Stamping Fuel Filler Doors: Manufacturing Process & Sourcing Guide

TL;DR

Stamping fuel filler doors is a high-precision automotive manufacturing process that typically utilizes progressive die technology to transform flat metal coils into complex, deep-drawn assemblies. This process ensures consistent Class A surface finishes, which are critical for maintaining the cosmetic integrity of a vehicle's exterior while providing functional access to the fuel system. Manufacturers primarily use deep-drawing quality (DDQ) steel, stainless steel, or aluminum to balance durability with corrosion resistance.

For automotive engineers and sourcing managers, the key challenges involve managing material flow during the deep drawing of the fuel bowl to prevent tearing and ensuring tight tolerances for flush fitment against the body panel. Whether for high-volume OEM production or specialized aftermarket restoration, success depends on selecting a stamping partner with the right press capacity and engineering expertise to handle complex geometries.

The Manufacturing Process: Progressive Die Stamping

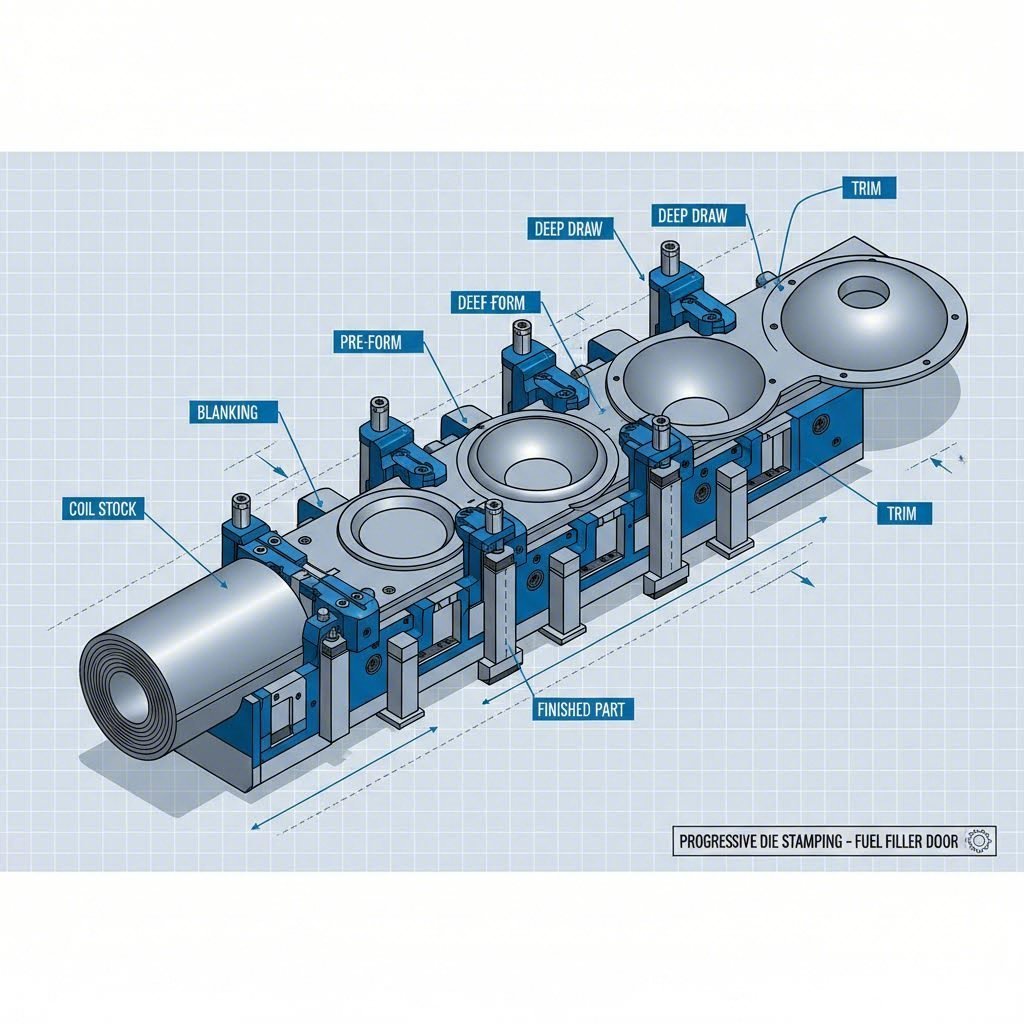

The most efficient method for mass-producing fuel filler doors is progressive die stamping. Unlike transfer dies that move parts between separate stations, a progressive die feeds a continuous strip of metal through a single press containing multiple stations. Each station performs a specific operation on the metal as it moves forward, resulting in a finished part at the end of the line. This method is essential for achieving the high production speeds required by the automotive industry while maintaining strict dimensional repeatability.

The process generally follows a precise sequence of operations tailored to the fuel door's design:

- Blanking: The outer perimeter of the door skin or inner housing is cut from the coil strip.

- Deep Drawing: This is the most critical step for the fuel bowl (the recessed area). A punch forces the metal into a die cavity to create the cup shape. Manufacturers must carefully control the clearance and lubrication to prevent the metal from thinning excessively or tearing.

- Piercing and Trimming: Excess material is removed, and mounting holes for the hinge mechanism, drain tubes, and filler neck are punched with high precision.

- Hemming: For the outer door skin, the edges are often folded over an inner reinforcement panel. This "hemming" process creates a smooth, safe edge and adds structural rigidity to the assembly.

To handle these operations, manufacturers often employ presses with capacities ranging from 400 to 800 tons. High-tonnage presses are necessary to apply the immense force required for deep drawing steel or stainless steel without spring-back issues.

Material Selection & Specifications

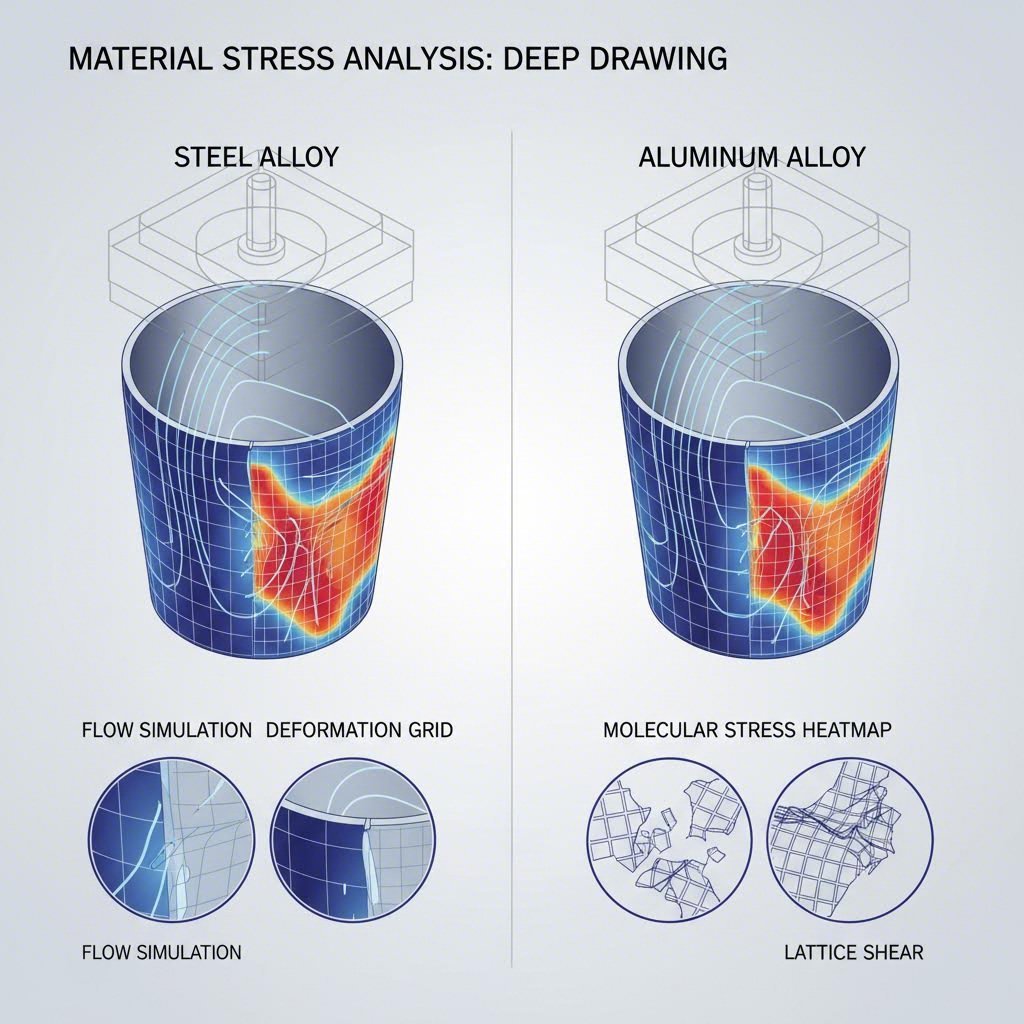

Choosing the right material is a balancing act between formability, strength, and corrosion resistance. Since fuel filler doors are exposed to both the elements and potential fuel spills, the material must withstand harsh conditions without degrading.

Carbon Steel (Deep Drawing Quality)

For standard OEM applications where the part will be painted, Cold Rolled Carbon Steel is the industry standard. Engineers specify "Deep Drawing Quality" (DDQ) or "Extra Deep Drawing Quality" (EDDQ) grades. These steels have high ductility, allowing them to be stretched into the deep recess of a fuel bowl without splitting. They are typically galvanized or given an electro-deposition primer (E-coat) immediately after stamping to prevent rust.

Stainless Steel

For resto-mod projects or exposed metal applications, stamped stainless steel is often the material of choice. Grades like 304 Stainless Steel offer excellent natural corrosion resistance. However, stainless steel work-hardens rapidly, requiring higher press forces and more durable tooling materials (such as carbide inserts) to prevent die wear.

Aluminum

In modern lightweight vehicles, aluminum alloys (such as 5000 or 6000 series) are increasingly used to reduce weight. Stamping aluminum presents unique challenges, as it has less formability than steel and is more prone to cracking. It often requires specific lubricants and sometimes warm forming techniques to achieve the desired depth.

Design & Engineering Challenges

Stamping a fuel filler door is not just about cutting metal; it requires overcoming significant engineering hurdles related to geometry and assembly. The primary challenge is the compound curve. Most vehicle bodies are not flat; they have subtle curvatures. The fuel door must match this curvature perfectly to sit flush with the quarter panel. If the stamping die does not account for spring-back (the metal's tendency to return to its original shape), the door will not align, creating unsightly gaps.

Deep Drawing the Bowl: Creating the recessed bucket that holds the gas cap involves severe plastic deformation. If the draw ratio (depth vs. diameter) is too aggressive, the metal will tear. Engineers use simulation software to optimize the die design, adding radii and controlling material flow to ensure a uniform wall thickness.

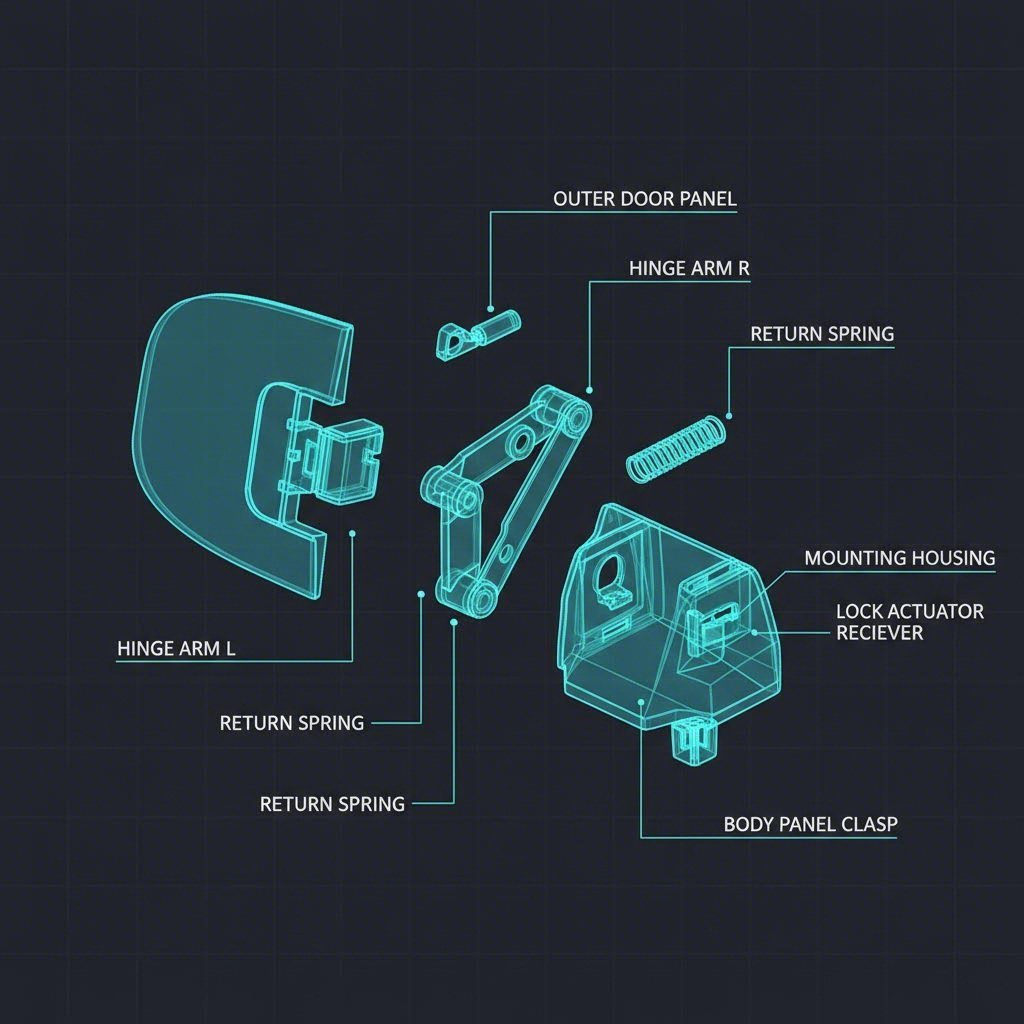

Assembly Integration: A complete fuel door is rarely a single stamped part. It is an assembly of the outer skin, the inner hinge arm, the spring mechanism, and the housing bowl. Fuel door assemblies often require secondary operations like spot welding or clinching to join these components. The hinge mechanism must be robust enough to withstand thousands of cycles while maintaining the door's alignment.

Sourcing & Quality Standards

When sourcing stamped fuel doors, quality is measured by fitment and finish. For OEM parts, the standard is "Class A," meaning the surface must be free of any visual defects like ripples, dings, or die marks, as these will show through the paint. For B2B buyers, evaluating a supplier's capability involves inspecting their tooling maintenance programs and quality control certifications.

OEM vs. Aftermarket: OEM suppliers are set up for massive volumes (tens of thousands of units) and rely on automated progressive dies. In contrast, the aftermarket and restoration sector—such as those looking for weld-in fuel doors for custom trucks—often relies on lower-volume production methods or repurposed parts. The precision in aftermarket parts can vary, making it crucial to verify the gauge of the steel and the accuracy of the mounting points.

If you are bridging the gap between prototype validation and mass manufacturing, consider partnering with a specialized fabrication firm. Shaoyi Metal Technology offers comprehensive stamping solutions backed by IATF 16949 certification. With press capabilities up to 600 tons, they can handle the demanding deep-draw requirements of fuel door components while offering the flexibility to scale from 50 prototype units to millions of production parts.

Key Quality Metrics for Buyers:

- Flushness: The door must sit perfectly even with the surrounding body panel (typically within ±0.5mm).

- Gap Consistency: The gap around the door perimeter must be uniform.

- Burr-Free Edges: All stamped edges must be deburred to prevent injury during assembly and ensure paint adhesion.

Precision in Every Detail

The humble fuel filler door represents a convergence of aesthetic design and mechanical engineering. Achieving a seamless look requires mastery of progressive die stamping and a deep understanding of material science. For manufacturers, the goal is repeatability and efficiency; for vehicle owners, it is durability and seamless integration.

Whether you are engineering the next generation of electric vehicle charging ports or restoring a classic truck with a custom fuel bowl, the quality of the stamping determines the final result. By prioritizing high-grade materials and precise tooling, manufacturers ensure that this functional component enhances rather than detracts from the vehicle's design.

Frequently Asked Questions

1. How much does a replacement fuel door cost?

The cost varies significantly based on the vehicle and material. A standard aftermarket stamped steel replacement door can range from $20 to $90. Specialized restoration parts, such as stainless steel recessed bowls or custom weld-in assemblies, may cost more due to the lower production volumes and higher material costs.

2. What is the difference between a fuel door and a fuel bowl?

The fuel door is the exterior hinged cover that matches the vehicle's bodywork. The fuel bowl (or housing) is the deep-drawn recessed pocket behind the door that houses the filler neck and gas cap. In many modern assemblies, these are integrated into a single unit, but in restoration projects, they are often purchased and installed separately.

3. Are locking fuel doors necessary?

While modern vehicles often include remote-release locking mechanisms integrated into the latch, older vehicles or custom builds may benefit from locking fuel caps or doors. If security is a concern, investing in a locking mechanism is a cost-effective way to prevent fuel siphoning and tampering.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —