Mastering Thermal Expansion in Aluminum Assemblies

TL;DR

Effectively managing thermal expansion in aluminum assemblies is critical due to aluminum's high coefficient of thermal expansion (CTE), which causes significant size changes with temperature. Key strategies involve selecting materials with matched CTEs, incorporating design allowances for movement, and utilizing specialized components like flexible adhesives or tolerance rings to absorb stress and prevent warping, joint failure, and reduced performance.

Understanding the Fundamentals of Aluminum's Thermal Expansion

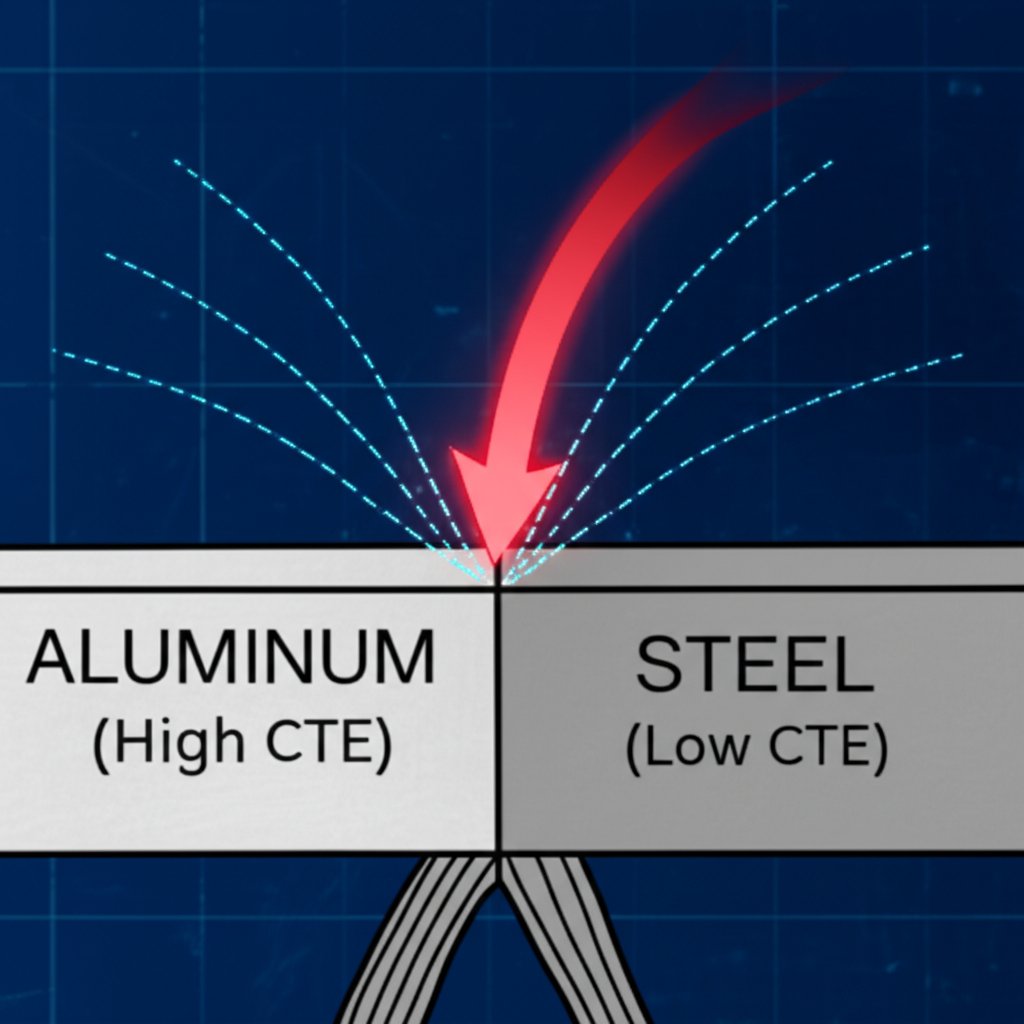

Thermal expansion is a fundamental property of matter, describing its tendency to change in shape, area, and volume in response to a change in temperature. For engineering materials, this is quantified by the coefficient of thermal expansion (CTE), which measures the fractional change in size per degree of temperature change. Materials with a high CTE expand and contract more significantly than those with a low CTE.

Aluminum and its alloys are known for having a relatively high CTE, typically around 23 parts per million per degree Celsius (ppm/°C). In contrast, steel has a CTE of about 12 ppm/°C. This disparity is a primary source of challenges in multi-material assemblies. As temperatures rise, an aluminum component will attempt to grow nearly twice as much as an adjacent steel part of the same size. This differential expansion induces significant mechanical stress, which can lead to warping, fastener fatigue, and ultimately, joint failure.

This behavior is particularly critical in applications with wide operating temperature ranges, such as automotive engines, aerospace components, and outdoor electronic enclosures. As noted in a detailed tutorial by Domadia, failing to account for aluminum's thermal expansion can compromise the structural integrity and precise tolerances required in high-performance designs. Therefore, understanding this core principle is the first step toward designing robust and reliable aluminum assemblies.

Core Engineering Strategies for Managing Expansion

Several engineering strategies can be employed to mitigate the challenges posed by aluminum's high thermal expansion. These approaches range from material science and specialized components to active thermal management, each offering unique benefits depending on the application's specific requirements.

Material Selection and Alloying

The first line of defense is careful material selection. Whenever possible, pairing aluminum with materials that have a similar CTE can minimize differential expansion. When this is not feasible, modifying the aluminum itself is an option. Alloying aluminum with elements like silicon can reduce its CTE. For example, Al-Si alloys create a eutectic matrix that restrains thermal growth. Similarly, microalloying with elements like zirconium can stabilize the material's grain structure, limiting expansion variability during thermal cycling.

Specialized Mechanical Components

In many assemblies, specialized components are used to absorb or accommodate movement. A prime example is the tolerance ring, a precision-engineered fastener with corrugated waves that act like springs. According to an analysis by USA Tolerance Rings, these components are highly effective in mixed-material bearing assemblies, such as a steel bearing in an aluminum housing. While a traditional press fit might lose all retention force as the aluminum housing expands away from the steel bearing, a tolerance ring maintains a consistent radial force, preventing slippage and failure across a wide temperature range.

Active Thermal Management

Another effective approach is to control the component's temperature directly. Active thermal management aims to reduce the temperature swings (ΔT) that drive expansion. Common strategies include:

- Radiative Coatings: Applying coatings with low solar absorptivity can reduce heat gain from sunlight, lowering the peak temperature of outdoor components.

- Forced Convection: In enclosed systems like electronics cabinets, fans or blowers can circulate air to dissipate heat and maintain a more stable operating temperature.

- Shading: Simply shielding components from direct solar radiation can significantly curtail daytime temperature spikes and reduce the overall thermal load.

Design Considerations for Assemblies with Dissimilar Materials

The most common and challenging scenario involves joining aluminum to materials with a significantly different CTE, such as steel, composites, or ceramics. This CTE mismatch is a leading cause of stress and failure in bonded or fastened joints. The primary design goal in these situations is to create an assembly that can accommodate differential movement without building up destructive stress.

One of the most effective solutions is the use of specialized adhesives. As explained by adhesive experts at MasterBond, there are two primary adhesive strategies. The first is to use a rigid, low-CTE adhesive, often filled with ceramic or specialty fillers, which minimizes the expansion of the bond line itself. The second, and often more robust, approach is to use a flexible or toughened adhesive system. These adhesives have a lower modulus and higher elongation, allowing them to stretch and absorb the stresses generated by the differential movement of the substrates. This flexibility prevents stress from concentrating at the bond interface, which could otherwise lead to delamination or substrate failure.

Beyond adhesives, mechanical design features can also provide the necessary compliance. Designing with slotted holes instead of round holes for fasteners allows one substrate to slide relative to the other as they expand and contract. Similarly, incorporating slip joints, flexible connectors, or bellows into a design can build in the required freedom of movement, effectively decoupling the components and preventing stress accumulation.

Practical Applications and Industry Examples

The principles of managing thermal expansion in aluminum are applied across numerous industries, with solutions tailored to specific challenges. Each application highlights the importance of selecting the right strategy to ensure long-term reliability and performance.

Bearing and Rotating Assemblies

In industrial pumps and motors, steel bearings are frequently mounted in lightweight aluminum housings. As the machinery heats up during operation, the aluminum housing expands more than the steel bearing, which can cause the bearing's outer race to slip. This leads to vibration, excessive wear, and premature failure. Using tolerance rings in these assemblies provides a compliant interface that maintains the required retention force even at elevated temperatures, ensuring the bearing remains securely in place.

Electronics and Avionics

Modern electronics, especially in aerospace and defense applications, rely on aluminum enclosures to dissipate heat and provide lightweight structural support. However, these enclosures house printed circuit boards (PCBs) and other components with much lower CTEs. As explained by S-Bond Technologies, temperature cycles during operation can cause stress on solder joints and connectors. Here, thermally conductive, flexible adhesives are often used to bond heat sinks to components, providing an effective thermal path while absorbing the mechanical stress from differential expansion.

Automotive and High-Performance Engines

The automotive industry extensively uses aluminum for engine blocks, cylinder heads, and powertrain components to reduce weight and improve efficiency. These components are bolted to steel and other alloy parts, creating complex assemblies that experience extreme thermal cycling. For automotive projects demanding precision-engineered components, sourcing custom parts is often essential. For instance, a provider of custom aluminum extrusions, Shaoyi Metal Technology, offers a comprehensive one-stop service from prototyping to production under the IATF 16949 quality system, ensuring parts are tailored to handle such demanding thermal environments. Proper design, including the use of specific fasteners and gaskets that allow for slight movement, is critical to prevent warping and maintain seal integrity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —