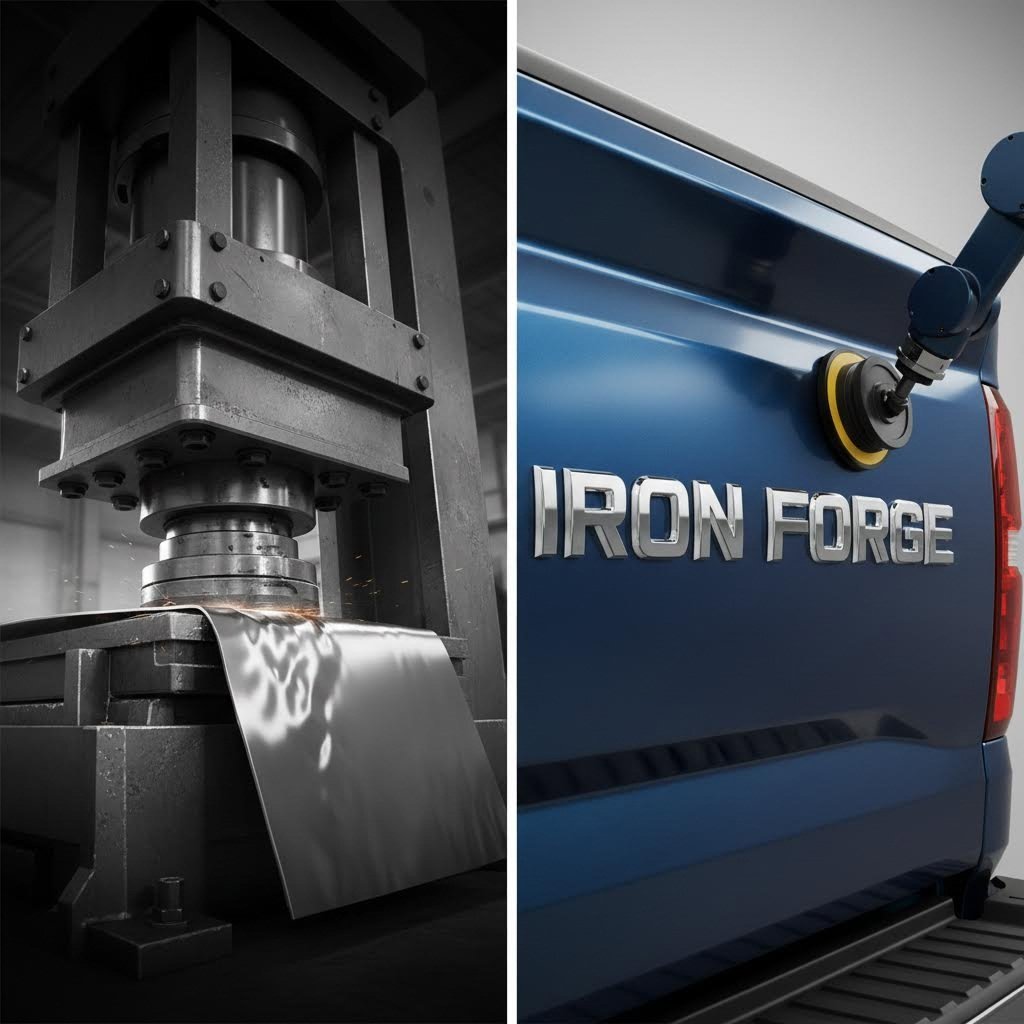

Tailgate Stamping Automotive: From Factory Press to Custom Lettering

TL;DR

Tailgate stamping automotive refers to two distinct concepts depending on your needs: the industrial manufacturing process of forming truck tailgates from sheet metal using high-tonnage presses, and the popular aftermarket customization of filling these stamped brand indentations (like CHEVROLET or TOYOTA) with 3D lettering.

For manufacturers, this involves precision engineering with hydraulic presses to create "Class A" surfaces from aluminum or steel blanks. For truck owners, it means upgrading the factory look with insert lettering kits made from vinyl, ABS plastic, or stainless steel to make the logo pop. This guide covers both the engineering science behind the stamp and the practical steps to customize it.

The Engineering Behind the Stamp: Manufacturing Process

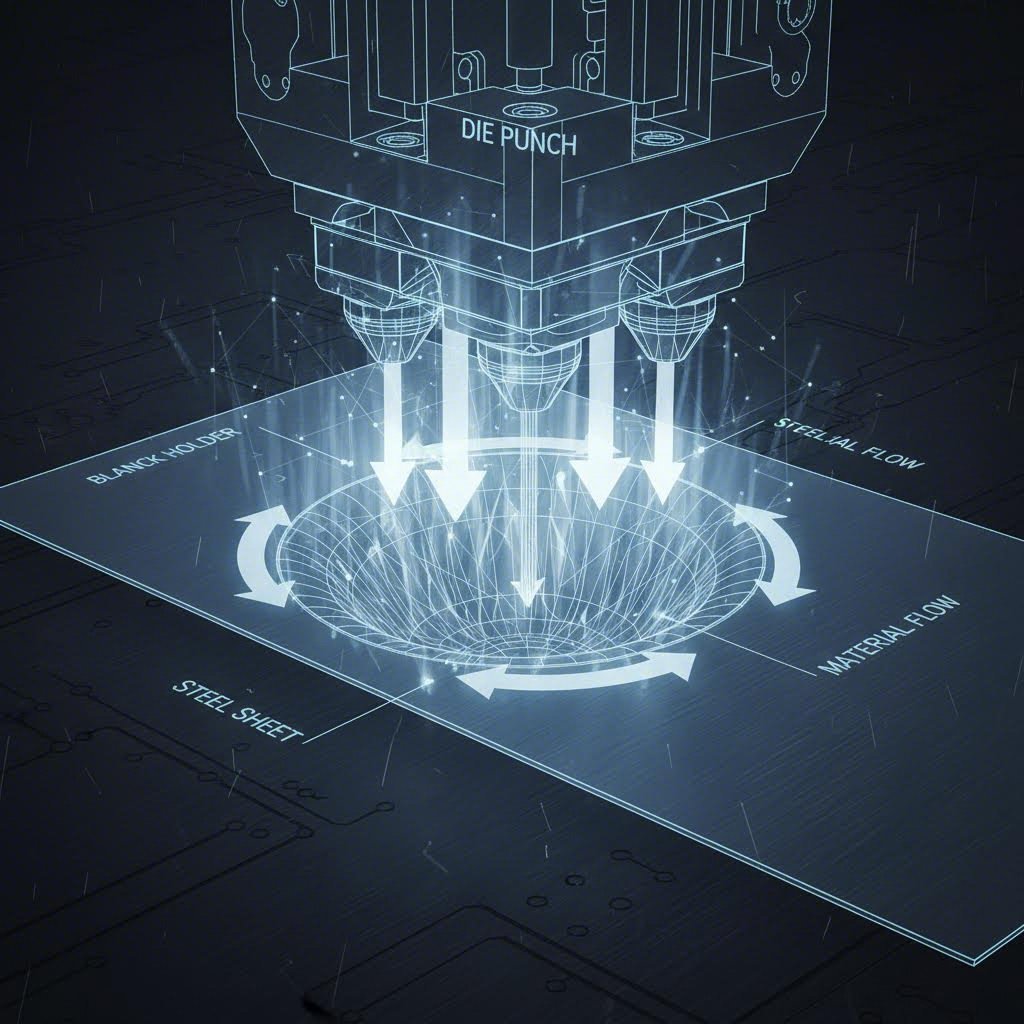

Before a tailgate ever reaches a dealership lot, it undergoes a violent yet precise transformation. Automotive stamping is the process of turning flat sheet metal "blanks" into complex, three-dimensional shapes using massive dies and hydraulic presses. For exterior parts like tailgates, this is a critical stage that defines the vehicle's structural integrity and aesthetic appeal.

The process typically begins with cold stamping for standard body panels, where sheet metal is fed into a press at room temperature. A male "punch" forces the metal into a female "die," drawing it into the desired shape. However, for structural components requiring immense strength without added weight, manufacturers increasingly turn to hot stamping (or press hardening). As detailed by The Fabricator, this involves heating boron steel to nearly 900°C before stamping, creating parts with tensile strengths up to 2,000 MPa—crucial for safety cages and pillars.

For visible components like the tailgate skin, the priority is achieving a Class A surface. This engineering term refers to a flawless, mirror-smooth finish free of ripples or defects, which is essential for painting. Achieving this while stamping deep, embossed logos (like the massive "RAM" or "FORD" block letters) requires "deep draw" capabilities to stretch the metal without tearing it. Manufacturers must balance the material's elasticity with the die's pressure to prevent "springback," where the metal tries to return to its original shape.

If you are an automotive engineer or procurement officer looking to scale this type of production, specialized partners are often required. Shaoyi Metal Technology provides comprehensive stamping solutions that bridge the gap from rapid prototyping to high-volume manufacturing, utilizing presses up to 600 tons to deliver precision components compliant with IATF 16949 standards.

Customizing Your Stamped Tailgate: Lettering & Inserts

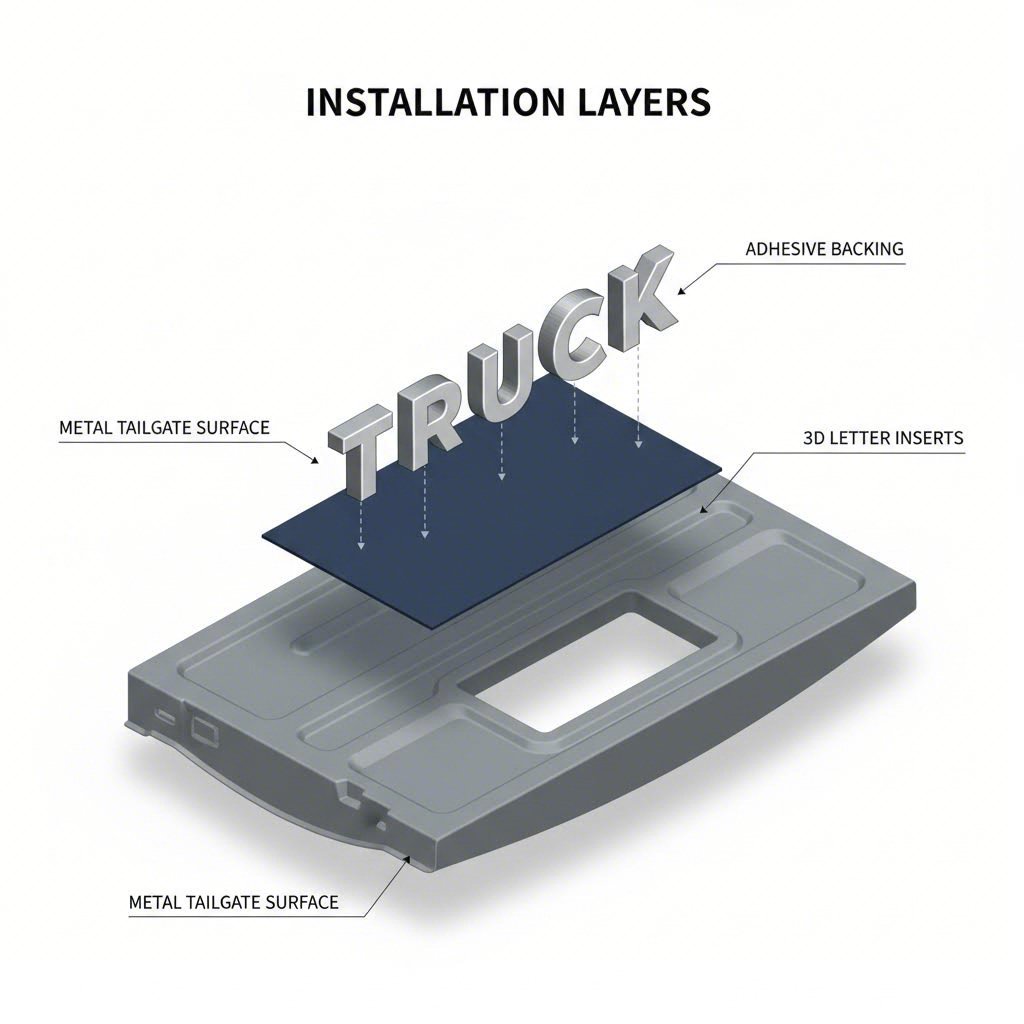

For most truck owners, "tailgate stamping" isn't about hydraulic presses—it's about aesthetics. Factory tailgates often come with the brand name stamped (indented) into the metal but painted the same color as the truck, making the logo fade into the background. The most popular modification today is filling these indentations with aftermarket lettering to create a high-contrast, custom look.

The market offers three primary materials for these inserts, each with distinct durability and visual characteristics:

- Vinyl Decals: The most affordable option. These are essentially thin stickers. While cheap ($20–$40), they are prone to peeling after a few years of car washes and UV exposure.

- ABS Plastic (3D Domed): A significant upgrade, these are rigid, thick letters often with a beveled edge. They offer a factory-like "badge" appearance and are usually durable enough for daily drivers.

- Stainless Steel: The premium choice for enthusiasts. Brands like Putco offer polished or black platinum stainless steel letters that are laser-cut to fit the specific curvature of the stamped area. These are virtually indestructible and offer the highest visual impact.

Installation Pro-Tip: The success of these kits relies entirely on surface preparation. The stamped recesses in your tailgate act as catch-basins for road grime and wax. Before peeling the adhesive backing, you must scrub the indentations with alcohol wipes (usually provided) until the cloth comes away white. Installing stamped components or accessories below 60°F (15°C) can prevent the 3M adhesive from bonding correctly, so use a heat gun or hair dryer to warm the metal if working in a cold garage.

DIY Fabrication: Custom Metal Stamping Projects

Beyond stickers and manufacturing, there is a niche of hot rod enthusiasts who want to physically alter the metal of their tailgate. This often involves "shaving" the tailgate (removing the handle and emblems for a smooth look) or welding in a "roll pan" to replace the rear bumper.

A common question in enthusiast circles, such as on the AACA forums, is whether a hobbyist can stamp their own custom logo into a tailgate. The reality is that true stamping requires tons of force and machined steel dies, which is cost-prohibitive for a one-off project. Some fabricators try to use MDF (wood) dies in a shop press, but this rarely produces the crisp definition needed for automotive sheet metal.

Instead of stamping, skilled fabricators use bead rolling or CNC engraving to create custom designs on a separate sheet of metal (a "skin"), which is then welded over the existing tailgate. This achieves the custom stamped look without the million-dollar tooling costs.

Comparison Guide: Stamped Lettering Materials

Choosing the right insert for your truck depends on your budget and how you use your vehicle. Use this matrix to decide:

| Feature | Vinyl Decals | ABS Plastic (Domed) | Stainless Steel |

|---|---|---|---|

| Price Range | $15 – $40 | $30 – $80 | $90 – $150+ |

| Visual Style | Flat, printed look | Raised 3D, matte or gloss | Premium metal shine/sheen |

| Durability | 3–5 years (fades/peels) | 5–10 years | Lifetime (corrosion resistant) |

| Installation Difficulty | High (prone to bubbles) | Low (rigid shape guides placement) | Medium (requires precise alignment) |

| Best Application | Budget builds / Temporary | OEM+ look for daily drivers | Show trucks / Heavy duty use |

Final Thoughts on Stamping & Style

Tailgate stamping bridges the gap between heavy industrial engineering and personal expression. Whether you are analyzing the deep-draw capabilities of a 600-ton press for a manufacturing contract or simply trying to decide between matte black and polished stainless letters for your Silverado, the core concept remains the same: precision forms function.

For the truck owner, the "stamped" look is more than just branding; it's a canvas for customization. By selecting the right grade of insert material and following proper installation protocols, you can transform a mass-produced body panel into a distinct statement that sets your vehicle apart on the road.

Frequently Asked Questions

1. What is stamping in cars?

Automotive stamping is a manufacturing process where sheet metal is fed into a press and shaped by a die. It is used to create the body panels of the car, such as doors, hoods, fenders, and tailgates. The process ensures that parts are identical, structurally sound, and have the smooth surfaces required for painting.

2. Can I stamp a custom logo into my existing tailgate?

Not directly. Stamping requires the metal to be formed while it is a flat sheet using massive pressure. Once a tailgate is built, you cannot "re-stamp" it without destroying the structure. Custom logos are usually achieved by welding in a pre-fabricated "skin" or using 3D adhesive emblems that sit on top of the surface.

3. What is a powered tailgate?

A powered tailgate (or power liftgate) is an electronic feature that allows the tailgate to open and close automatically via a key fob, button, or sensor. While unrelated to the stamping process itself, the stamped metal shell must be engineered with specific reinforcement points to mount the motors and hydraulic struts that operate the system.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —