Stamped Steel Control Arms: The Essential Upgrade for Lifted Trucks

TL;DR

For lifted trucks, particularly 2007-2018 GM models like the Silverado and Sierra, factory stamped steel upper control arms are a significant weak point. Lifting your truck alters the suspension geometry, and these stock arms cannot correct the ball joint angle, leading to poor alignment, premature tire wear, and a high risk of ball joint failure. Upgrading to aftermarket upper control arms is essential to restore proper camber and caster, ensure safety, and protect your investment.

Why Lifted Trucks Need Aftermarket Control Arms

Upper control arms (UCAs) are a critical component of your truck's independent front suspension, connecting the top of the steering knuckle to the vehicle's frame. Their primary job is to guide the vertical movement of the wheels while maintaining proper alignment. When a truck is at its factory ride height, the original UCAs are engineered to keep the alignment angles—specifically camber and caster—within the manufacturer's specifications.

However, installing a leveling or lift kit of two inches or more dramatically changes this dynamic. The lift pushes the suspension downward, forcing the factory UCA into a severe angle. This extreme angle puts the upper ball joint in a bind at the edge of its articulation range. On many GM trucks, the factory stamped steel control arms are particularly vulnerable. Their design, which sandwiches the ball joint between two pieces of stamped metal without a retaining clip, creates a high-risk failure point. Under the increased stress, the ball joint can separate from the arm entirely.

The consequences of ignoring this issue are both costly and dangerous. An incorrect ball joint angle prevents a proper alignment, leading to a cascade of problems that negatively impact your vehicle's handling and safety. The most common effects include:

- Premature and Uneven Tire Wear: Improper camber causes tires to wear excessively on the inner or outer edges, drastically shortening their lifespan.

- Poor Handling: Incorrect caster angles can lead to wandering steering, instability at high speeds, and a poor return-to-center feel after a turn.

- Increased Stress on Components: The constant bind on the ball joint accelerates wear and can strain other suspension and steering parts.

- Catastrophic Failure: In the worst-case scenario, the ball joint can completely separate from the control arm, leading to a total loss of steering control on that wheel.

For any truck lifted two inches or more, especially those with factory stamped steel UCAs, upgrading to a set of aftermarket control arms is not just a recommendation—it's a necessary step to maintain proper suspension geometry, drivability, and safety.

Stamped Steel vs. Cast Steel vs. Aluminum: A Detailed Comparison

General Motors equipped trucks like the Silverado and Sierra with three different types of factory upper control arms: stamped steel, cast steel (or forged steel), and cast aluminum. Understanding the differences is crucial, as the material and construction directly impact their performance on a lifted vehicle. Identifying which type your truck has is the first step in determining the urgency of an upgrade.

Stamped steel arms are formed by pressing sheets of steel into shape and welding them together. This manufacturing process is cost-effective but results in the weakest of the three designs. As noted by suspension experts, the key flaw in many GM stamped steel arms is the ball joint's press-fit design, which lacks a retention clip for security. For automotive manufacturers, producing such components requires immense precision, with specialized suppliers like Shaoyi (Ningbo) Metal Technology Co., Ltd. providing the advanced metal stamping capabilities needed to meet strict industry standards. In contrast, cast steel and cast aluminum arms are made from molten metal poured into a mold, creating a stronger, single-piece design that typically includes a retaining clip for the ball joint.

A simple way to tell them apart is the magnet test. As explained by several manufacturers, a magnet will stick firmly to both stamped steel and cast steel arms, but it will not stick to aluminum arms. To differentiate between the two steel types, look at the construction: stamped steel arms often have visible welded seams and a more hollow, rounded appearance, while cast steel arms are solid, bulkier, and have a rougher surface texture.

To help you identify your factory arms and understand their limitations, here is a detailed comparison:

| Material | Construction | Strength/Weakness for Lifting | How to Identify |

|---|---|---|---|

| Stamped Steel | Two pieces of steel pressed and welded together. | Weakest design; high risk of ball joint failure when lifted due to poor angle and lack of a retaining clip. | Black finish, visible seams, magnet sticks. |

| Cast/Forged Steel | Molded from a single piece of steel. | Very strong and durable. Ball joint typically has a retaining clip for safety. | Black finish, solid/bulky appearance, magnet sticks. |

| Cast Aluminum | Molded from a single piece of aluminum. | Strong and lightweight. Ball joint typically has a retaining clip for safety. | Natural silver/gray finish, magnet will NOT stick. |

While all lifted trucks benefit from aftermarket UCAs, vehicles with factory stamped steel arms are the most critical candidates for an upgrade. Their inherent design weakness is dangerously amplified by the altered suspension angles of a lift kit.

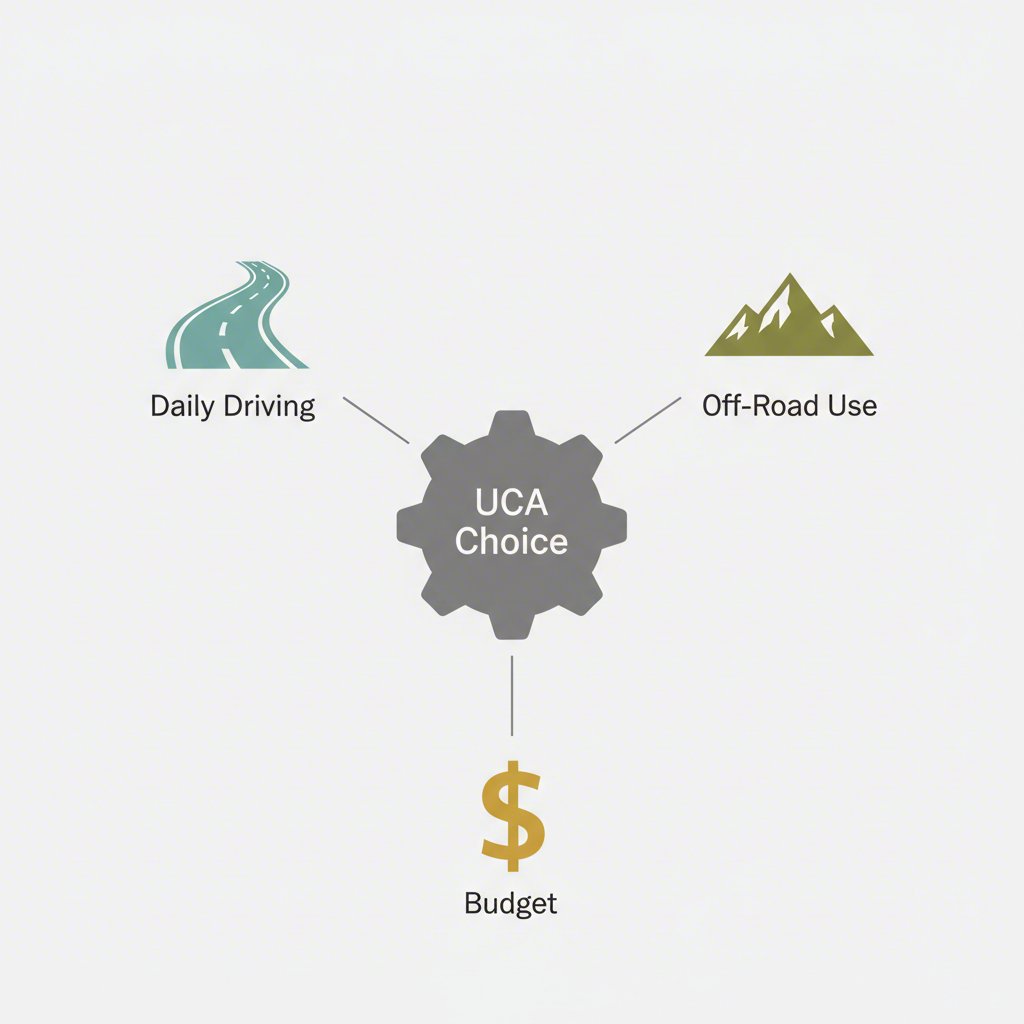

Buyer's Guide: How to Choose the Right Aftermarket UCAs

Once you've identified the need for an upgrade, the next step is selecting the right aftermarket upper control arms. The market offers a wide variety of options, each with different materials, designs, and features tailored to specific needs. The primary benefits of any quality aftermarket UCA are corrected suspension geometry for proper alignment, increased strength, and improved suspension travel without ball joint binding.

When comparing options, you will encounter several key design differences. As detailed by retailers like Jack-It, the main features to consider are construction material, bushing type, and joint type. Tubular steel is the most common construction, offering a great balance of strength and cost. Forged aluminum and boxed steel arms provide even greater durability for heavy-duty or extreme off-road use.

The bushings and joints are where performance and ride quality are fine-tuned. Rubber bushings offer a quiet, comfortable ride similar to stock, while polyurethane bushings provide a firmer response but may require occasional greasing to prevent squeaking. The connection to the knuckle is handled by either a heavy-duty ball joint or a uni-ball. A traditional ball joint is sealed and maintenance-free, making it ideal for daily drivers. A uni-ball offers a greater range of motion for maximum suspension articulation, which is preferred for serious off-roading, but it is typically unsealed and may require more frequent maintenance.

To make an informed decision, consider the following checklist:

- What is my lift height? Ensure the control arms are engineered for your specific lift range (e.g., 2-4 inches or 6+ inches).

- What is my primary use? For daily driving and light trails, a tubular arm with a heavy-duty ball joint and rubber bushings is an excellent choice. For aggressive off-roading, a boxed or forged arm with a uni-ball will provide the necessary strength and articulation.

- What is my budget? Prices vary based on material and features. While budget-friendly options exist, investing in a reputable brand like Kryptonite or Reklez known for quality components ensures long-term reliability.

- Do I need adjustability? Most aftermarket arms have fixed geometry correction built-in. Adjustable arms offer the ability to fine-tune camber and caster, which is useful for custom applications but often unnecessary for standard lift kits.

By answering these questions, you can narrow down the options and select a set of upper control arms that perfectly matches your truck's setup and your performance needs, ensuring a safe and reliable ride.

Fitment and Compatibility for Lifted Trucks

Selecting the right aftermarket upper control arms goes beyond just choosing materials and joint types; ensuring proper fitment for your specific vehicle and lift kit is absolutely critical. Not all UCAs are compatible with all trucks, and a mismatch can lead to installation problems, poor performance, and unresolved alignment issues. The most important factor is matching the control arm's designed geometry correction to your truck's lift height.

Aftermarket UCAs are engineered with specific caster and camber corrections built-in to compensate for a certain amount of lift. For example, a set of arms from SuperPro might be designed for a 2-3 inch lift, while arms from Reklez may be suitable for a wider range, from a 3-inch leveling kit up to a 10-inch lift. Using arms designed for a 6-inch lift on a truck with a 2-inch leveling kit will result in incorrect alignment angles, and vice versa. Always check the manufacturer's recommended lift range before purchasing.

Another key compatibility point, especially on 2014-2018 GM 1500 trucks, is the factory steering knuckle material. GM used both steel and aluminum knuckles, which have different sized tapers for the upper ball joint. Aftermarket control arms are sold with ball joints that match a specific knuckle type. You must verify whether your truck has the original stamped steel/aluminum arms (which pair with one knuckle type) or the cast steel arms (which pair with another) to order the correct replacement.

Finally, consider the choice between fixed and adjustable control arms. Fixed arms are the most common and are a simple, bolt-on solution with pre-set alignment correction. This is sufficient for the vast majority of lifted trucks. Adjustable arms allow a technician to fine-tune the alignment angles, which can be beneficial for trucks with custom lift heights or for dialing in perfect handling characteristics. However, they add complexity and cost to the installation and alignment process.

Critical Final Steps: Before finalizing your purchase, double-check your truck's model year, 2WD/4WD configuration, original control arm type (stamped, cast, or aluminum), and the exact height of your lift kit. After installation, a professional wheel alignment is not optional—it is mandatory to lock in the corrected geometry and ensure your truck drives safely and your tires wear evenly.

Your Suspension's Strongest Link

For owners of lifted trucks, particularly those that came from the factory with stamped steel control arms, upgrading the UCAs is one of the most important modifications you can make. It's a foundational change that moves beyond aesthetics and directly addresses the mechanical realities of altered suspension geometry. By correcting the ball joint angle, you restore the vehicle's ability to be properly aligned, which is the cornerstone of safe handling and predictable steering.

This upgrade is about more than just preventing tire wear; it's about reinforcing a known weak point in the factory suspension system. A quality set of aftermarket control arms provides the strength and articulation needed to handle the increased demands of larger tires and a higher center of gravity. It transforms a critical point of failure into a pillar of strength, giving you the confidence to use your lifted truck as intended, whether on the highway or off the beaten path.

Frequently Asked Questions

1. Do lifted trucks need different control arms?

Yes, in most cases. When a truck is lifted 2 inches or more, the factory upper control arms are forced into an extreme angle that puts the ball joint in a bind. This prevents proper wheel alignment, leading to rapid tire wear and poor handling. Aftermarket control arms are designed with corrected angles to solve this problem, restore proper geometry, and provide greater strength.

2. How do I know if my truck has stamped steel control arms?

The easiest method is the magnet test. Place a magnet on the upper control arm; if it sticks, the arm is either stamped steel or cast steel. If it does not stick, it's aluminum. To tell the difference between the steel types, look for construction details. Stamped steel arms are typically made of two pieces of metal welded together and may have visible seams, while cast steel arms are a single, solid piece with a rougher texture.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —