Key Challenges of Forging Complex Geometries Explained

TL;DR

Forging complex geometries presents significant manufacturing challenges primarily centered on controlling metal flow and preventing defects. Intricate designs with sharp corners, thin sections, and asymmetrical features can disrupt the metal's internal grain structure, leading to weak points and potential component failure. Key difficulties include preventing defects like unfilled sections and warping, maintaining tight dimensional tolerances, and managing increased die complexity and wear.

The Core Challenge: Ensuring Proper Metal and Grain Flow

The fundamental advantage of forging is its ability to shape metal while refining its internal grain structure. This structure, known as grain flow, consists of the aligned crystals within the metal. When forging a simple shape, the pressure aligns these grains to follow the component's contour, creating continuous lines of strength that enhance durability and resistance to fatigue. This uninterrupted flow is what gives forged parts their superior mechanical properties compared to cast or machined components.

However, the primary challenge of forging complex geometries lies in maintaining this beneficial grain flow. Intricate designs inherently create obstacles to the smooth movement of metal within the die. According to an analysis by Frigate Manufacturing, parts with sharp corners, deep recesses, or asymmetrical features force the metal to change direction abruptly. This action can disrupt the continuous flow, creating areas of turbulence, folding the grain structure back on itself, or leaving voids. These disruptions become weak points, making the component more susceptible to failure under stress.

Furthermore, design elements like undercuts or sudden changes in thickness can block the material's path, leading to incomplete filling of the die cavity. As noted in forging design considerations by Greg Sewell Forgings, such features can lead to defects or compromise the part's structural integrity. The result is a component that does not possess the uniform strength expected from a forged product. Therefore, managing and directing metal flow is the most critical hurdle to overcome when producing parts with sophisticated designs.

Common Defects Arising from Geometric Complexity

The struggle to control metal flow in complex forgings directly leads to a higher incidence of specific manufacturing defects. These flaws can compromise the part's structural integrity, performance, and appearance. Engineers must anticipate and mitigate these issues, which are often a direct consequence of the part's intricate design.

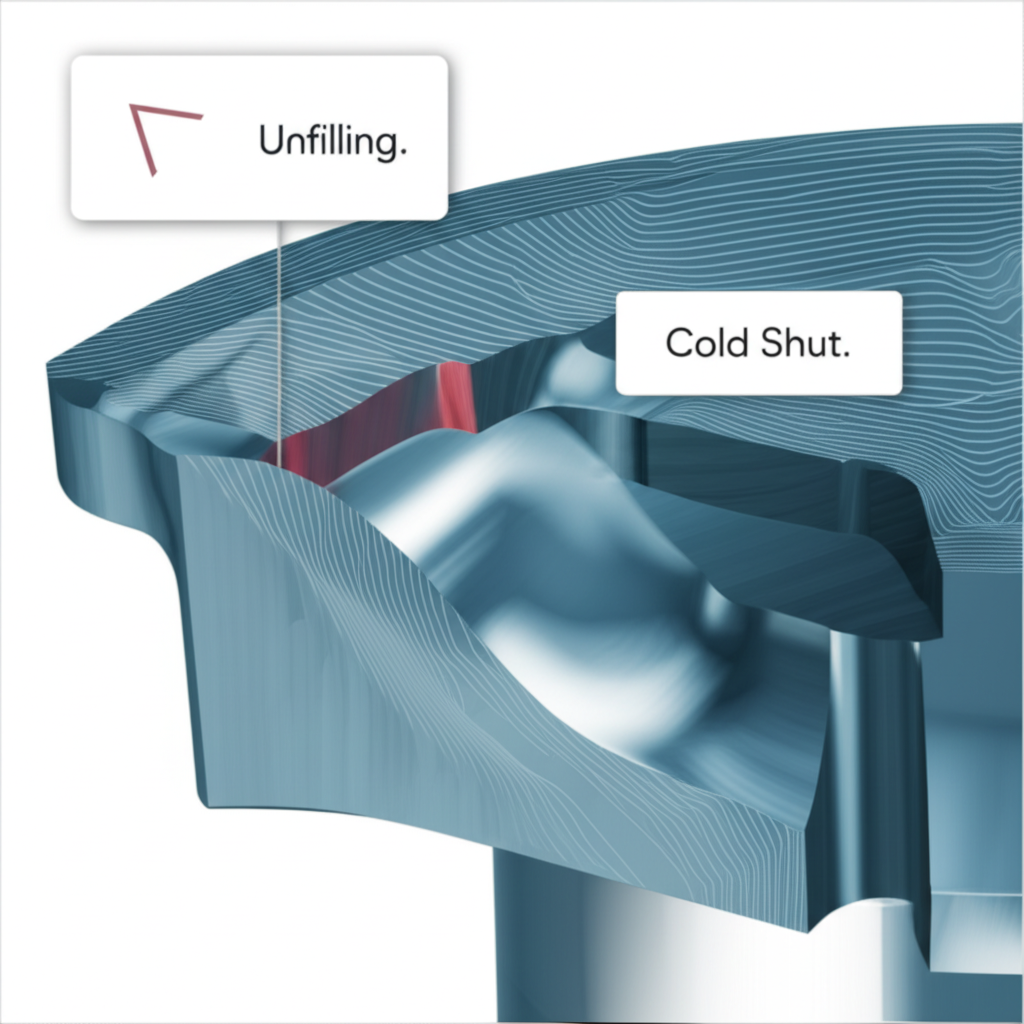

Unfilled Sections (Unfilling)

This defect occurs when the metal fails to completely fill the die cavity. In complex geometries with thin walls, deep pockets, or sharp internal corners, the metal may cool too quickly or encounter too much resistance to flow into these remote areas. The result is a part with missing features or incomplete sections, rendering it unusable.

Laps and Cold Shuts

A lap, or cold shut, is a discontinuity caused by a fold in the metal's surface. This happens when two streams of flowing metal meet but fail to fuse together properly, often due to premature cooling or the presence of surface oxides. Complex shapes that require material to flow around pins or into separate cavities are particularly prone to this defect, creating a crack-like flaw that severely weakens the component.

Surface Cracking

When a part's geometry includes thin sections next to much thicker ones, the difference in cooling rates and material flow can create immense internal stress. If the stress exceeds the material's ductility at forging temperature, surface cracks can form. This is especially challenging in high-strength alloys that have a narrower forging temperature range.

Warping and Distortion

Asymmetrical parts or those with significant variations in cross-sectional thickness are highly susceptible to warping. During the cooling phase after forging, thinner sections cool and contract faster than thicker sections. This uneven cooling creates internal stresses that can distort or twist the part, making it impossible to meet dimensional specifications without costly and difficult straightening operations.

Maintaining Dimensional Accuracy and Tolerances

Achieving and maintaining tight dimensional tolerances is another significant challenge when forging complex parts. While forging is known for producing near-net-shape components, intricate geometries push the limits of the process's precision. The final dimensions of a forged part are influenced by a combination of factors that become harder to control as complexity increases.

One major factor is thermal contraction. After being removed from the hot dies, the part cools and shrinks. For a simple, uniform shape, this shrinkage is predictable. However, for a complex part with varying thicknesses, the shrinkage is non-uniform. Thicker sections retain heat longer and shrink more slowly than thinner sections, leading to warping and dimensional instability. This makes it difficult to hold tight tolerances across the entire component without extensive post-forging machining, which can negate some of the cost benefits of forging.

Die wear also plays a critical role. The dies used to forge complex shapes are themselves intricate and subject to extreme pressures and thermal cycling. Features like sharp corners and small radii on the die wear down more quickly, which directly affects the dimensions of the parts produced. Compensating for this gradual die wear requires careful monitoring and planning, adding another layer of complexity to maintaining consistent quality over a long production run. The combination of unpredictable shrinkage and progressive die wear makes dimensional control a constant battle in precision forging.

Advanced Challenges: Die Design, Material, and Process Limits

Beyond the primary issues of metal flow and dimensional accuracy, forging complex geometries introduces several advanced challenges related to tooling, materials, and the inherent limitations of the process itself. These factors require specialized expertise and technology to manage effectively.

Die Design and Wear

The complexity of the final part is directly reflected in the complexity of the forging dies. Intricate components require multi-part, sophisticated dies that are expensive to design and manufacture. These dies often have deep cavities, sharp angles, and small features that are subjected to immense force and thermal shock. As a result, they experience significantly higher wear rates than dies for simpler shapes. The increased stress concentration on small features can lead to premature die failure, causing production downtime and raising costs substantially. Proper die design, material selection, and maintenance are critical to mitigating these issues.

Material Inconsistency

The quality of the raw material is paramount in forging, and its importance is magnified with complex parts. As highlighted by experts at Carbo Forge, variations in metal composition or the presence of internal defects like inclusions can compromise the integrity of the final component. In a complex forging process, these minor inconsistencies can disrupt metal flow, initiate cracks, or create weak spots that might not be detected until the part is in service. Ensuring a consistent, high-quality supply of raw material is essential for producing reliable complex forgings.

Process Limitations and Specialization

Finally, the forging process has inherent size and weight limitations that vary based on the equipment used. Extremely large or heavy complex parts may be impossible to produce with standard forging presses. Furthermore, some geometries, such as those requiring high radial expansion or combining dissimilar materials, present extreme formability challenges. Research on forging bimetal components, for instance, shows that achieving a solid bond without defects requires precise, tailored heating and forming strategies to accommodate the different properties of the materials. For industries like automotive where complex components must meet stringent standards, partnering with a specialized provider is crucial. For example, firms like Shaoyi Metal Technology offer custom hot forging services with IATF 16949 certification, handling everything from in-house die manufacturing to mass production for intricate automotive parts.

Frequently Asked Questions

1. What are the main limitations of the forging process?

The primary limitations of forging include constraints on size and weight, which depend on the equipment, and challenges with achieving extremely complex designs. The high cost of tooling (dies) makes it less economical for small production runs, and achieving very tight tolerances may require secondary machining operations.

2. What is the complexity factor of a forging?

The complexity factor refers to how a part's shape influences the forging process. Thin sections, sharp corners, and non-symmetrical features increase complexity. This leads to higher shaping forces, increased die wear, and greater variation in dimensional shrinkage, making the part more difficult and costly to produce accurately.

3. What are some common defects that can occur during forging?

Common forging defects include unfilled sections where the metal doesn't fill the die completely, cold shuts where metal streams fail to fuse, surface cracking due to stress, die shift causing misalignment, and flakes or internal voids. Many of these are more likely to occur when forging complex geometries.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —