Forged vs. Fabricated Parts: Which Is Stronger for Structures?

TL;DR

For structural applications, forged parts are generally stronger, more durable, and more reliable than fabricated parts. Forging shapes metal using intense pressure and heat, creating a continuous and aligned grain structure that enhances resistance to impact and fatigue. Fabrication, which involves welding or joining separate pieces of metal, offers greater design flexibility and is often more cost-effective for custom or low-volume projects, but its strength is dependent on the quality of the welds.

Understanding the Core Processes: Forging and Fabrication

Choosing the right manufacturing process is critical for ensuring the safety, longevity, and performance of structural components. The decision between forging and fabrication hinges on understanding how each method fundamentally works and how that impacts the final product's mechanical properties.

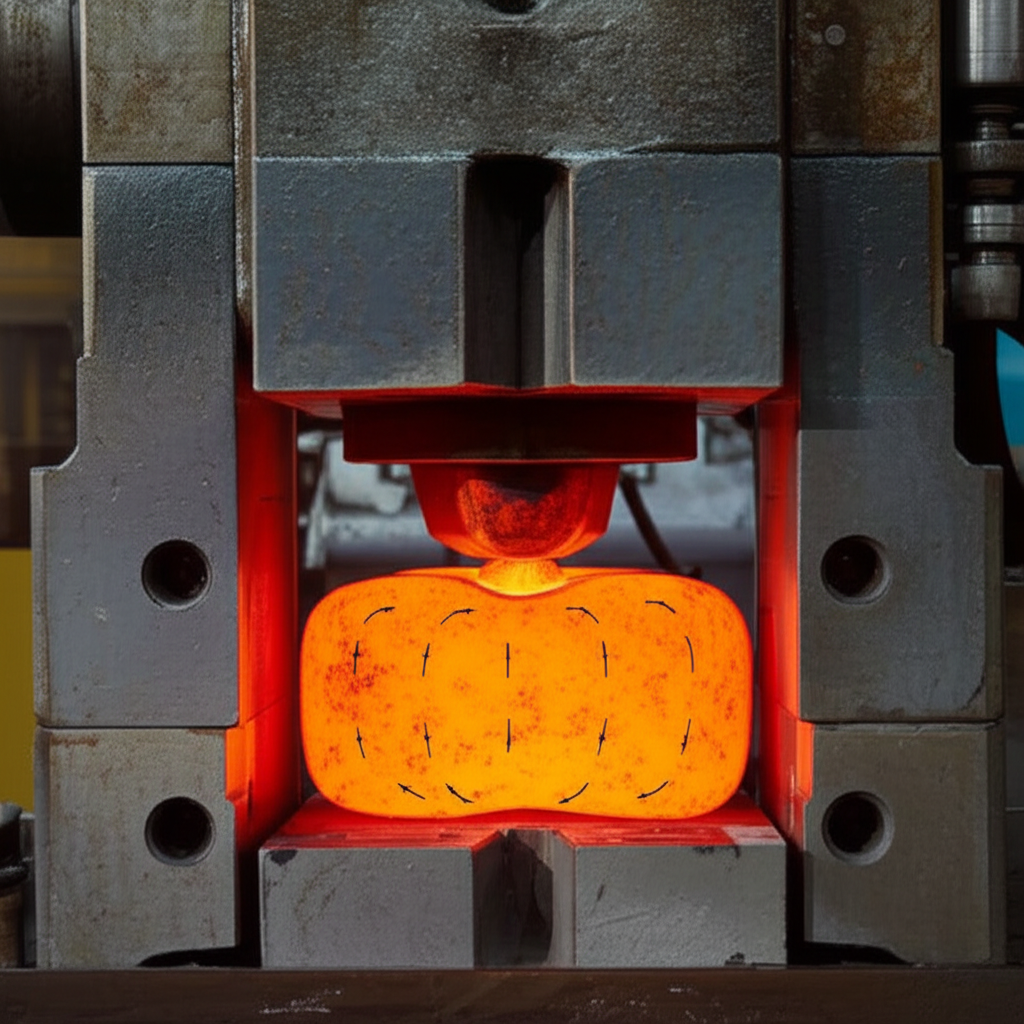

Forging is a metalworking process that shapes a single piece of metal through localized compressive forces, often at elevated temperatures. The metal is heated until malleable and then hammered or pressed into a die to achieve the desired shape. This intense deformation refines the metal's internal grain structure, aligning it with the part's contours. This continuous grain flow is the primary reason forged parts exhibit superior strength and toughness, as it eliminates the internal voids and inconsistencies that can lead to component failure under stress. Forged parts are known for their high tensile strength, impact resistance, and fatigue life.

Fabrication, in contrast, is an additive or assembly process. It involves cutting, bending, and assembling separate pieces of metal to create a final structure. These individual components are joined together using techniques like welding, bolting, or riveting. While fabrication offers immense versatility in creating complex and large-scale designs that would be impossible to forge, the strength of the final part is inherently limited by the strength of its joints. Welds, for example, can introduce points of weakness, residual stress, and potential defects that may compromise the overall integrity of the component, especially in high-stress or cyclical loading environments.

Head-to-Head Comparison: Key Differentiators for Structural Use

When evaluating forged vs. fabricated parts for structural applications, several key factors determine the optimal choice. The trade-offs between strength, design freedom, and cost are central to the decision-making process. Forging typically produces a stronger, more reliable component, while fabrication provides greater flexibility and is often more economical for unique or small-batch productions.

Strength and Durability

The most significant advantage of forging is its exceptional strength-to-weight ratio. The forging process creates an uninterrupted grain flow that follows the shape of the part, eliminating weak spots and enhancing its mechanical properties. According to some analyses, forged parts can have a yield strength up to 26% greater than components made by other methods. This makes them highly resistant to impact and fatigue failure. Fabricated parts, however, rely on the integrity of their welded joints. Even with high-quality welding, the heat-affected zone around a weld can have different mechanical properties than the base metal, creating potential points of failure under cyclic stress.

Material Integrity and Reliability

Forging produces a dense, non-porous material structure. This uniformity ensures predictable performance and reliability, which is crucial for critical structural applications where failure is not an option. Fabricated structures, with their multiple pieces and joints, have a higher potential for hidden defects such as incomplete weld penetration, cracks, or porosity. These inconsistencies can be difficult to detect and may propagate over time, leading to premature failure. The homogenous nature of a single-piece forged part provides a higher degree of confidence in its structural integrity.

Design Complexity and Versatility

Fabrication holds a clear advantage when it comes to design flexibility. Because it involves assembling components, it can be used to create large, intricate, and custom structures that would be impractical or prohibitively expensive to produce via forging. Forging is limited by the need for dies, which can be complex and costly to create, making it less suitable for one-off parts or highly complex geometries. Fabrication is the ideal choice for bespoke frameworks, architectural elements, and situations where design adaptability is paramount.

Cost Implications

The cost-effectiveness of each method depends heavily on production volume. Forging requires significant upfront investment in tooling and dies, making it more economical for high-volume production runs where the cost per part decreases over time. For small batches or prototypes, fabrication is generally less expensive as it avoids high tooling costs. However, it's essential to consider the total lifecycle cost. The superior durability of forged parts can lead to longer service life and lower maintenance or replacement costs, potentially offering better long-term value in demanding applications as noted by experts at Greg Sewell Forgings.

| Feature | Forged Parts | Fabricated Parts |

|---|---|---|

| Strength & Durability | Superior due to continuous grain flow and high density. Excellent fatigue and impact resistance. | Strength is limited by the quality of welds and joints, which can be potential failure points. |

| Structural Integrity | High reliability with a single-piece, homogenous structure. No hidden defects from joints. | Potential for defects like porosity or cracks in welds. Requires rigorous inspection. |

| Design Flexibility | Limited by die complexity. Best for simpler, repeatable shapes. | High versatility. Ideal for large, complex, or custom designs. |

| Cost | High initial tooling cost. Cost-effective for high-volume production. | Low initial setup cost. Economical for low-volume and one-off projects. |

Application-Specific Guidance: When to Choose Forged vs. Fabricated

Selecting the right process ultimately depends on the specific demands of the application. There is no single answer; the choice requires a careful evaluation of performance requirements, design complexity, production volume, and budget. By understanding the ideal scenarios for each method, engineers and designers can make more informed decisions.

Ideal Scenarios for Forged Parts

Forging is the preferred method for components subjected to high stress, heavy loads, and extreme conditions where reliability is paramount. Its inherent strength and fatigue resistance make it indispensable in critical applications. Examples include:

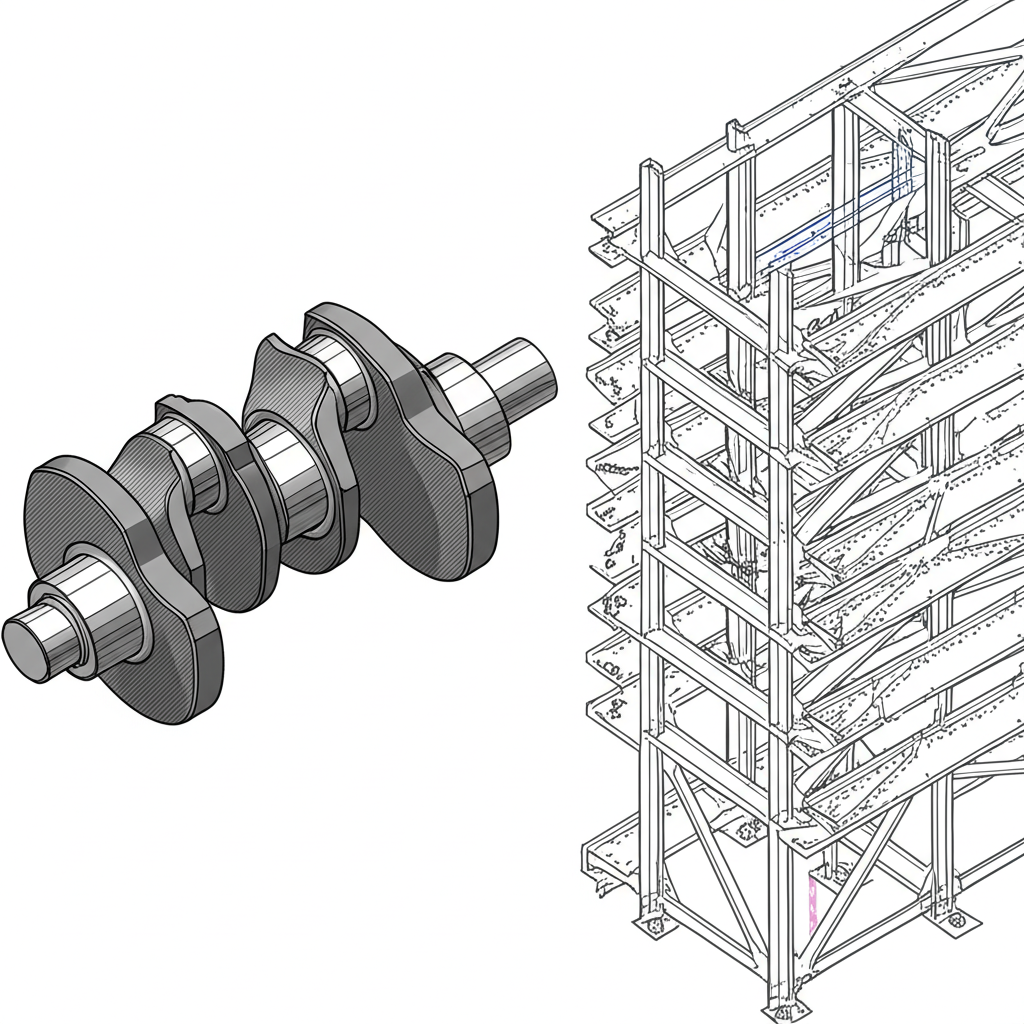

- Automotive Components: Crankshafts, connecting rods, and suspension parts that must withstand constant vibration and stress. For robust and reliable automotive components, some companies specialize in high-quality hot forging. For instance, providers of custom forging services like Shaoyi Metal Technology offer solutions from prototyping to mass production for the automotive industry.

- Aerospace and Defense: Landing gear, turbine discs, and structural airframe components where strength-to-weight ratio and failure resistance are critical.

- Oil & Gas Industry: Valves, flanges, and fittings that operate under high pressure and in corrosive environments.

- Heavy Machinery: Gears, shafts, and lifting hardware used in construction and mining equipment that require maximum durability.

Ideal Scenarios for Fabricated Parts

Fabrication shines in applications where design flexibility, customization, and speed are more important than achieving maximum material strength. It is well-suited for large-scale or unique projects. Ideal scenarios include:

- Structural Steel Frameworks: Beams, columns, and trusses for buildings and bridges where large, customized components are needed.

- Custom Machinery and Equipment: Frames, housings, and supports for specialized industrial machines built in low volumes.

- Prototyping: Creating initial versions of a design for testing and validation before committing to expensive forging dies.

- Architectural Metalwork: Custom staircases, railings, and decorative elements where aesthetic design and form are key drivers.

A Quick Reference: Pros and Cons

To summarize the key trade-offs, this reference guide breaks down the primary advantages and disadvantages of each manufacturing process for structural parts.

Forging

Pros

- Superior Strength: Aligned grain structure provides exceptional tensile strength, toughness, and fatigue resistance.

- High Reliability: Single-piece construction eliminates weak points associated with joints and welds.

- Material Efficiency: Less material waste compared to subtractive methods like machining from billet.

- Durability: Excellent for high-stress, load-bearing, and critical applications, leading to a long service life.

Cons

- High Tooling Costs: The initial investment for dies can be substantial, making it less viable for small runs.

- Limited Design Complexity: Intricate shapes, internal cavities, or very large components can be difficult or impossible to forge.

- Longer Lead Times: Die creation and setup can result in longer initial production times.

- Secondary Machining: Often requires additional machining to achieve final tolerances and surface finishes.

Fabrication

Pros

- Excellent Design Freedom: Allows for the creation of large, complex, and highly customized structures.

- Low Initial Costs: No need for expensive dies, making it cost-effective for prototypes and low-volume production.

- Versatility: A wide range of materials and component sizes can be joined together.

- Faster Prototyping: Quick turnaround for one-off parts allows for rapid design iteration.

Cons

- Weaker than Forging: The strength of the part is limited by its weakest point, typically the welds or joints.

- Potential for Defects: Welds can introduce vulnerabilities like cracks, porosity, and residual stress, reducing reliability.

- Inconsistent Performance: Part-to-part consistency can be lower compared to the repeatable nature of closed-die forging.

- Labor-Intensive: Can require significant skilled labor for cutting, fitting, and welding, especially for complex assemblies.

Frequently Asked Questions

1. What is the main difference between forged and fabricated parts?

The core difference lies in the manufacturing method and resulting grain structure. Forging shapes a single piece of metal with heat and pressure, aligning the grain structure to the part's shape for superior strength. Fabrication involves assembling multiple, separate pieces of metal using methods like welding, where the strength depends on the quality of the joints.

2. Are forged parts stronger than machined parts?

Yes, forged parts are generally stronger than parts machined from a solid block of metal (a billet). While both start from a solid piece, forging realigns and refines the grain structure, enhancing fatigue and impact resistance. As explained by manufacturing experts at EZG Manufacturing, machining cuts through these grains, resulting in a uniform but non-optimized structure that lacks the directional strength of a forged component.

3. What are the disadvantages of forged steel?

The primary disadvantages of forging include high initial tooling costs for dies, limitations on producing highly complex or intricate shapes, and the common need for secondary machining to achieve tight tolerances and a smooth surface finish. The process is also less flexible for design changes once the dies are made.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —