Stamping Shock Towers: Decoding Vintage Dates & Fabricated Upgrades

TL;DR

Stamping shock towers generally refers to two distinct automotive needs: verifying vintage car authenticity or upgrading suspension durability. For classic car restorers (especially Ford Mustang and Bronco), “stamping” denotes the production date codes and VINs stamped into the sheet metal, which are critical for matching-numbers verification. For off-road and performance enthusiasts, it refers to the construction method—specifically the difference between factory “stamped steel” towers (pressed from sheet metal) and aftermarket “fabricated” towers (welded from heavy-gauge steel). This guide covers both: how to decode the numbers on your vintage shock tower and when you should upgrade from stamped to fabricated parts.

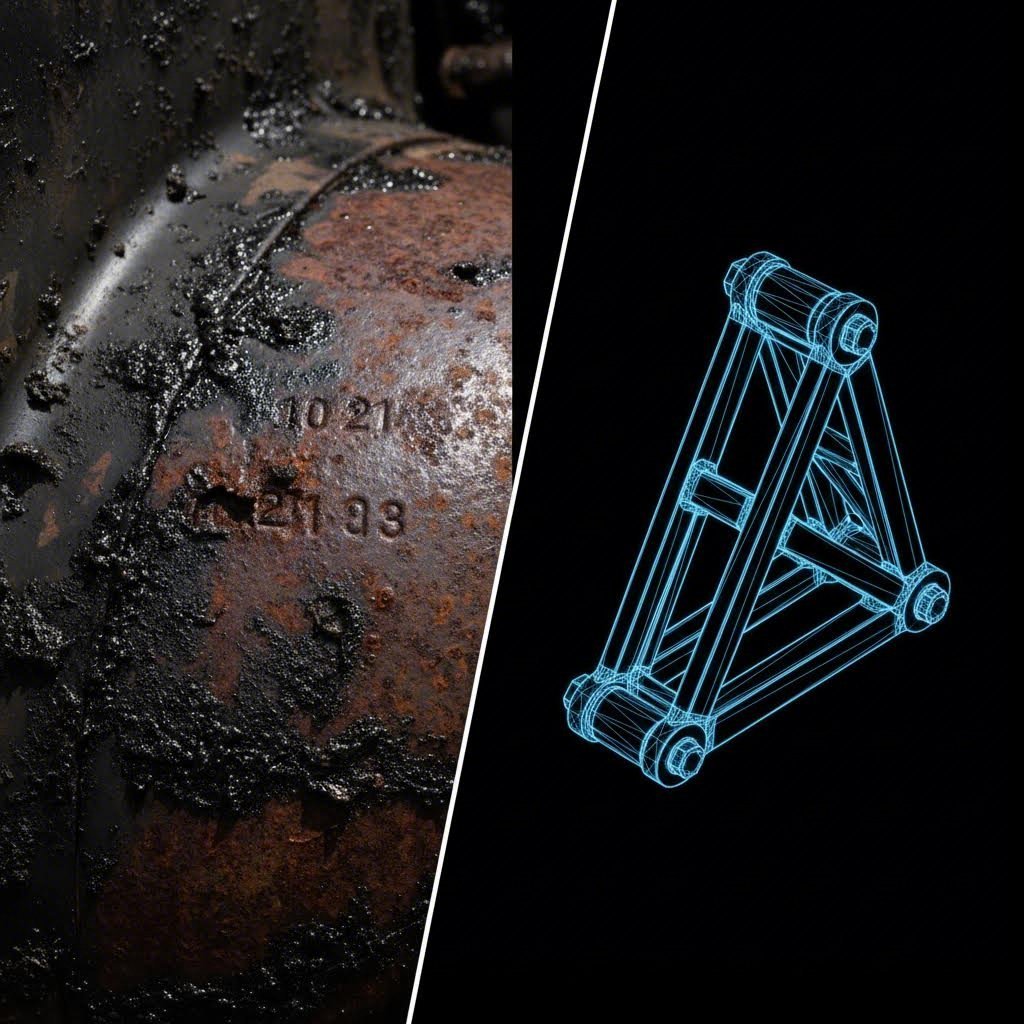

Decoding Vintage Ford Shock Tower Stampings

For restorers of 1960s and 70s Fords (particularly Mustangs, Falcons, and Broncos), the numbers stamped on the shock towers are vital clues to the vehicle's history. A common misconception is that the main number found on the tower is always the VIN. While partial VINs typically appear on the inner fender aprons (the flat metal panels connecting the tower to the firewall), the stamping found directly on the shock tower face is often a production date code.

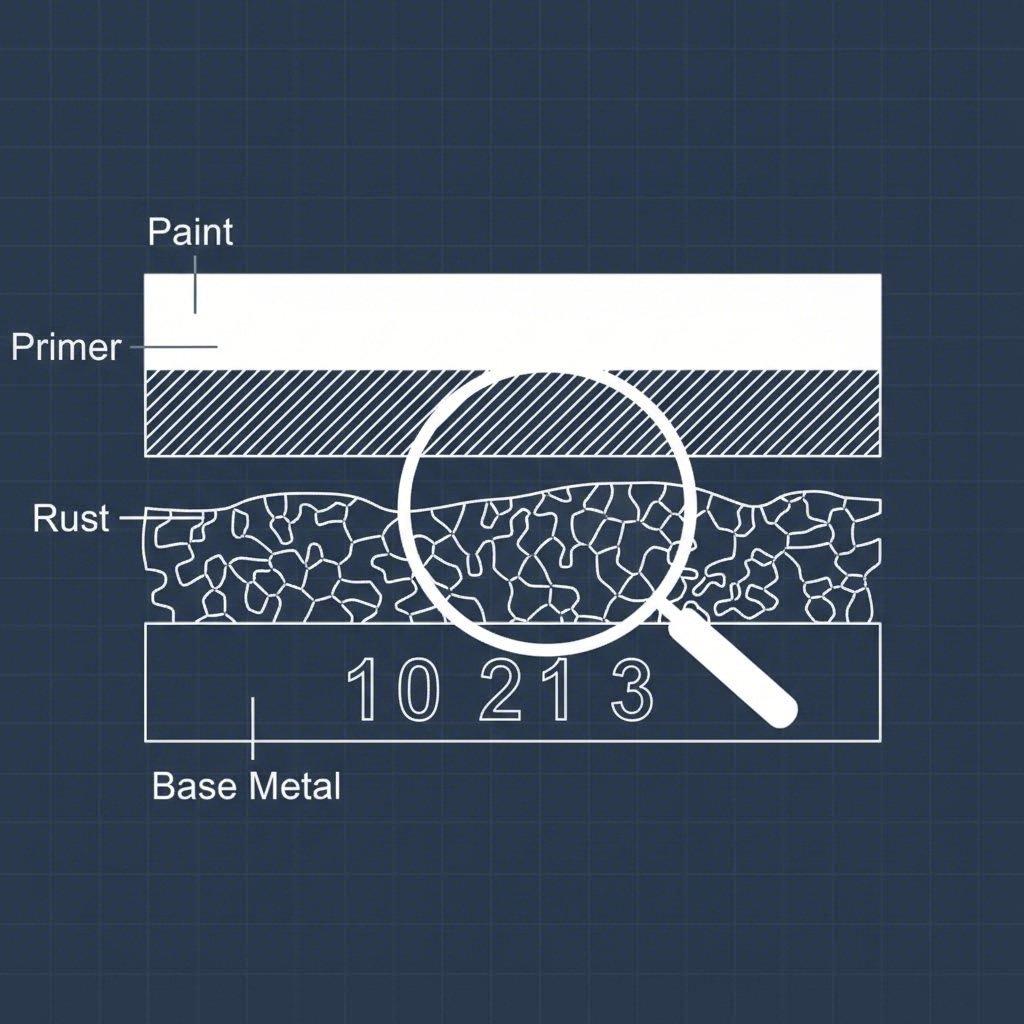

Understanding these codes requires forensic attention to detail. Factory assembly lines did not always use a “Year/Month/Day” format. Instead, you will frequently encounter a raw “Month/Day/Shift” sequence. For example, a stamping reading 10 21 3 translates to October 21st, 3rd Shift. This tells you exactly when that specific metal component was pressed. Crucially, this date should precede the vehicle's final assembly date found on the door data plate or Marti Report, typically by a few weeks to a month.

Matching Numbers Myth: Do the left and right towers need to match perfectly? Not necessarily. It is common to find a driver-side tower stamped 10 21 3 and a passenger-side tower stamped 10 26 1. This 5-day variance simply means the parts were pulled from different batches in the bin. However, a massive discrepancy—such as one tower stamped October and the other December on a car built in October—often indicates a collision repair where a tower was replaced with a salvage part.

Locating Hidden Stamps

If you cannot see the stampings, they are likely buried under fifty years of engine grease, re-sprayed paint, or undercoating. The most common locations are:

- Top of the Tower: Near the shock mounting bolts.

- Outer Face: Facing the wheel well (requires wheel removal).

- Inner Fender Apron: The “hidden VINs” are often located here, sometimes obscured by the fender lip itself, requiring you to loosen the fender bolts to verify the chassis number.

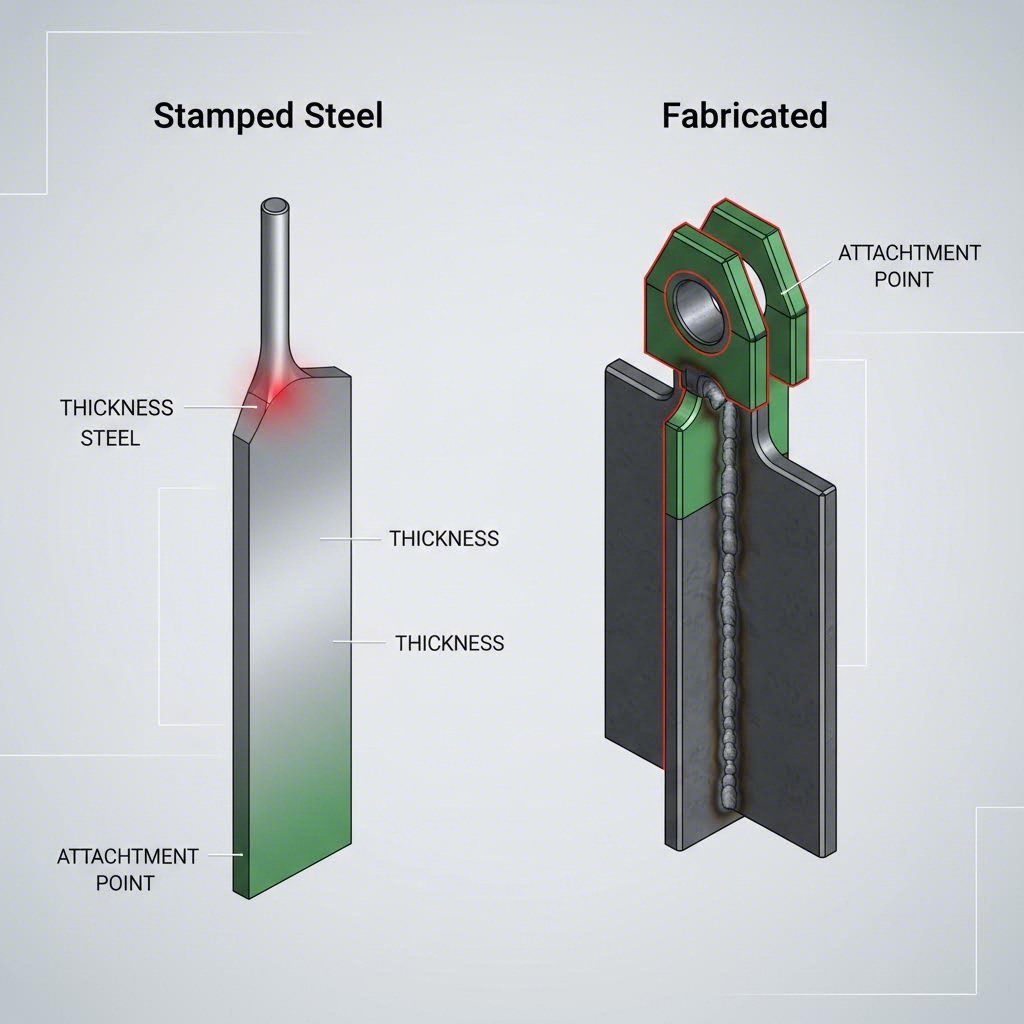

Engineering Comparison: Stamped Steel vs. Fabricated Towers

In the context of performance and off-road engineering, the term “stamping” describes the manufacturing process. OEM (Original Equipment Manufacturer) shock towers are almost exclusively stamped steel. This process involves pressing a flat sheet of mild steel (typically 14-gauge) into a complex 3D shape using massive hydraulic dies. This method is cost-effective for mass production and provides adequate strength for daily driving.

However, stamped towers have structural limitations. The stretching of the metal during the stamping process can thin the material at critical bends. For heavy-duty trucks (like Dodge Ram 2500/3500) or rock-crawling Broncos, the factory stamped towers use a “stem-style” shock mount that is prone to failure under extreme articulation. This is where fabricated shock towers come into play.

| Feature | Stamped Steel (OEM) | Fabricated (Aftermarket) |

|---|---|---|

| Material Thickness | ~14 Gauge (Thin) | 1/4" Cold Rolled Steel (Thick) |

| Construction | Pressed sheet metal | MIG/TIG Welded plates |

| Mounting Style | Stem (Single stud) | Eyelet (Double shear bolt) |

| Primary Failure | Cracking, Snap-through | Weld fatigue (rare) |

| Best Use | Restoration, Street | Off-road, Lifted Suspension |

Fabricated towers are constructed by welding thick steel plates (often 1/4-inch or thicker) into a box or truss structure. This design eliminates the “stem” weak point by converting the shock mount to a stronger “eyelet” style, which uses a through-bolt in double shear. This is virtually indestructible compared to the factory stamping.

Manufacturing Insight: The quality of a stamped component relies entirely on the precision of the tooling. For automotive suppliers looking to bridge the gap between prototype fabrication and high-volume consistency, specialized manufacturers like Shaoyi Metal Technology utilize advanced presses (up to 600 tons) to deliver OEM-grade stamped components. Whether validating a new suspension design with rapid prototyping or moving to mass production, their IATF 16949-certified processes ensure that even stamped parts meet rigorous structural standards.

Inspection and Repair of Stamped Towers

For those keeping the factory stamped towers (either for budget or authenticity), regular inspection is mandatory. The most common failure mode for stamped towers, particularly in unibody cars like the Mustang, is stress cracking at the base where the tower meets the frame rail.

Look for hairline cracks radiating from the mounting bolt holes or along the spot-weld seams. In “sandwich” areas where multiple stamped sheets overlap, moisture can get trapped, causing the metal to swell and separate (a condition known as “rust jacking”). If you find cracks, stop drilling immediately. Small cracks can be stop-drilled and TIG welded, but significant structural fatigue requires a reinforcement plate kit or a complete tower replacement.

Clarification: RC Car Shock Towers

A minor but distinct search intent relates to Radio Controlled (RC) cars. In this hobby, “Stamp” is often shorthand for the Traxxas Stampede model or the vintage Team Associated RC10 “A Stamp” chassis. If you are looking for parts in this category, be aware that stock RC towers are molded plastic (nylon), which flexes and eventually snaps. Upgrading to stamped aluminum or carbon fiber shock towers is the standard fix for durability, mirroring the full-scale automotive “fabricated vs. stamped” debate on a miniature scale.

Summary

Whether you are decoding a 1969 manufacturing date to prove your car's pedigree or welding in 1/4-inch fabricated towers to survive a Baja trail, understanding the nature of “stamping” is key. For restorers, the numbers tell the story; for builders, the metal thickness dictates the limit. Always verify your dates before assuming a part is non-original, and inspect your stamped steel for stress cracks before they become structural failures.

Frequently Asked Questions

1. What is the difference between a VIN and a Date Code on a shock tower?

The VIN (Vehicle Identification Number) is a unique serial number that identifies the specific car, often found on the inner fender apron or dashboard. The Date Code, frequently stamped directly on the shock tower face, identifies when that specific metal part was manufactured (e.g., Month/Day/Shift). They are different numbers but should correlate chronologically.

2. Why do my left and right shock tower stamps not match?

It is normal for left and right towers to have slightly different date codes (e.g., a few days apart). On the assembly line, parts were pulled from bins filled with components stamped on different days or shifts. However, a difference of several months usually indicates a replacement part.

3. Are fabricated shock towers better than stamped steel?

For off-road and heavy-duty performance, yes. Fabricated towers are typically made from much thicker steel (1/4") and use stronger mounting points (eyelet vs. stem). For stock restoration or daily driving, factory stamped steel is sufficient and maintains the original look.

4. How do I read a Ford date code like "10 21 3"?

This format typically reads as Month / Day / Shift. So, "10 21 3" would be October 21st, 3rd Shift. Note that Ford used various formats depending on the year and plant, so consulting a model-specific decoding book is recommended for exact verification.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —