Steel vs Aluminum Control Arms: Weight, Strength, and Cost

TL;DR

Choosing between stamped steel and aluminum control arms involves a trade-off between weight, strength, and cost. Aluminum control arms are significantly lighter (often 40-50% less) than steel, which reduces unsprung weight and can noticeably improve handling and suspension responsiveness. However, stamped steel offers superior strength and durability at a lower price point, making it a robust choice for heavy-duty applications and budget-conscious builders.

The Core Question: Weight Savings and Unsprung Mass

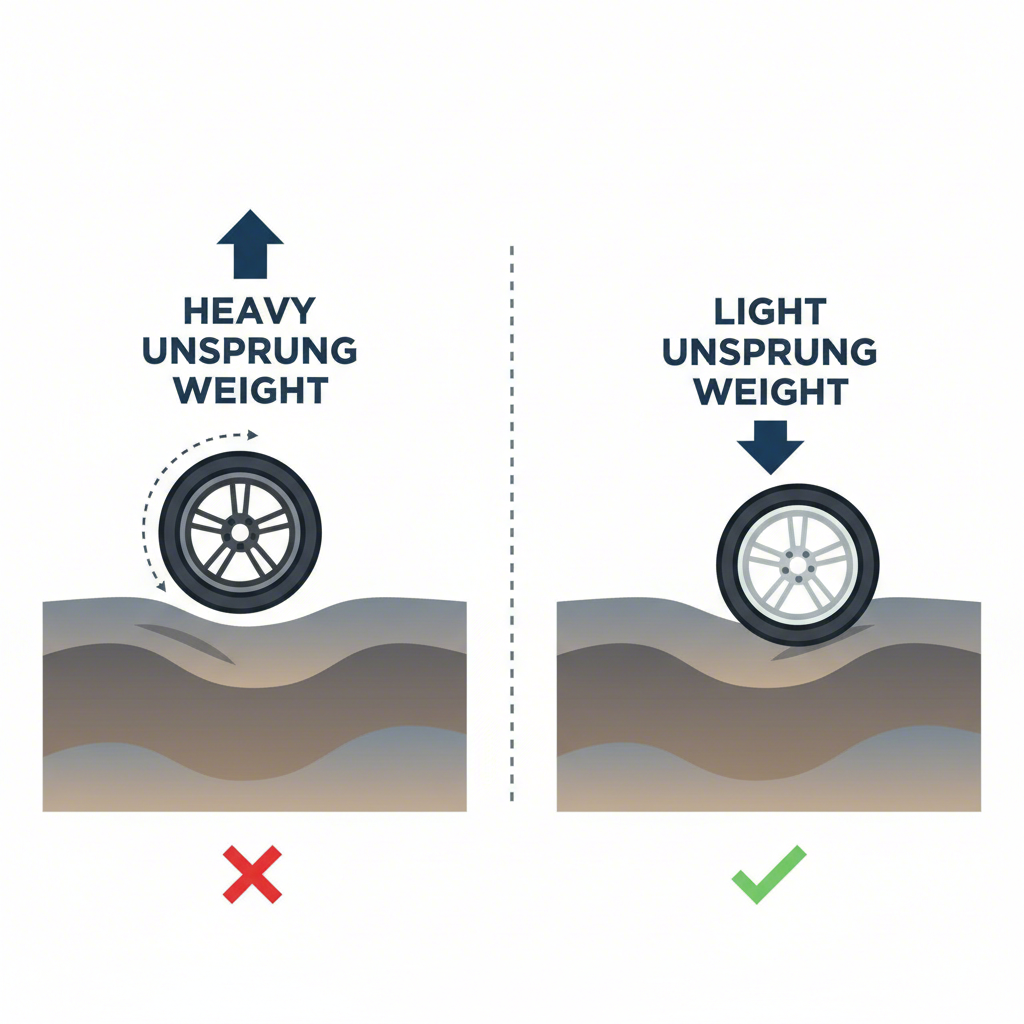

The primary driver behind the stamped steel versus aluminum control arm debate is weight. To understand why a few pounds matter so much, we need to talk about 'unsprung weight' or 'unsprung mass.' This term refers to the total weight of all components not supported by the vehicle's suspension system, including your wheels, tires, brakes, and the control arms themselves. The less unsprung weight you have, the better your suspension can perform.

Reducing unsprung weight allows the wheel and tire assembly to react more quickly to changes in the road surface. Instead of a heavy wheel crashing over a bump and unsettling the chassis, a lighter wheel assembly can track the contours of the pavement more effectively. This translates to improved traction, more responsive steering, and a smoother ride quality. As noted by industry experts, this is the main advantage of aluminum. According to Aldan American, aluminum control arms can weigh 40-50% less than their steel counterparts. This significant reduction can make a tangible difference in how a vehicle feels, especially during spirited driving.

While the percentage sounds dramatic, forum discussions among enthusiasts often point out that the real-world difference between a modern stamped steel control arm and an aluminum one might only be a few pounds per corner. This is a smaller gap than when comparing aluminum to older, heavier cast iron or cast steel parts. The decision then becomes a cost-benefit analysis: is the performance gain from shedding a few pounds of unsprung mass worth the typically higher cost of aluminum for your specific needs?

Strength, Durability, and Material Properties

Beyond weight, the inherent physical properties of steel and aluminum dictate where each material excels. It's a classic battle of brute force versus lightweight rigidity. Steel is universally recognized for its raw strength and durability. It can withstand heavy loads and significant impacts, making it the preferred material for heavy-duty trucks, off-road vehicles, and high-horsepower drag cars where components are under extreme stress. A key characteristic of steel is its ability to bend or deform under an impact that would cause a more brittle material to fail catastrophically. This forgiving nature can be a safety advantage in extreme situations.

Aluminum, particularly forged aluminum, offers a different kind of strength: rigidity. While it may not have the same ultimate tensile strength as steel, it is incredibly stiff for its weight. This rigidity prevents the control arm from flexing under cornering loads, which helps maintain precise suspension geometry and provides a more direct, responsive feel to the driver. However, this stiffness has a trade-off. As explained by suspension component specialists, an aluminum arm may resist bending up to a certain point, but an impact beyond its limit could cause it to crack or break rather than bend.

This fundamental difference creates clear use cases. If you prioritize durability for a heavy vehicle or frequent rough terrain, steel is often the more reliable choice. If your goal is to sharpen handling for a performance car used on the street or for autocross, the rigidity and weight savings of aluminum offer a distinct advantage. Your vehicle type and driving style should be the primary factors guiding your decision on this front.

Real-World Performance: Handling, Ride Quality, and Corrosion

Translating material science to the driver's seat, the choice between steel and aluminum has tangible effects on performance. The weight reduction from aluminum control arms directly enhances handling. With less mass to control, the suspension can keep the tires planted more consistently on uneven surfaces, leading to sharper turn-in and better grip when exiting corners. This is why aluminum is a popular upgrade for track-day cars and modern performance vehicles where every ounce of unsprung weight is scrutinized.

Another significant real-world factor is corrosion resistance. Steel, even when coated, is susceptible to rust, especially in regions with heavy rainfall, snow, and salted roads. Over time, rust can compromise the structural integrity of the component. Aluminum, by contrast, naturally forms a protective oxide layer that prevents corrosion. This makes it an excellent choice for daily drivers in harsh climates, ensuring a longer service life with less maintenance. For show cars, the clean, rust-free appearance of aluminum is also a major aesthetic plus.

Consider these practical scenarios. For a classic, heavy muscle car like a Chevelle built for drag racing, the immense stress of a hard launch makes durable steel control arms the logical choice. For a modern Mustang GT that sees track days, lightweight aluminum arms help the advanced suspension system perform at its peak. And for a daily-driven Dodge Challenger in a snowy climate, aluminum's corrosion resistance is a huge long-term benefit, preventing future rust-related failures.

Beyond Material: Stamped vs. Cast vs. Forged Explained

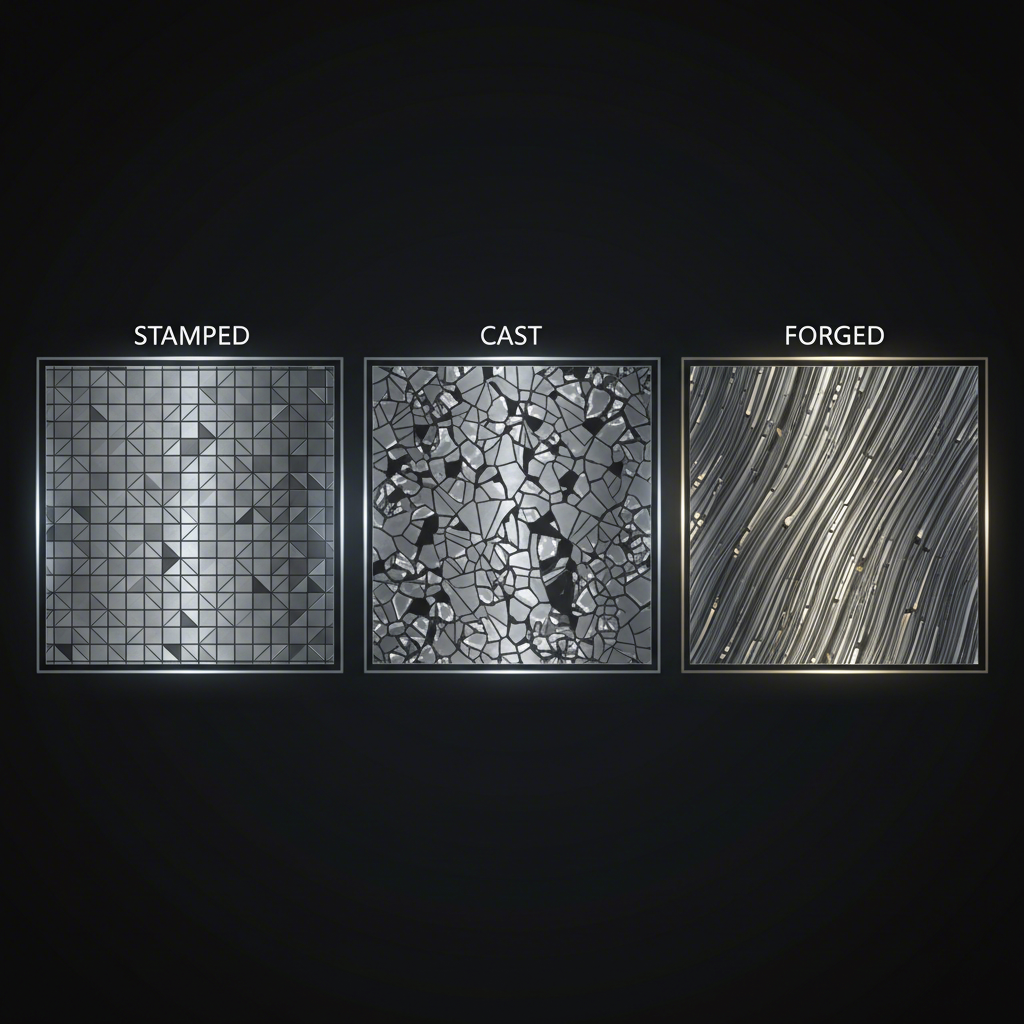

Simply choosing between "steel" and "aluminum" is an oversimplification. The manufacturing process plays a vital role in a control arm's performance and cost. Understanding the difference between stamped, cast, and forged components is key to making a truly informed decision. This distinction is so important that vehicle manufacturers may use different types on the same model, as detailed in a guide on Silverado control arms.

The three primary types you'll encounter are:

- Stamped Steel: These are formed by pressing and welding sheets of steel into the desired shape. This method is highly cost-effective and produces a component that is relatively lightweight for steel. You can often identify them by their smooth, painted finish and visible welded seams.

- Cast Steel/Aluminum: This process involves pouring molten metal into a mold. Cast parts can be complex in shape but are often heavier and can be more brittle than forged parts due to the grain structure of the cooled metal. They typically have a rougher, textured surface.

- Forged Aluminum: This is the premium manufacturing process. A solid piece of aluminum is heated and then pressed into shape under extreme pressure. This aligns the metal's grain structure, resulting in a component that is exceptionally strong, rigid, and lightweight.

The quality of a stamped steel part is heavily dependent on the precision of the manufacturing process. For automotive manufacturers, achieving this precision at scale is critical. Companies specializing in high-volume metal stamping provide the engineering expertise needed to produce these complex components reliably. For those seeking comprehensive solutions from prototyping to mass production, Shaoyi (Ningbo) Metal Technology Co., Ltd. offers advanced automated facilities and IATF 16949 certification, ensuring high-quality and cost-effective results for parts like stamped steel control arms.

| Manufacturing Process | Relative Strength | Relative Weight | Typical Cost |

|---|---|---|---|

| Stamped Steel | Good | Moderate | Low |

| Cast Steel/Aluminum | Good to Fair | Moderate to High | Moderate |

| Forged Aluminum | Excellent | Low | High |

This context is crucial. A high-quality stamped steel arm may offer better overall performance and reliability than a cheaply made cast aluminum part. Always consider the manufacturing method in addition to the base material when evaluating an upgrade.

Making the Right Choice for Your Vehicle

Ultimately, there is no single "best" material for control arms; there is only the best material for your specific application. The decision between stamped steel and aluminum hinges on a clear understanding of your priorities. If your primary goals are maximizing handling performance, sharpening steering response, and reducing unsprung weight for a street performance or track car, aluminum is a superior choice. Its corrosion resistance is also a compelling benefit for daily drivers in harsh climates.

On the other hand, if you value strength, maximum durability, and affordability above all else, stamped steel remains an excellent option. For heavy vehicles, work trucks, off-road applications, or budget-focused builds, the robustness and lower cost of steel provide a dependable and practical solution. By evaluating your vehicle, your driving style, and your budget, you can confidently select the control arm that delivers the performance and reliability you need.

Frequently Asked Questions

1. What is the weight ratio of aluminium to steel?

Steel is significantly denser than aluminum. Steel's density is approximately 7.85 grams per cubic centimeter (g/cm³), while aluminum's is only about 2.7 g/cm³. This makes steel nearly three times heavier than aluminum by volume, which is why aluminum components can offer such substantial weight savings in automotive applications.

2. What is the best material for control arms?

The best material depends entirely on your needs. For performance-oriented vehicles where handling and responsiveness are top priorities, or for cars in wet/salty climates, aluminum is often considered ideal due to its light weight and corrosion resistance. For heavy-duty applications, off-roading, or when cost is the primary concern, steel is the better choice for its superior strength and lower price point.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —