5 Signs of Worn Control Arm Bushings You Can't Ignore

TL;DR

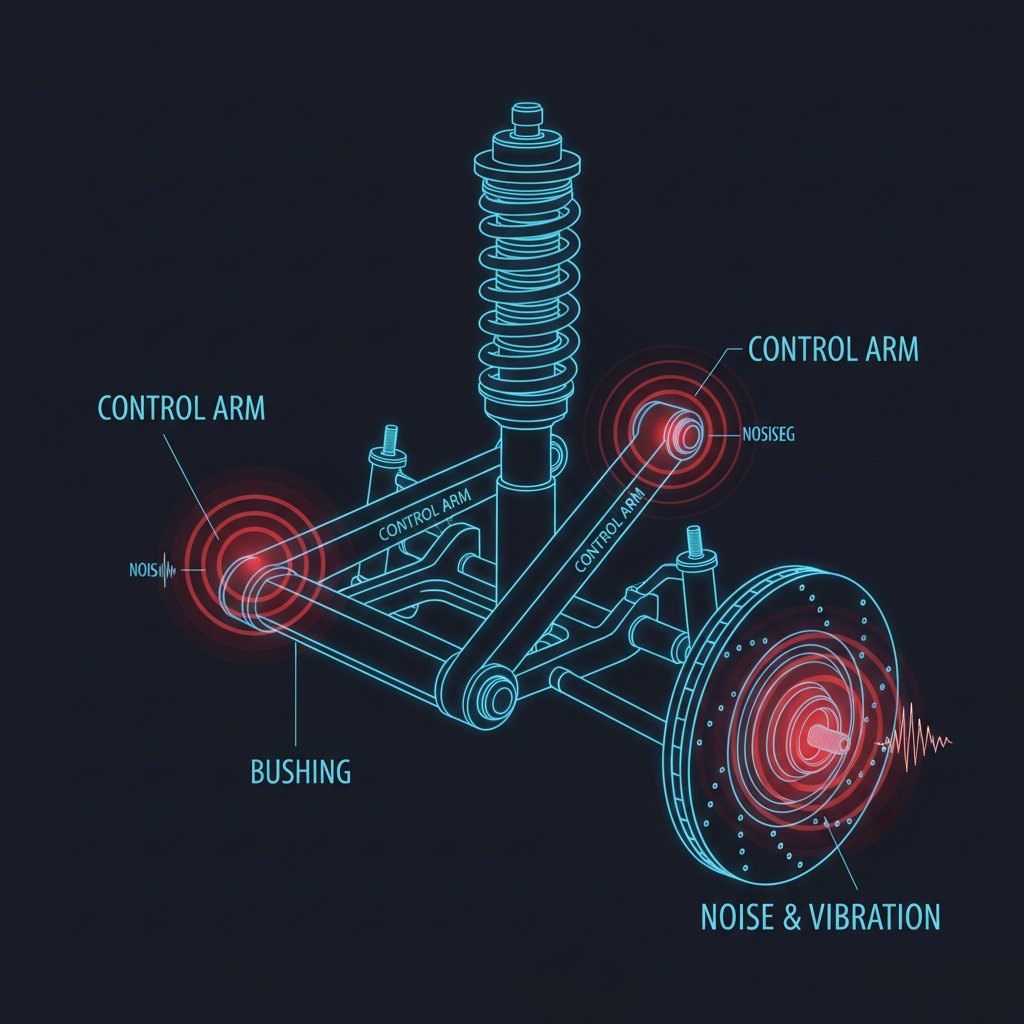

Worn stamped steel control arm bushings announce their presence with unmistakable warning signs. The most common symptoms include clunking or knocking noises when driving over bumps, persistent vibrations in the steering wheel at highway speeds, and a feeling of vague or 'loose' steering. You may also notice uneven tire wear, particularly on the inner or outer edges. These issues arise because the degraded bushings allow for excessive metal-on-metal movement in the suspension, compromising your vehicle's stability and safety.

The Top 5 Telltale Symptoms of Worn Control Arm Bushings

Control arm bushings are the quiet workhorses of your vehicle's suspension, absorbing road shock and allowing for controlled movement. When they wear out, the resulting symptoms are anything but quiet. Recognizing these signs early can prevent more extensive damage to your suspension and tires. Here are the five most common indicators that your control arm bushings require attention.

1. Clunking and Knocking Noises

What it is: A distinct, deep clunking or knocking sound that comes from the vehicle's front or rear wheels, especially when driving over speed bumps, potholes, or uneven road surfaces. This is often one of the first and most noticeable symptoms.

Why it happens: Control arm bushings are designed to cushion the connection between the control arm and the vehicle's frame. When the rubber or polymer material deteriorates, it creates a gap. This allows the metal control arm to slam against the frame or mounting bracket during suspension travel, producing a solid clunking sound. As noted in an article by NAPA Auto Parts, this noise is a clear signal that the joints are loose enough for components to collide.

2. Steering Wheel Vibration or Shimmy

What it is: A noticeable vibration or side-to-side shimmy felt through the steering wheel, which often becomes more intense at highway speeds (typically between 55-70 mph). The vibration may fluctuate with changes in speed.

Why it happens: Healthy bushings hold the wheel assembly in a precise alignment. When they wear, they can no longer effectively dampen road vibrations or maintain the correct alignment angle during high-speed rotation. This instability translates directly to the steering wheel. This symptom can feel very similar to a tire imbalance, which also causes vibrations at highway speeds.

3. Loose or Vague Steering

What it is: A sensation that the steering has become imprecise, floaty, or unresponsive. You might find yourself constantly making small corrections to keep the car driving in a straight line, and the vehicle may feel like it's wandering on the road.

Why it happens: The entire geometry of your vehicle changes as bushings age, placing additional stress on steering and suspension components. Worn bushings absorb some of the driver's steering input before it reaches the wheels, creating a delay or 'slop' in the steering response. This looseness compromises handling and can significantly reduce driver confidence and control.

4. Uneven and Premature Tire Wear

What it is: Accelerated wear on the inner or outer edges of your tires. You might observe a 'scalloping' or 'cupping' pattern, where the tread wears down in uneven patches.

Why it happens: Worn bushings allow for excessive and uncontrolled movement of the control arm, which directly affects the wheel's camber and toe angles. This constant, erratic shifting prevents the tire from maintaining consistent contact with the road, scrubbing the tread off unevenly. As experts from Mevotech explain, this unwanted tire camber is a direct result of degraded bushings placing extra load on the suspension system.

5. Rough Ride and Instability

What it is: A general degradation in ride quality. The suspension feels harsher, and the vehicle may feel less stable, especially when braking or cornering.

Why it happens: As a critical suspension component, the control arm's ability to manage wheel movement is compromised when its bushings fail. According to MOOG Parts, failing control arms lose their ability to reduce the impact of bumps, resulting in a rougher ride. The vehicle can no longer absorb road imperfections effectively, transmitting more jolts and harshness into the cabin.

Stamped Steel vs. Other Materials: Why It Matters

While the symptoms of worn bushings are similar across all control arm types, the material of the arm itself—especially stamped steel—has significant implications for the repair process. Control arms are typically made from one of three materials: stamped steel, cast iron, or cast aluminum, each with unique properties.

Stamped steel control arms are common due to their low manufacturing cost. They are formed by stamping and welding sheets of steel into the desired shape. However, their primary weakness is a high susceptibility to rust and corrosion, especially in regions that use road salt in the winter. This corrosion can weaken the arm and, more critically, can make replacing just the bushings nearly impossible as the rust effectively fuses the bushing sleeve to the arm.

The manufacturing process for these components is a crucial factor in their durability. For automotive manufacturers seeking reliable and precise metal components, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. provide specialized services in automotive stamping parts, ensuring components meet strict industry standards from prototyping to mass production. High-quality stamping is the first step in creating a durable control arm.

To help you understand the differences, here is a comparison of the common materials:

| Material | Pros | Cons | Common Failure Mode |

|---|---|---|---|

| Stamped Steel | Lightweight, inexpensive to produce | Prone to rust and corrosion, can bend under impact | Corrosion makes bushing replacement difficult or impossible |

| Cast Iron | Very strong and durable, resistant to bending | Heavy, more expensive to manufacture | Can crack under severe impact |

| Cast Aluminum | Lightweight, strong, and corrosion-resistant | Most expensive, can crack or break from sharp impacts | Cracking from impact (e.g., hitting a curb) |

You can often identify the material with a simple magnet test. A magnet will stick firmly to stamped steel and cast iron but will not stick to cast aluminum. This distinction is vital because while you might be able to press new bushings into a cast aluminum arm, a rusty stamped steel arm almost always requires a full assembly replacement for a safe and lasting repair.

Diagnosing the Problem: A Practical Inspection Guide

If you're experiencing the symptoms above, a physical inspection can help confirm if worn control arm bushings are the culprit. This guide is for diagnostic purposes only; always prioritize safety and consult a professional for repairs if you are not experienced. You will need a floor jack, jack stands, a flashlight, and a pry bar.

- Safely Lift and Secure the Vehicle: Park on a level surface and engage the parking brake. Use a floor jack to lift the front of the vehicle and securely place jack stands under the recommended lift points on the frame. Never work under a vehicle supported only by a jack.

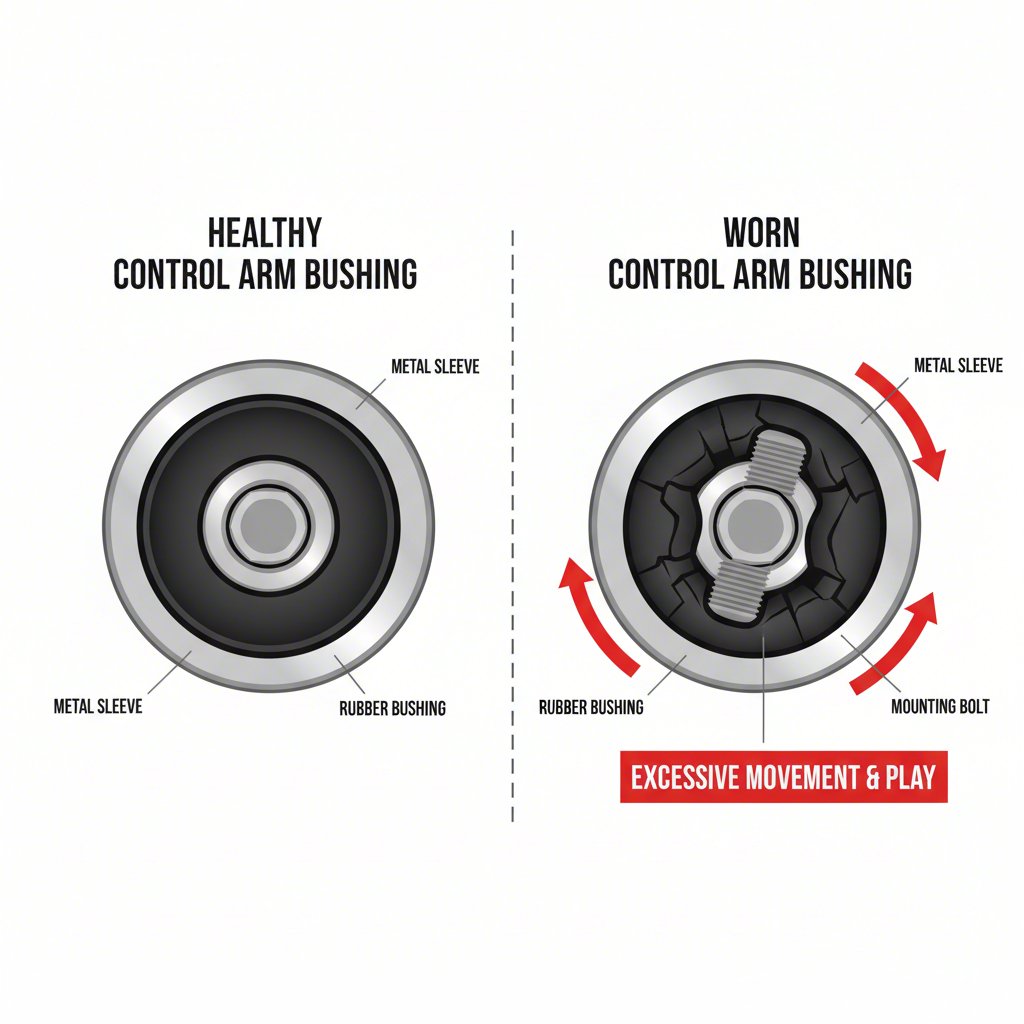

- Perform a Visual Inspection: With the wheel off the ground, use a flashlight to get a clear view of the control arm bushings where they connect to the frame and the subframe. Look for obvious signs of damage, such as deep cracks, dry rot, torn rubber, or fluid leaking from grease-filled bushings. According to a guide from Loosoo, you should also check if the bushing has separated from its metal sleeve.

- Check for Excessive Movement: Carefully place a pry bar between the control arm and its mounting bracket on the frame. Gently pry to see how much movement or 'play' there is in the bushing. A small amount of flex is normal, but more than a fraction of an inch of movement indicates the bushing is worn and needs replacement.

- Observe While Steering: For an additional test, have a friend sit in the driver's seat (with the engine off) and rock the steering wheel back and forth. While they do this, watch the control arm bushings closely. If you can see the arm shifting excessively within its mount, the bushings have failed.

Beyond the Bushing: Causes and Replacement Strategy

Control arm bushings don't fail without reason. The primary causes are simple wear and tear from millions of cycles of suspension movement, but failure can be accelerated by environmental factors and driving habits. Frequent impacts from hitting potholes or curbs, exposure to road salt that corrodes steel components, and contamination from oil or other fluids can all cause the bushing material to degrade prematurely.

When a replacement is necessary, you face a strategic choice: replace only the failed bushings or replace the entire control arm assembly, which includes new bushings and a new ball joint. For most modern vehicles, especially those with stamped steel control arms, replacing the entire assembly is the recommended approach. Pressing old bushings out and new ones in requires special tools and can be very labor-intensive. Furthermore, if the bushings have failed, the ball joint on the same arm is often nearing the end of its service life as well.

Replacing the complete control arm assembly is often more time-efficient and cost-effective in the long run. It ensures all related components are new, restoring the suspension's original geometry and performance. Crucially, it is best practice to replace control arms in pairs (both left and right sides) to maintain balanced handling and prevent one side of the suspension from behaving differently than the other. Finally, any time a control arm is replaced, a professional wheel alignment is essential to correct the camber, caster, and toe angles, ensuring even tire wear and proper vehicle tracking.

Frequently Asked Questions

1. How do you visually inspect control arm bushings?

To visually inspect control arm bushings, safely raise and support the vehicle on jack stands. Use a flashlight to examine the rubber or polymer part of the bushing where the control arm connects to the vehicle's frame. Look for visible cracks, signs of dry rot, tearing, or separation of the bushing from its metal sleeve. Some bushings are fluid-filled, so any sign of leakage is a clear indicator of failure.

2. How do I know if my control arms are stamped steel?

The easiest way to determine if your control arms are made of stamped steel is to use a magnet. If the magnet sticks firmly to the control arm, it is made of either stamped steel or cast iron. Stamped steel arms often look like they are made of two or more pieces of metal welded together, whereas cast iron arms are typically a single, solid piece. If the magnet does not stick at all, the control arm is made of cast aluminum.

3. What are common control arm bushing replacement issues?

A common issue during replacement is the difficulty of removing the old bushing, especially from a corroded stamped steel arm where rust may have seized it in place. This often makes replacing the entire control arm assembly a more practical solution. If you do replace only the bushing, another challenge is ensuring the new one is pressed in correctly and 'clocked' to the proper orientation, as some bushings are designed to flex in a specific direction.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —