Custom Forging: The Key to Specialty Vehicle Performance

TL;DR

Custom forging for specialty and aftermarket vehicles is a manufacturing process that shapes metal alloys using intense heat and pressure. This method produces components that are significantly stronger, more durable, and more reliable than parts made by casting or machining. It is the preferred choice for high-performance applications where failure is not an option, from professional racing engines to critical suspension parts for custom-built cars.

What Is Custom Forging for Automotive Applications?

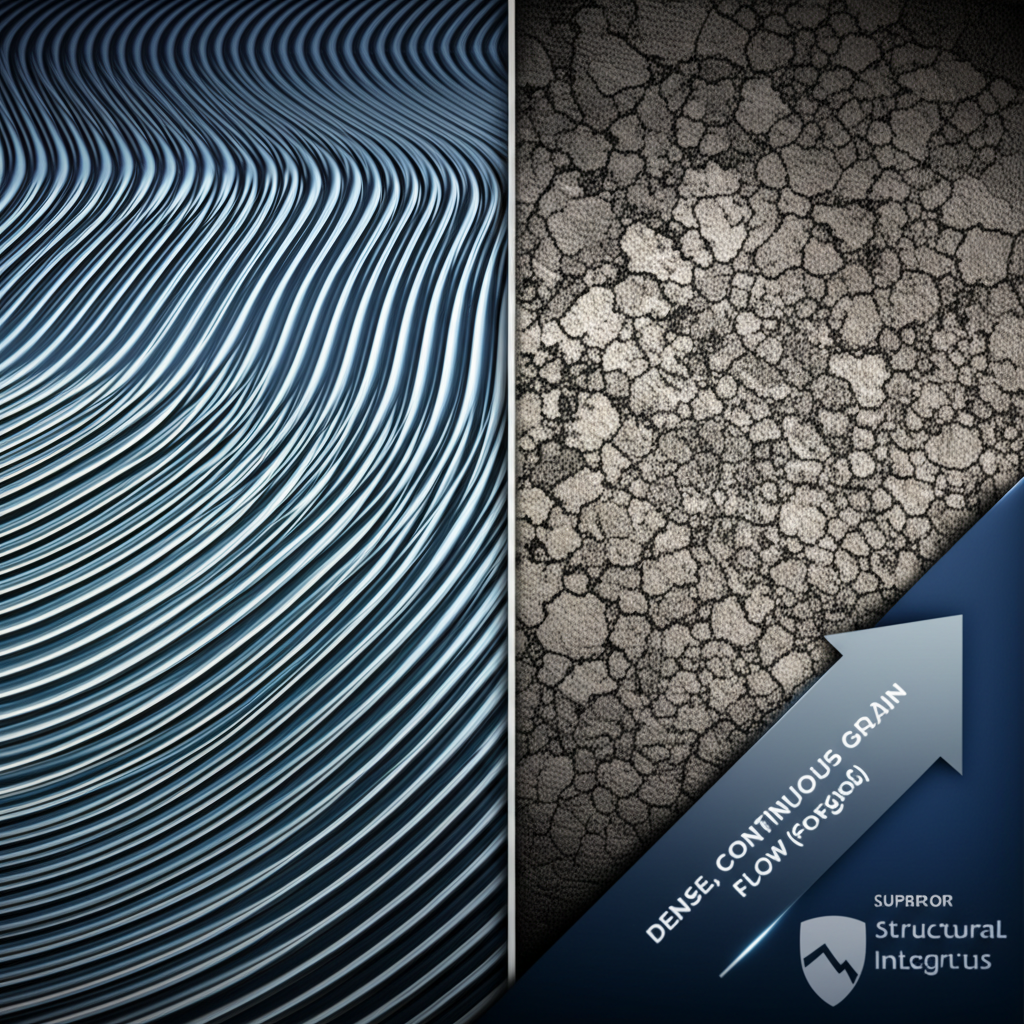

At its core, forging is a manufacturing process that involves shaping metal through localized compressive forces. Forged automotive parts are created by heating metal to a malleable temperature and then shaping it with high pressure, often using a press or a hammer. This technique refines the metal's internal grain structure, aligning it with the final shape of the component. This results in a continuous, unbroken grain flow that gives the part exceptional strength and resistance to impact and fatigue.

Custom forging takes this process a step further by tailoring it to unique specifications. Unlike standard, mass-produced components, custom forged parts are engineered for a specific application, vehicle, or performance requirement. This is particularly crucial for the specialty and aftermarket sectors, where off-the-shelf parts may not meet the extreme demands of racing, restoration, or custom modifications. The process often involves a close collaboration between the client's engineers and the forging company's metallurgists to ensure the final product meets exact tolerances and material properties.

A prevalent method in this field is closed-die forging, also known as impression-die forging. In this technique, the metal workpiece is placed between two dies that contain a precise impression of the desired part. As the dies press together, the metal is forced to flow and fill the entire cavity. This method is ideal for producing complex, three-dimensional shapes with tight tolerances, making it perfect for intricate automotive components like steering knuckles and engine crankshafts.

Key Benefits of Forged Components in High-Performance Vehicles

Opting for custom forged parts over cast or machined alternatives provides a distinct set of advantages that are critical for high-performance and specialty vehicles. These benefits directly translate to improved safety, longevity, and performance on the road or track. The refined grain structure created during the forging process is the foundation for these superior characteristics.

- Superior Strength-to-Weight Ratio: Forging produces a denser, non-porous material structure. This allows for the creation of components that are significantly stronger than their cast or machined counterparts without adding unnecessary weight. This is vital in motorsports and electric vehicles, where reducing unsprung mass and overall vehicle weight is key to performance and efficiency.

- Enhanced Durability and Fatigue Resistance: The aligned grain flow of forged parts eliminates the internal voids and defects often found in cast parts. This structural integrity makes forged components highly resistant to fatigue, shock, and impact. For parts that endure constant stress, such as connecting rods and suspension arms, this durability can triple or even quadruple the component's service life.

- Improved Structural Reliability: Because the forging process works with a single piece of metal rather than melting and pouring it, the final part is free of the potential inconsistencies and weak points that can arise during casting. This ensures predictable and reliable performance under extreme conditions, which is essential for safety-critical components in braking and steering systems.

- Greater Design Flexibility: The forging process allows for the creation of complex, custom shapes that might not be achievable with other manufacturing methods. This provides engineers with greater freedom to design parts optimized for performance, fitment, and aesthetics in specialty and aftermarket applications.

Common Forged Parts for Specialty and Aftermarket Vehicles

The applications for custom forging span the entire spectrum of specialty and high-performance vehicles, from professional racing circuits to meticulously restored classic cars. The process is essential for creating parts that can withstand the unique stresses of these demanding environments. By leveraging custom forging, manufacturers can produce components that meet the highest standards of performance and reliability.

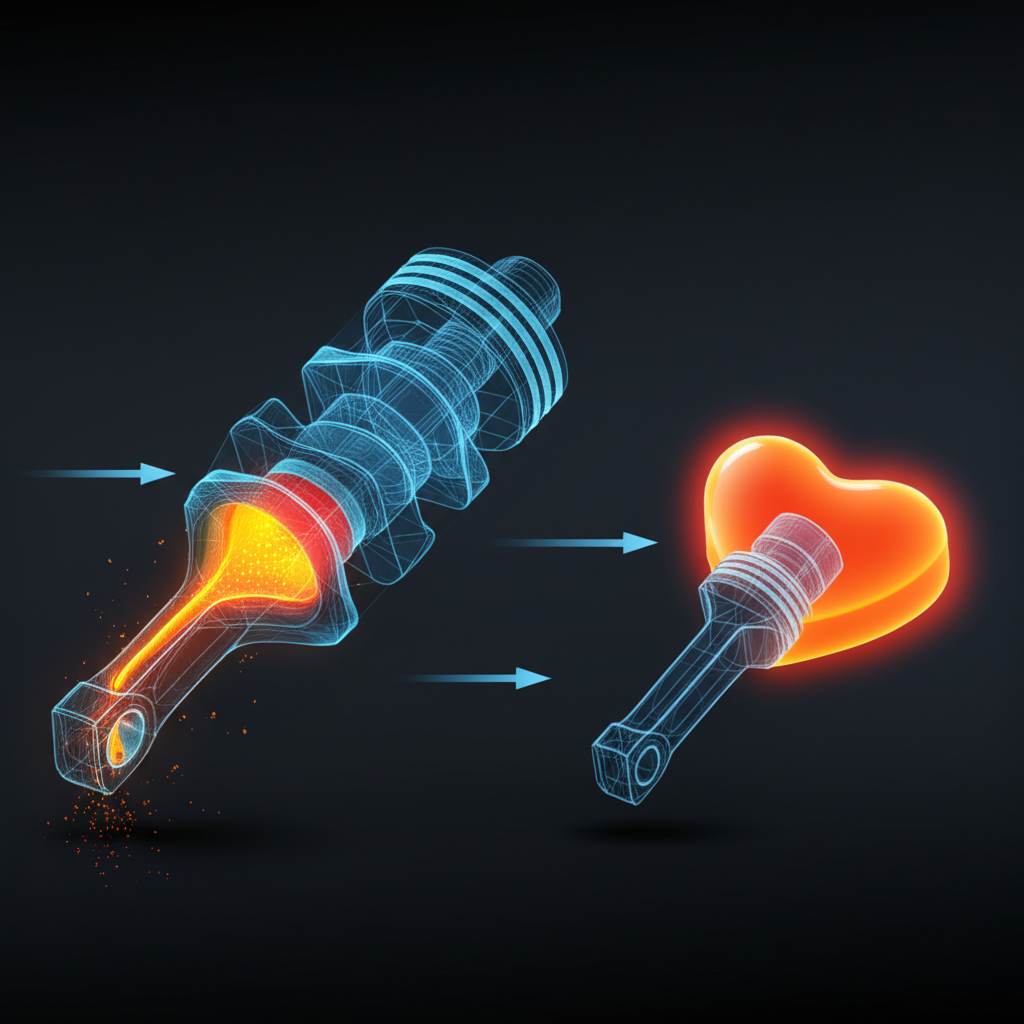

Engine and Drivetrain Components

The heart of any performance vehicle is its engine and drivetrain, where components are subjected to immense heat, pressure, and rotational forces. Forging is the go-to method for parts like crankshafts, connecting rods, pistons, and yokes. For racing series like Formula 1 and NASCAR, forged engine internals are standard, providing the strength needed to handle extreme RPMs and power outputs. Similarly, forged axle shafts and drivetrain joints ensure that power is transmitted reliably to the wheels without failure.

Suspension and Chassis Parts

A vehicle's handling and safety depend on the integrity of its suspension and chassis. Custom forging is used to produce a wide range of these critical components, including control arms, steering knuckles, wheel hubs, and brake calipers. As noted by providers like Anchor Harvey, these parts demand exceptional precision and durability to manage the forces of cornering, braking, and rough road surfaces. Forged suspension links and struts provide the rigidity and strength required for a responsive and predictable driving experience.

Custom Wheels and Restoration Components

In the aftermarket and classic car worlds, both aesthetics and performance are paramount. Forged aluminum wheels are highly sought after for their combination of strength, light weight, and intricate designs. For classic car restoration, custom forging is often the only way to reproduce obsolete parts that meet or exceed original specifications. This allows restorers to maintain authenticity while enhancing the vehicle's durability and safety for modern use.

Material Selection: Choosing the Right Alloy for Performance

The choice of material is as critical as the forging process itself. Different alloys offer distinct properties related to strength, weight, corrosion resistance, and heat tolerance. A professional forging partner will have a metallurgist on staff to help select the ideal material for a specific application, ensuring the final component performs flawlessly under its intended operational conditions.

Here are some of the common materials used in custom automotive forging:

| Material | Key Properties | Common Automotive Applications |

|---|---|---|

| Steel Alloys | Exceptional strength, hardness, and durability. Can be micro-alloyed for specific performance characteristics. | Crankshafts, connecting rods, gears, axle shafts, suspension components. |

| Aluminum Alloys | Excellent strength-to-weight ratio, good thermal conductivity, and corrosion resistance. | High-performance wheels, suspension arms, brake calipers, engine blocks, pistons. |

| Titanium Alloys | Very high strength-to-weight ratio, superior corrosion resistance, and performance at high temperatures. | Exhaust components, valves, connecting rods, and critical fasteners in racing applications. |

| Specialty Alloys | Includes nickel-based superalloys and others designed for extreme heat and stress environments. | Turbocharger components, exhaust valves, and parts for ultra-high-performance engines. |

The Custom Forging Process: From Consultation to Final Product

Engaging a custom forging provider involves a structured, collaborative process designed to translate a concept into a precision-engineered component. Understanding this workflow helps set clear expectations and ensures the final product meets all technical requirements. The journey from an idea to a finished part requires expertise at every stage, from initial design to final inspection.

For businesses looking to source high-quality components, partnering with a full-service provider is key. For example, some companies like Shaoyi Metal Technology offer a comprehensive approach that includes in-house die manufacturing and IATF16949 certification, ensuring quality control from start to finish. This integrated model is crucial for delivering everything from rapid prototypes to mass production efficiently.

- Initial Consultation and Engineering Review: The process begins with a detailed discussion of the component's requirements. Engineers review drawings, 3D CAD models, or even existing parts to understand the application, stress loads, and performance goals. At this stage, material selection and potential design-for-manufacturability improvements are addressed.

- Die and Tooling Creation: Once the design is finalized, highly precise dies are engineered and manufactured. These tools are the mirror image of the final part and are typically made from hardened tool steel to withstand the immense pressures of the forging process. This is a critical step, as the quality of the die directly impacts the dimensional accuracy of the forged component.

- Forging and Heat Treatment: The raw material, or billet, is heated to the optimal forging temperature. It is then placed in the die and shaped by the immense force of a forging press or hammer. Following the forging process, the part undergoes heat treatment—such as quenching and tempering—to achieve the desired mechanical properties like hardness and tensile strength.

- Finishing, Machining, and Inspection: After forging and heat treatment, the component moves to finishing operations. This can include trimming excess material (flash), shot blasting to clean the surface, and precision CNC machining to achieve final dimensions and tight tolerances. Rigorous quality control inspections, including metallurgical testing and dimensional analysis, are performed to verify that every part meets the required specifications before delivery.

Frequently Asked Questions

1. What are the 4 types of forging?

While there are several methods, four common types of industrial forging are open-die forging, impression-die (or closed-die) forging, cold forging, and seamless rolled ring forging. Impression-die is most common for complex automotive parts, while open-die is used for simpler, larger components. Cold forging is done at or near room temperature, and seamless rolled ring forging is used to create ring-shaped parts like bearings and gears.

2. What metals cannot be forged?

Metals with very limited ductility are difficult or impossible to forge without fracturing. This includes materials like cast iron and certain high-carbon steels. Additionally, some very high-strength alloys may be too brittle to withstand the stresses of the forging process. The suitability of a metal for forging depends on its ability to deform plastically without cracking.

3. Which is the world's largest forging company?

According to public sources, Bharat Forge, based in India, is often cited as one of the world's largest forging companies. It serves a wide range of industries, including automotive, aerospace, and energy.

4. Is forging stronger than welding?

Generally, a forged component is stronger than a welded assembly. Forging refines the grain structure of a single piece of metal, creating continuous strength throughout the part. Welding joins two separate pieces of metal by melting them at the joint, which can create a heat-affected zone that may be weaker or more brittle than the base metal. For critical, high-stress applications, a single forged part is almost always preferred for its superior structural integrity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —