Stamping Suspension Subframes: Manufacturing & Performance Guide

TL;DR

Stamping suspension subframes describes the automotive manufacturing process where high-tonnage presses form steel sheets into structural chassis components. Unlike tubular or hydroformed alternatives, stamped subframes typically utilize a "clamshell" design—two stamped halves welded together—to balance cost-efficiency with structural rigidity for mass-produced vehicles.

This method allows OEMs to employ High-Strength Low-Alloy (HSLA) steels to reduce weight while maintaining the crash safety and torsional stiffness required for modern suspension geometry. For engineers and sourcing professionals, understanding the trade-offs between stamping, hydroforming, and aluminum extrusion is critical for optimizing vehicle dynamics and production budgets.

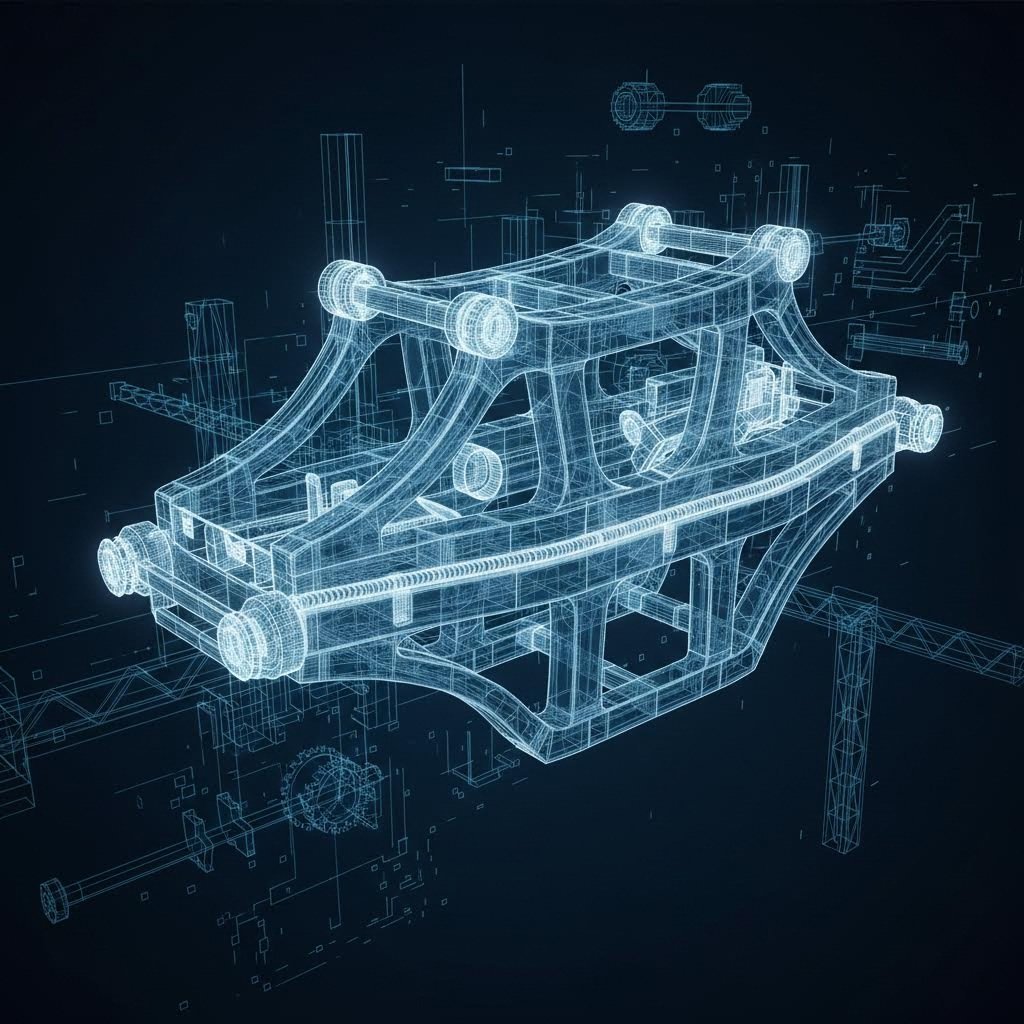

The Engineering Behind Stamped Subframes

The manufacturing of stamped subframes is a triumph of precision metalforming, bridging raw material science with high-volume industrial capability. The process begins with coiled steel, which is fed into large-scale presses—often rated between 600 and 3,000 tons—equipped with progressive or transfer dies. These dies cut, bend, and shape the metal in sequential stages to achieve complex geometries that simple tubing cannot replicate.

In modern automotive applications, the shift from mild steel to High-Strength Low-Alloy (HSLA) and Advanced High-Strength Steels (AHSS) has revolutionized stamped designs. By using materials with higher tensile strength (often exceeding 590 MPa), manufacturers can utilize thinner gauge sheets to reduce mass without compromising the subframe's structural integrity. This "lightweighting" strategy is essential for meeting fuel economy standards and compensating for the added weight of EV battery packs.

However, stamping AHSS introduces challenges such as "springback"—the tendency of metal to return to its original shape after forming. To mitigate this, manufacturers like F&P America utilize advanced simulation software and specialized die coatings to ensure dimensional accuracy. Furthermore, the stamping process must accommodate subsequent assembly steps; the stamped halves are typically joined via robotic MIG or spot welding to form a rigid box section, followed by E-coating for corrosion resistance.

For companies seeking to navigate these complexities—from initial prototyping to mass production—partners like Shaoyi Metal Technology offer critical expertise. Their capabilities in IATF 16949-certified precision stamping (up to 600 tons) bridge the gap between low-volume validation and high-volume delivery for components like control arms and subframes. You can verify their engineering specifications at Shaoyi Metal Technology to see how they align with global OEM standards.

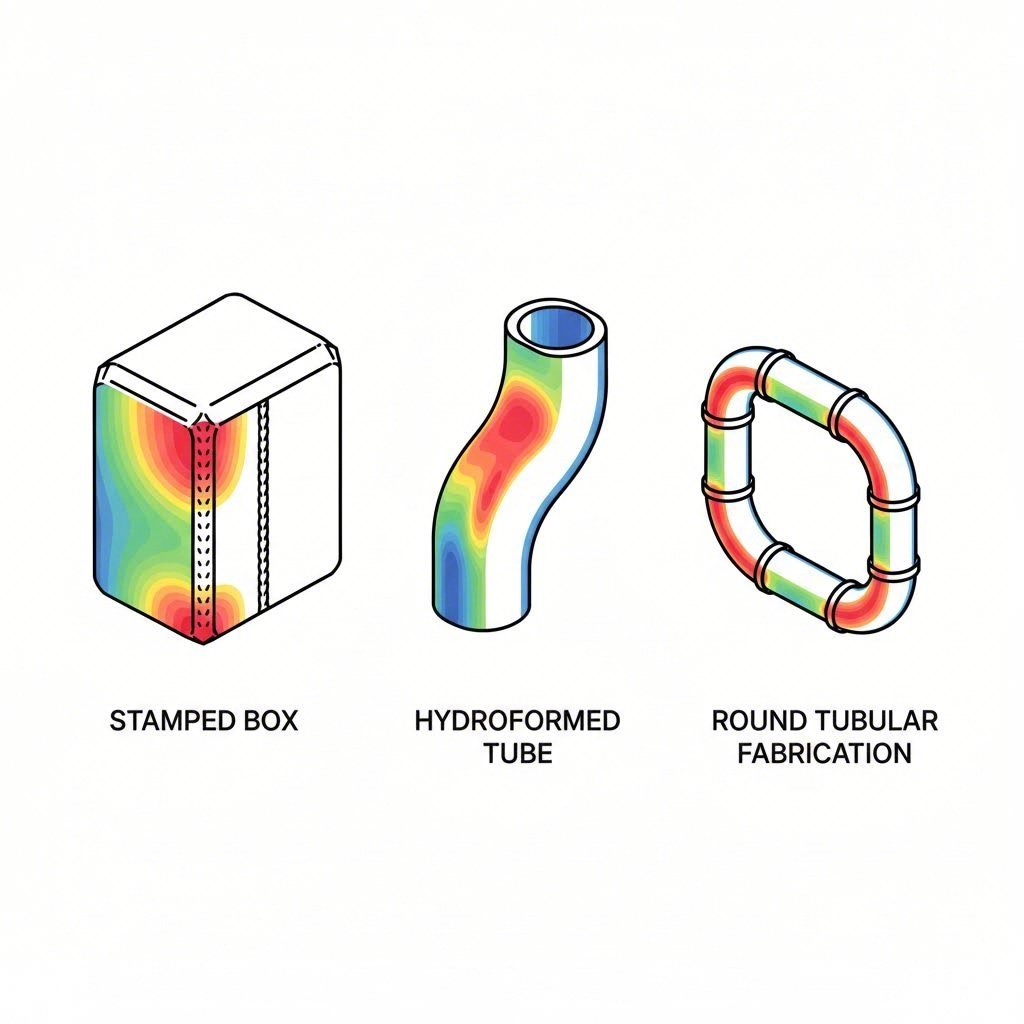

Stamped vs. Hydroformed vs. Tubular: A Technical Comparison

Choosing the right subframe construction impacts everything from vehicle handling to manufacturing costs. While stamping is the king of mass production, hydroforming and tubular fabrication hold specific advantages for performance applications.

| Feature | Stamped Steel (OEM Standard) | Hydroformed Steel | Tubular / Fabricated |

|---|---|---|---|

| Manufacturing Process | Sheet metal pressed in dies, then welded (Clamshell) | Seamless tube expanded by fluid pressure | Cut tubes welded together manually or robotically |

| Rigidity & Stiffness | High (dependent on weld quality) | Very High (seamless rails, work-hardened) | Variable (design dependent, often less rigid than OEM) |

| Weight | Moderate (thinner with HSLA) | Moderate to Heavy (thick walls) | Lightest (Chromoly/DOM tubing) |

| Tooling Cost | Very High (expensive dies) | High (specialized molds) | Low (jigs and fixtures) |

| Piece Price | Lowest (at high volume) | Moderate | Highest (labor intensive) |

Stamped Subframes dominate the OEM market because they offer the lowest piece price at high volumes. The ability to stamp complex mounting points and pockets directly into the shell reduces the need for external brackets. However, the reliance on long weld seams creates potential fatigue points and heat-affected zones that must be carefully managed.

Hydroformed Subframes, such as those engineered by Detroit Speed, utilize fluid pressure to shape steel tubes without the heat of welding. This results in a seamless rail with superior dimensional accuracy and structural efficiency. Interestingly, even high-end hydroformed assemblies often utilize stamped cross-members to tie the rails together, creating a hybrid design that leverages the best of both worlds—seamless strength for the rails and stamped rigidity for the connectors.

Material Innovation: Steel vs. Aluminum

The battle for chassis supremacy is no longer just about geometry, but metallurgy. While stamped steel remains the standard, aluminum is encroaching on the subframe market, particularly in premium and electric vehicles. According to the Aluminum Extruders Council, replacing a stamped steel subframe with an aluminum extrusion design can yield a weight reduction of up to 35%.

Aluminum offers distinct advantages beyond weight. It forms a natural oxide layer that resists corrosion, whereas stamped steel requires aggressive zinc-nickel coatings or E-coat to survive harsh road salts. Additionally, aluminum tooling for extrusions can be significantly cheaper—sometimes up to 1,000% less—than the massive dies required for steel stamping. This makes aluminum attractive for lower-volume models or mid-cycle refreshes where capital investment is limited.

However, steel fights back with cost and packaging efficiency. Advanced stamping lubricants, as noted by IRMCO, enable the forming of ultra-high-strength steels that approach the weight-to-strength ratio of aluminum at a fraction of the raw material cost. Moreover, hybrid designs are emerging where stamped steel shells are joined with cast aluminum corners, optimizing the material properties for specific load paths.

Applications & Performance Impact

The impact of a subframe extends far beyond holding the engine; it is a primary determinant of NVH (Noise, Vibration, and Harshness) and suspension geometry. Stamped subframes are particularly effective at managing NVH because their hollow, box-like structures can be tuned to dampen specific frequencies, preventing road noise from entering the cabin.

In performance applications, rigidity is paramount. A flexing subframe allows suspension pickup points to migrate under load, causing unpredictable handling. This is why aftermarket upgrades often replace factory stamped units with reinforced tubular or hydroformed versions. However, for 99% of road vehicles, the European Aluminium industry data suggests that a well-engineered stamped or hybrid subframe provides the optimal balance of crash energy management (crumple zones) and cabin comfort.

Durability is also a key differentiator. Stamped subframes can be prone to internal rust if drainage is poor, as water collects inside the "clamshell." Regular inspection of the weld seams and E-coat integrity is vital, especially in regions using road salt. In contrast, seamless hydroformed or extruded designs have fewer crevices for corrosion to initiate, potentially offering a longer service life in corrosive environments.

Optimizing Chassis Strategy

The choice between stamping, hydroforming, and extrusion is rarely binary; it is a strategic calculation involving volume, budget, and performance targets. For mass-market vehicles, stamping suspension subframes remains the undefeated champion of cost-efficiency and structural integration. As steel technology evolves, we can expect stamped components to become thinner, stronger, and more intricate, maintaining their dominance in the automotive chassis hierarchy.

Frequently Asked Questions

1. Is a subframe considered part of the suspension?

Yes, the subframe is a critical interface in the suspension system. It acts as the structural foundation that connects the control arms, steering rack, and engine to the main unibody of the vehicle. By isolating these components on a subframe (often with rubber bushings), manufacturers can significantly reduce vibration and improve ride quality.

2. Can a rusted stamped subframe be repaired?

Generally, surface rust can be treated, but structural rot on a stamped subframe is often terminal. Because these subframes are constructed from thin sheets of high-strength steel welded together, extensive corrosion compromises their ability to handle suspension loads and crash forces. Replacement is usually the safer and more cost-effective option compared to attempting complex weld repairs on fatigued metal.

3. Why do OEMs prefer stamping over tubular fabrication?

OEMs prioritize cycle time and consistency. A stamping press can produce a subframe part every few seconds with perfect repeatability, whereas tubular fabrication involves cutting, bending, and coping tubes followed by time-consuming welding. While tubular frames are excellent for low-volume performance cars, they cannot match the production speed or per-unit cost efficiency of stamping for millions of vehicles.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —