Aluminum vs Steel Stamping: Automotive Manufacturing Trade-offs

TL;DR

In the automotive sector, the choice between aluminum vs steel stamping represents a critical trade-off between vehicle performance and manufacturing complexity. Aluminum offers a 30% to 50% weight reduction that is vital for extending electric vehicle (EV) range and improving fuel economy, but it introduces significant production challenges, including 3x higher springback and increased material costs. Steel, particularly Advanced High-Strength Steel (AHSS), remains the cost-effective standard for structural integrity, offering superior formability and simpler magnetic handling in the press shop. Engineers must weigh aluminum's premium scrap value and corrosion resistance against steel's lower upfront tooling and processing costs.

Material Properties: The Weight-Strength Equation

The primary driver for shifting from steel to aluminum in automotive design is density. Aluminum is approximately one-third the density of steel, allowing for substantial mass reduction in the Body-in-White (BIW). According to data from TenRal, replacing steel components with aluminum can achieve weight savings of 30% to 50%, a metric that directly correlates to improved range for electric vehicles and better emissions compliance for internal combustion engines.

However, strength-to-weight ratios tell a more nuanced story. While mild steel is heavier, modern Advanced High-Strength Steels (AHSS) and press-hardened steels offer exceptional tensile strength, often exceeding 1,000 MPa. Aluminum alloys, particularly the 5000 and 6000 series used in panels, require careful alloying and heat treatment to approach the structural performance of steel. In crash scenarios, Engineering.com notes that aluminum folds predictably to absorb energy, whereas high-strength steel provides rigid intrusion resistance for safety cages.

| Property | Aluminum (Typical Auto Grades) | Steel (Typical Auto Grades) |

|---|---|---|

| Density | ~2.7 g/cm³ | ~7.85 g/cm³ |

| Young's Modulus | ~70 GPa (High flexibility) | ~210 GPa (High stiffness) |

| Corrosion | Naturally forms protective oxide | Rests easily; requires galvanization |

| Magnetism | Non-magnetic | Ferromagnetic |

Stamping Process: Formability and Springback

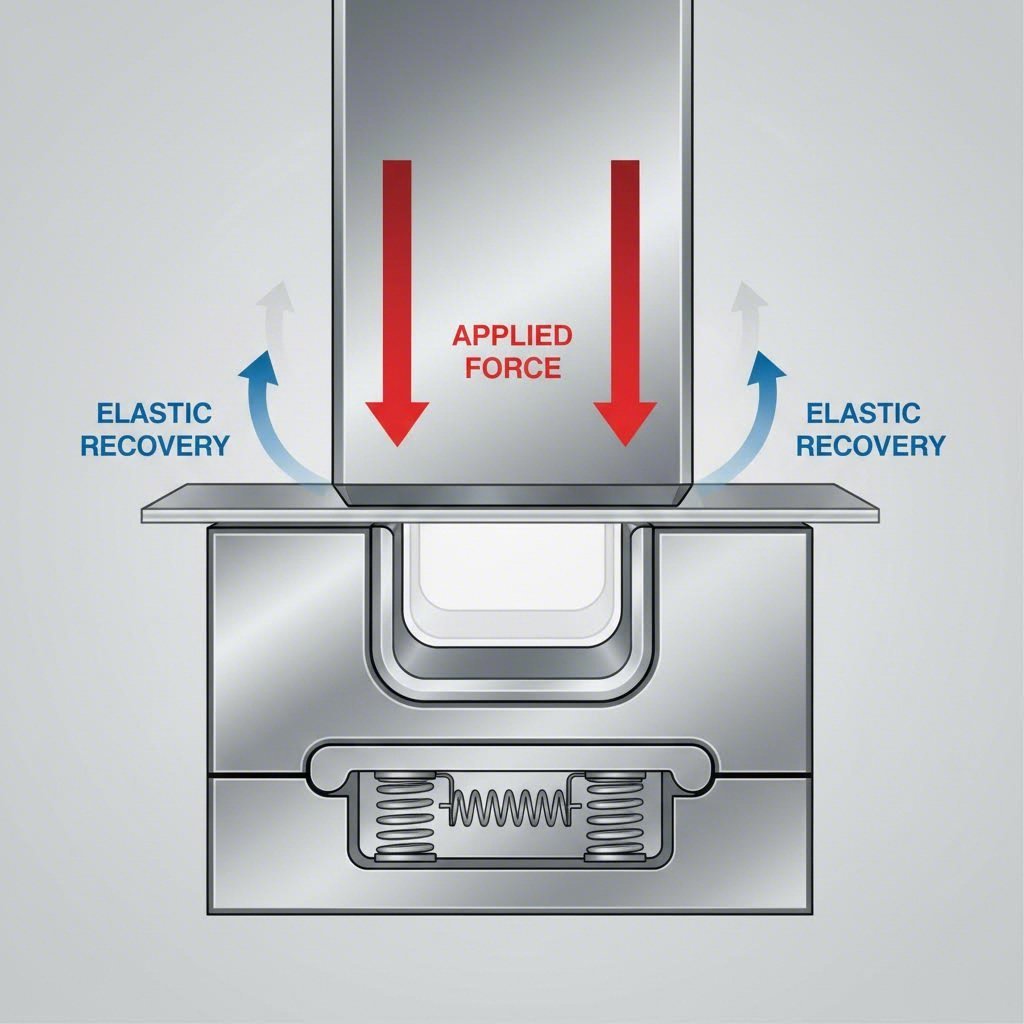

The behavior of these metals under the press is where the engineering challenges diverge most sharply. The most significant differentiator is springback—the tendency of the metal to return to its original shape after forming. Because aluminum has a Modulus of Elasticity (Young’s Modulus) roughly one-third that of steel, it exhibits approximately three times the springback.

This elasticity forces stamping engineers to over-bend parts or design complex restrike stations to achieve the final geometric tolerance. FormingWorld highlights that while steel's formability curves (FLD) allow for significant stretching and deep drawing, aluminum is prone to tearing if pushed beyond its lower ductility limits. Consequently, aluminum stamping often requires larger radii and more precise simulation analysis to predict failure points compared to the more forgiving nature of mild steel.

Temperature control also plays a pivotal role. While steel is frequently cold formed, complex aluminum parts often demand warm forming or specialized Hot Form Quench (HFQ) processes to improve ductility. As noted by MetalForming Magazine, hot stamping aluminum requires strict thermal management because its melting point is significantly lower than steel, narrowing the process window for achieving the desired mechanical properties.

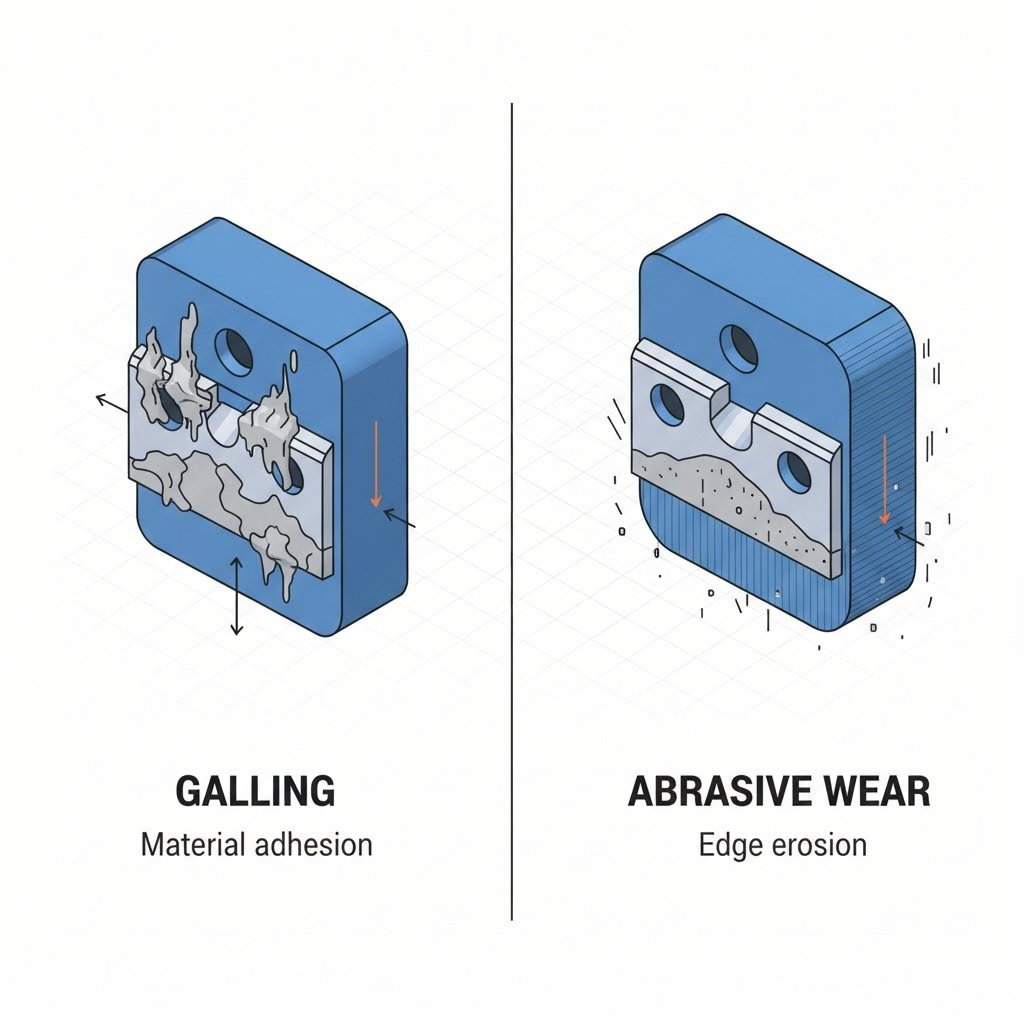

Tooling and Die Maintenance: Galling vs. Wear

The interaction between the sheet metal and the die surface dictates maintenance schedules and tool life. Steel, particularly high-strength variants, causes abrasive wear on tooling. The high contact pressures required to form AHSS can degrade die surfaces rapidly, necessitating the use of carbide inserts and frequent sharpening.

Conversely, aluminum presents a different failure mode: galling. Aluminum tends to adhere to the tool steel, leading to material pickup that scratches subsequent parts and compromises surface finish. Preventing this requires:

- Specialized Coatings: Diamond-Like Carbon (DLC) or Titanium Carbo-Nitride (TiCN) coatings on dies to reduce friction.

- Lubrication: Heavier, specialized lubricants that may require aggressive post-process washing.

- Maintenance: Frequent polishing of dies to remove aluminum buildup rather than just sharpening edges.

Material handling in the press shop also differs fundamentally. Steel's ferromagnetism allows for the use of magnetic conveyors, fanners, and overhead cranes. Aluminum is non-magnetic, requiring vacuum cups or mechanical grippers for automation, which can increase the complexity of the scrap removal and part transfer systems.

Cost Analysis: Raw Material vs. Lifecycle

The economic decision framework extends beyond the price per pound. Raw aluminum is consistently more expensive than steel, often by a factor of three or more depending on market volatility. However, the total lifecycle cost can narrow this gap.

- Scrap Value: Aluminum offal (scrap) commands a high market price. An efficient stamping operation that segregates scrap can recoup a significant portion of material costs, whereas steel scrap offers lower returns.

- Tooling Costs: While aluminum is softer, the need for precision dies to manage springback and the inability to use magnetic workholding can increase tooling investments.

- Operational Cost: For automakers, the premium for aluminum is often justified by the "lightweighting value"—the cost savings in batteries for EVs or the avoidance of gas-guzzler taxes for ICE vehicles.

For manufacturers navigating these cost structures, selecting a partner with versatility is key. Whether you require rapid prototypes to validate design geometry or high-volume production for global OEMs, Shaoyi Metal Technology provides comprehensive stamping solutions. Their IATF 16949-certified facilities utilize presses up to 600 tons to handle the distinct processing needs of both aluminum control arms and high-strength steel subframes, ensuring precision from 50 prototype parts to millions of mass-produced units.

Automotive Applications: Material Suitability

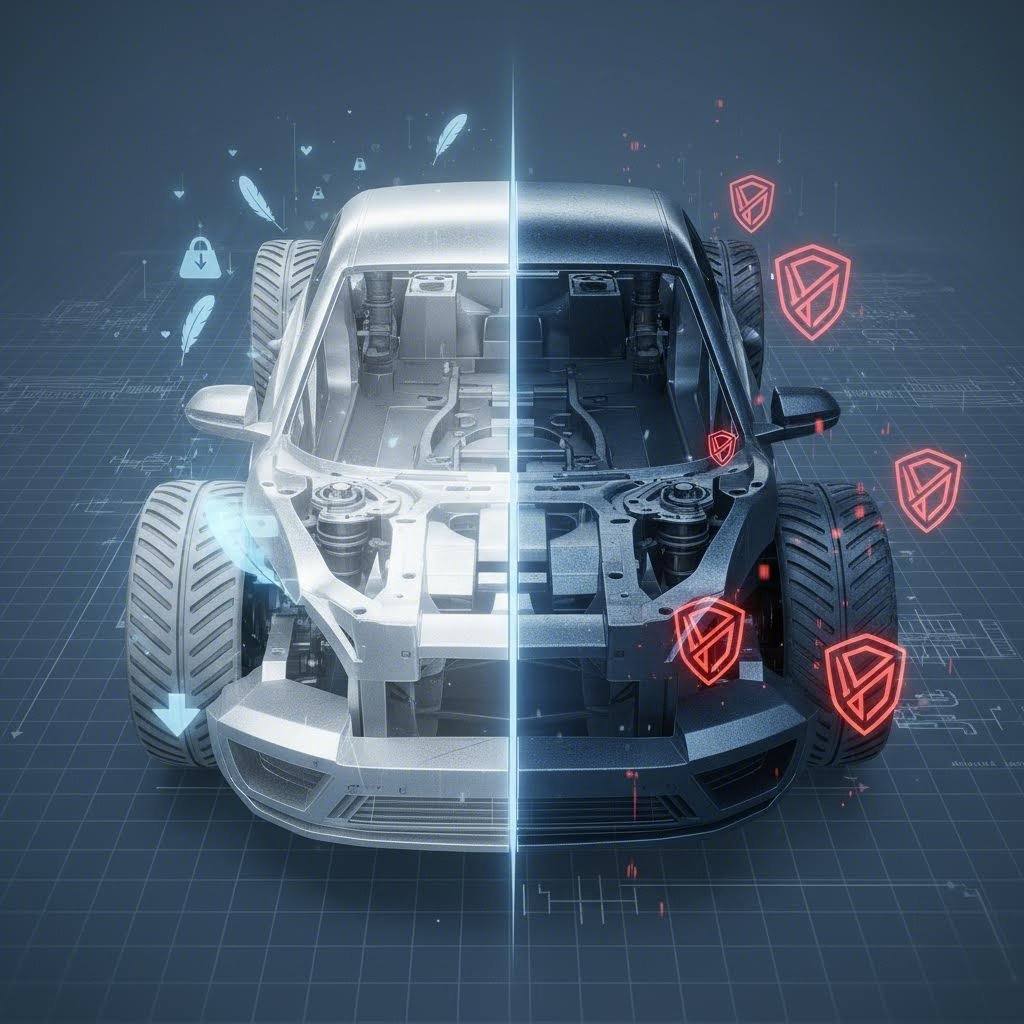

The industry has moved toward a "multi-material" vehicle architecture, placing the right metal in the right location. Kenmode suggests that aluminum is the ideal choice for "unsprung weight" components like wheels and suspension arms, as well as closure panels (hoods, doors, liftgates) where stiffness is less critical than weight.

Steel retains its dominance in the safety cage—the A-pillars, B-pillars, and rocker panels—where ultra-high-strength steel (UHSS) provides maximum intrusion protection in a thin profile. The challenge for modern assembly lines is joining these dissimilar materials. Welding aluminum to steel is metallurgically difficult due to the formation of brittle intermetallic compounds, leading manufacturers to adopt self-piercing rivets (SPR), structural adhesives, and flow-drill screws.

Conclusion: Balancing Performance and Manufacturability

The decision between aluminum and steel is rarely binary; it is a strategic calculation of weight targets versus budget constraints. Aluminum remains the premium choice for range-critical EV applications and exterior panels, despite its higher material cost and the technical hurdles of springback control. Steel continues to evolve, with new grades offering competitive strength-to-weight ratios that keep it relevant for structural manufacturing.

For automotive engineers, the path forward often involves hybrid designs that leverage the best properties of both metals. Success lies in anticipating the unique stamping behaviors of each—planning for aluminum's elasticity and managing steel's hardness—to deliver vehicles that are both lightweight and cost-effective.

Frequently Asked Questions

1. Is steel or aluminum better for car bodies?

Neither is universally "better"; it depends on the vehicle's goals. Aluminum is superior for performance and fuel efficiency due to its low weight, making it ideal for sports cars and EVs. Steel is better for cost reduction and impact resistance in critical structural areas. Most modern vehicles use a mix of both.

2. What are the main disadvantages of aluminum stamping?

The primary disadvantages are high material cost and difficult formability. Aluminum exhibits significant springback (elastic recovery), making it harder to hold tight geometric tolerances compared to steel. It is also prone to galling, which requires expensive die coatings and maintenance.

3. Why is aluminum harder to stamp than steel?

Aluminum has a lower formability limit and is more prone to tearing during deep draw processes. Its lower elastic modulus causes it to "spring back" more after the die releases, requiring complex over-bending strategies in the tool design to achieve the correct final shape.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —