Essential Stages of the Forging Sampling Process

TL;DR

The forging sampling process is a critical quality control step performed before mass production. It involves testing representative samples from a production run to verify material properties like strength, ductility, and internal soundness. This procedure ensures the final parts meet strict engineering specifications and are free from defects that could compromise performance and safety.

The Purpose of Forging Sampling: Quality Assurance Before Mass Production

In manufacturing, especially for high-stress applications in the automotive, aerospace, and energy sectors, component failure is not an option. The forging sampling process serves as a fundamental quality assurance gatekeeper. As an industry-standard practice, a sample production run must be produced, evaluated, and approved before full-scale serial production can commence. This pre-production validation is designed to confirm that the entire manufacturing workflow—from raw material to the final forging and heat treatment processes—can consistently produce parts that meet precise engineering requirements.

The primary objective is to evaluate a component's fitness for its intended application. This involves a thorough assessment of its mechanical and physical properties. Key evaluations focus on verifying internal soundness, ensuring the metal is free from hidden voids or inclusions that could become failure points under stress. Additionally, sampling confirms metallurgical properties such as chemical composition, grain structure, ductility (the ability to deform without fracturing), and overall strength. By identifying potential issues early, manufacturers can adjust their processes, preventing the enormous cost and risk associated with producing a large batch of defective parts.

Ultimately, the sampling process builds a bridge of confidence between the manufacturer and the customer. It provides tangible evidence that the forged components will perform reliably and safely. Using modern techniques like solidification modeling can improve the success rate of the first sample run, but the physical testing of samples remains the definitive proof of quality, ensuring every part that comes off the production line is fit for purpose.

Key Stages in the Forging Sampling Workflow

Understanding what to expect during the forging sampling process involves recognizing its structured workflow. The procedure is methodical, designed to move from the bulk forged part to a standardized test piece that yields reliable and repeatable data. Each stage is crucial for maintaining the integrity of the evaluation.

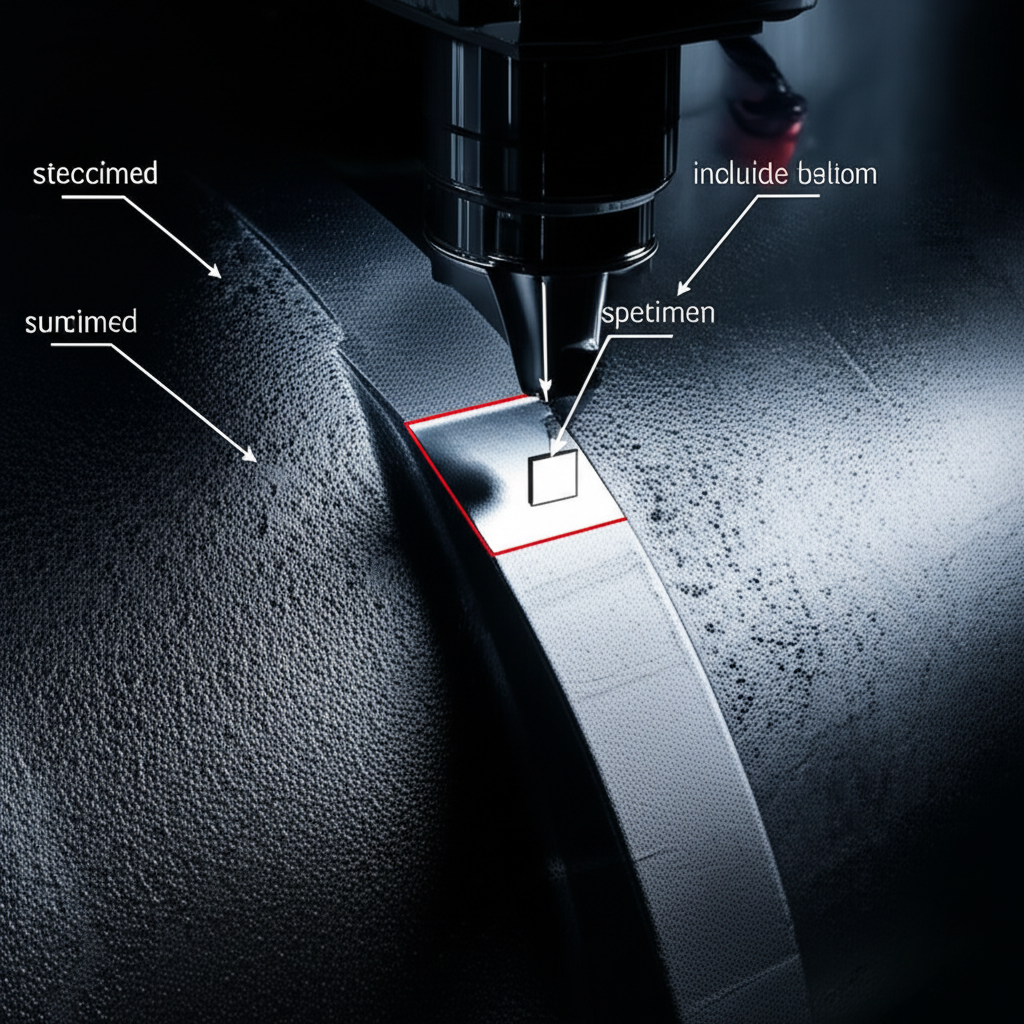

- Sample Extraction: The process begins by taking a representative sample directly from a forged component. This might be a piece cut from the forging itself or from a test coupon or prolongation—an extra piece of material forged alongside the main part under identical conditions. The location of the sample is critical, as material properties can vary across a complex shape. The extraction method must be carefully controlled to avoid introducing heat or stress that could alter the material's properties before testing even begins.

- Specimen Preparation: Once extracted, the rough sample is not yet ready for testing. It must be precisely machined into a standardized specimen with specific dimensions and surface finish. This step, often performed using CNC machines, is vital because inconsistencies in the specimen's shape or surface quality could skew test results. Standardized shapes, such as the common "dog bone" for tensile tests, ensure that the stress is concentrated in the desired area, providing an accurate representation of the material's true properties.

- Testing and Analysis: With a properly prepared specimen, the testing phase can begin. The specimen is subjected to one or more inspection methods, which can be either destructive or non-destructive. The data collected—such as the force required to fracture the part or the presence of internal flaws—is meticulously recorded and analyzed. These results are then compared against the engineering specifications and industry standards to determine if the sample passes or fails, thereby approving or rejecting the production batch.

Common Inspection and Testing Methods for Forged Samples

A variety of testing methods are used to evaluate forged samples, each providing unique insights into the material's quality. These techniques are broadly categorized as either destructive, where the sample is tested to failure, or non-destructive, which evaluates the part without damaging it.

Destructive Testing

Destructive tests provide quantitative data on a material's mechanical limits. Although the specimen is destroyed, the information gained is invaluable for validating the forging's performance capabilities.

- Tensile Testing: This is one of the most common destructive tests. A specimen is pulled apart until it fractures, measuring its ultimate tensile strength (UTS), yield strength, and ductility (elongation). According to experts at TensileMill CNC, this test directly confirms if the forging process and heat treatment have achieved the desired mechanical properties.

- Hardness Testing: This test measures the material's resistance to localized surface indentation. Techniques like Rockwell or Brinell testing press a hard indenter into the surface to determine its hardness, which often correlates with wear resistance and strength.

- Impact Testing (Charpy): To determine a material's toughness, or its ability to absorb energy under sudden impact, a Charpy test is used. It involves striking a notched specimen with a weighted pendulum and measuring the energy absorbed during fracture.

Non-Destructive Testing (NDT)

NDT methods are essential for identifying flaws without rendering the component unusable. They are particularly useful for inspecting for hidden, internal defects.

- Ultrasonic Testing (UT): High-frequency sound waves are sent through the material. Echoes from internal discontinuities like cracks, voids, or inclusions are detected, allowing inspectors to map the size and location of flaws.

- Magnetic Particle Inspection (MPI): Used for ferromagnetic materials, this method involves creating a magnetic field in the part. Fine iron particles are applied to the surface and accumulate at areas of magnetic flux leakage, revealing surface and near-surface cracks.

- Liquid Penetrant Inspection (LPI): A colored or fluorescent dye is applied to the surface and seeps into any surface-breaking defects. After the excess dye is removed, a developer is applied, which draws the penetrant out of the flaws, making them visible.

- Radiographic Testing (RT): Similar to a medical X-ray, this technique uses gamma rays or X-rays to create an image of the forging's internal structure, revealing voids, porosity, and other density variations.

From Sample to Solution: Identifying and Mitigating Forging Defects

The ultimate goal of the sampling and testing process is to create a feedback loop for quality improvement. When tests reveal a problem, the data is used to diagnose the root cause and refine the manufacturing process. Forging defects can compromise the structural integrity of a component, and identifying them early is crucial for preventing in-service failures. Common defects include surface issues like cracks and cold shuts (where two metal flows fail to fuse) and internal flaws like voids or inclusions.

Each testing method is adept at finding specific types of flaws. For instance, magnetic particle inspection is excellent for detecting surface cracks caused by thermal stress, while ultrasonic testing can uncover internal bursts or voids resulting from trapped gas. If a tensile test shows lower-than-expected ductility, it might point to an improper heat treatment cycle. By linking a specific defect to a test result, engineers can pinpoint whether the issue lies with the raw material quality, heating temperature, die design, or cooling rate.

For industries with stringent safety requirements, such as automotive manufacturing, partnering with a certified specialist is crucial to manage this complex quality control process. For example, some companies leverage these quality control processes to produce high-quality custom automotive parts, from prototypes to mass production. For those seeking specialized services, Shaoyi Metal Technology is an IATF16949 certified provider offering advanced hot forging solutions. The insights gained from the forging sampling process enable continuous improvement, ensuring that the final products are not only free of defects but also optimized for strength, durability, and performance.

The Critical Role of Sampling in Forging Integrity

The forging sampling process is far more than a procedural checkpoint; it is the cornerstone of manufacturing integrity and product reliability. It provides the verifiable data needed to confirm that a component can withstand the real-world stresses it was designed for. By systematically extracting, preparing, and testing samples, manufacturers can move beyond theoretical models and gain concrete evidence of a part's metallurgical soundness and mechanical strength.

This rigorous evaluation protects both the manufacturer and the end-user. It prevents the financial losses associated with large-scale recalls and production of faulty parts while safeguarding against catastrophic failures in critical applications. Ultimately, a successful sampling process validates the entire production chain, building confidence and ensuring that every forged component delivered is synonymous with quality and safety.

Frequently Asked Questions

1. What is the main purpose of the forging sampling process?

The main purpose is quality assurance. It is a pre-production approval step to test and evaluate a small run of forged parts to ensure they meet all engineering requirements for mechanical properties, metallurgical soundness, and dimensional accuracy before starting mass production.

2. What is the difference between destructive and non-destructive testing in forging?

Destructive testing involves stressing a sample specimen until it fails or breaks to measure properties like tensile strength and toughness. The sample is destroyed in the process. Non-destructive testing (NDT) inspects a component for flaws like internal cracks or surface defects without damaging it, using methods like ultrasonic or magnetic particle inspection.

3. What happens if a forging sample fails testing?

If a sample fails to meet the required specifications, an investigation is launched to identify the root cause of the failure. This could involve adjusting process parameters such as heating temperature, press force, die design, or the heat treatment cycle. Serial production is halted until the issue is resolved and a new set of samples passes all required tests, ensuring the defect does not carry over into the final products.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —