Stamping Engine Mounts: Manufacturing Secrets & Restoration Guide

TL;DR

Stamping engine mounts refers to two distinct concepts in the automotive world: the manufacturing process of pressing sheet metal to create OEM-style brackets, and the specific identification codes stamped into these parts for restoration authenticity. While stamped steel mounts are the industry standard for vibration dampening and cost-effective durability, they differ significantly from billet aluminum upgrades designed for high-performance rigidity. For restorers, finding mounts with the correct date codes and part numbers stamped into the metal is critical for achieving a "numbers-matching" chassis.

What Are Stamped Engine Mounts? (Manufacturing & Design)

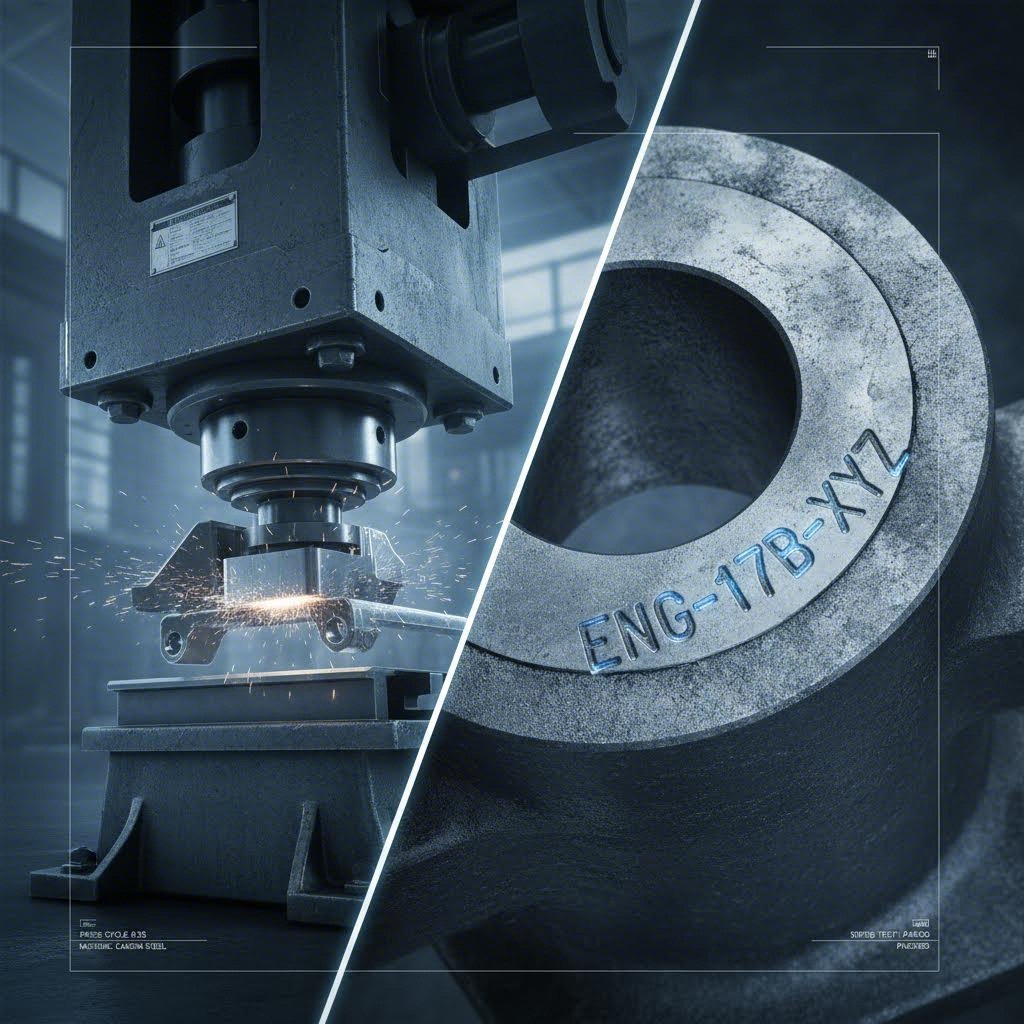

At its core, a "stamped" engine mount is manufactured by pressing flat sheet metal—typically heavy-gauge steel—into a specific shape using high-tonnage dies. This process contrasts sharply with casting (pouring molten metal into a mold) or machining (cutting a part from a solid block). The stamping process allows for the rapid mass production of lightweight, strong, and flexible brackets that can absorb the natural twisting forces of a chassis.

According to industry specialists like Fairchild Industries, the manufacturing of these mounts involves advanced molding and bonding processes where the stamped metal bracket is permanently fused with rubber isolation pads. This combination is engineered to dampen engine vibrations, preventing noise and harshness from transferring to the cabin—a critical requirement for daily-driven vehicles. The steel gauge used in these stampings is selected to balance tensile strength with a slight amount of engineered flex, which helps prevent fatigue cracks in the vehicle's frame.

For automotive engineers and parts procurers, the stamping process is vital for scalability. Manufacturers like Shaoyi Metal Technology specialize in these auto stamping parts, offering solutions that range from rapid prototyping to high-volume production under strict IATF 16949 standards. Their ability to use presses up to 600 tons allows for the creation of complex, deep-draw brackets that meet global OEM specifications, bridging the gap between custom prototypes and the millions of stamped mounts needed for mass assembly.

The design of a stamped mount often includes captive nuts, welded reinforcement tabs, and specific contours that clear steering components or exhaust headers. Unlike rigid solid mounts, the stamped steel design is forgiving; if an engine moves slightly under torque, the stamped steel (combined with rubber) absorbs the energy rather than transferring it directly to the frame rails, potentially saving the chassis from stress fractures over time.

Performance Showdown: Stamped Steel vs. Billet Aluminum

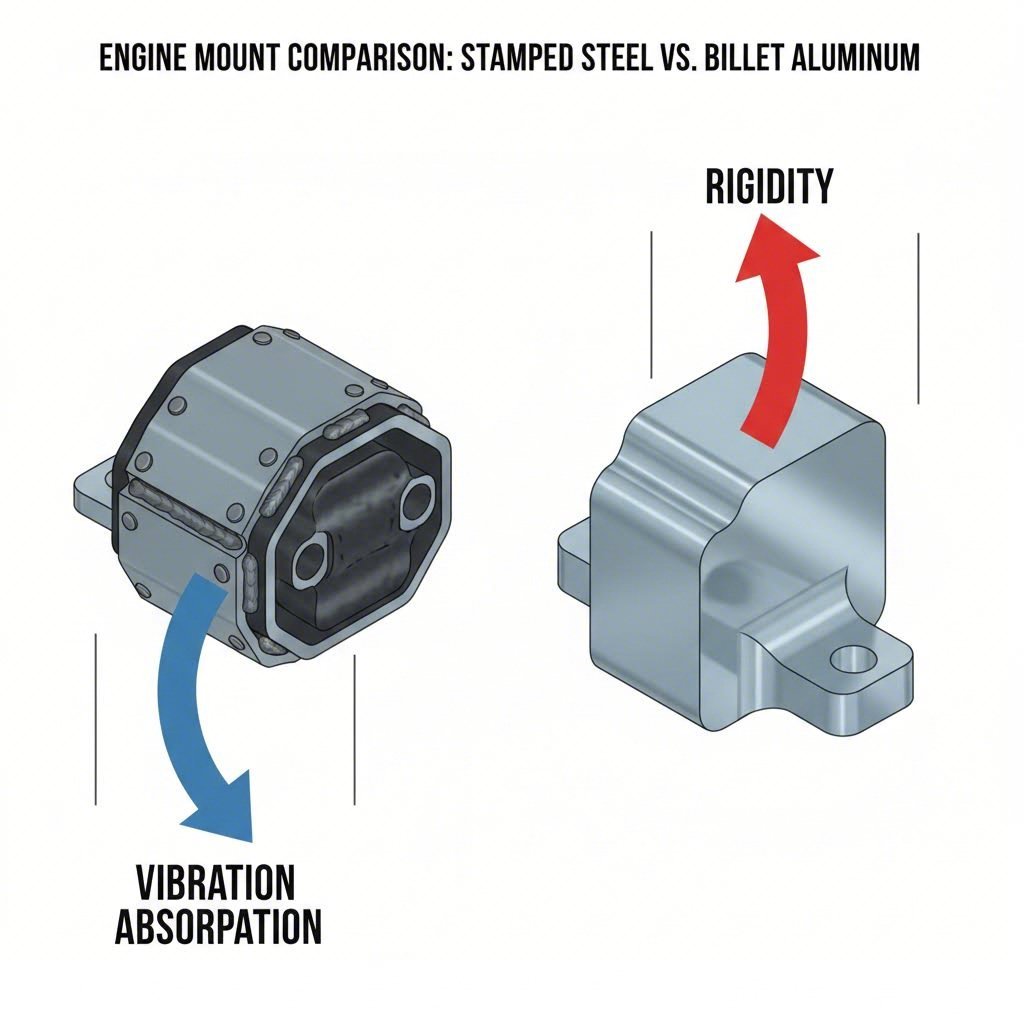

The debate between stamped steel and billet aluminum is one of the most common discussions among performance enthusiasts. The choice typically depends on the vehicle's intended use: comfortable street driving or aggressive track performance.

The Case for Billet Aluminum

Billet mounts are machined from a solid block of aluminum, often 6061-T6 aircraft grade. As noted by Evolution Industries, these kits offer superior strength compared to stamped steel brackets. Because they are carved from a solid piece, they have zero flex. This rigidity ensures that 100% of the engine's torque is transferred to the wheels rather than being lost to drivetrain slop. Billet mounts are also aesthetically pleasing, often anodized in colors like black or silver to dress up the engine bay of a show car.

The Case for Stamped Steel

Stamped steel mounts, particularly heavy-duty versions like those for the Early Bronco V8 conversions, are designed to mimic the factory engineering. Their primary advantage is compliance. The slight flex inherent in stamped steel, combined with softer rubber bushings, effectively isolates NVH (Noise, Vibration, and Harshness). For a restoration project or an off-road vehicle where frame flex is necessary to keep wheels on the ground, stamped steel is often the superior choice. They are also significantly more affordable and maintain the authentic "factory" look that many builders desire.

| Feature | Stamped Steel Mounts | Billet Aluminum Mounts |

|---|---|---|

| Manufacturing | Pressed sheet metal | CNC Machined from solid block |

| Primary Benefit | Vibration dampening & Cost | Maximum strength & Rigidity |

| NVH Levels | Low (Quiet & Smooth) | High (More vibration transfer) |

| Durability | Good (Can rust over time) | Excellent (Corrosion resistant) |

| Best Application | Daily Drivers, Restorations | Track Cars, High-HP Builds |

Decoding the Stamp: Identification for Restoration

For the concours restoration crowd, "stamping engine mounts" refers to the forensic process of identifying the correct part numbers and date codes indented into the metal. Unlike casting numbers which are raised, stamped numbers are pressed into the surface and can tell the story of a car's origin.

High-quality reproductions, such as those available through OER Parts, often feature these correct stampings to satisfy judges at car shows. For example, a 1969 Camaro or Chevelle mount might require a specific GM part number stamped on the flange to verify it as an authentic or period-correct replacement. These stamps help distinguish between generic aftermarket replacements (which often have no codes or incorrect fonts) and high-end restoration parts.

When inspecting a potential "survivor" car, savvy buyers look for these stamps to verify if the engine has been pulled or if the mounts are original assembly line units. The stamp is typically located on the flat face of the bracket or near the frame mounting points. Rust and grease often obscure these marks, so careful cleaning with a wire brush (without grinding the metal away) is often necessary to reveal the hidden history.

Restorers should also pay attention to the finish. Original stamped mounts were often coated in a black EDP (Electro-Deposit Primer) or semi-gloss paint. Finding a mount with the correct stamp but the wrong finish can still deduct points in a judged competition. The market places a premium on "correct GM P/N stamped" parts because they represent the final 1% of detail that separates a nice car from a museum-quality example.

Inspection & Replacement: When Stamped Mounts Fail

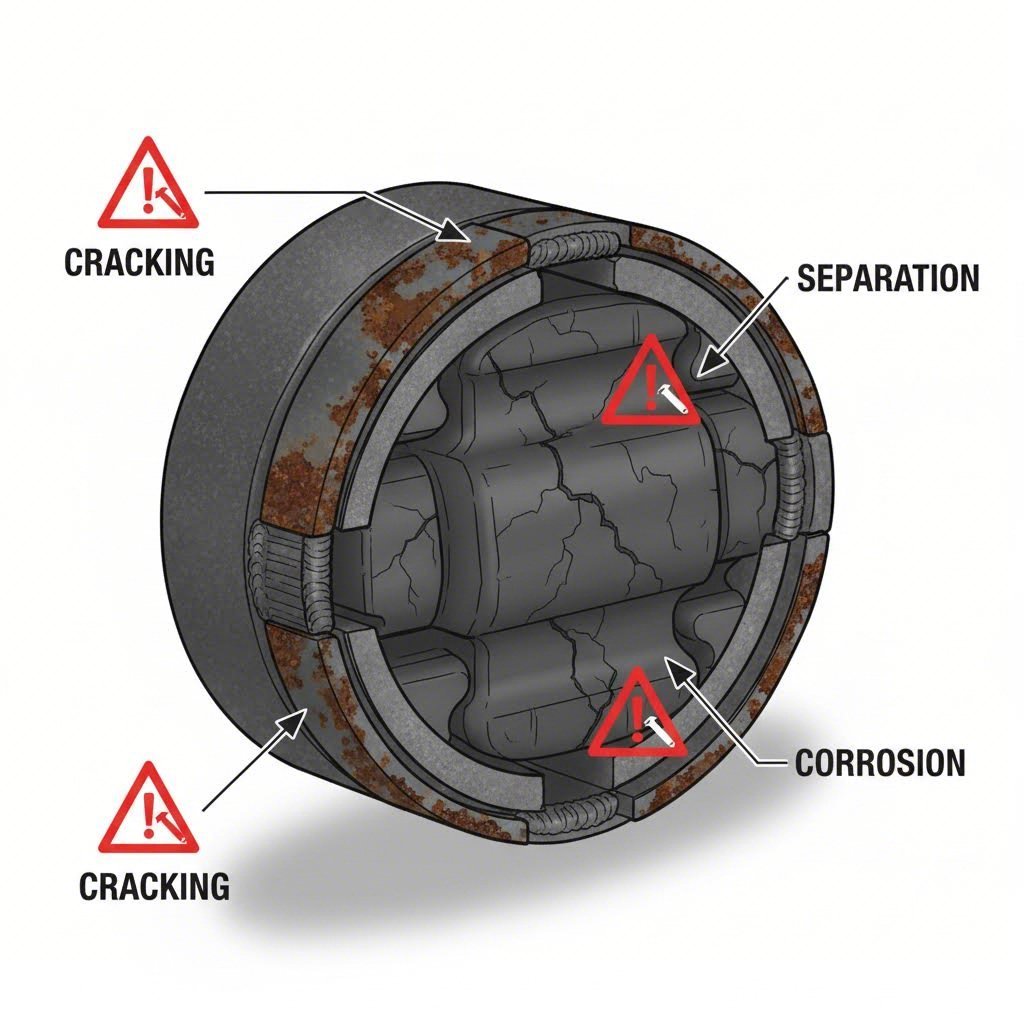

Despite their durability, stamped engine mounts are wear items. The most common failure point is not the steel stamping itself, but the rubber cushion bonded to it. Over time, heat cycles and oil leaks can degrade the rubber, causing it to separate from the stamped metal shell.

A clear sign of failure is excessive engine movement. You might hear a "clunk" when shifting from Park to Drive, or feel a vibration at idle that disappears when accelerating. In severe cases, the rubber can shear completely, allowing the engine to lift and the metal bracket to slam against the frame or steering linkage. This is often described as a "broken motor mount" and requires immediate attention to prevent damage to the radiator fan, hoses, or transmission linkage.

When inspecting stamped mounts, look for:

- Separation gaps: Use a pry bar to gently lift the engine; if the rubber pulls away from the metal stamping, it's failed.

- Rust at weld points: Stamped mounts are often spot-welded layers of steel. Deep rust can compromise these welds.

- Distortion: If the vehicle has been in a collision, the stamped bracket may be bent, causing driveline misalignment.

Replacing stamped mounts is generally straightforward but requires lifting the engine slightly to relieve pressure. Always replace them in pairs, as a new stiff mount on one side will quickly destroy an old, weak mount on the other.

Conclusion: Choosing the Right Foundation

Whether you are engineering a mass-production vehicle, building a 9-second drag car, or restoring a classic muscle car to showroom condition, the humble engine mount plays a pivotal role. Understanding the difference between the manufacturing process of stamping and the identification value of the stamps themselves allows you to make informed decisions.

For most drivers and restorers, high-quality stamped steel mounts offer the perfect balance of performance, comfort, and authenticity. They absorb the road's harshness while keeping the engine securely in place. However, for those pushing the limits of horsepower, stepping up to billet aluminum eliminates the weak link in the drivetrain. Ultimately, the "best" mount is the one that aligns with your specific goals—be it a smooth commute, a winning lap time, or a perfect score on the concours field.

Frequently Asked Questions

1. How can an engine mount snap?

Engine mounts typically "snap" when the rubber isolation material separates from the metal bracket due to age, heat, or fluid contamination (like oil leaks). In extreme cases, high torque or a collision can cause the stamped steel bracket itself to shear or crack, though rubber failure is far more common.

2. How can I tell if my motor mounts are shot?

Common symptoms include excessive vibration at idle, a loud clunking noise when accelerating or shifting gears, and visible movement of the engine in the bay. You can often see cracks in the rubber or separation between the metal and rubber components during a visual inspection.

3. Can I weld a broken stamped engine mount?

It is generally not recommended to weld a broken stamped mount. The heat from welding can destroy the bonded rubber bushing, and the structural integrity of the stamped steel may be compromised. Replacing the unit with a high-quality reproduction or OEM-style part is the safer and more reliable solution.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —