Stamping Radiator Supports: Manufacturing Specs & Restoration Secrets

TL;DR

Stamping radiator supports involves two distinct categories: the industrial manufacturing process of forming heavy-gauge metal into structural vehicle frames, and the selection of these parts for automotive restoration or performance. In the manufacturing sector, this process utilizes high-tonnage presses (often 600–800 tons) to shape materials like 0.250-inch aluminum or steel with precision tolerances as tight as +/- 0.010 inches. For car enthusiasts, the choice lies between OEM-style stamped steel supports, which offer factory rigidity and authenticity, and aftermarket tubular versions designed for weight reduction in racing applications. Whether you are engineering a Class 8 truck assembly or restoring a classic Mustang, understanding the mechanics of stamping and date code identification is critical for ensuring structural integrity and vehicle value.

The Manufacturing Mechanics: How Radiator Supports Are Stamped

The production of a radiator core support is a feat of heavy industrial engineering. Unlike simple body panels, these supports are structural components that must bear the weight of the radiator, condenser, and often the front-end sheet metal, while maintaining rigid alignment for the hood and fenders. The process begins with material selection, typically high-strength steel or thick-gauge aluminum. For instance, in heavy-duty applications like Class 8 trucks, manufacturers may use 0.250-inch thick aluminum to balance strength with weight.

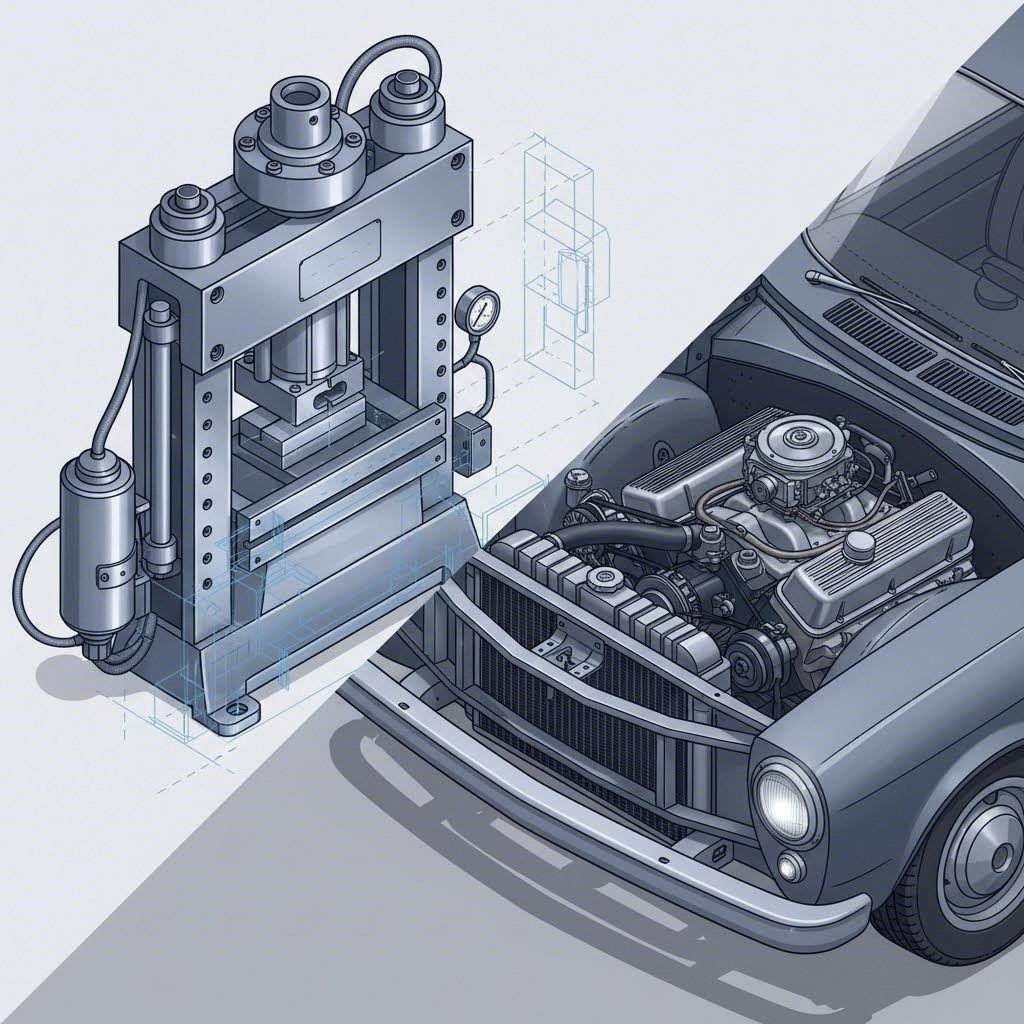

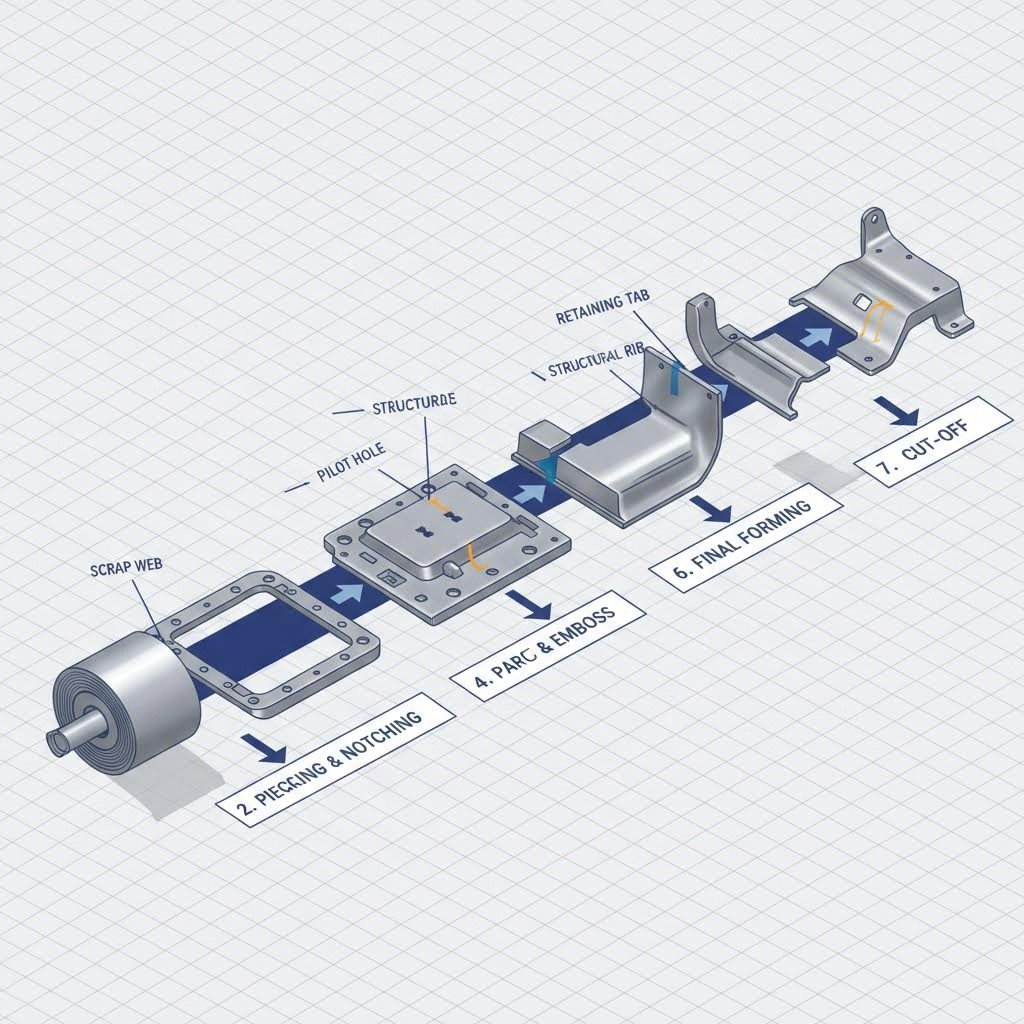

To form these robust materials, manufacturers employ massive hydraulic or mechanical presses. Data from industry specialists like Aranda Tooling highlights the use of 800-ton presses to stamp radiator frame assemblies. The process often involves progressive die stamping, where a continuous strip of metal is fed through multiple stations. Each station performs a specific cut, bend, or punch, gradually shaping the flat sheet into a complex three-dimensional frame. This method ensures high repeatability and efficiency, capable of producing volumes upwards of 15,000 units annually.

Precision is non-negotiable in this sector. A radiator support is not just a bracket; it is a reference point for the entire front end of the vehicle. Leading manufacturers adhere to strict quality control standards, maintaining tolerances as tight as +/- 0.010 inches. This level of accuracy is achieved through advanced tooling and secondary operations, such as robotic welding, to assemble multiple stamped components into a single, cohesive unit. For automotive entities seeking to bridge the gap between rapid prototyping and high-volume manufacturing, Shaoyi Metal Technology offers IATF 16949-certified precision. With press capabilities up to 600 tons—comparable to major industry standards—they deliver critical structural components like control arms and subframes while adhering to global OEM specifications.

Companies like Regal Metal Products also utilize large bed sizes (up to 60” x 168”) to accommodate the substantial footprint of automotive core supports. These capabilities allow for the production of single-piece stampings or complex assemblies that integrate mounting points for suspension and cooling systems, ensuring the part meets the rigorous demands of modern automotive assembly lines.

Stamped Steel vs. Tubular Supports: A Performance Comparison

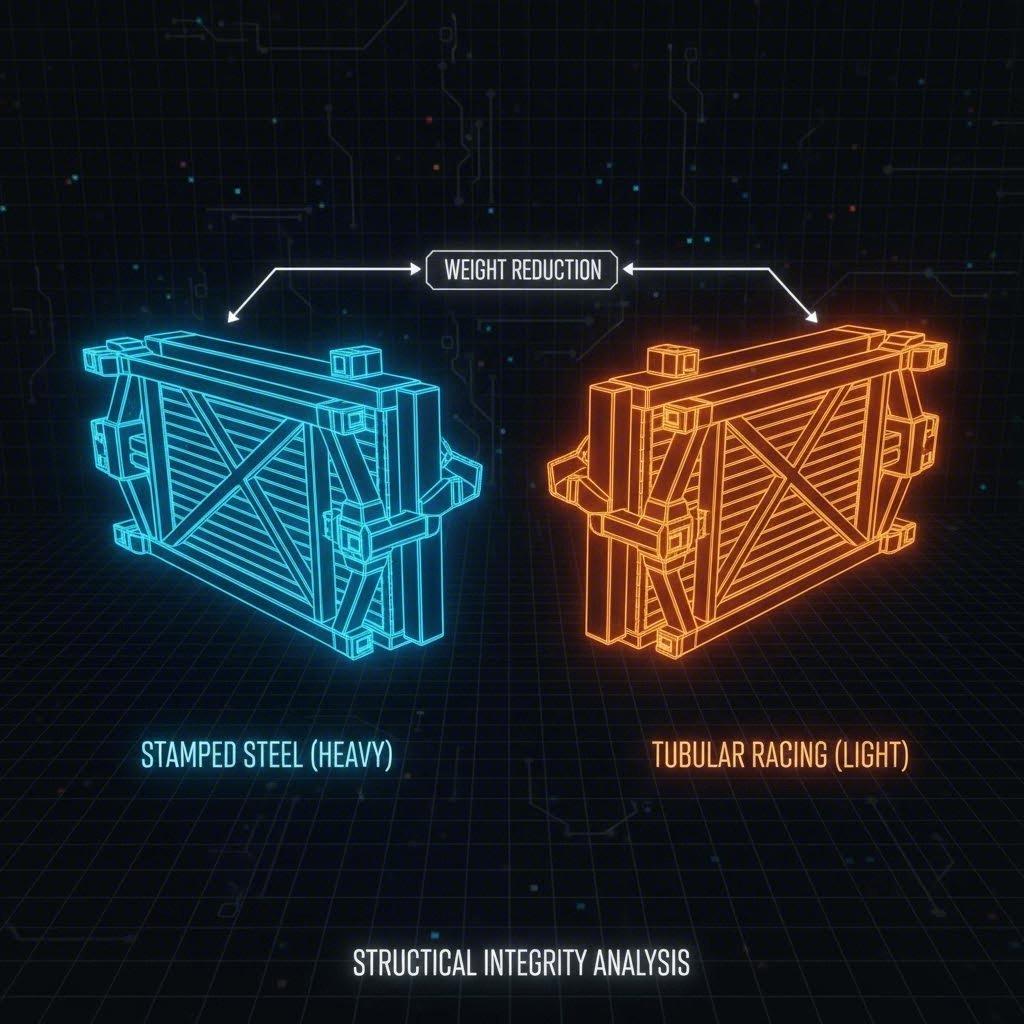

For the automotive enthusiast, the term "stamping radiator supports" often signals a decision point: should you stick with the factory stamped steel part or upgrade to a tubular alternative? This choice fundamentally alters the vehicle's character, affecting everything from weight distribution to cooling efficiency.

OEM Stamped Steel Supports are the standard for restoration and street cars. Manufactured using the heavy press methods described above, these parts are designed to flex and absorb energy during a crash, protecting the chassis. They offer factory-correct fitment, pre-drilled holes for wiring harnesses, and mounting points for stock accessories like windshield washer bottles and horns. However, they are heavy and can restrict airflow to the radiator due to their bulky, solid construction.

Tubular and Chromoly Supports, such as those from Rhodes Custom Auto, are the preferred choice for drag racing and track applications. Fabricated from lightweight tubing (often 4130 Chromoly), these supports can shed significant weight—often saving 10 to 20 pounds off the nose of the car where it matters most. Their open design maximizes airflow to the radiator, a critical benefit for high-performance engines. The trade-off is often rigidity in daily driving scenarios and a lack of mounting points for stock accessories, making them less ideal for a fully equipped street car.

| Feature | OEM Stamped Steel | Aftermarket Tubular / Chromoly |

|---|---|---|

| Primary Use | Restoration, Daily Driving, Collision Repair | Drag Racing, Track Day, Pro-Touring |

| Material | Stamped Sheet Metal (Steel/Aluminum) | Welded Tubing (Mild Steel or Chromoly) |

| Weight | Heavy (Standard Factory Weight) | Lightweight (10-20 lbs savings) |

| Airflow | Restricted (Solid panels block air) | Maximum (Open design) |

| Fitment | Direct Bolt-on with Factory Accessories | May require modification for accessories |

Restoration & Authenticity: Decoding Radiator Support Date Stamps

In the world of classic car restoration, particularly for Mustangs, Chevelles, and Camaros, the stamped radiator support holds the key to verification. Authenticity judges and serious collectors look for specific date stamps and manufacturer codes to determine if a car retains its original sheet metal or if it has been repaired with service parts.

On vehicles like the classic Ford Mustang, the date stamp is notoriously difficult to find but vital for concours judging. Enthusiasts on the Concours Mustang Forum note that these stamps are often located below the battery tray or behind the lateral brace. A typical production line stamp might read as a date code (e.g., "4/14/64"), aligning with the vehicle's build date. However, discrepancies here are red flags. A stamp that reads "A 62" or similar non-date formats often indicates a Service Replacement Part—a component installed by a dealer or body shop after an accident, rather than on the factory assembly line.

Decoding these stamps requires a keen eye. For Chevrolet restorations, date codes may appear on the top plate near the hood latch or on the engine side of the support. The format usually follows a Month/Week/Day structure. Beyond the characters themselves, the method of attachment is a tell-tale sign. Factory supports were typically spot-welded with high-amperage industrial resistance welders, leaving small, precise dimples. Replacement supports are often plug-welded (MIG welded through drilled holes), a clear visual indicator that the "stamping radiator supports" history of that vehicle includes a collision repair.

Installation & Alignment Challenges

Replacing a stamped radiator support is not a simple bolt-on affair; it is a structural surgery that determines the alignment of the entire front clip. Because the support ties the left and right inner fenders together, it dictates the squareness of the engine bay. A common issue with aftermarket stamped replacements is slight dimensional variance. Even a deviation of a few millimeters can result in poor hood gaps or fender misalignment.

Successful installation begins with preparation. Most replacement stamped supports arrive in a black EDP (Electro-Deposit Primer) coating. While this prevents rust during shipping, it must be scuffed or removed at weld points to ensure proper adhesion. Experienced restorers recommend "dry fitting" the entire front end—fenders, hood, and grille—before fully welding the new support in place. This allows for adjustments to be made to the mounting holes or shims to be added.

For those repairing a vintage vehicle, preserving the original VIN stamp (often found on the radiator support in certain models) is a legal and value-critical consideration. If the support is rusted but the stamped area is intact, some restorers opt to graft the original stamped section into the new support, though this requires expert metal finishing skills to remain undetectable.

FAQ

1. Can you drive without a radiator support?

No, it is highly unsafe and mechanically risky to drive without a radiator support. The component does more than just hold the radiator; it provides structural rigidity to the front of the vehicle, tying the frame rails and inner fenders together. Without it, the front end can flex significantly, leading to misalignment of body panels and potential hood latch failure. Furthermore, the radiator would have no secure mounting, causing it to vibrate, damage cooling lines, and eventually lead to catastrophic overheating or engine damage.

2. What kind of solder is used on radiator repairs?

When repairing brass or copper radiators often found in vehicles with older stamped supports, specific lead-tin solders are standard. Common compositions include 40/60 (40% tin, 60% lead) or 30/70. However, precision is key; as noted in industry discussions, excessive heat or improper material can weaken the core. Modern aluminum radiators with plastic tanks, which pair with newer stamped supports, generally cannot be soldered and typically require core replacement or epoxy patches for temporary fixes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —