Progressive Die vs. Transfer Die Automotive: The Technical Stamping Guide

TL;DR

The choice between progressive die and transfer die stamping fundamentally depends on part size, complexity, and production volume. Progressive die stamping is the superior choice for small, intricate parts (like electrical terminals or brackets) produced in high volumes (typically over 1 million/year), offering the lowest cost per part due to speeds reaching hundreds of strokes per minute. In contrast, transfer die stamping is essential for large, deep-drawn components (like automotive body panels or suspension arms) or parts requiring rotation during forming, as it decouples the part from the metal strip early in the process.

Ultimately, if your design requires deep draws or structural rigidity that exceeds strip layout constraints, transfer is necessary. For speed and efficiency on smaller components, progressive is the industry standard.

The Core Difference: Continuous Strip vs. Free Blank

The most significant technical distinction between these two processes lies in how the material is handled and transported through the press. This difference dictates every other factor, from speed to part geometry.

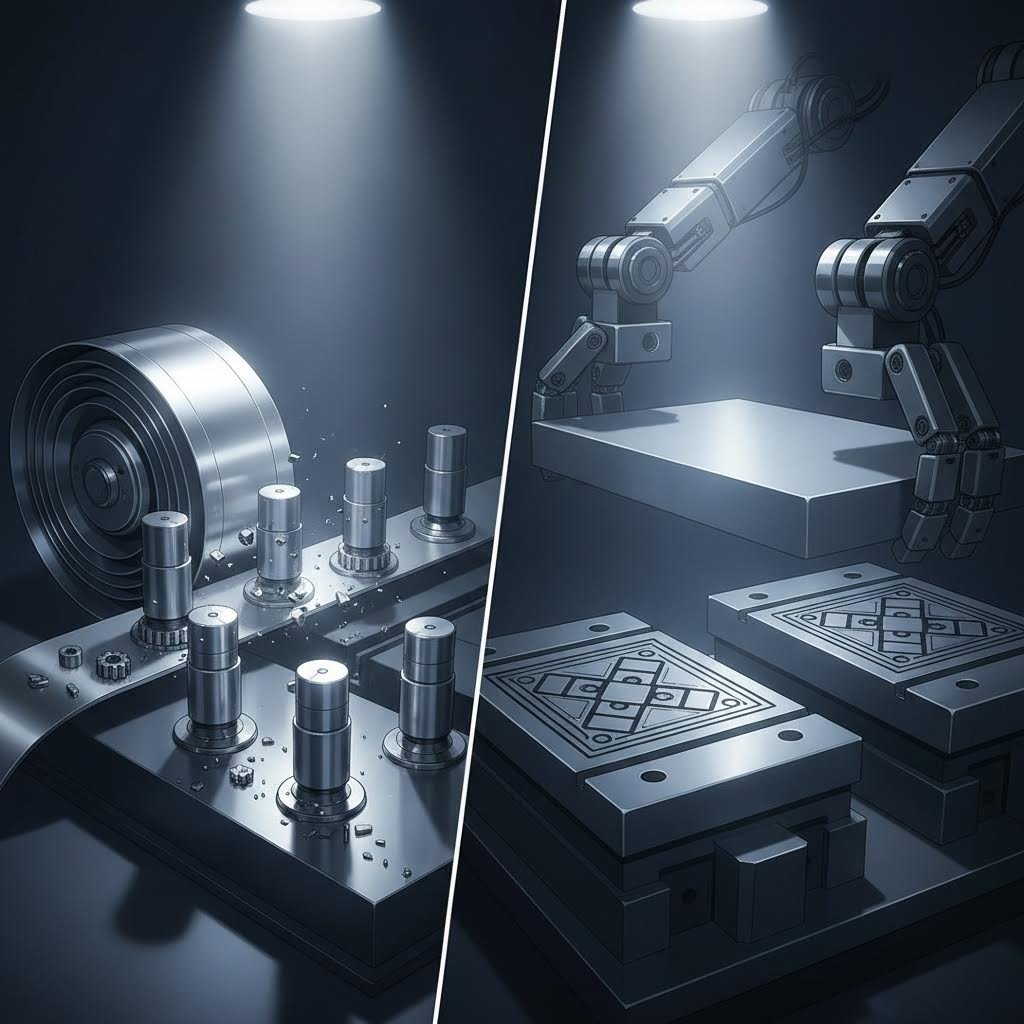

Progressive Die: The Continuous Strip Method

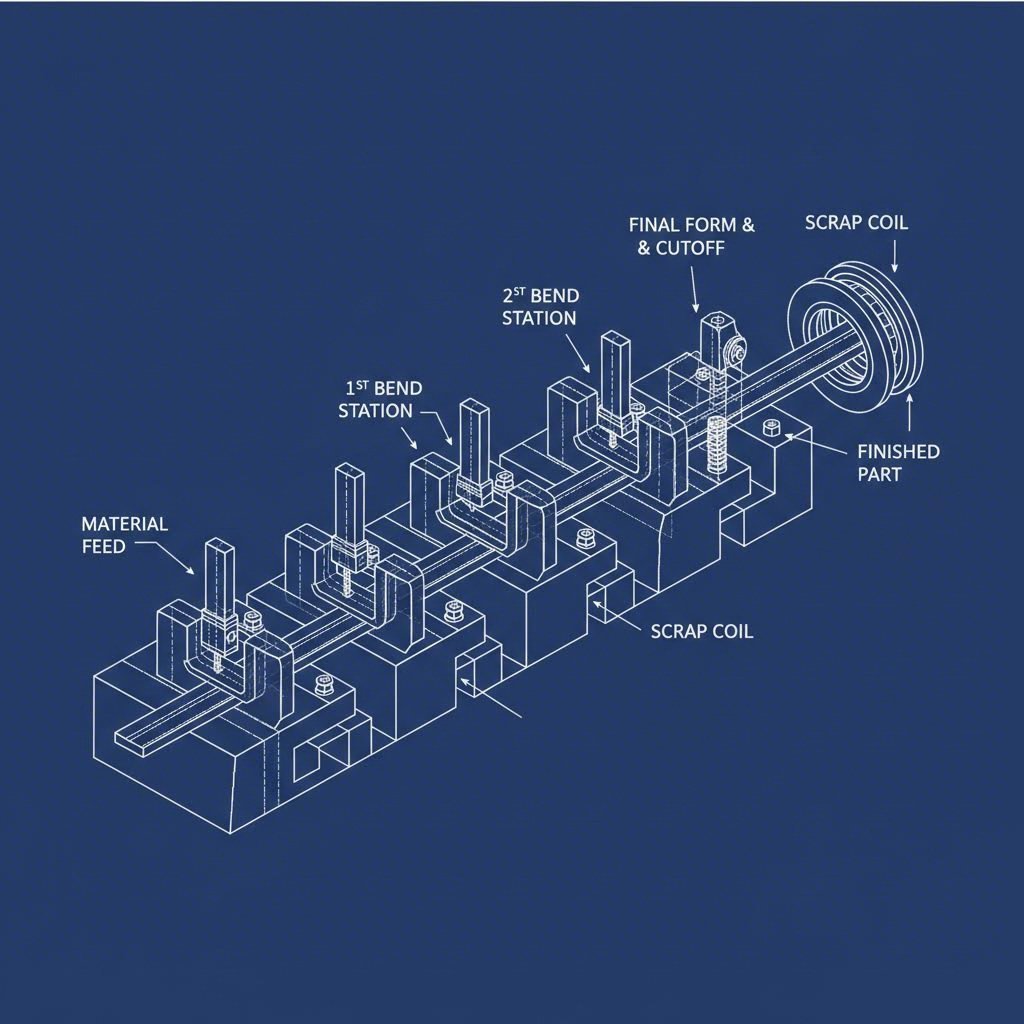

In progressive die stamping, the metal coil is fed through the press as a single continuous strip. The part remains physically attached to this base strip (carrier ribbon) as it advances through sequential stations. Each station performs a specific operation—punching, bending, or coining—simultaneously with every stroke of the press.

Because the part is tethered to the strip until the very final station (cutoff), the process is incredibly stable at high speeds. However, this attachment limits the range of motion; the part cannot be rotated or flipped freely between stations. It must follow the linear progression of the strip layout.

Transfer Die: The Free Part Method

Transfer die stamping separates the individual part (blank) from the strip at the very first station. Once cut free, the part is moved from station to station by a mechanical transport system—typically a series of servo-driven "fingers," grippers, or robotic arms.

This "free state" allows for significantly more complex manipulations. Since the part is not bound to a strip, it can be rotated 180 degrees, tilted, or deeply formed without deforming a carrier web. This mechanical transfer, however, introduces a time penalty, making the cycle time slower than the continuous feed of a progressive die.

Production Volume & Speed: The Economic Equation

For automotive procurement managers and engineers, the decision often comes down to the "break-even" point between tooling investment and piece price.

| Feature | Progressive Die | Transfer Die |

|---|---|---|

| Production Speed | High (Up to 800+ strokes/min) | Moderate (Typically 15–60 strokes/min) |

| Ideal Volume | High Volume (>1 Million parts/yr) | Low to Medium Volume (or Large Parts) |

| Cycle Efficiency | One finished part per stroke (multi-out possible) | One finished part per cycle (slower transfer) |

| Scrap Rate | Higher (requires carrier strip) | Lower (parts can be nested efficiently) |

Progressive dies are the engines of mass production. The ability to run at hundreds of strokes per minute means that the initial high cost of the complex tooling is rapidly amortized over millions of parts, resulting in the lowest possible piece price.

Transfer dies are generally slower because the mechanical transfer system must physically pick up and move the part between strokes. However, for lower volumes or instances where material cost outweighs processing speed (e.g., expensive alloys), transfer stamping can be more economical because it eliminates the scrap waste associated with the carrier strip used in progressive dies.

For manufacturers navigating the transition from prototyping to mass production, partners like Shaoyi Metal Technology bridge this gap by offering scalable solutions, from rapid prototyping to high-volume IATF 16949-certified production, ensuring the process matches the lifecycle stage of the component.

Design Flexibility: Deep Draws and Complex Geometries

While progressive dies are faster, they are bound by the physics of the metal strip. Transfer dies offer the freedom required for complex forming operations.

- Deep Drawing Capabilities: Transfer stamping is the dominant method for "deep drawn" parts—components where the depth exceeds the diameter (e.g., filter housings, oil pans). In a progressive die, deep drawing is difficult because the material flow is restricted by the attachment to the strip, which can cause tearing. In a transfer die, the free blank can draw in material from all sides without restriction.

- Part Manipulation: If a part requires features like knurling, threading, or side-piercing that necessitate rotating the part, transfer dies are the only viable option. The mechanical fingers can orient the part at precise angles that a fixed strip layout cannot accommodate.

- Size Constraints: Progressive dies are typically limited to small-to-medium parts (connectors, brackets) due to the size of the die bed required to house all stations linearly. Transfer dies are the standard for large automotive components like body pillars, frames, and cross-members, as these parts are too large to travel on a delicate strip.

Automotive Applications: Real-World Use Cases

To visualize which process fits your needs, consider these common automotive components:

Best for Progressive Die Stamping

- Electrical Terminals & Connectors: Tiny, high-volume parts requiring intricate bending and tight tolerances.

- Small Brackets & Clips: Fasteners and mounting hardware produced in the millions.

- Washers & Shims: Simple flat parts where speed is the only metric that matters.

- Lead Frames: Precision electronics components where pitch accuracy is paramount.

Best for Transfer Die Stamping

- Body Panels & Structural Frames: Hoods, door panels, and pillars that are large and require complex contouring.

- Deep Drawn Shells: Cylindrical housings, air bag canisters, and sensor covers.

- Suspension Components: Control arms and subframes that use high-strength steel and require multi-axis forming.

- Tube Applications: Parts formed from tube stock rather than flat sheet often utilize transfer systems to move between forming stations.

Cost Analysis: CapEx vs. OpEx

The financial decision involves balancing Capital Expenditure (CapEx) on tooling against Operational Expenditure (OpEx) on piece price.

Tooling Investment (CapEx): Progressive dies are generally more expensive to build. They require a single, highly complex die block with precise feeding mechanisms and pilot pins. Transfer dies can sometimes be cheaper initially if they consist of simpler, separate die stations, though the transfer automation system itself represents a significant capital cost.

Piece Price (OpEx): This is where progressive stamping wins. The labor cost is minimal (often one operator per multiple presses), and the machine throughput is massive. Transfer stamping has a higher piece price due to slower cycle times and often higher machine overhead. However, if the part is large or the material is extremely expensive (e.g., copper or high-performance alloys), the material savings from better nesting in transfer stamping can flip the equation in its favor.

Conclusion: Choosing the Right Process

Selecting between progressive and transfer die stamping is rarely a matter of preference; it is usually dictated by the part design and the program volume. If your automotive component is small, intricate, and needed in volumes exceeding 500,000 to 1 million units annually, progressive die stamping will deliver the ROI you need.

However, if your design involves deep draws, large structural geometries, or requires freedom from strip constraints, transfer die stamping is the technically superior option. Evaluate your specific needs—tonnage, geometry, and annual usage—to make the data-driven choice that aligns with your manufacturing strategy.

Frequently Asked Questions

1. Can progressive dies handle deep draw stamping?

While possible for shallow draws, progressive dies are generally not recommended for deep drawing (where depth exceeds diameter). The attachment to the carrier strip restricts material flow, leading to thinning or tearing. Transfer dies are superior for deep draws as the free blank allows material to flow evenly from all sides.

2. What is the production volume threshold for progressive stamping?

Progressive die stamping becomes most cost-effective at volumes above 250,000 to 500,000 parts per year. For volumes over 1 million, it is almost exclusively the method of choice for compatible parts due to the low per-part labor cost.

3. Is transfer die stamping more expensive than progressive stamping?

Typically, yes, on a per-part basis. Transfer stamping runs at slower speeds (fewer strokes per minute), which increases machine time and labor costs per unit. However, for low-volume runs or large parts, the lower material scrap rate and potential for simpler tooling can sometimes make transfer stamping the more economical choice for the total project cost.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —