Simulation in Forging Design: Optimizing Modern Manufacturing

TL;DR

Forging simulation is an essential digital technique in modern manufacturing that uses computational methods, primarily Finite Element Analysis (FEA), to virtually test and predict how metal will behave during the forging process. The primary role of simulation in modern forging design is to optimize component and tool design, reduce production costs, and ensure high product quality by identifying potential defects like cracks or incomplete die filling before any physical tooling is made. This predictive capability significantly shortens development cycles and minimizes material waste.

What Is Forging Simulation and Why Is It Critical in Modern Design?

Forging simulation is a computer-aided engineering (CAE) process that creates a virtual model of the entire forging operation. Using sophisticated software, engineers can accurately predict the complex interplay of forces, temperatures, and material flow as a metal workpiece is shaped between dies. This technique essentially provides a digital preview of a physical process, allowing for detailed analysis without the need for expensive and time-consuming shop floor trials. At its core, the simulation solves complex mathematical equations that govern material behavior under extreme conditions.

The most prevalent technology behind this process is the Finite Element Method (FEM), also known as Finite Element Analysis (FEA). As detailed in research on the topic, FEA breaks down a complex component into thousands of smaller, simpler elements to model variables like stress, strain, and temperature distribution with high accuracy. This computational method enables engineers to visualize material flow, identify areas of high stress on the tooling, and predict the final properties of the forged part.

The critical importance of simulation in modern design lies in its ability to mitigate risk and uncertainty. In industries like aerospace and automotive, where components must withstand extreme conditions, there is no margin for error. Traditional trial-and-error methods are not only costly but can lead to catastrophic failures if defects are not caught. Simulation allows designers to validate a process virtually, ensuring that the final product will meet stringent performance and safety standards from the outset.

Furthermore, as designs become more intricate and materials more advanced (such as titanium or high-strength superalloys), predicting their behavior becomes exponentially more difficult. Forging simulation provides a reliable method to understand how these complex materials deform, ensuring that the manufacturing process is tailored for optimal results. It transforms forging from an experience-based craft into a precise, data-driven science, which is indispensable for modern, high-tech manufacturing.

The Core Benefits of Integrating Simulation into the Forging Process

Integrating simulation into the forging design workflow offers substantial, measurable advantages that directly impact efficiency, cost, and product quality. By moving the initial testing and refinement phases into a digital environment, manufacturers can bypass many of the costly and time-consuming drawbacks of traditional physical prototyping. This proactive approach leads to a more streamlined, predictable, and profitable production cycle.

One of the most significant benefits is the drastic reduction in cost and development time. Forging dies are incredibly expensive to manufacture, and each physical iteration adds weeks or even months to a project timeline. Simulation allows engineers to test and optimize die designs virtually, identifying potential issues like premature wear or stress concentrations before committing to tooling. This can reduce the need for physical prototypes, leading to significant savings in both material and machining costs. As noted by industry experts, this virtual validation helps prevent project failures that might otherwise only be discovered weeks into production.

Simulation also plays a crucial role in minimizing material and energy waste. By accurately predicting material flow, engineers can optimize the initial billet size and shape to ensure the die cavity is filled completely with minimal excess material (flash). This not only reduces scrap but also lowers the required press tonnage, saving energy. Some manufacturers have reported material waste reductions of up to 20%, contributing to more sustainable and cost-effective operations. Companies specializing in high-stakes industries rely on these simulations to produce reliable components. For instance, providers of custom automotive forging parts leverage these advanced techniques to move from rapid prototyping to mass production while ensuring IATF16949 certification standards are met.

Finally, the use of simulation leads to a marked improvement in final part quality and performance. The software can predict and help eliminate forging defects such as laps (where metal folds over itself), cracks, and areas of incomplete die fill. By analyzing the grain flow within the material, engineers can ensure the component has superior strength and fatigue resistance in critical areas. This level of control and foresight is essential for producing high-performance parts that meet the demanding specifications of modern industry.

Key Stages and Parameters of a Forging Simulation

A successful forging simulation is a systematic process that involves several distinct stages, each requiring precise data input to generate reliable results. This structured approach ensures that the virtual model accurately reflects real-world conditions, providing actionable insights for process optimization. The entire workflow is designed to deconstruct a complex physical event into manageable digital inputs and outputs.

The typical stages of a forging simulation include:

- Digital Model Creation: The process begins with creating 3D CAD (Computer-Aided Design) models of the workpiece (billet) and the tooling (dies). These geometric models serve as the foundation for the simulation.

- Meshing and Material Definition: The CAD models are converted into a mesh of small, interconnected elements (the basis of FEA). The user then assigns a material model to the workpiece, defining its properties, such as flow stress, thermal conductivity, and heat capacity, which dictate how it behaves at different temperatures and strain rates.

- Defining Process Parameters and Boundary Conditions: This is a critical stage where the real-world forging environment is defined. Key parameters include the press or hammer speed, initial billet and die temperatures, and friction conditions at the die-workpiece interface. These inputs must be as accurate as possible to ensure the simulation's validity.

- Running the Simulation and Analysis: The software solver then calculates the material's response over time, predicting metal flow, die filling, and the distribution of various field variables. Engineers analyze the results to assess key outcomes, such as identifying potential defects, predicting forging loads, and evaluating die wear.

To achieve an accurate simulation, a variety of input parameters must be carefully considered. These variables directly influence the behavior of the material and the tooling during the forging process.

| Parameter | Significance in Simulation |

|---|---|

| Flow Stress | Defines the material's resistance to deformation at specific temperatures and strain rates. It is the most critical material property for accurate results. |

| Friction Factor | Models the friction between the workpiece and the die. It significantly affects material flow, die filling, and the required forging load. |

| Heat Transfer Coefficient | Governs the rate of heat exchange between the hot billet and the cooler dies, influencing material temperature and flow characteristics. |

| Die & Billet Temperature | The initial temperatures of the components, which determine the material's initial plasticity and cooling rate during the process. |

| Press/Hammer Speed | Determines the strain rate, which in turn affects the material's flow stress and the heat generated by deformation. |

The Future of Forging: Advanced Techniques and Simulation-Driven Design

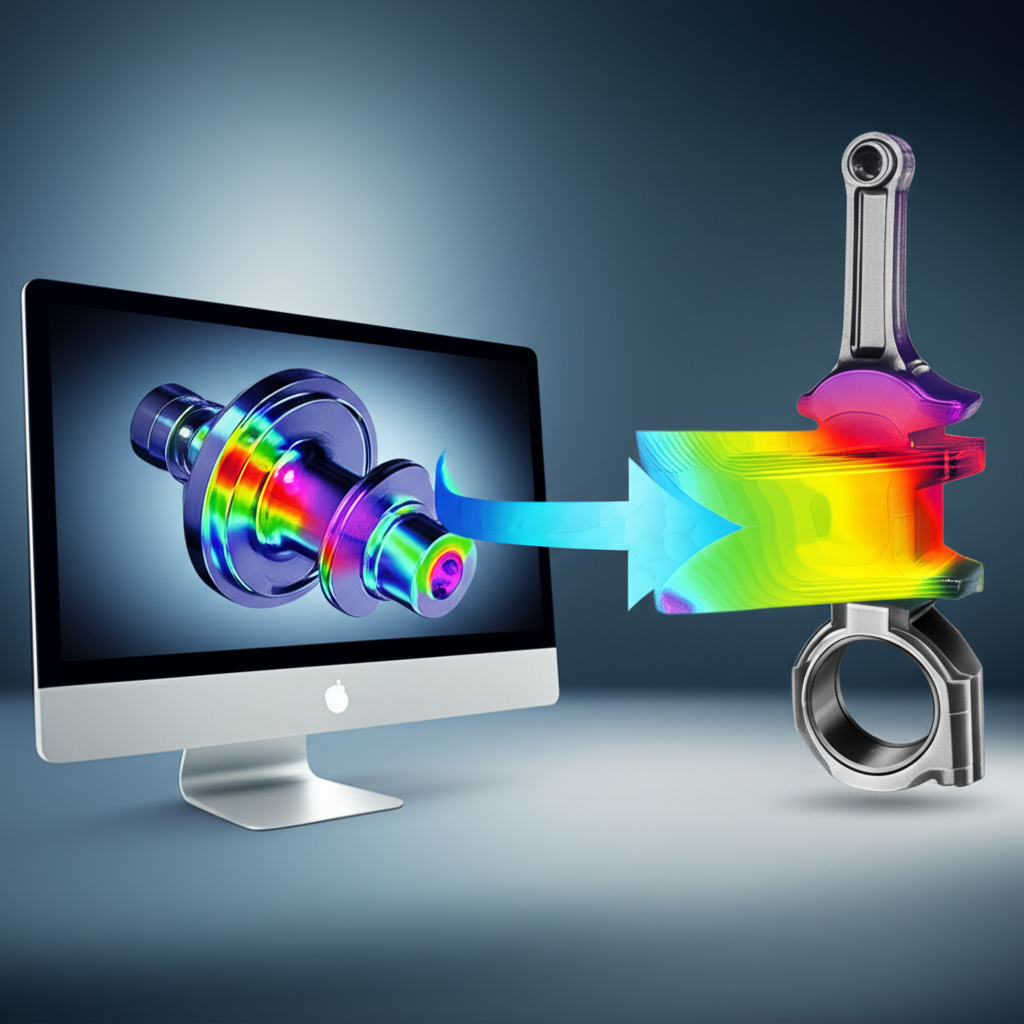

The evolution of forging simulation is pushing the boundaries of manufacturing, moving beyond simple process validation toward a future of fully integrated, intelligent design. Emerging technologies are making simulations faster, more accurate, and more predictive, fundamentally changing how forged components are developed. This shift is leading to the concept of Simulation-Driven Design, where simulation is no longer just a verification tool but a core component of the creative process itself.

One of the key drivers of this evolution is the integration of Artificial Intelligence (AI) and Machine Learning (ML). AI algorithms can analyze vast datasets from previous simulations and real-world production to identify subtle patterns and optimize process parameters with a level of insight that surpasses human capability. This can lead to continuous improvement in simulation accuracy and the automated design of preforming stages, significantly accelerating the development cycle. As noted by software developers like Transvalor, these advancements allow users to investigate innovative methods and push the envelope of what is possible in forging.

Another transformative technology is the Digital Twin. A digital twin is a virtual replica of a physical forging press and its entire process, updated in real-time with sensor data from the factory floor. By linking simulation data with live production data, manufacturers can monitor operations, predict equipment failures before they happen, and make dynamic adjustments to optimize efficiency and quality on the fly. This creates a powerful feedback loop where the simulation improves the physical process, and the physical process provides data to refine the simulation.

This convergence of technologies is ushering in the era of Simulation-Driven Design. Instead of an engineer creating a design and then using simulation to test it, the simulation software itself can suggest optimal shapes, tool paths, and process parameters based on a given set of performance requirements and constraints. This methodology enables the automated design of tooling and processes, drastically reducing the reliance on manual expertise and iterative guesswork. The result is a faster, more agile development process capable of producing highly optimized, complex components that were previously unachievable.

Frequently Asked Questions

1. What is the difference between forging simulation and Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is the underlying numerical method used to perform a forging simulation. Forging simulation is the specific application of FEA to model the metal forming process. In short, FEA is the engine, and forging simulation is the car built around it to solve a specific engineering problem.

2. How accurate are forging simulations?

The accuracy of modern forging simulations is very high, provided that the input data is accurate. Key factors influencing accuracy include the quality of the material data (flow stress), the precision of the friction models, and the correct definition of thermal properties. When properly calibrated, simulations can accurately predict material flow, final geometry, and forging loads to within a small margin of error compared to physical trials.

3. What software is commonly used for forging simulation?

Several commercial software packages are widely used in the industry for forging simulation. Some of the most well-known include DEFORM, QForm, Simufact Forming, and FORGE®. Each software has its own strengths, but all are based on the finite element method and are designed to predict the complex behaviors inherent in bulk metal forming processes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —