Magnesium Stamping: The Frontier of Automotive Lightweighting

TL;DR

Magnesium stamping for automotive lightweighting is a specialized manufacturing process that utilizes warm forming technology (typically 200°C–300°C) to shape magnesium alloy sheets into structural components. Unlike traditional die casting, stamping wrought magnesium (primarily AZ31B) eliminates porosity and enables thinner wall sections, offering a 33% weight reduction over aluminum and up to 75% over steel. This process overcomes the metal's hexagonal close-packed (HCP) crystal structure, which causes brittleness at room temperature, making it a critical frontier for next-generation vehicle efficiency.

The Lightweighting Frontier: Why Stamp Magnesium?

In the relentless pursuit of automotive efficiency, engineers are constantly battling the "mass spiral." While aluminum has long been the standard for lightweighting, magnesium stamping represents the next logical step in material evolution. Magnesium is the lightest structural metal available, with a density of approximately 1.74 g/cm³, making it roughly 33% lighter than aluminum and 75% lighter than steel. For an electric vehicle (EV), where every kilogram saved translates directly to increased range, these margins are not just incremental—they are transformative.

Historically, magnesium in automotive applications has been synonymous with die casting—think instrument panel beams, steering wheel armatures, and transfer cases. However, die casting has inherent limitations: it requires thicker walls (typically minimum 2.0–2.5mm) to ensure molten flow, and the resulting parts often suffer from porosity that limits heat treatment options. Metal stamping changes this paradigm. By forming wrought magnesium sheet, engineers can achieve wall thicknesses as low as 1.0mm or less, further compounding the weight savings while benefiting from the superior mechanical properties of wrought material, such as higher ductility and fatigue strength.

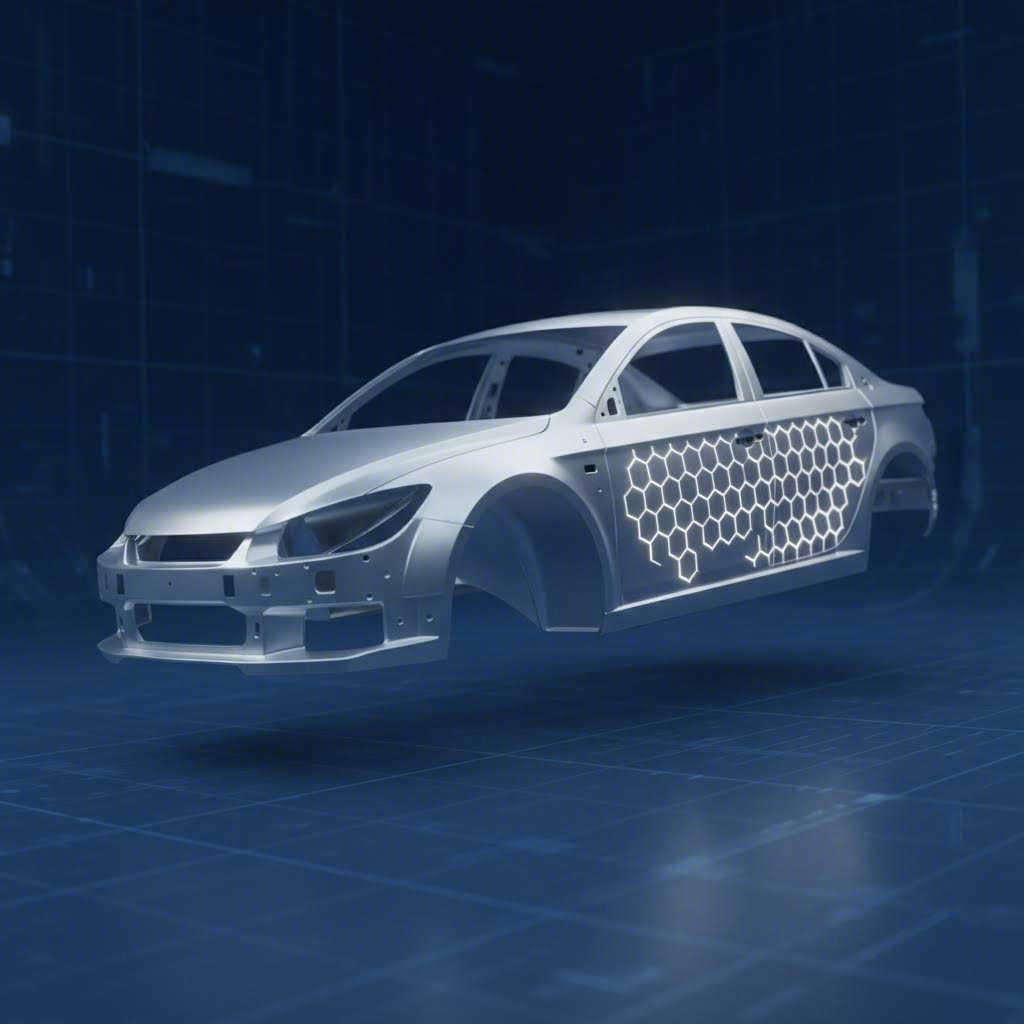

The application potential for stamped magnesium extends beyond simple brackets. Major automotive OEMs and research bodies have successfully validated the process for large-surface components like inner door panels, seat frames, and roof bows. These applications leverage magnesium's high specific stiffness and exceptional damping capacity—its ability to absorb vibration and noise (NVH) better than aluminum or steel—turning a structural necessity into a comfort feature.

The Technical Challenge: Room Temperature Formability

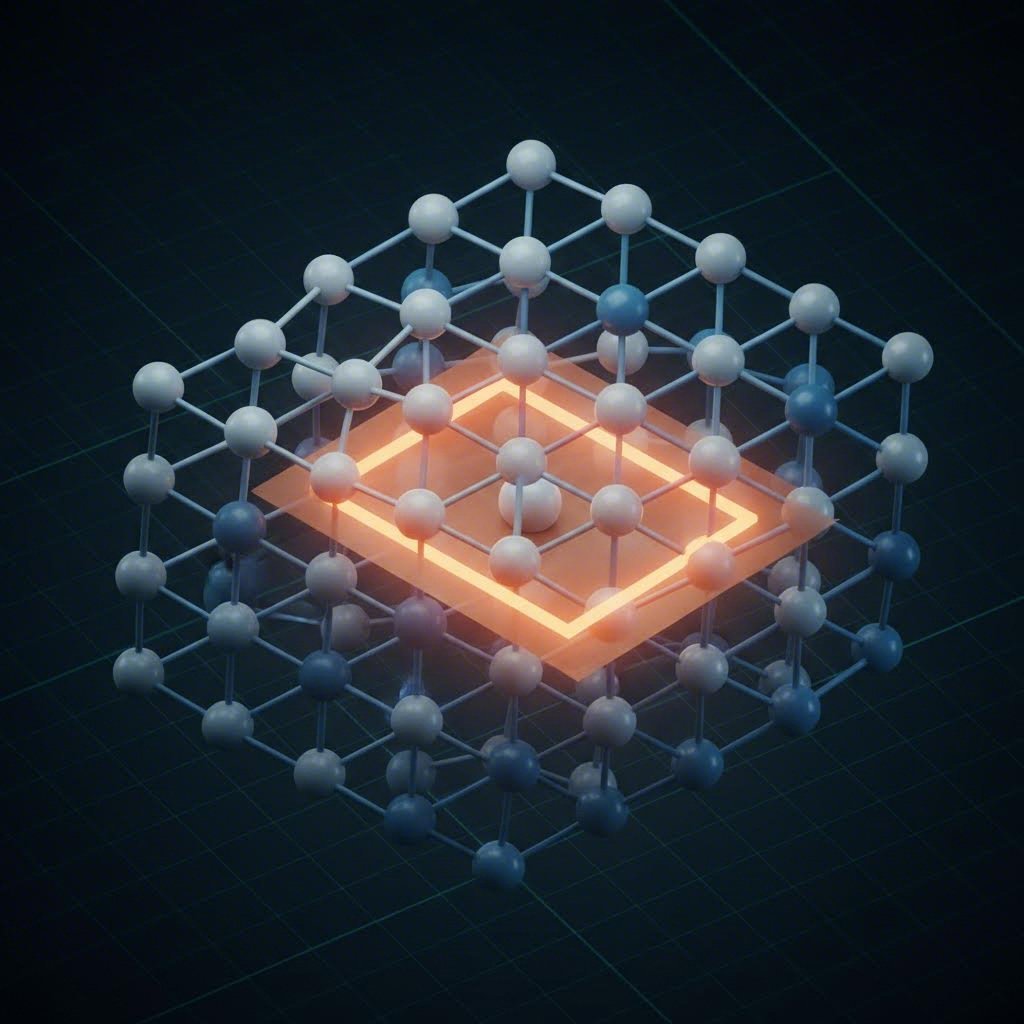

If stamped magnesium offers such compelling advantages, why isn't it the industry standard? The answer lies in its crystallography. Unlike steel or aluminum, which possess a Face-Centered Cubic (FCC) or Body-Centered Cubic (BCC) structure with many slip systems, magnesium has a Hexagonal Close-Packed (HCP) crystal structure. At room temperature, this structure is notoriously uncooperative.

Plastic deformation in metals occurs when crystal planes slide over one another, a mechanism known as "slip." At ambient temperatures (25°C), magnesium relies almost exclusively on the basal slip system, which provides only two independent slip modes. According to the von Mises criterion, a material needs at least five independent slip systems to undergo complex deformation without fracturing. Consequently, attempting to deep-draw or stamp complex magnesium parts cold results in immediate failure modes like severe cracking or splitting. The material simply cannot accommodate the strain.

This limitation creates a strong tension-compression asymmetry and anisotropy (directionality of properties). A magnesium sheet might stretch reasonably well in one direction but fail brittlely in another. To unlock the material's potential, engineers must activate additional slip systems—specifically the prismatic and pyramidal slip planes—which only become active when the material is energized by heat.

The Solution: Warm Forming Technology (200°C–300°C)

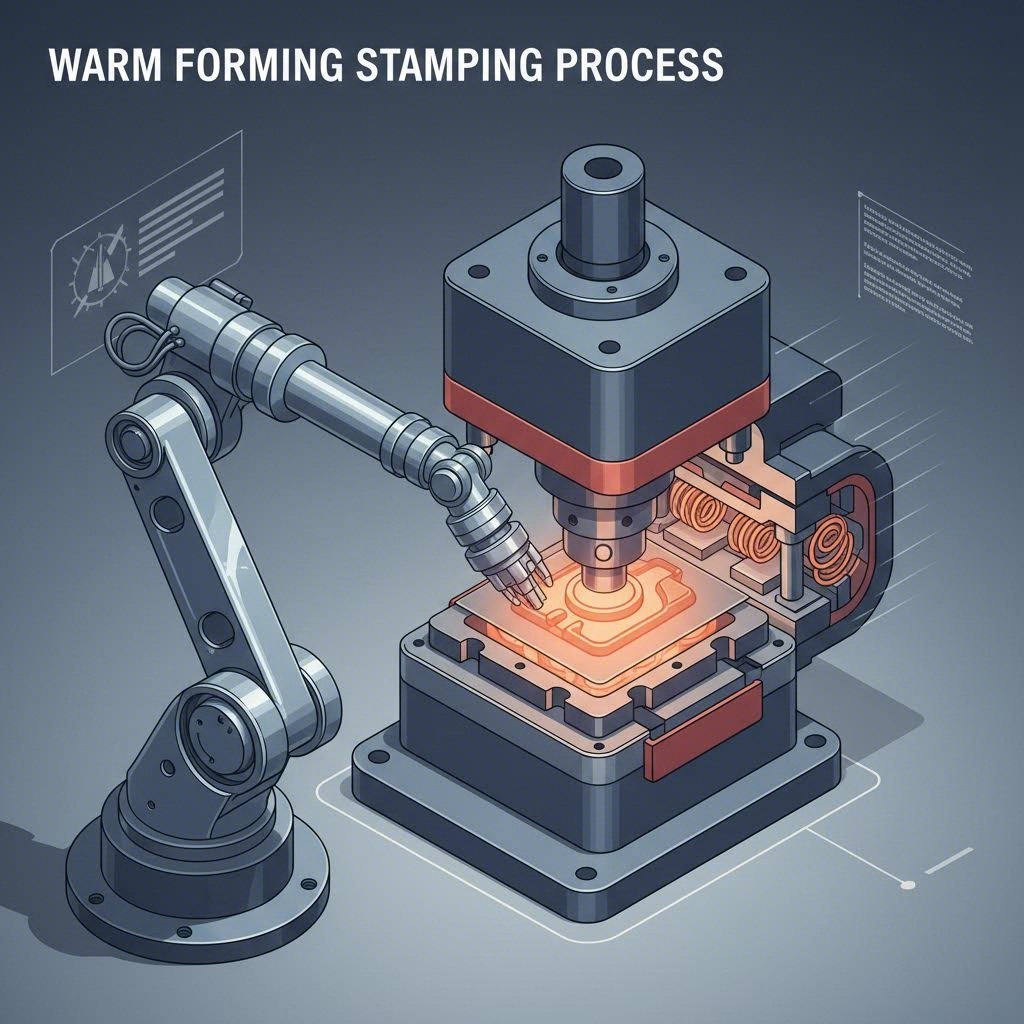

The breakthrough in magnesium stamping is warm forming. Research indicates that raising the temperature of the magnesium sheet to between 200°C and 300°C significantly increases the critical resolved shear stress (CRSS) needed for basal slip while simultaneously lowering the activation energy for non-basal slip systems. In this "sweet spot," the material transforms from brittle to ductile, allowing for complex geometries comparable to mild steel.

Implementing warm forming requires a fundamental shift in tooling strategy. Unlike cold stamping, where the tool absorbs heat generated by friction, warm forming requires the tool itself to be a heat source (or at least heat-managed). The process typically involves heating the blank and maintaining the die at a specific temperature. For AZ31B, the optimal window is often cited around 250°C. Go too cold, and the part cracks; go too hot (above 300°C), and the material suffers from thermal softening or grain coarsening, reducing the final part strength.

Lubrication is another critical variable. Standard oil-based stamping lubricants break down or smoke at these temperatures. specialized solid lubricants (like graphite or PTFE-based coatings) or high-temperature polymer films are required to prevent galling between the sheet and the die. While this adds complexity, the trade-off is high-volume feasibility. Cycle times have been reduced to mere seconds, making the process viable for mass production. Executing this at scale, however, requires specialized expertise. Partners like Shaoyi Metal Technology bridge this gap, offering precision stamping solutions that can navigate the transition from rapid prototypes to high-volume manufacturing while adhering to strict OEM quality standards.

Material Selection: Key Magnesium Sheet Alloys

Not all magnesium is created equal. The success of a stamping project often begins with alloy selection, balancing formability against cost and mechanical performance.

- AZ31B (Mg-3%Al-1%Zn): This is the workhorse of the magnesium sheet world. It is commercially available, moderately priced, and well-understood. While it has poor room-temperature formability (Limiting Dome Height of ~12mm), it responds excellently to warm forming at 250°C. It is the default choice for most structural automotive applications.

- ZEK100 (Mg-Zn-RE-Zr): This advanced alloy incorporates Rare Earth (RE) elements like neodymium. The addition of rare earths alters the crystallographic texture, randomizing the grain orientation. This "weakened texture" reduces anisotropy, allowing ZEK100 to be formed at lower temperatures (as low as 150°C) or with greater complexity than AZ31B. It is the premium choice for difficult geometries where AZ31B fails.

- E-Form Plus / Specialized Alloys: New proprietary alloys are constantly emerging, aiming to lower the forming temperature further to reduce energy costs and cycle times. These often focus on refining grain size to improve ductility through grain boundary sliding mechanisms.

Comparative Analysis: Stamping vs. Die Casting

For automotive engineers, the decision often comes down to a trade-off between the mature process of die casting and the performance benefits of stamping. The following comparison highlights why stamping is gaining ground for specific applications:

| Feature | Magnesium Stamping (Warm) | Magnesium Die Casting |

|---|---|---|

| Wall Thickness | Ultra-thin (< 1.0 mm possible) | Limited (Typically > 2.0 mm) |

| Material Properties | High ductility, no porosity, higher fatigue strength | Lower ductility, prone to porosity |

| Process Temp | Warm (200°C – 300°C sheet temp) | Molten (650°C+ injection temp) |

| Surface Finish | Class A surface possible (wrought sheet) | Requires significant finishing |

| Tooling Cost | Moderate (requires heating elements) | High (complex molds) |

| Primary Use Case | Large, thin panels (Roofs, Door Inners) | Complex, thick nodes (Housings, Brackets) |

Future Outlook

As global emission standards tighten and the EV race accelerates, the role of magnesium stamping automotive lightweighting technology will only expand. The industry is moving toward multi-material assemblies—joining stamped magnesium panels to aluminum or high-strength steel frames using advanced adhesives and self-piercing rivets (to prevent galvanic corrosion). While challenges in raw material cost and supply chain stability remain, the engineering case for warm-formed magnesium is undeniable: it offers the ultimate combination of lightness and strength for the vehicles of tomorrow.

Frequently Asked Questions

1. Why did they stop making magnesium wheels?

Magnesium wheels ("mags") fell out of favor for general consumer vehicles due to corrosion issues and high maintenance costs. Early magnesium alloys were highly susceptible to pitting and galvanic corrosion from road salts. Additionally, magnesium can be brittle and difficult to repair compared to aluminum. Modern forged magnesium wheels exist but are largely reserved for racing or ultra-luxury segments where performance outweighs cost.

2. Can magnesium alloy be stamped?

Yes, but typically not at room temperature. Standard magnesium alloys like AZ31B must be warm formed at temperatures between 200°C and 300°C. This heat activates additional slip systems in the crystal structure, allowing the metal to stretch and form without cracking. Some advanced alloys like ZEK100 offer better formability at lower temperatures.

3. What is the disadvantage of magnesium alloy?

The primary disadvantages are corrosion and cost. Magnesium is highly reactive and sits low on the galvanic series, meaning it corrodes rapidly if in contact with steel or moisture without proper coatings. It is also more expensive per kilogram than steel or aluminum. Furthermore, the hexagonal crystal structure makes it difficult to form cold, requiring energy-intensive warm forming processes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —