferrous contaminants like steel. Advanced technologies are also emerging to handle more complex sorting challenges. For instance, as detailed by Constellium, Laser-Induced Breakdown Spectroscopy (LIBS) can rapidly differentiate between various aluminum alloys, such as the 5xxx and 6xxx series used in car bodies, preventing the valuable wrought alloys from being downcycled.

- Shredding and Cleaning: Once sorted, the scrap is shredded into smaller, uniform pieces. This increases the surface area for more efficient melting and allows for further cleaning. The pieces are cleaned to remove coatings, paints, oils, and other non-metallic contaminants.

- Melting and Alloying: The clean, shredded aluminum is loaded into large furnaces and melted down. During this stage, the molten metal's composition is carefully analyzed. Alloying elements can be added to adjust the chemistry and achieve the specific properties required for a particular die casting alloy, such as the common ADC12.

- Purification and Dross Removal: A key challenge in recycling die-cast aluminum is managing impurities, particularly iron. Iron contamination can make the final casting brittle and prone to failure. Traditionally, this issue was managed by diluting the molten scrap with high-purity primary aluminum. However, modern processes focus on directly removing or neutralizing these impurities through advanced filtration and chemical treatments, which is the foundation of true closed-loop recycling.

Successfully managing this process, especially the control of iron content, is the primary technical hurdle that separates simple recycling from the high-value, closed-loop systems that the automotive industry is striving to perfect. Overcoming this challenge is essential for producing structural components that are both sustainable and safe.

Technological Innovations: Achieving True Closed-Loop Recycling

The ambition to use 100% recycled aluminum in demanding automotive applications has spurred significant technological innovation. The industry is moving beyond traditional dilution methods and developing sophisticated techniques to manage impurities and guarantee performance. Two leading approaches—physical purification and chemical neutralization—are paving the way for a truly circular aluminum economy.

One of the most prominent breakthroughs comes from Honda, which developed a technology for "Complete Closed-Loop Recycling." As detailed in their announcements, this system is designed to process die-cast aluminum scrap (specifically ADC12 alloy) without needing to add high-purity virgin aluminum. The core of the Honda technology lies in precise impurity removal and compositional control during the melting phase. After more than 17 rounds of trials, this process has proven effective enough to support the production of large structural parts for EVs, including those made through gigacasting, where material integrity is paramount.

In parallel, research organizations are exploring metallurgical solutions. The REMADE Institute is leading projects focused on neutralizing the harmful effects of iron impurities. Instead of physically removing the iron, their research investigates adding other elements—such as Manganese (Mn), Chromium (Cr), and Cerium (Ce)—to the molten aluminum. These elements alter the crystalline structure of the iron-containing intermetallics, changing them from sharp, needle-like platelets that cause brittleness into more compact, less detrimental shapes. This chemical approach aims to make high-iron secondary aluminum suitable for structural applications.

These advancements in materials science are part of a broader industry trend toward specialized, high-performance components. For instance, in related fields like automotive metal forming, companies such as Shaoyi (Ningbo) Metal Technology specialize in precision-engineered automotive forging parts, demonstrating the sector-wide commitment to robust, quality-controlled manufacturing processes from prototyping to mass production.

The Practical Advantages: Performance and Cost of Recycled Aluminum Alloys

Beyond the compelling environmental benefits, the shift to recycled aluminum in die casting is driven by strong practical and economic advantages. A common misconception is that recycled materials are inherently inferior to their primary counterparts. In the case of aluminum, this is false. The metal's atomic structure does not degrade during the recycling process, meaning it retains all its fundamental physical and mechanical properties, such as strength, durability, and corrosion resistance. With precise composition control during melting, secondary aluminum alloys can be engineered to meet or even exceed the specifications of primary alloys.

The most significant practical advantage is cost. The economic calculus is tied directly to energy consumption. Since producing secondary aluminum requires up to 95% less energy than creating primary aluminum, the associated production costs are substantially lower. This cost-effectiveness allows manufacturers to produce high-quality components more affordably, a competitive edge that is especially important in the price-sensitive automotive market. This financial incentive is a powerful driver for expanding recycling infrastructure and adopting closed-loop systems.

When evaluating the two material sources, the choice becomes clear for most applications. While certain highly specialized sectors like aerospace may still rely on primary aluminum due to stringent regulations, secondary aluminum is the superior option for the vast majority of automotive die casting needs, offering an optimal balance of performance, cost, and sustainability.

Primary vs. Secondary Aluminum: A Comparison

| Factor | Primary Aluminum | Secondary (Recycled) Aluminum |

|---|---|---|

| Environmental Impact | High (Bauxite mining, high CO2 emissions) | Low (Reduces landfill waste and mining) |

| Energy Consumption | Very High | Up to 95% lower than primary |

| Cost | High (Driven by energy prices) | Significantly Lower |

| Performance | High quality, precisely controlled | Equivalent quality with proper processing |

Frequently Asked Questions

1. Is die cast aluminum recyclable?

Yes, die-cast aluminum is highly recyclable. In fact, the majority of aluminum die-cast products are made from secondary (recycled) aluminum alloys. After a vehicle reaches the end of its life, its aluminum components can be collected, re-melted, and purified to create new secondary alloys, which are then used to manufacture new die-cast parts in a circular process.

2. What is automotive aluminum recycling at end of life a grave to gate analysis?

A "grave-to-gate" analysis is a comprehensive assessment used to measure the efficiency of a recycling system. In the context of automotive aluminum, it tracks the material from its disposal phase (the vehicle's "grave") through every step of the collection, sorting, and reprocessing chain to the point where it becomes a usable raw material (the recycled ingot, or "gate"). This type of analysis helps identify material losses and process inefficiencies, providing a clear picture of the overall recycling rate, which for automotive aluminum is very high, often exceeding 90%.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —