Precision and Power: Die Casting for Luxury Vehicle Components

TL;DR

High-pressure die casting is a pivotal manufacturing process for the luxury automotive sector, enabling the creation of intricate, lightweight, and high-strength components from aluminum and zinc alloys. This technology is essential for enhancing vehicle performance, improving fuel efficiency, and increasing structural integrity. Innovations like mega-casting are further revolutionizing production by consolidating numerous parts into a single, large component, drastically reducing weight and manufacturing complexity for the next generation of premium vehicles.

The Critical Role of Die Casting in Premium Automotive Manufacturing

In the world of luxury vehicles, where performance, precision, and innovation are paramount, die casting has emerged as a cornerstone of modern manufacturing. This process involves injecting molten metal, typically aluminum or zinc, into a hardened steel mold (or die) under immense pressure. The result is a component with exceptional dimensional accuracy, a smooth surface finish, and complex geometries that would be difficult or impossible to achieve with other methods. For luxury brands, this means creating parts that are not only strong and durable but also lightweight, a critical factor in enhancing handling, acceleration, and fuel economy. According to Autocast Inc., this method allows automakers to significantly boost vehicle performance and durability.

The preference for die casting in the premium automotive space stems from its ability to produce 'net-shape' or 'near-net-shape' parts, minimizing the need for costly and time-consuming secondary machining operations. This efficiency is vital for maintaining competitive production cycles. Furthermore, the process allows for the creation of thin-walled yet robust components, contributing directly to the industry-wide goal of vehicle lightweighting without compromising safety or structural rigidity. As noted by Zintilon, die casting effectively aligns with the automotive industry's need for precision, efficiency, and strength.

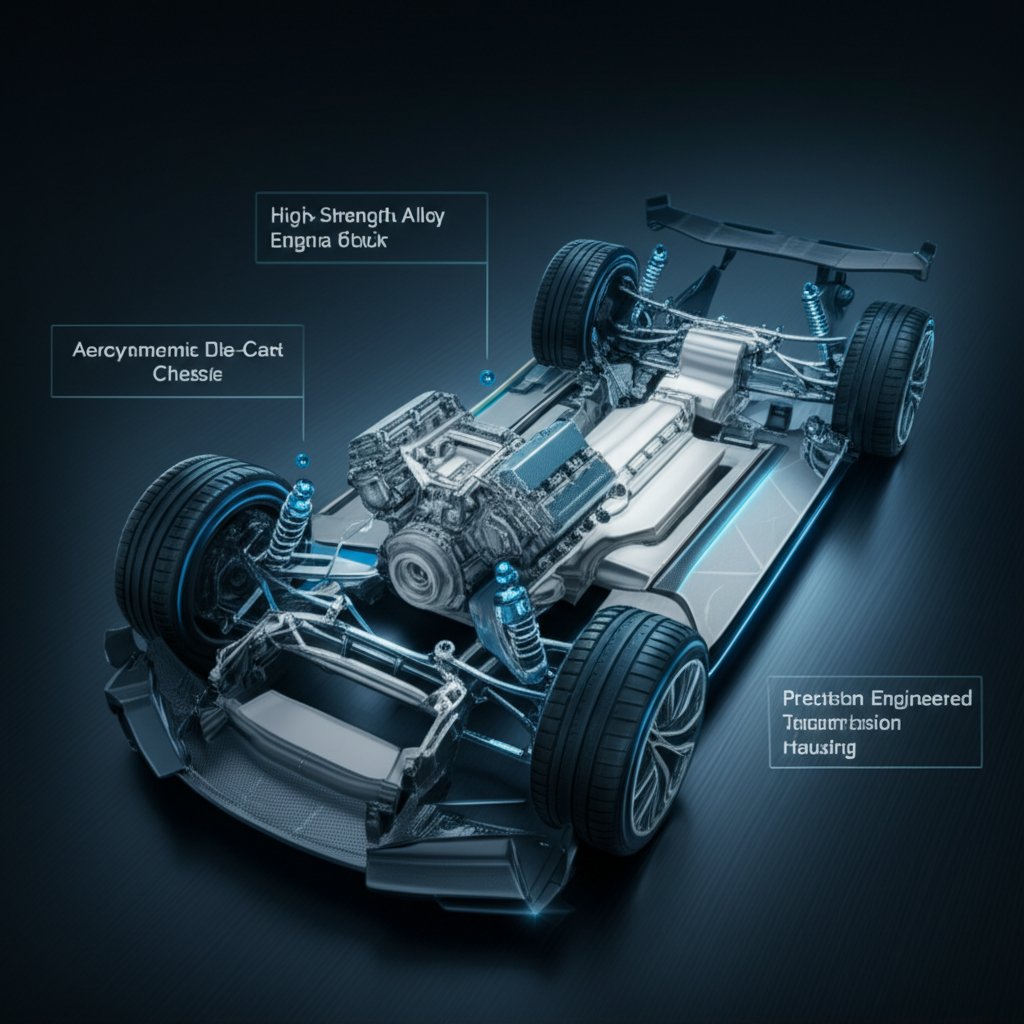

The applications of die casting in a luxury vehicle are extensive and integral to its function and feel. From powertrain to chassis, these precision-engineered components are everywhere. Common examples include:

- Structural Components: Items like shock towers and chassis nodes benefit from the high strength-to-weight ratio of die-cast aluminum, improving vehicle dynamics and crash performance.

- Engine and Powertrain Parts: Engine blocks, transmission cases, and valve covers are often die-cast to ensure precise tolerances for optimal performance and to aid in heat dissipation.

- Electronic Housings: The growing number of sensors, ECUs (Electronic Control Units), and LiDAR components in luxury cars require complex, lightweight, and durable enclosures that die casting can provide efficiently.

- Suspension and Braking Systems: Components such as steering knuckles, control arms, and brake calipers are produced via die casting to withstand significant stress while minimizing unsprung weight, which directly improves ride comfort and handling.

Mega-Casting: A Revolution in Luxury Vehicle Architecture

While traditional die casting has been an industry staple for decades, a groundbreaking evolution known as mega-casting (or giga-casting) is reshaping the future of vehicle architecture. This process utilizes enormous high-pressure die casting machines to produce very large, single-piece components, such as the entire front or rear underbody of a vehicle. Pioneered and popularized by Tesla, this innovation represents a paradigm shift from assembling hundreds of individual stamped and welded parts to integrating them into one massive, precisely engineered casting.

The primary benefit of mega-casting is a dramatic simplification of the manufacturing process. By replacing 70 to 100 or more individual parts with a single casting, automakers can eliminate a vast number of steps, including stamping, welding, and riveting. This consolidation leads to significant reductions in factory footprint, assembly time, and labor costs. According to industry reports cited in the SERP, this method can lead to a weight reduction of up to 30% and a manufacturing cost decrease of 40% for the associated vehicle section. This level of efficiency is particularly attractive to luxury manufacturers seeking to streamline production while advancing technological boundaries.

Despite its transformative potential, mega-casting presents its own set of challenges and considerations that the industry must navigate. A balanced perspective reveals both the opportunities and the hurdles of this emerging technology.

| Pros of Mega-Casting | Cons of Mega-Casting |

|---|---|

| Radical Simplification: Drastically reduces part count, simplifying supply chains and assembly line complexity. | High Capital Investment: The massive presses required represent a significant upfront financial commitment. |

| Weight Reduction: A single, optimized casting is typically lighter than a complex assembly of smaller parts, improving vehicle efficiency and range. | Repairability Concerns: Damage to a large, single-piece casting can be more difficult and expensive to repair than replacing a smaller, conventional component. |

| Improved Structural Integrity: Eliminates potential points of failure at joints and welds, leading to a stiffer, more consistent chassis. | Quality Control Complexity: Ensuring the integrity of such a large and complex casting without defects like porosity requires advanced process control and inspection. |

| Design Flexibility: Allows for more integrated and complex designs that can optimize space and performance. | Limited Material Flexibility: The process is currently optimized for specific aluminum alloys, limiting the use of mixed materials in that section of the vehicle. |

Material Selection for High-Performance Components: Aluminum vs. Zinc Alloys

The choice of material is fundamental to the success of any die-cast component, directly influencing its performance, weight, durability, and cost. In the luxury automotive sector, aluminum and zinc alloys are the two dominant material families, each offering a distinct set of properties suited for different applications. Understanding their respective strengths is key to optimizing component design for the demanding standards of a premium vehicle.

Aluminum alloys are celebrated for their exceptional strength-to-weight ratio, making them the go-to choice for lightweighting initiatives. They offer excellent corrosion resistance and good thermal conductivity, which is crucial for parts like engine blocks and housings for electronic components that need to dissipate heat. As Transvalor highlights, the push for energy efficiency makes lightweight aluminum parts highly sought after. These alloys are ideal for large structural components, transmission cases, and engine parts where reducing overall vehicle mass is a top priority.

Zinc alloys, on the other hand, are prized for their superior dimensional accuracy, stability, and the ability to be cast into very thin walls. They offer a smoother surface finish as-cast, often eliminating the need for secondary finishing operations for cosmetic parts. While heavier than aluminum, zinc's strength and fluidity make it perfect for smaller, more intricate components that require a high degree of precision, such as interior trim, lock housings, and the complex gears within seatbelt retractors. Dynacast points out that the process allows for net-shape designs, which is a key advantage of using highly fluid alloys like zinc.

To aid in the decision-making process, here is a comparison of the key properties of aluminum and zinc alloys in the context of luxury vehicle components:

| Property | Aluminum Alloys | Zinc Alloys |

|---|---|---|

| Strength-to-Weight Ratio | Excellent; ideal for lightweighting structural parts. | Good; higher density but offers high impact strength. |

| Operating Temperature | Maintains strength at higher temperatures, suitable for powertrain components. | Best suited for lower-temperature applications. |

| Finishing Requirements | Often requires surface finishing for cosmetic applications. | Excellent as-cast surface finish, ideal for plating and painting. |

| Corrosion Resistance | Excellent; forms a protective self-healing oxide layer. | Very good, but may require coating for long-term durability. |

| Cost | Material cost is generally higher, and tooling can have a shorter life due to higher casting temperatures. | Material cost is higher, but tooling life is significantly longer due to lower casting temperatures. |

Partnering with a Die Casting Specialist for Luxury Automotive Projects

Selecting the right manufacturing partner is as critical as the design and material choice, especially within the luxury automotive segment where standards for quality and precision are non-negotiable. The complexity of modern vehicle components demands a die casting supplier that is not just a vendor, but a technical partner capable of contributing expertise from the initial design phase through to mass production. A specialist partner can provide invaluable input on design for manufacturability (DFM), alloy selection, and process simulation to prevent defects and optimize performance.

When evaluating potential suppliers, luxury brands and Tier-1 manufacturers must look beyond mere production capacity. Key qualifications include a proven track record within the automotive industry, evidenced by certifications like IATF 16949, which is the global quality management standard for the automotive sector. Furthermore, a top-tier partner should possess advanced capabilities such as in-house tooling design and manufacturing, process simulation software to predict metal flow and solidification, and sophisticated quality control systems, including X-ray inspection and coordinate-measuring machines (CMM).

To ensure a potential partner can meet the rigorous demands of a luxury automotive project, procurement managers and engineers should come prepared with a detailed list of questions. This due diligence is crucial for mitigating risks and fostering a successful, long-term collaboration. Consider the following checklist when vetting a potential die casting specialist:

- Industry Experience: Can you provide case studies or examples of similar components you have produced for other luxury automotive brands or OEMs?

- Technical Capabilities: What simulation software (e.g., for mold flow, thermal analysis) do you use during the design and pre-production phases?

- Quality Assurance: What are your quality control processes for detecting and preventing defects such as porosity, cold shuts, or cracks? Are you IATF 16949 certified?

- Material Expertise: What is your experience with the specific high-performance aluminum or zinc alloys required for our application?

- Tooling and Maintenance: Do you design and build your tooling in-house? What is your preventative maintenance program for dies to ensure consistent quality over a long production run?

- Supply Chain and Logistics: How do you manage your supply chain to ensure material availability and on-time delivery for a high-volume production schedule?

Frequently Asked Questions

1. What are die casting parts in the automotive industry?

Die casting parts in the automotive industry are components created by forcing molten metal into a mold under high pressure. This process is used to manufacture a wide variety of parts, including structural components like chassis nodes and shock towers, powertrain parts like engine blocks and transmission cases, and smaller intricate items such as electronic housings, sensor bodies, and interior cosmetic pieces. The primary benefits are weight reduction, high precision, durability, and the ability to produce complex shapes efficiently.

2. What automobile parts are made by casting?

Casting, in general, is used for many automobile parts. High-pressure die casting, specifically, is favored for components requiring high precision and a good surface finish, such as transmission housings, engine blocks, and complex brackets. Other casting methods, like sand casting or gravity casting, are used for different components. However, for the high-volume, high-precision needs of the luxury automotive market, die casting is often the preferred method for its speed, consistency, and ability to create lightweight, strong parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —