Steel Cutting Service Secrets: Why Your Quotes Vary By Thousands

Understanding Steel Cutting Services and Their Industrial Importance

Ever wondered why two seemingly identical steel components can have wildly different price tags? The answer often lies in how they were cut. A steel cutting service transforms raw metal into precise, functional components through advanced cutting processes—and the method chosen can dramatically affect your project's timeline, budget, and final quality.

Think of it this way: steel is among the most widely used materials across global industries, but its strength and density demand specialized equipment to shape accurately. Professional cutting services bridge the gap between raw material and finished product, delivering the precision, consistency, and efficiency that modern manufacturing requires.

What Defines a Professional Steel Cutting Service

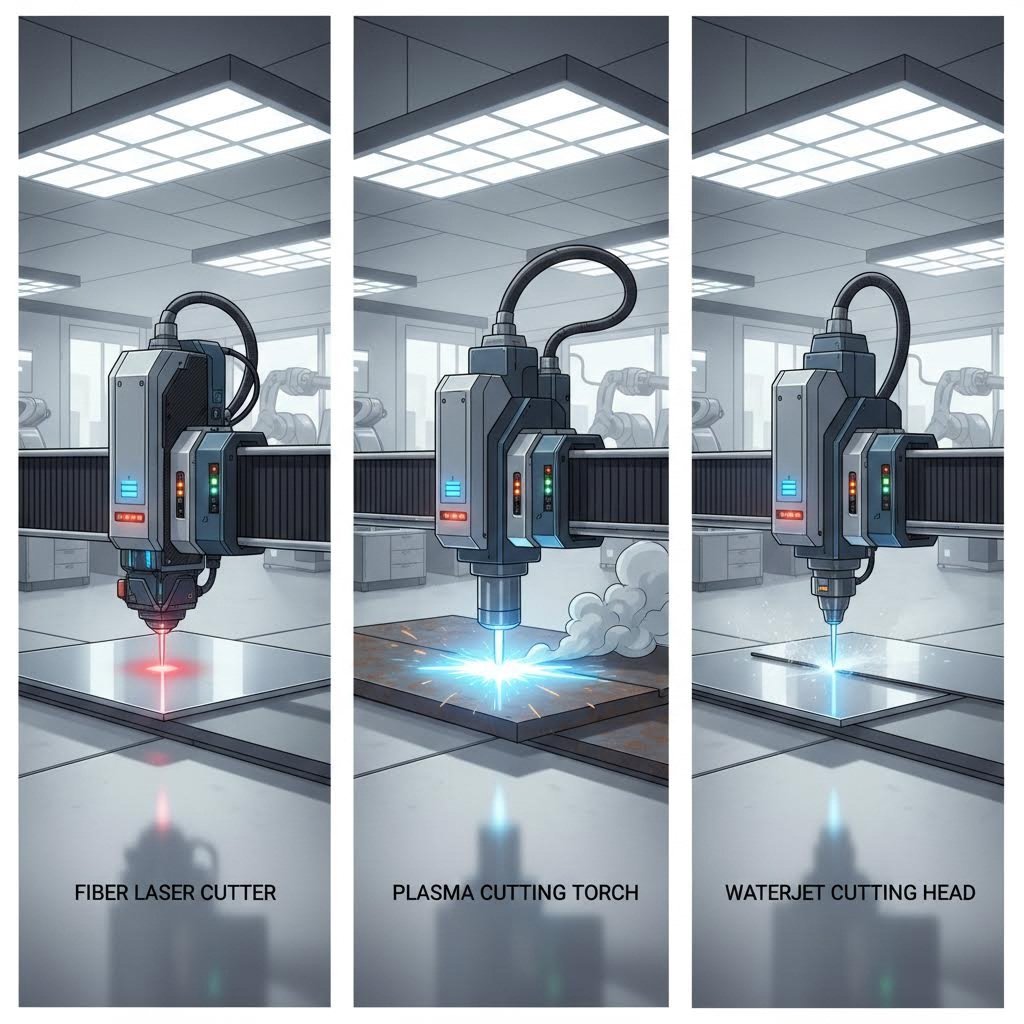

A professional steel cutting service does far more than simply slice through metal. These specialized operations use advanced machinery—including high-definition plasma cutters, oxy-fuel torches, laser systems, and water-jet equipment—to deliver cuts that meet exact specifications. The result? Straight edges, smooth finishes, and tight tolerances required for engineering accuracy.

Quality sheet metal fabrication relies on these services to produce components that fit together seamlessly. When precision laser services inc and similar providers execute cuts correctly, welded or bolted parts align effortlessly—reducing delays and ensuring structurally sound final products.

Industries that depend on these capabilities include:

- Automotive: Vehicle frames, body panels, engine components, and chassis parts

- Construction: Structural beams, columns, supports, plates, and reinforcement elements for construction sheet metal applications

- Aerospace: Precision components requiring exceptional tolerances and material integrity

- Custom Fabrication: Bespoke machinery parts, architectural features, and specialized industrial components

Why Cutting Method Selection Impacts Your Project

Here's what most people miss: not all cutting methods deliver the same results. Each technique—whether plasma, laser, waterjet, or oxy-fuel—has distinct advantages depending on your material thickness, desired edge quality, and production volume.

Choosing the wrong method can mean excessive post-processing, wasted material, or components that simply don't fit together. Conversely, selecting the right approach optimizes your budget while maintaining the quality your application demands.

Professional services bring something DIY approaches cannot match:

- Precision: CNC-guided systems achieve repeatable accuracy across hundreds or thousands of identical components

- Material efficiency: Computer-controlled nesting patterns minimize scrap and reduce raw material costs

- Clean edges: Advanced equipment produces surfaces ready for welding or assembly with minimal finishing required

- Expert guidance: Skilled technicians understand steel properties, cutting tolerances, and heat effects that impact final quality

This guide walks you through everything you need to understand about steel cutting—from comparing technologies and understanding materials to preparing your design files and evaluating providers. By the end, you'll know exactly what questions to ask and what factors truly drive those quote variations.

Comparing Steel Cutting Methods From Laser to Plasma

So you've received quotes from three different steel cutting service providers—and they're thousands of dollars apart. What gives? Often, the answer comes down to cutting method selection. Each technology brings distinct strengths and limitations that directly impact your costs, timelines, and final product quality.

Understanding these trade-offs empowers you to make informed decisions rather than simply accepting whatever a fabricator recommends. Let's break down the four primary cutting technologies and explore why each might—or might not—be right for your project.

Laser Cutting for Precision and Clean Edges

Imagine focusing a beam of light so intense it melts through steel with surgical accuracy. That's laser cutting in a nutshell. This method uses mirrors to direct extreme heat along predetermined cutting paths, creating exceptionally clean edges with minimal material loss.

When should you choose laser cutting? Consider it your go-to option when:

- Material thickness stays under 1.25 inches: Lasers excel with thinner steel but struggle to penetrate thicker plates efficiently

- Intricate designs matter: Small holes, sharp corners, and complex geometries come out crisp and precise

- Edge quality is critical: Parts often require no secondary finishing—ready for welding or assembly straight off the table

- Tight tolerances are non-negotiable: Accuracy typically reaches ±0.005 inches, making laser ideal for precision components

However, laser cutting isn't without drawbacks. The intense heat can create thermal stress in surrounding material, potentially causing warping on certain projects. It's also slower than plasma on thicker materials, which directly affects your per-part costs on larger production runs.

Plasma vs Waterjet Trade-offs Explained

Here's where many buyers get confused. Both plasma and waterjet can handle thicker materials than laser—but they achieve results through completely different mechanisms, each with distinct cost and quality implications.

Plasma cutting uses superheated ionized gas directed through a fine nozzle. An electric arc passes through the conductive plasma to melt steel, while high-pressure gas blows away molten material. Think of it as the workhorse of metal fabrication—fast, cost-effective, and capable of handling substantial thickness.

CNC plasma systems have transformed what's possible with this technology. Modern equipment delivers consistent, repeatable cuts across hundreds of identical parts. For a restaurant chain expanding locations and needing standardized kitchen equipment frames, plasma's speed and economy make it incredibly attractive.

Waterjet cutting takes an entirely different approach—no heat whatsoever. High-pressure water mixed with abrasive particles erodes material away, cutting through steel up to 8 inches thick without thermal distortion. This cold-cutting process preserves material properties that heat-based methods can compromise.

Why does this matter? When cutting heat-sensitive components or materials that would harden or warp under thermal stress, waterjet becomes essential rather than optional. Aerospace applications frequently demand this precision, as do projects involving pre-hardened tool steels.

Oxy-Fuel: The Heavy-Duty Option

Don't overlook flame cutting when dealing with seriously thick steel. This method combines oxygen and fuel gases to oxidize and melt metal away, handling plates up to 48 inches thick—far beyond what any other method can achieve.

Oxy-fuel cutting requires preheating the workpiece, making it slower than plasma. But for heavy structural steel, shipbuilding, and large-scale industrial applications, it remains the most cost-effective choice. The trade-off? Less precision than laser or waterjet, with wider kerfs and rougher edges requiring more post-processing.

Complete Cutting Method Comparison

This table summarizes what each technology delivers—and where each falls short:

| Cutting Method | Best Thickness Range | Edge Quality | Speed | Heat-Affected Zone | Ideal Applications |

|---|---|---|---|---|---|

| Laser | Up to 1.25 inches | Excellent—minimal finishing needed | Moderate | Small but present | Electronics, medical devices, precision parts |

| Plasma | Up to 2.5 inches (CNC) | Good—may need deburring | Fast | Moderate | Structural steel, heavy equipment, general fabrication |

| Waterjet | Up to 8 inches | Excellent—no thermal effects | Slow | None | Aerospace, heat-sensitive materials, stone, glass |

| Oxy-Fuel | Up to 48 inches | Rougher—requires more finishing | Slow (with preheat) | Large | Shipbuilding, heavy structural steel, thick plates |

What Tolerance Levels Actually Mean for Your Project

Numbers on a spec sheet only tell part of the story. Here's how tolerance capabilities translate to real-world outcomes:

- Laser (±0.005 inches): Components fit together with virtually no gap adjustment—critical for assemblies requiring precise alignment

- Plasma (±0.015-0.030 inches): Perfectly acceptable for structural applications where minor variations won't affect function

- Waterjet (±0.005-0.010 inches): Combines high precision with material versatility—excellent for prototype work

- Oxy-Fuel (±0.030+ inches): Best suited for applications where subsequent machining or generous tolerances are acceptable

According to industry testing, plasma cutting 1-inch steel runs about 3-4 times faster than waterjet, with operating costs roughly half as much per foot. However, a complete plasma system costs around $90,000 compared to approximately $195,000 for similar-sized waterjet equipment—capital investments that fabricators factor into their quotes.

Now that you understand how cutting methods differ, the next critical factor is your material itself. Different steel grades respond differently to each cutting technology—and matching your material to the right method can prevent costly surprises.

Steel Types and Material Selection for Optimal Cutting Results

You've selected your cutting method—but here's the catch. That decision only works if it matches your material. Different steel grades behave dramatically differently under each cutting technology, and choosing the wrong combination can mean ruined parts, blown budgets, or both.

Think about it: carbon steel, stainless steel, alloy steel, and tool steel each have unique properties that affect how they respond to heat, pressure, and abrasion. Understanding these characteristics before requesting quotes helps you avoid surprises and ensures your steel cutting service delivers exactly what your project demands.

How Steel Grade Affects Your Cutting Options

Not all steel is created equal—and that matters enormously when cutting. Here's what you need to know about each major category:

Carbon Steel remains the most commonly cut material in fabrication shops. Its relatively low alloy content makes it predictable and forgiving across most cutting methods. Mild carbon steel (low carbon content) cuts easily with plasma, laser, or oxy-fuel, while higher carbon grades require more careful heat management to prevent unwanted hardening at cut edges.

Stainless Steel presents more challenges. According to Outokumpu's machining guidelines, cutting stainless steel requires higher cutting forces than mild carbon steel, though the same general methods apply. Ferritic stainless grades behave similarly to carbon steels of equivalent strength, while austenitic grades (like 304 and 316) demand tighter process control. The higher alloying content increases difficulty—a critical factor when estimating costs.

Alloy Steel incorporates elements like chromium, molybdenum, nickel, or vanadium to enhance specific properties. These additions affect thermal conductivity and hardness, directly impacting which cutting methods work effectively. Some alloy steels harden when exposed to cutting heat, requiring post-cut treatments or alternative cold-cutting approaches.

Tool Steel represents the most demanding category. Designed for hardness and wear resistance, these materials often require waterjet cutting to avoid thermal damage. Pre-hardened tool steels especially benefit from cold cutting, as heat-based methods can alter the carefully engineered metallurgical properties.

Common Steel Grades and Cutting Compatibility

Here's a practical breakdown of what works—and what doesn't—for frequently requested materials:

- A36/1018 Carbon Steel: Compatible with all cutting methods; plasma and oxy-fuel offer best cost-efficiency for thicker sections

- 4140 Alloy Steel: Laser and plasma work well; watch for edge hardening that may require tempering

- 304/316 Stainless Steel: Laser cutting up to 20-25mm; plasma up to 38mm; waterjet preferred for heat-sensitive applications

- AR400/AR500 Abrasion-Resistant Plate: Plasma handles these high-hardness steels effectively; oxy-fuel struggles due to oxidation resistance

- D2/O1 Tool Steel: Waterjet strongly recommended to preserve hardness; laser possible but risks altering heat treatment

- Duplex Stainless (2205/2507): Requires careful parameter control; according to machining experts, LDX 2101 offers notably better machinability than other duplex grades

Matching Materials to Cutting Technologies

Material thickness dramatically influences your options—yet many fabricators gloss over these limitations. Here's what the data reveals about real-world thickness capabilities:

According to cutting technology research, maximum thickness limits vary significantly by method and material:

| Material | Laser Cutting | Plasma Cutting | Waterjet Cutting | Oxy-Fuel Cutting |

|---|---|---|---|---|

| Carbon Steel | Up to 30mm (fiber laser) | Up to 150mm | Up to 150mm+ | Up to 300mm |

| Stainless Steel | Up to 20-25mm | Up to 38mm | Up to 150mm | Not suitable |

| Aluminum | Up to 15-20mm | Up to 38mm | Up to 150mm | Not suitable |

Notice that oxy-fuel cannot cut stainless steel or aluminum—it relies on an oxidizing reaction that these materials resist. This single limitation can force an entirely different cutting approach for multi-material projects.

High-Hardness Steel and Specialty Alloy Considerations

When your project involves hardened or specialty steels, additional factors come into play:

- Heat-affected zones (HAZ): Thermal cutting methods create zones where material properties change. For pure metal works requiring consistent hardness throughout, waterjet eliminates this concern entirely

- Edge hardening: High-carbon and alloy steels can develop glass-hard edges from rapid heating and cooling—potentially cracking during subsequent bending or machining

- Reflectivity challenges: Copper, brass, and some aluminum alloys reflect laser energy, reducing cutting depth and efficiency

- Thermal conductivity: Materials that dissipate heat quickly (like copper) require higher power inputs, affecting both speed and cost

For custom engineering and fabrication projects in Fort Wayne and similar industrial regions, understanding these material-method relationships helps you specify exactly what you need—and recognize when a fabricator's recommendation truly serves your interests.

The bottom line? Your steel grade isn't just a line item on a material order. It's a fundamental variable that determines which cutting technologies will deliver acceptable results—and which will create problems you'll pay to fix later. With material selection sorted, the next step is preparing your design files correctly so quotes reflect actual production requirements.

Design File Preparation and Technical Requirements

You've selected your cutting method and matched it to your material. Now comes the step that separates smooth production runs from costly delays: file preparation. Sounds simple? Here's the reality—improperly prepared design files cause more quote inaccuracies and production headaches than almost any other factor.

Whether you're submitting your first steel cutting project or your fiftieth, understanding what fabricators need from your files eliminates back-and-forth revisions and ensures your quote reflects actual production costs.

Preparing Your Design Files for Steel Cutting

Before your design reaches a cutting table, it must pass through CAM software that translates geometry into machine instructions. According to CNC machining experts, your file is only as good as the data you provide—incomplete or incorrectly formatted files lead to rejected parts, wasted material, and delayed timelines.

Most steel cutting services accept these file formats:

- DXF (Drawing Exchange Format): The most universally accepted 2D format; works across virtually all CAM systems

- DWG (AutoCAD Drawing): Native AutoCAD format; widely supported but may require conversion

- STEP (Standard for Exchange of Product Data): Preferred for 3D geometry; preserves curves and surfaces accurately

- PDF: Acceptable for simple projects but requires vector-based content—raster images cannot be cut

- IGES: Older format still supported; good for cross-platform compatibility

Avoid mesh-based formats like STL or OBJ. While these work fine for 3D printing, they break smooth curves into tiny triangles—destroying the precision your cutting project requires.

File Preparation Checklist

Follow this numbered checklist before submitting files to any steel cutting service:

- Export as vector, not raster: Cutting machines follow paths, not pixel-based images. Ensure all geometry consists of lines, arcs, and curves rather than bitmap graphics

- Set correct units and scale: Verify your file uses the same measurement system (inches or millimeters) your fabricator expects. A 1:1 scale is essential—scaled drawings cause catastrophic sizing errors

- Remove excess information: Delete construction lines, dimension annotations, title blocks, and layer labels. According to Xometry's design guide, unnecessary elements confuse CAM software and create production delays

- Convert text to geometry: Fonts render differently across systems. Converting text to outlines or curves ensures your engraved lettering appears exactly as designed

- Close all paths: Open contours cannot be cut. Verify every shape forms a completely closed loop

- Eliminate duplicate lines: Overlapping geometry causes machines to cut the same path twice, damaging edges and wasting time

- Specify material and thickness: Include this information in your file name or accompanying documentation—it directly affects cutting parameters

Common Design Mistakes That Increase Costs

Even experienced engineers make these errors. Avoiding them keeps your project on budget and on schedule:

Ignoring kerf allowances: Every cutting method removes material—the kerf. Laser kerf runs approximately 0.006-0.015 inches, while plasma removes 0.06-0.15 inches. If your design doesn't account for this, parts come out undersized. Critical assemblies require offsetting cut paths by half the kerf width.

Designing features too small: According to laser cutting guidelines, minimum hole sizes typically shouldn't fall below 50% of material thickness. Holes smaller than this lose quality and resolution, with material potentially melting away entirely. For 0.250-inch aluminum, expect quality degradation on holes smaller than 0.125 inches.

Insufficient hole-to-edge distance: Placing holes too close to part edges creates weak sections that warp or break during cutting. The general rule? Maintain at least 1.5x material thickness between any hole edge and the part boundary.

Overlooking bridge requirements: Thin connecting sections between features—bridges—need adequate width to survive cutting forces and post-processing. Minimum bridge widths vary by material and thickness; check your fabricator's guidelines before finalizing designs.

Forgetting post-processing impacts: Planning for powder coating? Deburring? Ceramic tumbling? Each secondary operation has its own size requirements. As cutting specialists note, tumbling forces can wear down delicate features that survived the initial cut just fine.

How Proper Preparation Affects Your Quote

Here's what most buyers don't realize: sloppy files don't just delay production—they inflate quotes. Fabricators must spend engineering time fixing problems before cutting begins. That time gets billed, either explicitly or built into higher per-part pricing.

Conversely, production-ready files enable accurate automated quoting, faster turnaround, and fewer surprises. Many advanced steel cutting services now offer instant pricing portals that analyze your geometry and return quotes within minutes—but only when files meet their specifications.

With your design files properly prepared, the next critical question becomes: what will this actually cost? Understanding the factors that drive pricing helps you optimize your project budget before requesting quotes.

Pricing Factors and Cost Optimization Strategies

Here's the question everyone asks but few fabricators answer directly: why does one steel cutting service quote $500 while another quotes $2,000 for the same project? The answer isn't as mysterious as it seems—but it does require understanding what actually drives costs behind the scenes.

Unlike picking up an acai bowl where prices are posted clearly on the menu, steel cutting pricing involves multiple interconnected variables. Each factor compounds with others, creating the wide quote variations that frustrate buyers. Let's demystify this process so you can evaluate quotes intelligently and optimize your spending.

What Factors Determine Steel Cutting Costs

Every steel cutting quote reflects a combination of these core cost drivers:

- Material type and thickness: Different steels cost different amounts per pound, and thicker materials require more cutting time and wear consumables faster. According to SendCutSend's analysis, 304 stainless steel parts typically run about $12 each compared to $8.50 for identical parts in mild steel or aluminum—a 40% premium driven purely by material selection

- Cutting method complexity: Laser cutting costs more per hour than plasma but delivers cleaner edges. Waterjet commands premium rates due to slower speeds and higher consumable costs. Your method choice directly impacts the machine time billed to your project

- Quantity and batch size: This factor often creates the biggest surprises. A single zinc-plated steel part might cost $29, but ordering ten drops the per-unit price to just $3—an 86% reduction in some cases

- Design complexity: Intricate geometries with many small features take longer to cut than simple shapes. More cutting time means higher costs—complex parts can cost three times more than simpler designs in the same material

- Secondary operations: Powder coating, deburring, bending, and other finishing steps add processing time. Raw aluminum parts at $27 each jump to $43 with powder coating applied—a 60% increase for that single operation

- Turnaround time: Rush orders require schedule juggling, overtime, or expedited shipping. Expect premium pricing when you need parts faster than standard lead times allow

Why Setup Costs Hit Small Orders Hardest

Imagine walking into a shop that specializes in fresh-pressed juice rather than a quick acai bowl—every order requires washing equipment, preparing ingredients, and cleaning up afterward. Steel cutting works similarly. Before any cutting begins, fabricators must:

- Program cutting paths into CNC equipment

- Load material sheets onto cutting tables

- Configure machine parameters for your specific material and thickness

- Run test cuts to verify quality

- Handle, package, and ship completed parts

These fixed costs remain relatively constant whether you're cutting one part or fifty. According to industry experts, your shop rate—the hourly cost to produce parts—includes labor, equipment setup, overhead, and depreciation. Spreading these costs across larger quantities dramatically reduces per-unit pricing.

The first part of any production run is always the most expensive. Smart buyers consolidate orders and increase batch sizes whenever possible—even small quantity increases from one to five pieces can reduce per-part costs by over 50%.

How to Optimize Your Project Budget

Now that you understand what drives costs, here's how to work the system in your favor:

Simplify geometry where possible. Every intricate detail adds cutting time. As manufacturing cost analysts emphasize, over 85% of product costs are determined during design—before production ever begins. Increasing internal corner radii, eliminating unnecessary small holes, and streamlining shapes all reduce machine time.

Choose materials strategically. Sometimes you don't need stainless steel's corrosion resistance or tool steel's hardness. Carbon steel and aluminum offer excellent machinability at lower material costs. Ask yourself: does my application genuinely require premium material properties?

Batch similar projects together. If you need parts now and anticipate needing more later, ordering everything at once almost always costs less than splitting into separate runs. The quantity discounts often outweigh carrying a modest inventory.

Request DFM feedback. Many steel cutting services offer Design for Manufacturability reviews. They'll identify cost-saving modifications you might have missed—slightly larger holes, adjusted spacing, or material substitutions that maintain function while reducing price.

Understanding the Quote and Ordering Process

Most steel cutting services follow a similar workflow, though timelines vary:

- File submission: Upload your prepared design files through the fabricator's portal or email. Include material specifications, quantity, and any special requirements

- Engineering review: Technical staff analyze your geometry for manufacturability issues. Complex projects may require clarification calls; simple jobs proceed directly to quoting

- Quote generation: The fabricator calculates material costs, machine time, secondary operations, and margin. Advanced shops return quotes within hours; others may take days

- Revision cycle: If pricing exceeds budget, discuss alternatives. Different cutting methods, material substitutions, or design modifications can bring costs in line

- Order confirmation: Once you approve the quote and submit payment or purchase order, your job enters the production queue

- Production and QC: Parts are cut, inspected against specifications, and prepared for any secondary operations

- Shipping: Completed parts are packaged and shipped. Many services include free shipping above minimum order thresholds—SendCutSend offers free U.S. shipping on orders over $39

The key insight? Quotes aren't arbitrary numbers—they reflect real calculations based on predictable factors. By understanding those factors and preparing properly, you gain leverage to negotiate better pricing and avoid surprises when invoices arrive.

With cost factors clarified, the next consideration is what happens after cutting. Edge quality and surface finish vary significantly by method—and knowing what to expect helps you plan for any secondary finishing your project requires.

Edge Quality and Surface Finish Expectations

You've received your cut steel parts—now what? Here's something most fabricators won't tell you upfront: the edge that comes off the cutting table isn't always the edge you can use directly. Each cutting method leaves distinct surface characteristics that affect how parts perform, how they look, and what additional processing they'll need.

Understanding these differences before ordering saves you from budget-busting surprises. Think of it like ordering boba—you expect a certain consistency and quality. Steel cutting works the same way, with each method delivering predictable outcomes once you know what to look for.

Edge Quality Expectations by Cutting Method

Every thermal cutting process creates what experts call a heat-affected zone (HAZ)—an area where material properties change due to exposure to cutting temperatures. The size and severity of this zone varies dramatically by method.

Laser cutting produces the cleanest edges among thermal methods. The focused beam creates narrow kerfs with minimal material distortion. However, HAZ still exists. According to precision manufacturing specialists, effects can include:

- Slight discoloration: Heat exposure may create visible color changes at cut edges—often acceptable functionally but potentially problematic for cosmetic applications

- Micro-burrs: Thin materials may develop small redeposits of molten material that require light deburring

- Edge hardening: High-carbon steels can develop harder edges from rapid heating and cooling cycles

Plasma cutting works faster but creates more pronounced surface effects. Research on plasma cutting surfaces shows that current intensity exerts the maximum influence on surface roughness—higher amperage generally produces smoother finishes, though the relationship involves multiple interacting factors. Expect:

- Dross formation: Molten material that solidifies along the bottom edge, requiring removal before welding or assembly

- Angular striations: Characteristic curved lines running down the cut face, created by plasma column dynamics

- Wider HAZ: More heat input means larger zones of altered material properties

Waterjet cutting stands apart completely. No heat means no HAZ, no thermal distortion, and no metallurgical changes. The trade-off? A slightly frosted surface texture from abrasive erosion and potential taper on thicker materials.

Comparing Edge Characteristics Across Methods

| Characteristic | Laser Cutting | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Surface Roughness (Ra) | 1.5-6 μm (excellent) | 6-25 μm (varies with parameters) | 3-12 μm (good to excellent) |

| Heat-Affected Zone | 0.1-0.5mm (small) | 1-3mm (moderate to large) | None |

| Dross/Burrs | Minimal—often ready to use | Common—requires cleanup | None |

| Edge Perpendicularity | Excellent (minimal taper) | Good (slight bevel possible) | Good (taper increases with thickness) |

| Discoloration | Slight oxidation possible | More pronounced | None |

When Secondary Finishing Is Required

Not every application demands perfect edges. Structural components hidden inside assemblies rarely need finishing beyond basic dross removal. But visible parts, precision fits, and coated surfaces tell a different story.

Deburring becomes essential when:

- Parts will be handled frequently—sharp burrs create safety hazards

- Components must fit precisely together—burrs prevent proper seating

- Surfaces will receive powder coating or paint—burrs cause coating defects and poor adhesion

- Parts undergo subsequent machining—burrs interfere with fixturing and create quality issues

According to metal finishing specialists, professional deburring uses a combination of hand tools, soft wheel buffers, and Dyna files depending on material, cut type, and order volume. Even after deburring, they recommend wearing gloves when handling thin-gauge or heavy materials.

Powder coating preparation requires more than just deburring. The entire surface must be clean, free of oils, and properly textured for adhesion. Cut edges with significant HAZ discoloration may need additional treatment to ensure consistent coating appearance.

Common Problems and How Professional Services Prevent Them

DIY cutting and inexperienced fabricators often produce parts with issues that professional steel cutting services avoid through proper equipment and parameter control:

Warping and oil canning: Excessive heat concentration causes material to buckle and deform. Manufacturing experts prevent this by programming lower power with additional laser passes, spreading heat input over time rather than concentrating it.

Slag and redeposits: Molten material that reattaches along cut edges creates cleanup headaches. Professional shops optimize gas pressure, cutting speed, and standoff distance to minimize these deposits.

Delamination: Laminated materials and adhesive-backed components can separate when excessive heat affects bonding layers. Careful parameter selection and sometimes waterjet cutting eliminate this risk entirely.

Inconsistent quality: Manual plasma torches in garage setups produce wildly varying results. CNC-controlled professional equipment delivers repeatable quality across every part in your order.

The bottom line? Edge quality isn't an afterthought—it's a predictable outcome of method selection and process control. Professional services factor finishing requirements into their recommendations, helping you avoid paying twice: once for cutting and again for fixing problems that shouldn't have occurred. With realistic expectations about edge quality, you're ready to explore how these cutting capabilities apply to demanding applications like automotive manufacturing.

Automotive and Precision Manufacturing Applications

When it comes to demanding applications, few industries push steel cutting capabilities harder than automotive manufacturing. Every vehicle on the road—from economy sedans to high-performance sports cars—relies on precisely cut metal components that meet exacting specifications. The difference between a well-engineered chassis and a structural failure often comes down to cutting accuracy measured in thousandths of an inch.

Why does this matter for your projects? Understanding how automotive manufacturers leverage steel cutting services reveals best practices applicable across precision manufacturing—whether you're building prototypes, production parts, or custom fabrications.

Steel Cutting for Automotive Component Manufacturing

The automotive industry treats metal fabrication as the foundation upon which everything else is built. According to Endura Steel's industry analysis, skilled metal workers use specialized tools and techniques to cut, bend, and join pieces of metal with extreme precision—because even slight misalignment causes problems when attaching other parts like engines, wheels, and body panels.

Think about what goes into a modern vehicle. Steel cutting services produce components across virtually every system:

- Chassis components: The structural backbone providing essential support for all other parts—frames, subframes, and crossmembers that must withstand tremendous stress

- Suspension parts: Control arms, brackets, and mounting points requiring precise geometry for proper vehicle handling and ride quality

- Structural assemblies: Reinforcement panels, crash structures, and safety components engineered to protect occupants

- Body panels: Fenders, doors, hoods, and quarter panels shaped through stamping processes that start with precision-cut blanks

- Engine components: Brackets, mounts, and heat shields demanding tight tolerances for proper fit and function

- Exhaust systems: Complex tubing and flanges requiring skilled cutting and forming to manage temperatures and emissions

The industry's reliance on consistent quality has driven adoption of certifications like IATF 16949—the international standard specifically addressing automotive quality management systems. This certification ensures suppliers meet rigorous process controls that automotive OEMs demand. When evaluating steel cutting providers for automotive work, IATF 16949 certification signals a commitment to the systematic quality approaches this industry requires.

Precision Requirements in Chassis and Structural Parts

Imagine the chassis as the skeleton that keeps everything in place and gives the car its shape. As automotive fabrication experts explain, building this critical framework requires carefully cutting metal sheets into exact sizes and shapes, then bending them into necessary curves and angles before welding pieces together into strong, rigid structures.

Why such extreme precision? Consider what happens if chassis components don't align perfectly:

- Suspension geometry becomes compromised, affecting handling and tire wear

- Body panels won't mount correctly, creating visible gaps and wind noise

- Powertrain components may not fit, causing vibration and premature failure

- Safety systems like airbags and crumple zones won't perform as engineered

The stakes are simply too high for approximation. Professional steel cutting services use CNC-controlled equipment that delivers repeatable accuracy across thousands of identical components—the consistency mass production demands.

How Rapid Prototyping Accelerates Product Development

Before any vehicle reaches mass production, engineers need physical prototypes to test, refine, and validate designs. This is where rapid prototyping transforms the development timeline. According to Global Technology Ventures, sheet metal rapid prototyping has revolutionized the automotive industry by allowing manufacturers to craft high-performance models at a pace impossible with traditional methods.

Historically, metal components were made in foundries or stamping facilities unsuited to small-volume production—particularly the one-off designs used in prototype development. Today's technologies have changed everything:

- CNC machining: Produces parts with exacting tolerances while meeting timing needs of modern design cycles

- Laser cutting: When more two-dimensional shapes are required, laser cutting offers fast, inexpensive production of brackets or body components from CAD data

- Custom stamping and forming: For larger or more complex parts, these evolved techniques use CAD data to guide production of necessary tools and dies

The benefit? Automakers can quickly develop, test, and refine metal components without committing to full-scale production. This reduces costs, speeds development, and enhances vehicle performance before significant manufacturing investments are made.

Leading suppliers now offer 5-day rapid prototyping capabilities, compressing what once took weeks into days. For automotive programs racing against competitive timelines, this acceleration can mean the difference between market leadership and playing catch-up. Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this approach, combining rapid prototyping with automated mass production and IATF 16949-certified quality systems—precisely the integration automotive supply chains require.

The Complete Steel Cutting Journey: Conception Through Delivery

Understanding how professional automotive projects flow from initial concept to delivered parts helps you navigate your own manufacturing needs more effectively:

- Design and engineering: CAD models are created with manufacturing constraints in mind—DFM (Design for Manufacturability) analysis identifies potential issues before cutting begins

- Material selection: Engineers specify steel grades matching performance requirements—high-strength steels for structural components, formable grades for complex body panels

- Cutting method optimization: Based on material, thickness, volume, and tolerance requirements, the optimal cutting technology is selected

- Prototype production: Initial parts are cut, formed, and assembled to validate design intent and identify refinements

- Testing and iteration: Prototypes undergo physical testing; designs are modified and new prototypes produced as needed

- Production tooling: Once designs are validated, production tooling is developed for high-volume manufacturing

- Mass production: Automated systems produce thousands of identical components with consistent quality

- Quality verification: Statistical process controls and inspection ensure every part meets specifications

- Delivery and integration: Components are shipped to assembly operations and integrated into finished vehicles

The time from initial quote to delivered prototypes matters enormously in competitive industries. Suppliers offering 12-hour quote turnaround and comprehensive DFM support eliminate bottlenecks that delay product development. When your supply chain mapping requires reliable partners who understand automotive demands, these capabilities become selection criteria rather than nice-to-have features.

Whether you're developing automotive components, industrial equipment, or precision machinery, the principles automotive manufacturers have refined apply broadly. Consistent quality, rapid iteration, and reliable delivery timelines drive success across manufacturing sectors. With these application insights in mind, the final consideration becomes selecting the right steel cutting service provider for your specific needs.

Choosing the Right Steel Cutting Service Provider

You've learned about cutting methods, materials, file preparation, and pricing factors. Now comes the decision that ties everything together: selecting the right partner for your project. This choice affects not just the parts you receive, but your timeline, budget, and ultimately your project's success.

Finding a reliable steel cutting service isn't like searching for a dollar tree near me or soup near me—you can't simply pick the closest option and expect consistent results. The fabrication industry varies enormously in capabilities, quality standards, and customer service. Knowing what questions to ask—and which answers signal problems—separates satisfying partnerships from frustrating experiences.

Essential Questions to Ask Your Cutting Service Provider

Before committing to any fabricator, gather the information you need to evaluate their fit for your project. According to industry experts, asking targeted questions helps gauge expertise, flexibility, and reliability. Here's your evaluation checklist:

- What materials and thicknesses can you process? Not all services handle the same range. Confirm they work with your specific steel grade in the thickness you need. High-power fiber lasers handle thicker and more reflective materials than traditional CO₂ lasers—understanding their equipment matters

- What level of precision can you achieve? Clarify cutting accuracy and their ability to produce clean edges without burrs. Industries requiring tight tolerances—aerospace, medical devices, automotive—demand providers who can document their precision capabilities

- Do you offer prototyping services? Prototyping allows design validation before committing to full-scale production. This service proves invaluable for fine-tuning specifications. Look for providers offering rapid turnaround—5-day prototyping capabilities indicate serious commitment to supporting product development

- How do you optimize material usage? Efficient nesting reduces waste and costs. Providers with advanced CAD/CAM software position multiple designs on single sheets to maximize yield. Ask about their scrap rates and recycling practices

- What are your turnaround times, and do you offer expedited options? Standard production timelines vary widely. Some providers ship within a day or two for urgent jobs; others require weeks. Understanding their capacity helps you plan realistically

- What file formats do you accept, and can you assist with design modifications? Standard formats include DXF and DWG. Some services work with PDFs or even hand-drawn sketches. If you're uncertain about design compatibility, look for providers offering design review and optimization services

- Do you offer finishing, assembly, or packaging services? Projects requiring deburring, polishing, powder coating, or assembly benefit from one-stop providers. Consolidating services saves coordination time and logistics complexity

- How do you ensure quality control? Quality assurance involves regular inspections and adherence to specifications. Ask about their processes for verifying dimensions, checking material flaws, and ensuring part consistency across production runs

- What experience do you have with similar projects or my industry? A provider familiar with your industry's standards anticipates your needs more effectively. Architectural features differ significantly from automotive components—experience matters

- Do you offer flexible order sizes? Whether you need one-off prototypes or high-volume production, reliable services accommodate your order size. This flexibility ensures you can scale without switching providers

Why DFM Support Adds Genuine Value

Design for Manufacturability—DFM—isn't just a buzzword. According to manufacturing experts, DFM integrates manufacturability factors into designs from the beginning, setting them apart from conventional approaches. The focus? Simplifying, improving, and refining designs to enhance ease of manufacturing.

Why should you care? Consider the benefits DFM provides:

- Cost reduction: Early identification of manufacturing constraints prevents expensive redesigns later

- Faster production: Optimized designs move through fabrication without delays caused by manufacturability issues

- Higher quality: Parts designed for manufacturing processes yield more consistent results

- Reduced waste: Efficient designs minimize scrap material and rework

The DFM process typically takes about two weeks on average, enabling careful examination and modifications. Providers offering comprehensive DFM support—analyzing your designs, suggesting improvements, and catching potential problems—deliver value beyond simple cutting services.

Leading manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this approach, combining DFM expertise with IATF 16949-certified quality systems. Their 12-hour quote turnaround demonstrates how responsive service accelerates project planning—when you're comparing options, quote speed signals overall operational efficiency.

Red Flags When Evaluating Metal Fabricators

Not every steel cutting service delivers what they promise. Watch for these warning signs that suggest potential problems:

Vague capability claims without specifics. Statements like "we can cut anything" without thickness limits, tolerance specifications, or material restrictions suggest either inexperience or unwillingness to set realistic expectations. Quality providers state their capabilities precisely.

No quality certifications or unclear processes. Industries with demanding requirements—automotive, aerospace, medical—rely on certifications like IATF 16949 or ISO 9001 to ensure consistent quality management. Providers without certifications may lack the systematic approaches your project requires.

Slow or unresponsive communication. How quickly do they return calls or emails? If getting a simple answer takes days, imagine coordinating complex production issues. Responsiveness during the sales process typically reflects responsiveness during production.

No design support or file review. Fabricators who simply cut whatever you send—without reviewing files for manufacturability—leave you responsible for problems they could have prevented. Professional services catch issues before they become expensive mistakes.

Unwillingness to discuss equipment or processes. Quality providers happily explain their capabilities. Evasiveness about equipment types, maintenance practices, or quality control procedures raises concerns about what they're hiding.

Quotes that seem too good to be true. Significantly lower pricing often indicates cut corners—inferior materials, inadequate quality control, or hidden fees that appear later. Compare quotes carefully, understanding what's included and excluded.

No references or portfolio of similar work. Established providers can show examples of comparable projects and connect you with satisfied customers. Inability to demonstrate relevant experience suggests you might become their learning opportunity.

The Importance of Quote Turnaround Speed

Here's something many buyers overlook: quote speed matters beyond simple convenience. Fast turnaround indicates several underlying capabilities:

- Organized operations: Providers who return quotes quickly have streamlined internal processes

- Technical competence: Rapid quoting requires quick understanding of project requirements and manufacturing implications

- Adequate capacity: Overwhelmed shops struggle to respond promptly; fast responses suggest manageable workloads

- Customer focus: Prioritizing quote turnaround demonstrates respect for your time and project deadlines

When comparing providers, note how long each takes to respond. A 12-hour quote turnaround—like that offered by specialized manufacturers—sets a benchmark for responsiveness that supports aggressive project timelines.

Making Your Final Selection

Armed with answers to your evaluation questions and awareness of red flags, making an informed decision becomes straightforward. Consider creating a comparison matrix weighing the factors most important to your specific project:

| Evaluation Factor | Weight | Provider A | Provider B | Provider C |

|---|---|---|---|---|

| Equipment capabilities match needs | High | Score 1-5 | Score 1-5 | Score 1-5 |

| Quality certifications | High | Score 1-5 | Score 1-5 | Score 1-5 |

| Turnaround time meets schedule | Medium-High | Score 1-5 | Score 1-5 | Score 1-5 |

| DFM support availability | Medium | Score 1-5 | Score 1-5 | Score 1-5 |

| Communication responsiveness | Medium | Score 1-5 | Score 1-5 | Score 1-5 |

| Pricing competitiveness | Medium | Score 1-5 | Score 1-5 | Score 1-5 |

| Secondary services offered | Low-Medium | Score 1-5 | Score 1-5 | Score 1-5 |

The right steel cutting service becomes a partner in your manufacturing success—not just a vendor processing orders. By asking the right questions, recognizing warning signs, and prioritizing the capabilities that matter most for your applications, you'll build relationships that deliver consistent quality, competitive pricing, and reliable timelines project after project.

Frequently Asked Questions About Steel Cutting Services

1. How much does metal cutting cost?

Steel cutting costs vary based on multiple factors including material type, thickness, cutting method, and quantity. Laser cutting services typically charge $50-$150 per hour, while per-linear-inch costs range from $0.50 to $2 depending on material and method. Quantity dramatically affects pricing—a single part might cost $29, but ordering ten can drop per-unit costs to $3. Setup costs hit small orders hardest since programming, material loading, and machine configuration remain constant regardless of quantity. For accurate pricing, submit production-ready design files specifying material grade, thickness, and required tolerances.

2. Will a hardware store cut metal for you?

Hardware stores like Ace Hardware offer pipe cutting services but generally don't provide precision steel cutting for custom fabrication projects. For precise cuts meeting engineering specifications, professional steel cutting services with CNC-controlled laser, plasma, or waterjet equipment are necessary. These services deliver the accuracy, edge quality, and repeatability that hardware store tools cannot match. If you need many precise cuts or complex geometries, seek out dedicated metal fabrication shops or online cutting services that accept CAD files and provide instant quoting.

3. Will Home Depot cut a piece of metal for me?

Home Depot generally does not offer metal cutting services for custom steel work. While they may help load materials, precise steel cutting requires specialized equipment found at professional fabrication shops. For custom steel cutting needs, online services like SendCutSend, OSH Cut, or Xometry accept DXF and STEP files for instant pricing and deliver precision-cut parts within days. These professional services provide clean edges, tight tolerances, and consistent quality that retail stores cannot offer.

4. What is the typical cost of laser cutting?

Laser cutting services typically charge $50-$150 per hour, with actual costs depending on material type, thickness, and design complexity. Stainless steel parts run approximately 40% more than mild steel equivalents due to material costs. Complex geometries with intricate features can cost three times more than simpler designs. Adding secondary operations like powder coating increases costs by 60% or more. To optimize your budget, simplify geometry where possible, batch similar projects together, and request Design for Manufacturability feedback from your provider.

5. What file formats do steel cutting services accept?

Most steel cutting services accept DXF (Drawing Exchange Format) as the universal standard, along with DWG (AutoCAD), STEP files for 3D geometry, and vector-based PDFs. Avoid mesh formats like STL or OBJ, which break smooth curves into triangles unsuitable for cutting paths. Before submitting files, ensure correct units and 1:1 scale, remove excess annotations, convert text to geometry, close all paths, and eliminate duplicate lines. Production-ready files enable accurate automated quoting and faster turnaround times.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —