Press Hardening Steel Properties: Technical Guide to Strength & Formability

TL;DR

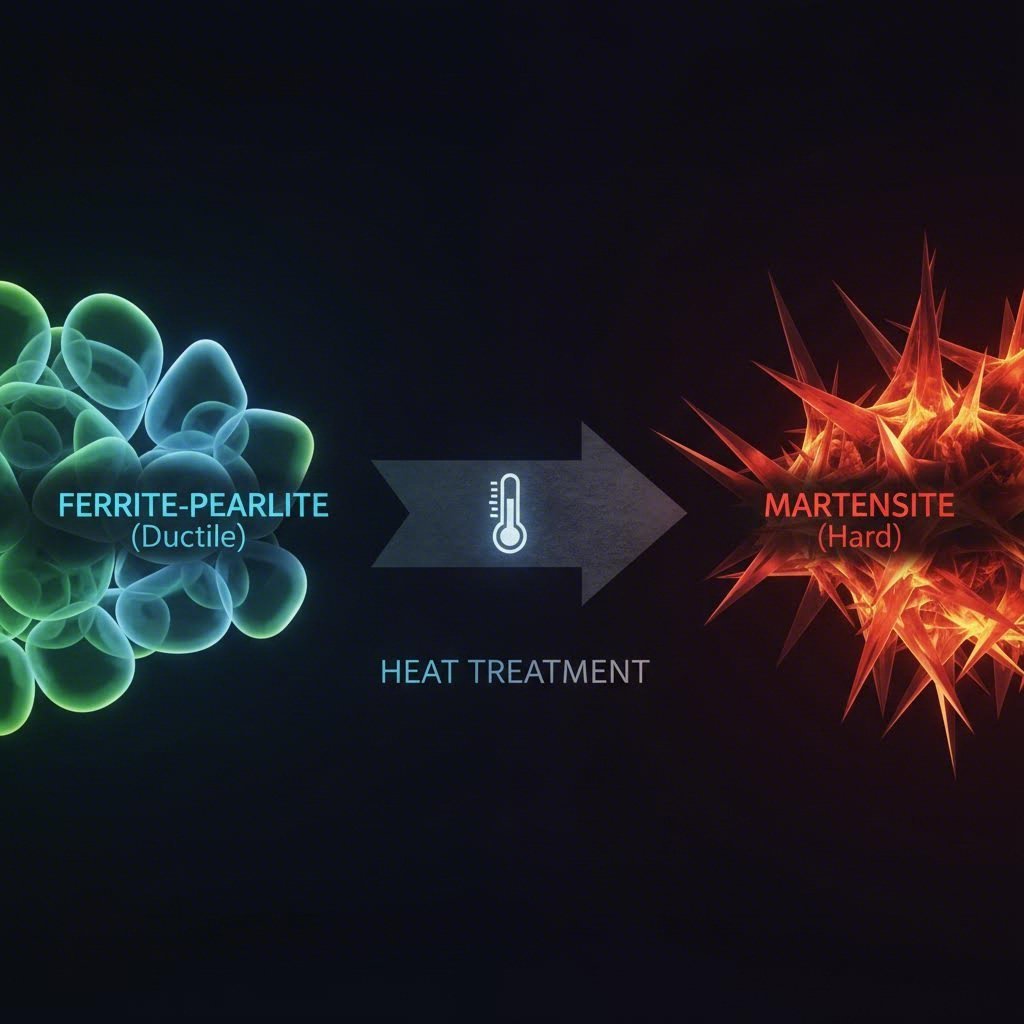

Press Hardening Steel (PHS), also known as hot-stamped or boron steel, is an ultra-high-strength alloy (typically 22MnB5) designed for automotive safety components. It is supplied in a malleable ferritic-pearlitic state (yield strength ~300–600 MPa) but transforms into an exceptionally hard martensitic structure (tensile strength 1300–2000 MPa) after being heated to ~900°C and quenched in a cooled die. This process eliminates springback, allows for complex geometries, and enables significant weight reduction in critical crash structures like A-pillars and bumpers.

What Is Press Hardening Steel (PHS)?

Press hardening steel (PHS), frequently referred to in the automotive industry as hot-stamped steel or hot-formed steel, represents a category of boron-alloyed steels that undergo a specialized thermal and mechanical forming process. Unlike conventional cold-stamped steels that are formed at room temperature, PHS is heated until it reaches an austenitic state and is then formed and quenched simultaneously within a cooled tool.

The standard grade for this process is 22MnB5, a carbon-manganese-boron alloy. The addition of boron (typically 0.002–0.005%) is critical as it drastically improves the steel's hardenability, ensuring that a fully martensitic microstructure can be achieved even at moderate cooling rates. Without boron, the material might transform into softer phases like bainite or pearlite during the quenching phase, failing to reach the target strength.

The fundamental transformation that gives PHS its value is microstructural. Delivered as a soft ferritic-pearlitic sheet, the material is easy to cut and handle. During the hot stamping process, it is heated above its austenitization temperature (typically around 900–950°C). When the hot blank is clamped in the die, it is cooled rapidly (at rates exceeding 27°C/s). This rapid cooling bypasses the formation of softer microstructures and transforms the austenite directly into martensite, the hardest form of steel structure.

Mechanical Properties: As-Delivered vs. Hardened

For engineers and procurement specialists, the most critical aspect of press hardening steel properties is the dramatic difference between its initial state and its final state. This duality allows for complex forming (when soft) and extreme performance (when hard).

The table below compares the typical mechanical properties of the standard 22MnB5 grade before and after the press hardening process:

| Property | As-Delivered (Soft State) | Finished Part (Hardened State) |

|---|---|---|

| Microstructure | Ferrite-Pearlite | Martensite |

| Yield Strength (Rp0.2) | 300 – 600 MPa | 950 – 1200+ MPa |

| Tensile Strength (Rm) | 450 – 750 MPa | 1300 – 1650 MPa (up to 2000) |

| Total Elongation | > 10% (often >18%) | 5 – 8% |

| Hardness | ~160 – 200 HV | 470 – 510 HV |

Yield Strength Analysis: The yield strength typically triples during the process. While the as-delivered material behaves similarly to standard structural steel, the finished component becomes rigid and resistant to deformation, making it ideal for anti-intrusion safety cages.

Hardness and Machinability: The final hardness of 470–510 HV makes mechanical trimming or punching extremely difficult and prone to tool wear. consequently, most trimming operations on finished PHS parts are performed using laser cutting (see SSAB technical data) or specialized hard-trimming dies immediately before the part fully cools.

Common PHS Grades and Chemical Composition

While 22MnB5 remains the industry workhorse, the demand for even lighter and stronger components has led to the development of several variants. Engineers typically select grades based on the balance between peak strength and necessary ductility for energy absorption.

- PHS1500 (22MnB5): The standard grade with ~1500 MPa tensile strength. It contains approx. 0.22% Carbon, 1.2% Manganese, and trace Boron. It balances strength with sufficient toughness for most safety applications.

- PHS1800 / PHS2000: Newer ultra-high-strength grades that push tensile strength up to 1800 or 2000 MPa. These achieve higher strength through slightly increased carbon content or modified alloying (e.g., Silicon/Niobium) but may have reduced toughness. They are used for parts where resistance to intrusion is the sole priority, such as bumper beams or roof rails.

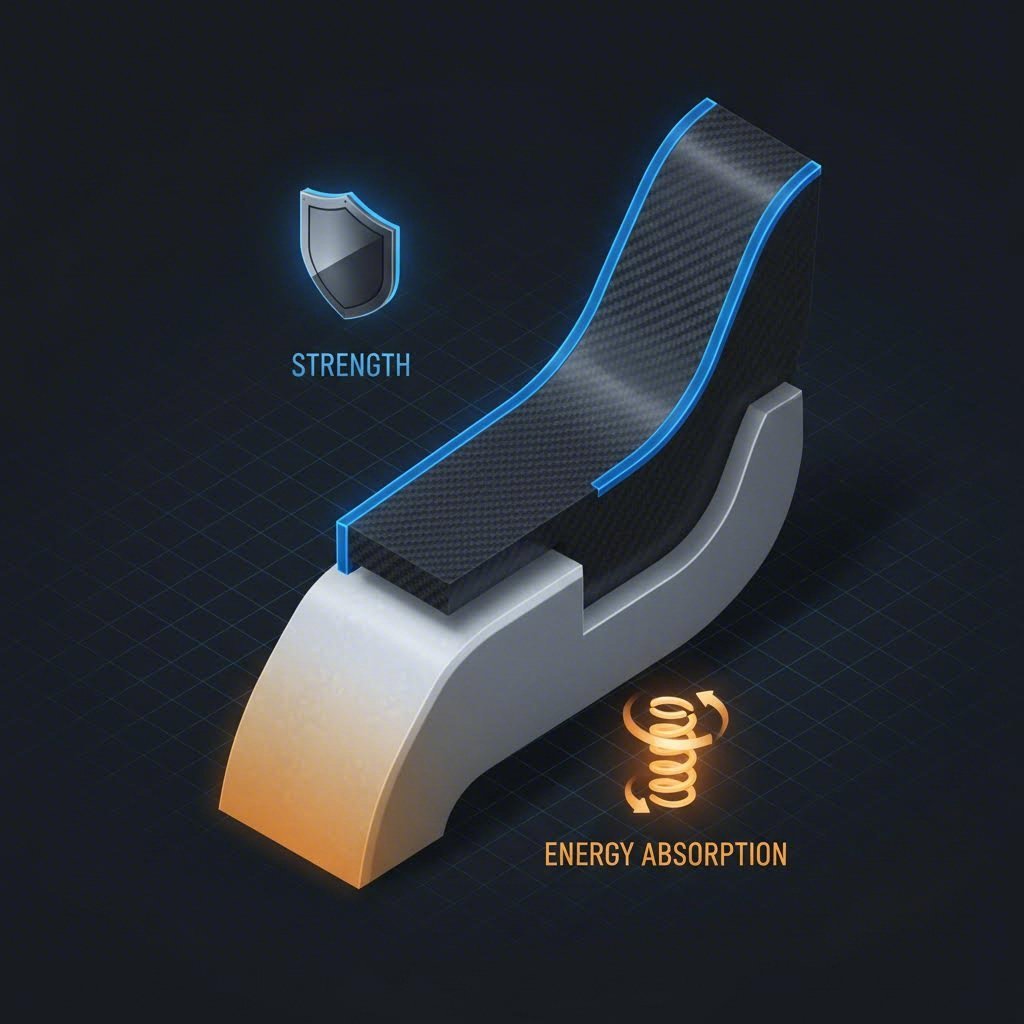

- Ductile Grades (PHS1000 / PHS1200): Also known as Press Quenched Steels (PQS), these grades (like PQS450 or PQS550) are designed to retain higher elongation (10–15%) after hardening. They are often used in "soft zones" of a B-pillar to absorb crash energy rather than transfer it.

The chemical composition is strictly controlled to prevent issues like hydrogen embrittlement, especially in the higher strength grades. Carbon content is generally kept below 0.30% to maintain reasonable weldability.

Coatings and Corrosion Resistance

Uncoated steel oxidizes rapidly when heated to 900°C, forming a hard scale that damages stamping dies and requires abrasive cleaning (shot blasting) after forming. To avoid this, most modern PHS applications use pre-coated sheets.

Aluminum-Silicon (AlSi): This is the dominant coating for direct hot stamping. It prevents scaling during heating and provides barrier corrosion protection. The AlSi layer forms an alloy with the steel iron during the heating phase, creating a robust surface that withstands the sliding friction of the die. Unlike Zinc, it does not offer galvanic (self-healing) protection.

Zinc (Zn) Coatings: Zinc-based coatings (Galvanized or Galvannealed) offer superior cathodic corrosion protection, which is valuable for parts exposed to wet environments (like rockers). However, standard hot stamping can cause Liquid Metal Embrittlement (LME), where liquid zinc penetrates the steel grain boundaries causing micro-cracks. Specialized "indirect" processes or "pre-cooling" techniques are often required to manage zinc-coated PHS safely.

Key Engineering Advantages

The adoption of press hardening steel properties has been driven by specific engineering challenges in vehicle design. The material offers solutions that cold-stamped High-Strength Low-Alloy (HSLA) or Dual-Phase (DP) steels cannot match.

- Extreme Lightweighting: By utilizing strengths of 1500 MPa or higher, engineers can reduce part thickness (downgauging) without compromising safety. A part that was once 2.0mm thick in standard steel might be reduced to 1.2mm in PHS, saving significant weight.

- Zero Springback: In cold stamping, high-strength steels tend to "spring back" to their original shape after the die opens, making dimensional accuracy difficult. PHS forms while hot and soft (austenite) and hardens while constrained in the die. This locks the geometry in place, resulting in virtually zero springback and exceptional dimensional precision.

- Complex Geometries: Because the forming happens when the steel is malleable (~900°C), intricate shapes with deep draws and tight radii can be formed in a single stroke—geometries that would split or crack if attempted with cold ultra-high-strength steel.

Typical Automotive Applications

PHS is the material of choice for the "safety cage" of modern vehicles—the rigid structure designed to protect occupants during a crash by preventing cabin intrusion.

Critical Components

Standard applications include A-pillars, B-pillars, roof rails, tunnel reinforcements, rocker panels, and door intrusion beams. More recently, manufacturers have begun integrating PHS into battery enclosures for electric vehicles to protect modules from side impacts.

Tailored Properties

Advanced manufacturing allows for "Tailored Tempering," where specific zones of a single part (like the bottom of a B-pillar) are cooled more slowly to remain soft and ductile, while the upper section becomes fully hard. This combination optimizes the part for both resisting intrusion and absorbing energy.

For manufacturers looking to implement these advanced materials, partnering with specialized fabricators is essential. Companies like Shaoyi Metal Technology offer comprehensive auto stamping parts solutions, capable of handling high-tonnage requirements (up to 600 tons) and managing the precise tooling needs for complex automotive components, from rapid prototyping to mass production under IATF 16949 standards.

Conclusion

Press hardening steel properties represent a vital synergy between metallurgy and manufacturing process. By leveraging the phase transformation from ferrite to martensite, engineers achieve a material that is formable enough for complex designs yet strong enough to protect lives. As grades evolve toward 2000 MPa and beyond, PHS will remain a cornerstone of automotive safety and lightweighting strategies.

Frequently Asked Questions

1. What is the difference between hot stamping and press hardening?

There is no difference; the terms are used interchangeably. "Press hardening" refers to the metallurgical hardening process that occurs in the press, while "hot stamping" refers to the forming method. Both describe the same manufacturing sequence used to produce high-strength martensitic steel parts.

2. Why is boron added to press hardening steel?

Boron is added in small amounts (0.002–0.005%) to significantly increase the hardenability of the steel. It delays the formation of softer microstructures like ferrite and pearlite during cooling, ensuring that the steel transforms into fully hard martensite even at the cooling rates achieved in industrial stamping dies.

3. Can press hardened steel be welded?

Yes, PHS is weldable, but it requires specific parameters. Since the material typically has a carbon content of around 0.22%, it is compatible with resistance spot welding (RSW) and laser welding. However, welding softens the Heat Affected Zone (HAZ) slightly, which must be accounted for in the design. For AlSi-coated steels, the coating must be removed (via laser ablation) or managed carefully during welding to prevent contamination of the weld pool.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —