Die Casting vs Forging: The Right Choice for Auto Parts

TL;DR

When choosing between die casting vs forging for automotive parts, the decision hinges on a trade-off between strength and complexity. Forging produces mechanically superior, stronger, and more durable parts by shaping solid metal, making it ideal for high-stress components like crankshafts and connecting rods. Conversely, die casting excels at creating complex, intricate shapes with high precision at a greater volume and lower unit cost by injecting molten metal into a mold, perfect for parts like engine blocks and transmission housings.

The Fundamental Difference: Shaping Molten vs. Solid Metal

Understanding the core distinction between die casting and forging is the first step in selecting the right process for an automotive application. Though both methods shape metal, they start from fundamentally different states of matter, which dictates their respective strengths and weaknesses. The primary choice depends on whether the part's geometry or its mechanical integrity is the top priority.

Die casting is a process where metal, typically a non-ferrous alloy like aluminum or zinc, is heated until it becomes completely molten. This liquid metal is then injected under high pressure into a hardened steel mold, known as a die. As the metal cools and solidifies, it takes the exact shape of the die's cavity, including complex internal passages and fine external details. Think of it like making a detailed ice cube in a tray; the liquid perfectly fills every nook and cranny before hardening.

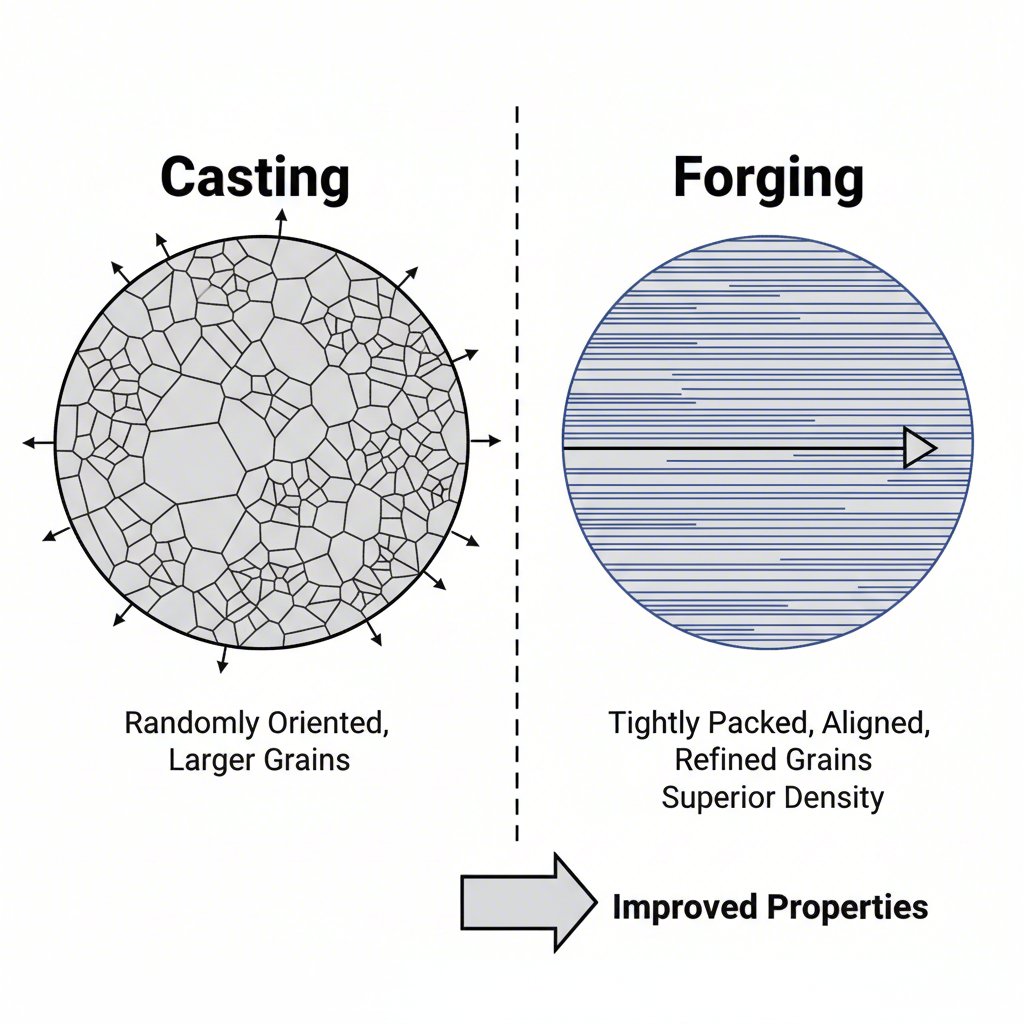

Forging, on the other hand, works with metal in a solid state. A metal billet or ingot is heated to a high temperature, but it remains solid—becoming malleable and plastic-like. Immense compressive force is then applied using hammers or presses to shape the metal into the desired form. This process is akin to a blacksmith shaping a glowing horseshoe on an anvil. The intense pressure refines the metal's internal grain structure, aligning it with the part's shape and eliminating internal defects like porosity.

This fundamental process difference is the source of the main trade-off engineers face. Die casting's use of liquid metal allows for unparalleled design freedom and complexity, enabling the creation of multi-functional, lightweight parts in a single step. Forging's method of deforming solid metal results in a denser, stronger component with superior fatigue resistance, making it the go-to choice for parts that simply cannot fail under extreme stress.

Head-to-Head Comparison: Critical Metrics for Automotive Engineers

For automotive engineers, selecting between die casting and forging requires a detailed analysis of key performance indicators. The optimal choice is not about which process is universally "better," but which one aligns with the specific functional requirements, budget constraints, and production volume of a given component. The decision involves a careful balance of strength, geometric complexity, cost, and manufacturing speed.

The following table provides a direct comparison of these critical metrics:

| Metric | Die Casting | Forging | Winner for Automotive Applications |

|---|---|---|---|

| Mechanical Strength & Durability | Good. Prone to potential porosity which can create weak points. | Superior. Refined and aligned grain structure creates exceptional tensile strength and fatigue resistance. | Forging (for safety-critical, high-stress parts) |

| Part Complexity & Geometry | Excellent. Can produce intricate shapes, thin walls, and complex internal features in a single piece. | Limited. Best for simpler, solid shapes. Complex internal features are not feasible. | Die Casting (for multi-functional, integrated designs) |

| Production Speed & Volume | Very high. Highly automated process is ideal for mass production (100+ parts per hour). | Slower. More labor-intensive process, not well-suited for extremely high volumes. | Die Casting (for high-volume manufacturing) |

| Cost | High initial tooling (die) cost, but low per-part cost at high volumes. | Tooling costs can be high, and per-part cost is generally higher due to slower cycle times. | Die Casting (for mass production runs) |

| Surface Finish | Excellent. Parts emerge with a smooth finish, often requiring minimal secondary processing. | Good, but typically requires more secondary machining or finishing operations. | Die Casting |

In terms of strength, forging is the undisputed leader. The process creates parts with a continuous grain structure that follows the contour of the component, eliminating the microscopic voids and inconsistencies common in casting. Forged parts can exhibit up to 26% higher tensile strength and significantly greater fatigue strength than their cast counterparts. This makes forging essential for automotive parts subjected to immense and repeated stress.

However, when it comes to design freedom, die casting is far superior. The ability to inject molten metal allows for the creation of complex geometries that would be impossible to forge, as noted by the North American Die Casting Association. This enables engineers to consolidate multiple components into a single, lightweight die-cast part, reducing assembly time and overall weight, which is critical for improving fuel efficiency.

Automotive Applications in Focus: Which Process for Which Part?

In the automotive industry, the choice between die casting and forging isn't theoretical; it directly maps to the function and location of specific components within a vehicle. High-stress, performance-critical parts rely on the strength of forging, while complex, multi-functional housings and structures benefit from the design flexibility of die casting.

Forged Automotive Parts

Components that are responsible for transferring power and absorbing immense operational forces are almost always forged. The refined grain structure and absence of porosity provide the reliability and fatigue resistance needed to prevent catastrophic failure. These parts are the backbone of a vehicle's powertrain and suspension.

- Crankshafts and Connecting Rods: These engine internals endure millions of cycles of tensile and compressive stress. Forging ensures they have the strength to manage combustion forces without failing.

- Gears and Axle Shafts: Responsible for transmitting torque, these parts require high torsional strength and resistance to wear and tear. The dense structure of forged steel is ideal for these applications.

- Control Arms and Suspension Knuckles: As key parts of the suspension system, these components must withstand constant impact and load from the road surface. Forging provides the necessary durability and impact resistance.

Die Cast Automotive Parts

Die casting is the preferred method for large, complex components that require precise dimensions, integrated features like cooling channels or mounting bosses, and lightweighting. Aluminum die casting is particularly prevalent as manufacturers strive to reduce vehicle weight and improve efficiency.

- Engine Blocks and Cylinder Heads: These parts have incredibly complex internal geometries for coolant and oil passages that can only be efficiently produced through casting.

- Transmission Housings: A transmission case must be strong, lightweight, and precisely shaped to house a complex array of gears and hydraulic components. Die casting achieves this combination of properties effectively.

- Electronic Enclosures and Structural Components: Housings for electronic control units (ECUs) or complex structural nodes in the vehicle frame benefit from die casting's ability to create thin walls, heat-dissipating fins, and precise mounting points in a single part.

The Decision Framework: Pros, Cons, and Final Recommendations

Ultimately, the decision between die casting and forging is a strategic engineering choice based on a clear set of project priorities. There is no single best process, only the most appropriate one for the application. Summarizing the advantages and disadvantages provides a clear framework for making this critical decision.

Advantages and Disadvantages of Die Casting

Pros

- Geometric Complexity: Unmatched ability to produce intricate parts with thin walls and internal passages.

- High Production Rate: Fast cycle times make it ideal for high-volume automotive manufacturing.

- Excellent Surface Finish: Parts often require little to no secondary machining.

- Cost-Effective at Scale: Low per-part cost in mass production offsets high initial tooling investment.

Cons

- Lower Mechanical Strength: Susceptible to porosity, resulting in lower tensile and fatigue strength compared to forging.

- High Tooling Costs: The initial investment in a hardened steel die can be substantial.

- Limited to Non-Ferrous Alloys: Primarily used for aluminum, zinc, and magnesium.

The high initial tooling cost for die casting necessitates partnering with expert die manufacturers. For instance, specialists in precision toolmaking demonstrate the level of engineering required, leveraging advanced simulations and certified processes to produce complex dies for the automotive sector, ensuring part quality and longevity.

Advantages and Disadvantages of Forging

Pros

- Superior Strength and Durability: Refined grain structure provides exceptional mechanical properties and reliability.

- High Fatigue Resistance: Ideal for components under cyclic stress and high loads.

- Structural Integrity: Lack of porosity ensures a dense, reliable internal structure.

Cons

- Limited Shape Complexity: Not suitable for intricate designs or parts with internal cavities.

- Slower Production Process: Lower output rates compared to die casting.

- Higher Per-Part Cost: More labor and energy-intensive, making it more expensive for high volumes.

In conclusion, your choice should be guided by a simple checklist. Choose forging when mechanical performance, durability, and reliability under extreme stress are non-negotiable. Choose die casting when intricate design, high production volume, component consolidation, and cost-efficiency are the primary drivers.

Frequently Asked Questions

1. When to use casting vs forging?

Use casting for parts with complex shapes, intricate details, or internal cavities, such as engine blocks or transmission housings. Casting is also ideal for high-volume production where cost per part is a major factor. Use forging for components that require maximum strength, durability, and fatigue resistance, like crankshafts, connecting rods, and high-stress suspension parts.

2. How much stronger is forged vs cast?

Forged parts are significantly stronger than cast parts. Due to the refined and aligned grain structure created during the forging process, forged steel can have up to 26% higher tensile strength and significantly higher fatigue strength. This results in a much longer service life for components that are under constant stress.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —