The Core Steps of the Automotive Die Casting Process

TL;DR

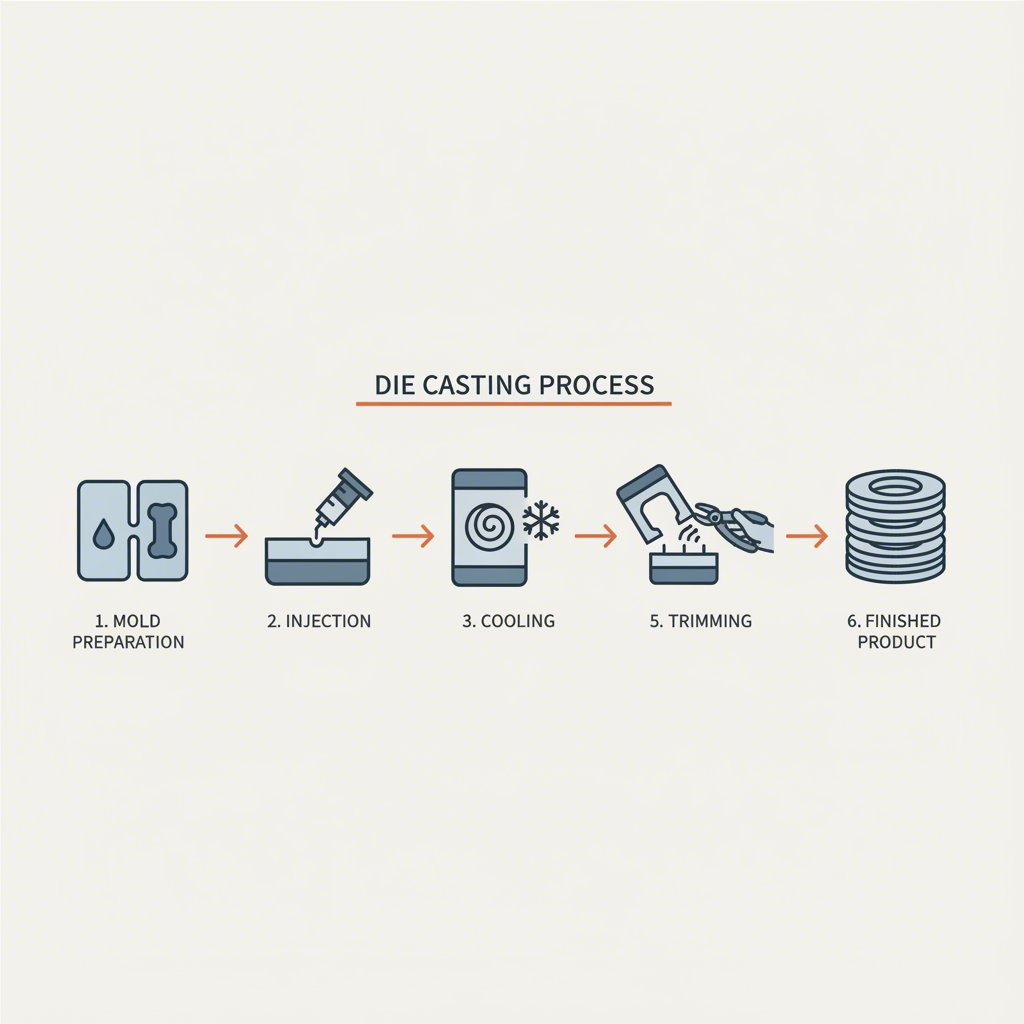

The automotive die casting process is a high-speed manufacturing technique that forces molten metal into a reusable steel mold, known as a die, under significant pressure. This process consists of six primary steps: mold preparation, metal melting, high-pressure injection, cooling and solidification, part ejection, and finally, trimming and finishing. It is the preferred method for producing large quantities of complex, high-precision, and lightweight metal components essential for the automotive industry.

Understanding Automotive Die Casting: An Overview

Die casting is a cornerstone of modern automotive manufacturing, valued for its ability to produce geometrically complex metal parts with high accuracy and consistency. In this process, a non-ferrous molten metal alloy is forced into a custom-engineered steel die at high pressure and speed. This method is crucial for creating components that are both strong and lightweight, a key requirement in enhancing vehicle fuel efficiency and performance. Parts like engine blocks, transmission housings, and structural components are commonly manufactured using this technique.

The advantages of die casting are significant. It allows for rapid production cycles, making it highly cost-effective for large-volume manufacturing runs. The process yields parts with an excellent surface finish and tight dimensional tolerances, often minimizing the need for secondary machining operations. Furthermore, it can produce parts with thin walls and intricate features that would be difficult or impossible to create with other manufacturing methods. For companies seeking to optimize their production, partnering with experienced specialists in custom tooling is crucial to achieve the high-quality outcomes demanded by automotive OEMs and Tier 1 suppliers.

However, the process is not without its challenges. The primary disadvantage is the high initial cost of tooling and machinery, which makes it less suitable for low-volume production. Additionally, if not properly controlled, the process can lead to defects such as porosity—tiny gas bubbles trapped within the metal—which can compromise the structural integrity of the part. Careful control over injection pressure, temperature, and die design is essential to mitigate these risks and ensure the final product meets stringent quality standards.

The Step-by-Step Die Casting Process in Detail

The automotive die casting process is a highly refined, sequential operation designed for precision and speed. Each step is critical to ensuring the final component meets exact specifications for strength, finish, and dimensional accuracy. The entire cycle can be broken down into six distinct stages.

- Mold Preparation: Before any metal is injected, the two halves of the steel die must be meticulously prepared. This involves cleaning the mold cavity to remove any residue from previous cycles and then spraying it with a lubricant. As detailed by sources like Monroe Engineering, this lubricant serves two purposes: it helps control the die's temperature and ensures the finished part can be easily removed after solidification. Once prepared, the two die halves are securely clamped together under immense force to withstand the pressure of the injection phase.

- Injection: With the die clamped shut, molten metal—melted to a precise temperature in a separate furnace—is injected into the die cavity. This is done under extremely high pressure, typically ranging from 1,500 to over 25,000 pounds per square inch (PSI). This intense pressure is necessary to force the metal into every intricate detail of the mold before it begins to solidify, a critical factor for producing parts with a smooth surface and high fidelity to the design.

- Cooling and Solidification: Once the die cavity is filled, the molten metal begins to cool and solidify, taking the exact shape of the mold. The cooling time is carefully calculated and depends on the type of metal alloy, the part's wall thickness, and the overall complexity of the casting. Proper cooling is vital to achieve the desired metallurgical properties and prevent internal stresses or defects.

- Ejection: After the casting has fully solidified, the two halves of the die are opened. Ejector pins built into the movable half of the die then push the solidified casting out of the cavity. In highly automated systems, robotic arms may assist in removing the part to ensure a smooth and rapid transition to the next stage.

- Trimming and Finishing: The newly ejected part, often called a 'shot,' is not yet complete. It includes excess material such as the runners, gates, and flash (a thin overflow of metal at the die's parting line). According to manufacturing guides like those from Intercast, this excess material is removed in a trimming process, which can involve a trim die, sawing, or grinding. Depending on the application, further finishing operations like sandblasting, machining, or powder coating may be performed to meet the final specifications.

Essential Materials for Automotive Die Casting

The selection of the right material is a critical decision in the automotive die casting process, as it directly impacts the component's performance, weight, and cost. The most commonly used materials are non-ferrous alloys, prized for their unique combination of properties. Aluminum, zinc, and magnesium alloys dominate the industry due to their excellent castability and mechanical characteristics.

Aluminum alloys are the most prevalent choice in automotive applications, largely due to their excellent strength-to-weight ratio, high-temperature resistance, and natural corrosion resistance. These properties make them ideal for structural components, engine parts, and transmission housings. Zinc alloys are another popular option, known for being one of the easiest materials to cast. They offer high ductility, impact strength, and allow for a long die life, making them suitable for smaller, more intricate parts like interior components and electronics housings. Magnesium is the lightest of the common die casting alloys, offering a superior strength-to-weight ratio, making it perfect for applications where minimizing weight is the top priority, such as in steering wheel frames and instrument panels.

Choosing between these materials involves a trade-off between cost, weight, and specific performance requirements. The table below, with information synthesized from resources like Fictiv, summarizes the key characteristics of these primary alloys.

| Alloy | Key Properties | Common Automotive Applications |

|---|---|---|

| Aluminum | Lightweight, high thermal conductivity, good strength & corrosion resistance. | Engine blocks, transmission cases, oil pans, structural components. |

| Zinc | Excellent castability, high ductility, good surface finish, high impact strength. | Interior hardware, locking mechanisms, electronic components, emblems. |

| Magnesium | Ultra-lightweight, excellent strength-to-weight ratio, good EMI/RFI shielding. | Seat frames, steering wheel cores, instrument panels, transfer cases. |

Die Casting Machines and Technology: A Closer Look

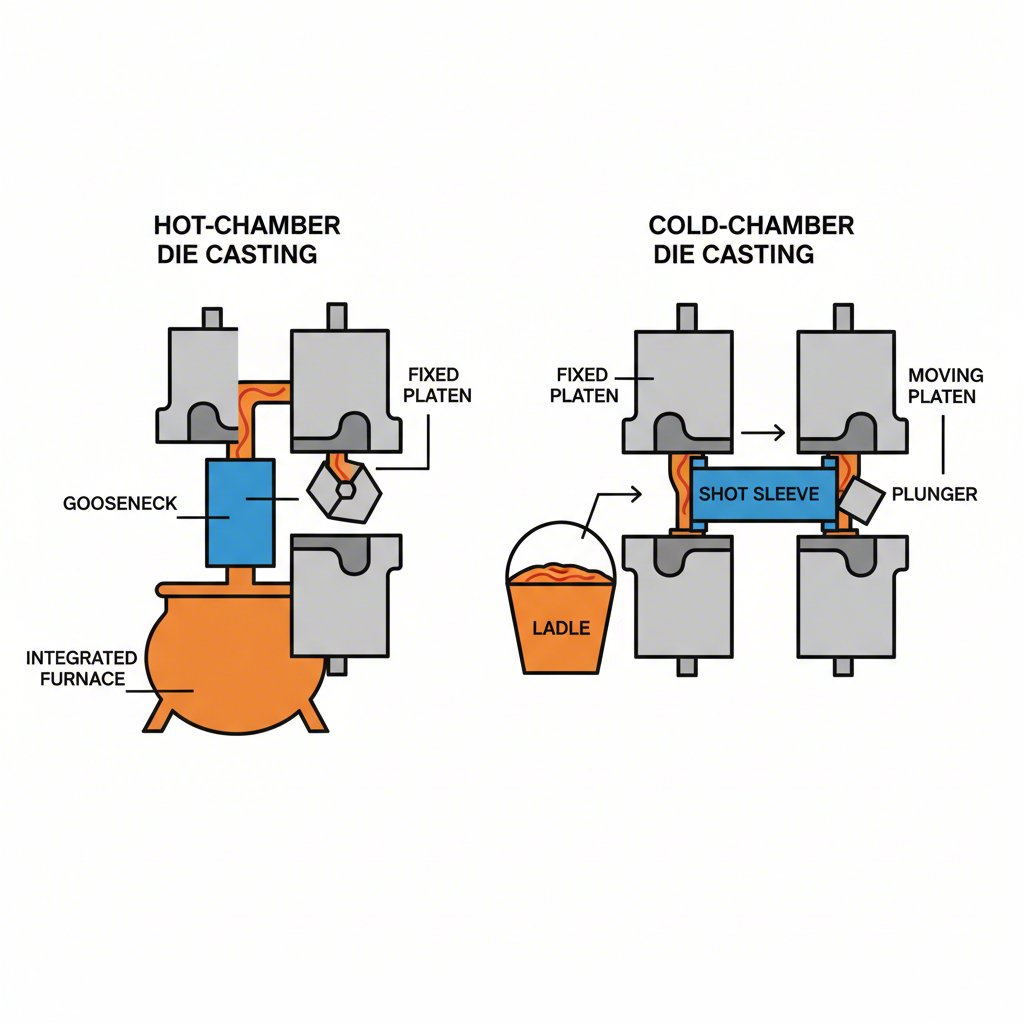

The machinery used for die casting is as important as the materials and the process itself. These machines are designed to handle immense pressures and high temperatures while operating at high speeds. The two primary types of die casting machines are the hot-chamber machine and the cold-chamber machine. The choice between them is almost entirely dictated by the melting point of the alloy being cast.

Hot-Chamber Die Casting Machines are used for alloys with low melting points, such as zinc, tin, and lead. In this design, the injection mechanism, including a metal pot or furnace, is integrated directly into the machine. A plunger mechanism is submerged in the molten metal, which allows for a very fast and direct injection cycle. Because the metal is fed directly into the die, the process is rapid and efficient, making it ideal for high-volume production of smaller parts. However, high-melting-point alloys like aluminum would damage the injection components over time, making this method unsuitable for them.

Cold-Chamber Die Casting Machines are required for alloys with high melting points, most notably aluminum and magnesium. In this setup, the melting furnace is separate from the machine. Molten metal is ladled, either manually or automatically, from the furnace into a 'cold chamber' or shot sleeve for each cycle. A hydraulic plunger then forces the metal into the die cavity. While this process is slightly slower than the hot-chamber method due to the ladling step, it prevents the machine's injection components from having prolonged contact with corrosive, high-temperature metals. This design is essential for producing the durable, lightweight aluminum parts that are ubiquitous in the automotive industry.

The fundamental difference lies in how the molten metal is introduced to the die. As explained by industry overviews from sources like Raga Group, hot-chamber machines offer faster cycles for low-temperature alloys, while cold-chamber machines provide the durability needed to handle high-temperature alloys, which are critical for many automotive structural and powertrain applications.

Frequently Asked Questions About Die Casting

1. What are the main steps of the die casting process?

The die casting process generally consists of six core steps: preparing the mold by cleaning and lubricating it, melting the metal alloy, injecting the molten metal into the mold under high pressure, allowing the metal to cool and solidify, ejecting the finished part from the mold, and finally, trimming away any excess material to complete the component.

2. What is the process of automobile casting?

Automobile casting, specifically die casting, is a manufacturing method used to produce high-precision metal parts for vehicles. It involves injecting molten metal like aluminum or magnesium into a steel die under high pressure. This technique is widely used in the automotive industry to create complex and lightweight components such as engine blocks and transmission housings with excellent dimensional accuracy and surface finish.

3. Why are there different numbers of steps mentioned (e.g., 4 vs. 6)?

Different sources may group the steps of the die casting process differently. For example, a 4-step model might combine 'Trimming' with 'Ejection' into a single finishing stage, or consider 'Melting' as a preliminary action rather than a core step. However, the fundamental sequence of preparing the mold, injecting metal, solidification, and removing the part remains consistent. The 6-step model simply provides a more detailed breakdown of the entire workflow from start to finish.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —