Stamping Windshield Wiper Arms: Engineering & Identification Guide

TL;DR

In the context of automotive components, stamping windshield wiper arms refers to two distinct concepts: the high-speed progressive die stamping manufacturing process used to form the metal structure, and the identification codes imprinted on the arm for part verification. Modern manufacturing has largely shifted from metal casting to stamping, allowing for production speeds of up to 60 parts per minute with superior accuracy.

For vehicle owners and restorers, these stamped markings (such as manufacturer logos like Trico, or directional indicators like 55L/55R) are critical for identifying OEM parts and ensuring correct fitment. Whether you are sourcing a manufacturer for mass production or decoding a vintage part number, understanding the stamping process is key.

The Manufacturing Process: Progressive Die Stamping

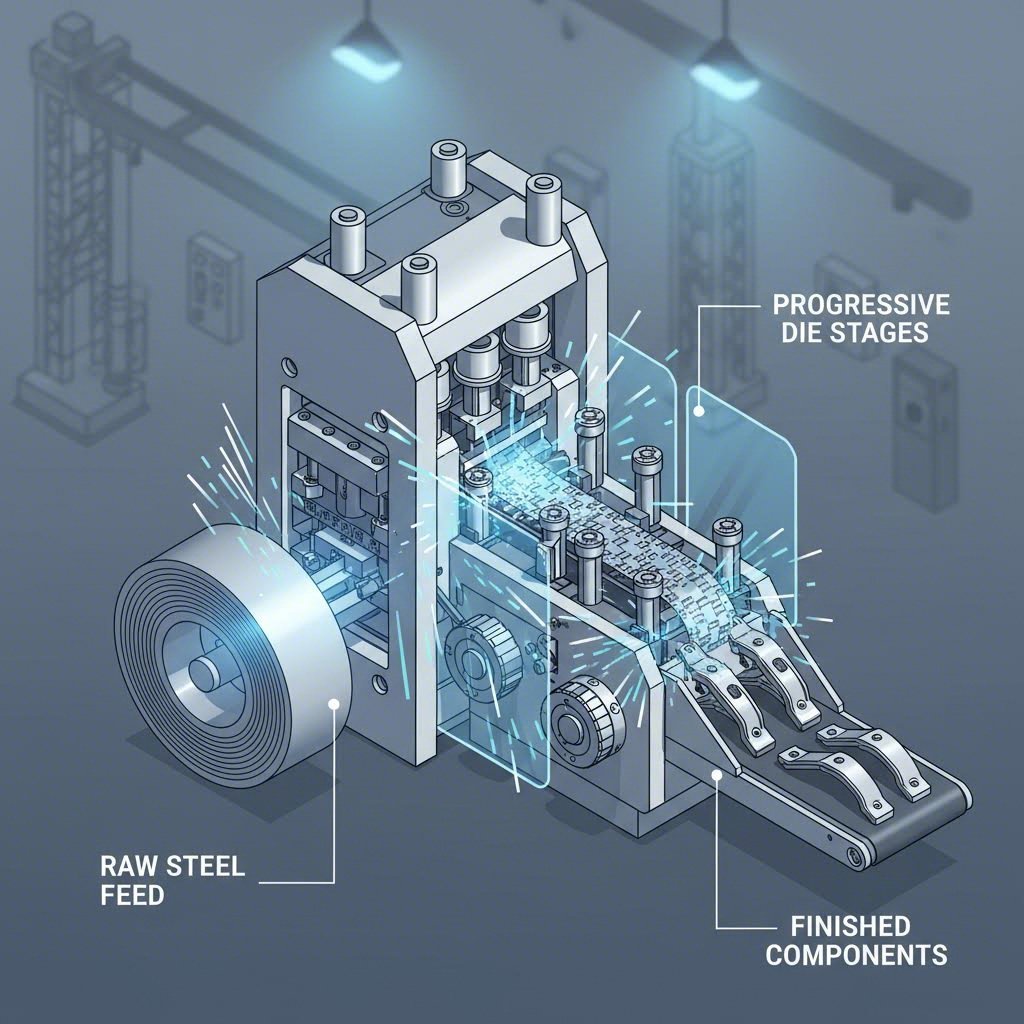

The production of windshield wiper arms has evolved significantly to meet the demands of the automotive industry. Traditionally, many wiper components were produced using metal casting. However, modern engineering has favored progressive die stamping, a method that transforms flat metal coils into complex, durable shapes in a continuous sequence.

This shift offers substantial efficiency gains. According to industry case studies, such as those by Penne, transitioning to progressive die stamping allows manufacturers to produce up to 60 wiper arms per minute. Unlike casting, which often requires secondary machining to remove excess material or smooth rough edges, stamped parts emerge from the press largely finished. The process involves feeding galvanized steel or aluminum strips into a press where a series of dies cut, bend, and form the metal brackets and channels with micron-level precision.

For automotive OEMs requiring this level of throughput and precision, selecting a partner with robust capabilities is essential. Shaoyi Metal Technology’s comprehensive stamping solutions bridge the gap from rapid prototyping to high-volume manufacturing, leveraging IATF 16949-certified precision and press capabilities up to 600 tons to deliver critical components that meet strict global standards. High-tonnage presses ensure that even thick-gauge steel used for heavy-duty wiper arms maintains structural integrity without metal fatigue.

Deciphering Wiper Arm Stamps: Codes & Identification

For enthusiasts and mechanics, the term "stamping" often refers to the alphanumeric codes pressed into the metal arm. These stamps are not merely decorative; they serve as the primary means of identification for fitment and authenticity, especially in classic car restoration.

The most common stampings indicate the manufacturer and the installation side. For instance, classic vehicle communities often reference specific codes like "55L" (Left/Driver side) and "55R" (Right/Passenger side) found on the underside of the arm. Identifying these marks is crucial because left and right wiper arms often have subtle differences in angles or lengths that are indistinguishable to the naked eye but critical for wiping performance.

Furthermore, original equipment manufacturer (OEM) arms, such as those made by Trico, often feature Trico patent stampings or specific date codes. These markings differentiate genuine OEM parts from generic aftermarket replacements, which typically lack detailed stamping or use simplified part numbers. When sourcing replacements, verify that the stamped "bayonet" or "hook" connection matches your vehicle's specifications to avoid mechanical failure.

Surface Finishing: Painting & Corrosion Protection

Raw stamped steel is highly susceptible to corrosion, necessitating rigorous surface finishing immediately after formation. In an industrial setting, wiper arms typically undergo Electro-coating (E-coat) or powder coating to provide a durable, weather-resistant barrier. This finish must withstand constant UV exposure, moisture, and road salts without peeling.

For DIY restorers, maintaining this finish is a common challenge. Over time, the original coating may fade or chip, leading to rust, particularly around the stamped hinge areas. To refinish a stamped wiper arm effectively, you must remove the old paint without sanding away the identification codes. Use a fine-grit sandpaper (around 400-600 grit) to scuff the surface, then clean it thoroughly with a solvent.

Applying a high-quality semi-gloss or satin black paint is the industry standard for restoring the factory look. Avoid heavy coats that could clog the stamped numbers or the spring mechanism. Detailed tutorials on platforms like GM-Trucks.com emphasize the importance of preparation—failing to remove rust from the stamped crevices will result in the new paint bubbling within months.

Troubleshooting & Maintenance of Stamped Arms

While stamped metal arms are robust, they are not immune to mechanical issues. The most common point of failure occurs at the splines—the stamped grooves inside the mounting hole that grip the wiper transmission post. If a wiper arm is forced or installed without proper torque, these soft metal splines can strip, causing the arm to slip and fail to move the blade, even if the motor is turning.

Another issue is physical deformation. Because stamped steel has a "memory," a bent arm can sometimes be corrected, but it requires careful manipulation. Using two wrenches to twist the arm back into alignment can fix "chatter" (where the blade skips across the glass), but excessive force can snap the metal or weaken the spring tension. If the internal spring—often anchored to a stamped tab—loses tension, the blade will not apply enough pressure to the windshield, rendering it ineffective regardless of how new the rubber blade is.

Final Thoughts on Wiper Arm Stamping

Understanding the dual nature of stamping—as both a high-precision manufacturing method and a vital identification system—empowers both engineers and vehicle owners. For manufacturers, the transition to progressive die stamping represents a leap in efficiency and consistency. For consumers, learning to read the stamped codes on a wiper arm can mean the difference between a perfect restoration and a frustrating fitment issue. Whether you are specifying a production run or restoring a classic, the details stamped into the metal tell the full story of the part's origin and function.

Frequently Asked Questions

1. Can you powder coat wiper arms?

Yes, powder coating is an excellent option for wiper arms as it provides a thicker, more durable finish than standard spray paint. It is highly resistant to chipping and UV damage. However, you must ensure that the coating does not interfere with the pivot hinge or fill in the mounting splines, which could prevent the arm from fitting correctly on the vehicle.

2. How do I identify my wiper arm type?

To identify your wiper arm, look for stamped alphanumeric codes on the underside or base of the arm. Codes ending in "L" or "R" typically indicate Left or Right placement. Additionally, examine the connection point where the blade attaches; common stamped styles include "Hook," "Bayonet," or "Side Pin." Comparing these stamps to OEM diagrams is the most reliable method.

3. What is the difference between stamped and cast wiper arms?

Stamped wiper arms are formed from sheet metal using high-tonnage presses, resulting in a lighter, more uniform part with a smooth surface finish. Cast arms are made by pouring molten metal into a mold, which can result in a heavier, more brittle component that may require more post-processing to smooth out seams and imperfections.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —