Structural Die Casting: The Future of Body-in-White Production

TL;DR

Structural die casting, particularly through a process known as mega casting, is transforming automotive manufacturing by allowing large, complex sections of a vehicle's Body-in-White (BIW) to be made as a single piece. This innovation drastically reduces part counts, which simplifies assembly lines, lowers production costs, and enhances the vehicle's structural rigidity. By consolidating numerous smaller components, automakers can build lighter, stronger, and more sustainable vehicles faster than ever before.

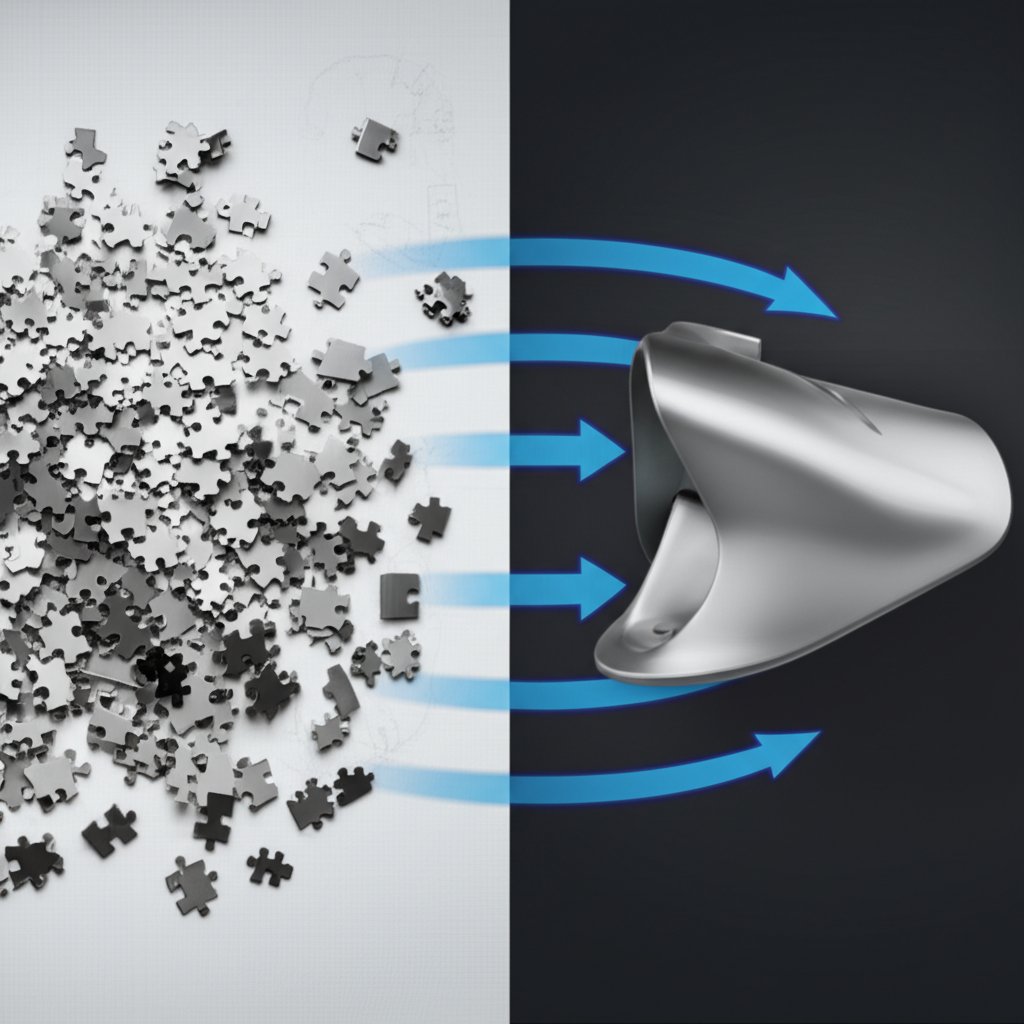

The Paradigm Shift in Automotive Manufacturing: From Stamped Assemblies to Mega Castings

For decades, the foundation of a vehicle, its Body-in-White (BIW), was an intricate puzzle assembled from hundreds of individual stamped metal parts. The BIW is the core structure of a car before moving parts like doors, the engine, or trim are added. This traditional method involves complex supply chains, extensive robotic assembly lines, and significant investments in tooling for each small component. However, the industry is undergoing a fundamental shift, moving away from this piecemeal approach toward a consolidated and far more efficient method: structural die casting, often referred to as mega casting or giga casting.

This transformative process replaces a multitude of stamped parts with a single, large, and complex aluminum casting. The strategic advantage of this approach is profound. Automakers can eliminate entire stages of logistics, welding, and assembly, leading to a leaner manufacturing footprint. A prime example of this evolution is Volvo Cars' strategic transition to mega casting for its future vehicle designs. As detailed in a case study by ESI Group, Volvo successfully replaced a rear body frame composed of approximately 100 individual parts with a single mega-cast component. To achieve this, the company installed massive 8400-ton die casting machines, often called Giga Presses, directly within its assembly facilities to streamline production.

This is not an isolated trend. Other leading automakers have embraced this technology for critical structural components. For instance, the Audi A8 Space Frame utilizes a large die-cast rear side member, a crucial connecting piece that provides strength and rigidity. According to GF Casting Solutions, this single part replaces an abundance of components that would otherwise form a complex assembly, reducing both vehicle weight and assembly time. The move to mega casting represents a clear paradigm shift, driven by the pursuit of efficiency, performance, and sustainability in modern vehicle production.

The differences between these two manufacturing philosophies are stark. While traditional stamping offers flexibility for minor design changes, its complexity at scale creates significant challenges in cost, time, and quality control. Mega casting, conversely, demands a higher upfront investment in tooling and design but delivers exponential savings and performance gains in mass production. The table below illustrates the key distinctions.

| Factor | Traditional Stamped Assembly | Structural Die Casting (Mega Casting) |

|---|---|---|

| Part Count | High (often hundreds of parts per section) | Extremely Low (as few as one part) |

| Assembly Process | Complex, multi-stage welding and bonding | Simplified, minimal assembly required |

| Tooling Costs | High cumulative cost for numerous small dies | Very high cost for a single large die, but fewer dies overall |

| Production Speed | Slower due to complex assembly logistics | Faster cycle times in the body shop |

| Structural Integrity | Reliant on the quality of numerous joints | Inherently high rigidity and consistency |

| Flexibility | Easier to modify individual small parts | Less flexible; design changes require new, expensive tooling |

| Factory Footprint | Large, requiring extensive space for robotics | Smaller footprint, with up to 30% space savings |

Core Technologies and Processes in Modern Structural Casting

Achieving the scale and precision required for mega casting relies on a suite of advanced technologies, from colossal machinery to specialized material science. The process is far more sophisticated than traditional casting, demanding immense pressure, vacuum conditions, and meticulous process control to create large components that meet stringent automotive safety and performance standards. These innovations are what enable automakers to cast entire vehicle underbodies in a single shot.

At the heart of this technology are large die-casting machines and specific casting processes. Companies like Bühler have developed solutions like the Carat series, which can generate locking forces of 84,000 kilonewtons (kN) and more. This immense force is necessary to hold the massive dies together as molten aluminum is injected under high pressure, ensuring dimensional accuracy across very large parts. Furthermore, the casting process itself is highly specialized. As explained by Magna International, a key method is high-pressure vacuum casting, which removes air from the die cavity before the metal is injected. This prevents porosity and allows the molten alloy to fill every detail of a complex mold, resulting in a stronger, more reliable final part.

Material science plays an equally critical role. The aluminum alloys used are not standard grades; they are advanced formulations designed for high strength, ductility, and excellent energy absorption during a crash. For the Audi A8's rear side member, a specific alloy known as Castasil-37 (AlSi9MnMoZr) was developed to meet demanding mechanical properties. However, there are trade-offs. For example, A360 aluminum is known for its exceptional strength at high temperatures, but it is more challenging to cast. The selection of the right alloy is a careful balance between performance requirements, castability, and cost.

While large-scale structural casting is revolutionary for BIW applications, other manufacturing processes like precision forging remain essential for different automotive components. For parts that demand the utmost fatigue resistance and strength, such as in powertrain and suspension systems, advanced hot forging is often the superior method. Industry specialists such as Shaoyi (Ningbo) Metal Technology provide these IATF16949-certified automotive forging parts, demonstrating how different advanced manufacturing techniques complement each other in building a modern vehicle.

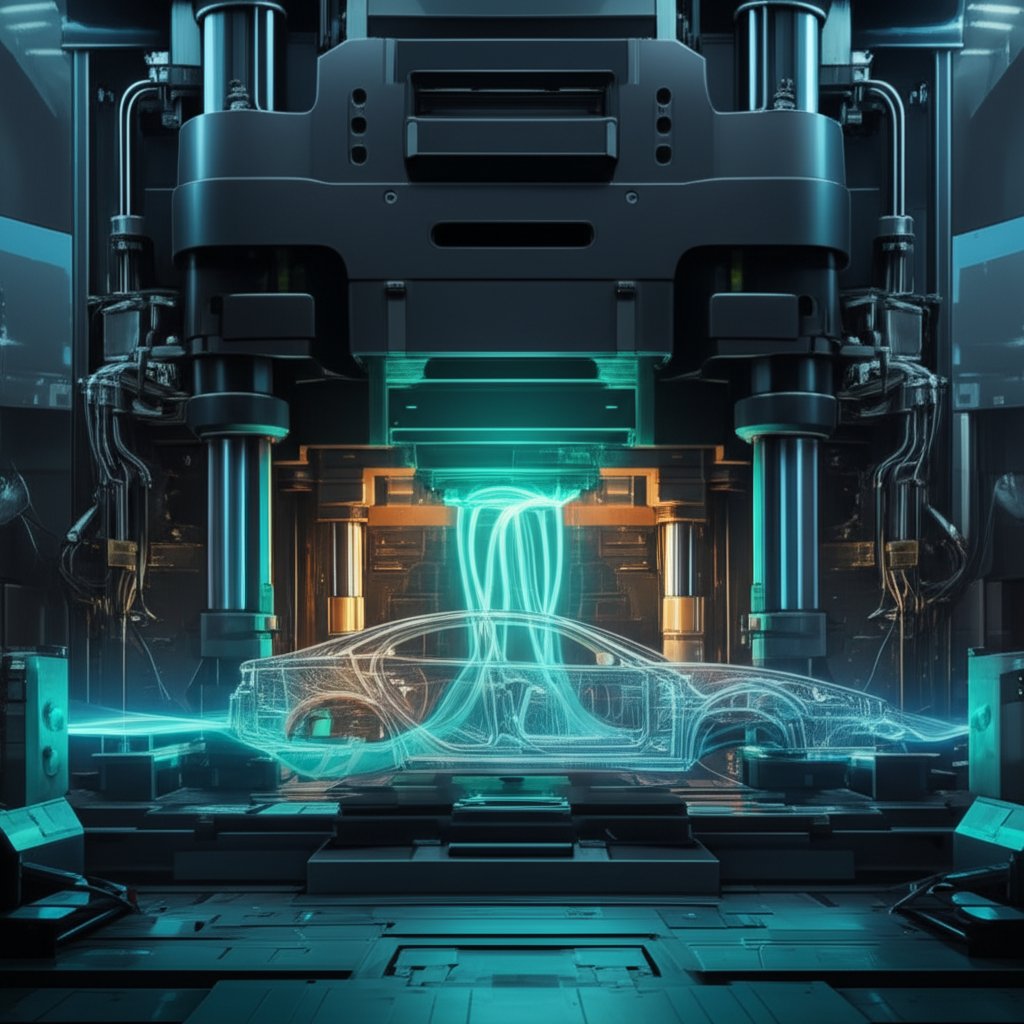

The successful implementation of structural die casting is impossible without a digital foundation. The sheer cost of tooling—often exceeding one million euros—makes physical trial-and-error unfeasible. Therefore, predictive simulation is an essential, non-negotiable step. Advanced software, such as ESI Group's ProCAST, allows engineers to virtually model the entire process, from die heating and molten metal flow to solidification and potential part distortion. This virtual prototyping de-risks the investment, optimizes the design for manufacturability, and ensures the final component will perform as expected.

Strategic Advantages of Die-Cast BIW Structures

The automotive industry's rapid adoption of structural die casting is driven by a compelling set of strategic advantages that impact everything from the factory floor to the vehicle's performance on the road. These benefits go far beyond simply reducing the number of parts; they create a cascading effect of efficiency, cost savings, and engineering innovation that gives automakers a significant competitive edge. By fundamentally rethinking how a car's body is constructed, manufacturers are unlocking new possibilities in design and production.

The most immediate benefit is the radical simplification of the manufacturing process. By consolidating nearly 100 parts into a single component, as in the Volvo example, automakers can dramatically reduce the complexity of their body shops. This translates into tangible operational gains. According to industry leader Bühler, this approach can eliminate the need for up to 300 robots on an assembly line and reduce the factory floor space required by 30%. This not only lowers capital expenditure but also reduces ongoing energy consumption and maintenance costs, contributing to a more sustainable production environment.

From a vehicle performance perspective, structural castings offer superior characteristics. The single-piece construction eliminates the inconsistencies and potential failure points of hundreds of welds and joints, resulting in a stiffer, stronger chassis. This enhanced structural rigidity improves vehicle handling, safety, and durability. Furthermore, castings made from advanced aluminum alloys provide an outstanding weight-to-energy absorption ratio, crucial for modern crash safety standards. The reduction in overall vehicle weight is another key advantage, particularly for electric vehicles (EVs), where every kilogram saved can extend battery range and improve efficiency.

Ultimately, these engineering and production benefits translate into significant financial and strategic gains. A summary of the core advantages includes:

- Part Consolidation: Replacing dozens or even hundreds of smaller stamped parts with a single, integrated casting.

- Production Simplification: Reducing the number of assembly steps, welding robots, and logistical complexity, leading to faster vehicle production.

- Cost Reduction: Lowering expenses related to tooling, assembly labor, supply chain management, and factory footprint.

- Improved Structural Performance: Achieving higher torsional rigidity and dimensional accuracy for better vehicle dynamics and safety.

- Weight Savings: Utilizing lightweight aluminum alloys to reduce overall vehicle mass, which is critical for improving the range and efficiency of EVs.

- Sustainability Gains: Decreasing energy consumption in the body shop and enabling easier recycling of the single-material component at the end of the vehicle's life.

Overcoming Challenges and The Future of Body-in-White Design

Despite its transformative potential, the path to implementing structural die casting is not without significant challenges. The sheer scale and complexity of producing mega castings introduce engineering hurdles that require a new level of precision, planning, and investment. These are not simple upgrades to existing processes but a fundamental re-engineering of vehicle design and manufacturing. Successfully navigating these complexities is the key to unlocking the technology's full benefits.

The primary challenge lies in the upfront design and validation phase. With physical tooling for a single mega casting costing over €1 million, there is virtually no room for error. The design must be perfected in the digital realm long before any metal is cut. This makes advanced simulation an indispensable tool. Engineers must virtually predict and mitigate potential issues like uneven die heating, turbulent metal flow during filling, and part distortion after cooling. This reliance on virtual prototyping represents a major shift, requiring new skill sets and a deep trust in the accuracy of simulation software to de-risk massive capital investments.

Another significant hurdle is ensuring consistent quality and mechanical properties during serial production. Maintaining tight dimensional tolerances across a very large and complex part, cast after cast, is a major technical feat. Fine-tuning the process parameters—from alloy temperature to injection speed and cooling rates—is critical to avoiding defects and ensuring that every component meets the required standards for strength and durability. This requires a deep integration of process control, sensor technology, and quality assurance throughout the production cycle.

The future of Body-in-White design is inextricably linked to the evolution of these digital tools. The next frontier is the creation of a seamless digital thread that connects the initial casting simulation with the final vehicle performance simulations. This means data on the 'as-manufactured' properties of a cast component—including any residual stresses or microscopic variations—can be fed directly into crash, fatigue, and noise, vibration, and harshness (NVH) models. This holistic, virtualized workflow will allow engineers to optimize vehicle design with an unprecedented level of accuracy, ensuring that the theoretical benefits of mega casting are fully realized in the safest, most efficient vehicles on the road.

Frequently Asked Questions

1. What is BIW body in white?

Body-in-White (BIW) refers to the stage in automotive manufacturing where a car's body frame and sheet metal components have been assembled, but before the moving parts (doors, hood, trunk lid), trim, chassis components, and powertrain are added. It represents the vehicle's core structural shell, forming the foundation for all other systems.

2. What is structural casting?

Structural casting is a manufacturing process used to create large, complex, and load-bearing components by injecting molten metal, typically an aluminum alloy, into a die under high pressure. In the automotive industry, it is used to produce critical BIW and chassis parts that require high strength, rigidity, and dimensional accuracy, often replacing assemblies of many smaller parts.

3. What is the strongest aluminum for die casting?

The 'strongest' aluminum alloy often depends on the specific application's requirements, such as temperature resistance, ductility, and corrosion resistance. Alloys like A360 are noted for their excellent strength, particularly at higher temperatures, and good corrosion resistance. However, these high-strength alloys can also be more difficult to cast, presenting a trade-off between material performance and manufacturability that engineers must balance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —