Automotive Stamping Material Utilization: Maximizing Yield & Profits

TL;DR

Automotive stamping material utilization is the critical ratio of finished part weight to the total raw metal consumed, determining up to 70% of a component's final production cost. Maximizing this yield requires moving beyond basic layouts to advanced strategies like Two-Pair nesting, which can improve material efficiency by over 11% compared to standard One-Up methods. This guide details the engineering formulas, nesting techniques, and process optimizations necessary to minimize scrap and protect profit margins in high-volume manufacturing.

The Economics of Material Utilization

In the high-stakes world of automotive manufacturing, raw material is not just a line item—it is the dominant cost driver. Industry data reveals that for most stamped components, raw material accounts for 60% to 70% of the total part cost. This percentage significantly outweighs the costs of labor, energy, and even the amortization of complex tooling.

The financial implication of this ratio is severe because material costs are recurring. While a stamping die is a one-time investment, the steel or aluminum coil is consumed continuously. A material utilization rate of 60% means that for every dollar spent on sheet metal, 40 cents is immediately converted into scrap (offal). In high-volume automotive production runs, where quantities often exceed 300,000 units annually, even a fractional improvement in yield percentage can translate into hundreds of thousands of dollars in savings.

Conversely, neglecting material utilization during the design phase creates a “yield gap”—a permanent cost penalty that persists for the lifecycle of the vehicle program. Decision-makers must view material efficiency not merely as a waste-reduction metric, but as the primary lever for competitive pricing and profitability.

Calculating Material Utilization Rates

To control material costs, engineers must first accurately measure utilization. The industry-standard definition of material utilization is the percentage of the coil or sheet that becomes the final product.

The Core Formula

The calculation is straightforward but requires precise inputs regarding the blank layout:

Material Utilization % = (Net Weight of Part / Gross Weight of Material Consumed) × 100

- Net Weight: The final weight of the finished stamped part after all trimming and piercing operations.

- Gross Weight: The total weight of the material required to produce that part, calculated using the Pitch (distance between parts on the strip) and the Coil Width.

For example, if a finished bracket weighs 0.679 kg, but the rectangular space it occupies on the coil (pitch × width × thickness × density) weighs 1.165 kg, the utilization is only 58.2%. The remaining 0.486 kg is engineered scrap. Raising that utilization to 68% significantly reduces the gross weight required per part, directly lowering the “purchase weight” of the coil.

Advanced Nesting Strategies for Maximum Yield

The most effective method to improve automotive stamping material utilization is blank nesting—optimizing how parts are oriented and laid out on the coil strip. Choosing the wrong nesting strategy is the most common cause of poor yield.

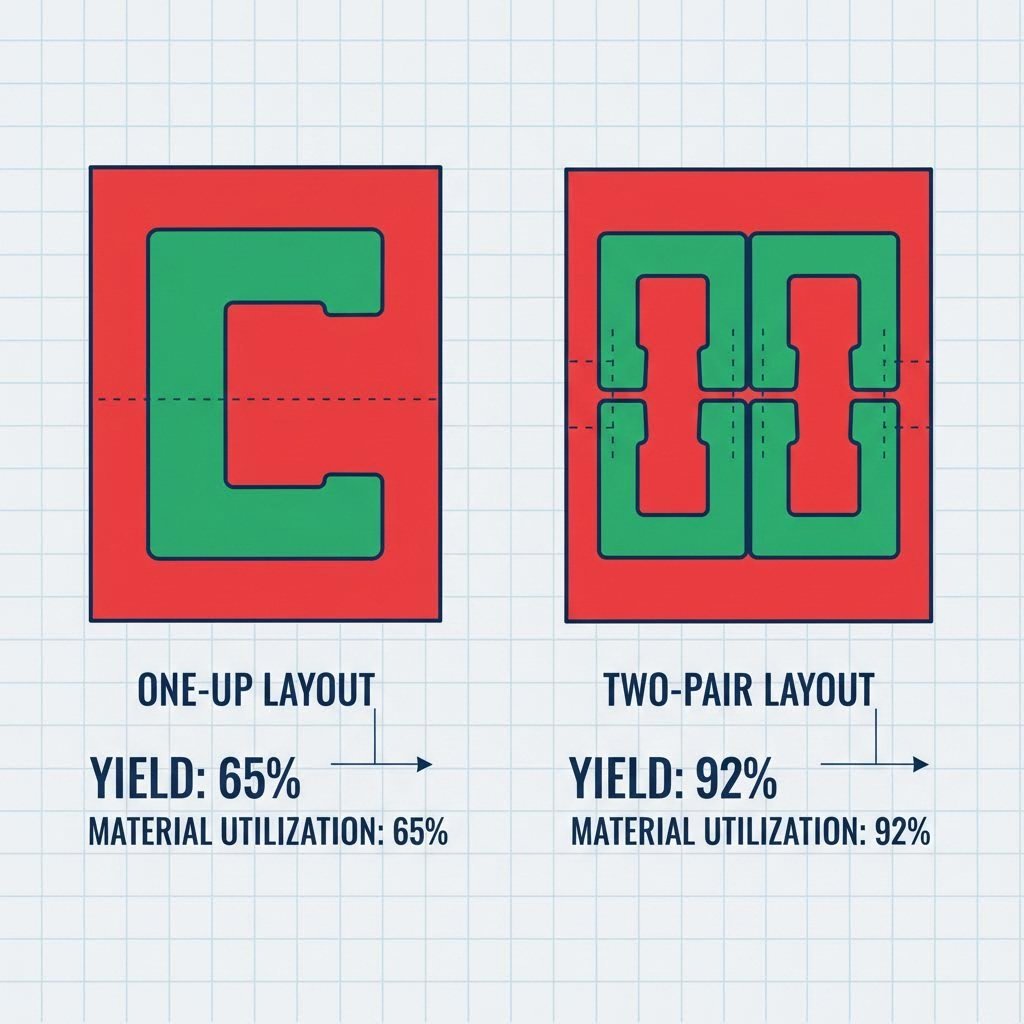

Below is a comparative analysis of common nesting layouts for a typical L-shaped automotive bracket. Data derived from industry simulations demonstrates how layout choice dramatically alters yield efficiency.

Nesting Strategy Comparison

| Nesting Method | Configuration Description | Typical Yield % | Material Efficiency Verdict |

|---|---|---|---|

| One-Up | Single part per pitch, usually aligned with coil width. | ~58% | Lowest. Creates excessive scrap on all sides. Often chosen for tooling simplicity but carries the highest piece price. |

| Two-Up | Two parts stamped side-by-side per stroke. | ~60-61% | Moderate. Improves throughput (parts per minute) but may not significantly reduce scrap if the geometry doesn't interlock. |

| Cutoff (Trapezoid) | Parts are cut directly from a shaped blank without a carrier web. | ~65% | High. Excellent for simple geometries but limited by edge quality requirements and formability. |

| Mirror / Two-Pair | Two parts rotated 180° to interlock with each other (nested like puzzle pieces). | ~69-70% | Optimal. Maximizes yield by using the negative space of one part to house the geometry of the next. |

As shown, shifting from a basic One-Up process to an optimized Two-Pair layout can improve yield by over 11 percentage points. In a production run of 300,000 parts, this shift reduces the total steel consumption by tons, eliminating the "cost penalty" associated with inefficient blanking.

Engineering & Process Optimization Techniques

Beyond nesting, advanced engineering interventions can squeeze further efficiency out of the stamping process. These techniques often require collaboration between product designers and manufacturing engineers early in the vehicle development cycle.

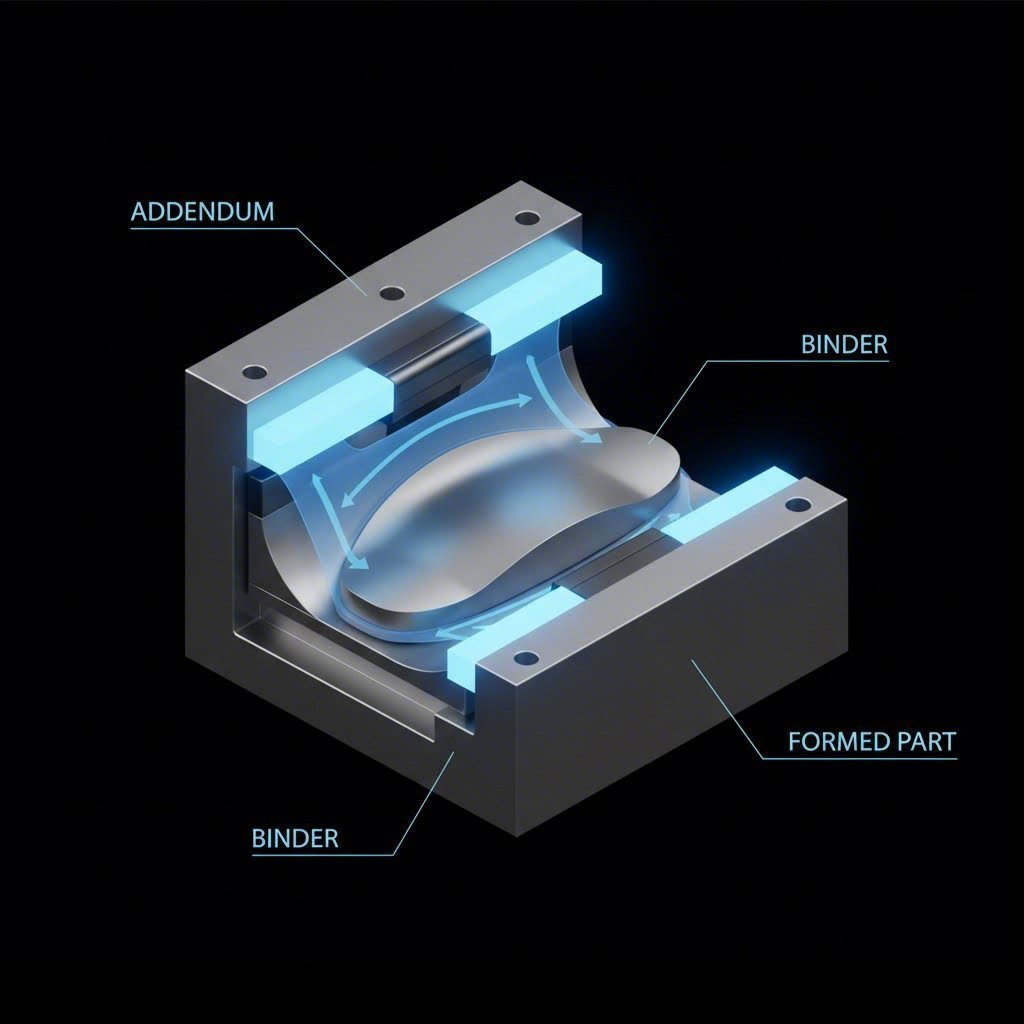

Addendum and Binder Optimization

In deep drawing processes, extra material (addendum) is required to hold the sheet metal in the die binders to control material flow and prevent wrinkling. However, this material is eventually trimmed off as scrap. Using simulation software like AutoForm or Dynaform allows engineers to minimize the addendum surface area without compromising the forming quality. Reducing the blank size by just a few millimeters on the binder edge can yield significant material savings across millions of strokes.

Partnering for Precision

Implementing these optimizations requires capabilities that bridge the gap between theoretical design and physical reality. For manufacturers seeking to validate these strategies, Shaoyi Metal Technology provides comprehensive stamping solutions. Leveraging IATF 16949-certified precision and press capabilities up to 600 tons, they help automotive clients transition from rapid prototyping to high-volume manufacturing. Whether you need to verify a nesting strategy with 50 prototypes in five days or scale a yield-optimized design to millions of parts, their engineering services ensure strict adherence to global OEM standards.

Coil Specification and TWB

Another avenue for optimization is the raw material format itself. Standard coil widths may force a manufacturer to accept wider scrap margins. Ordering custom slit widths tailored to the specific nesting pitch can eliminate edge waste. Additionally, Laser Welded Blanks (TWB) allow engineers to weld sheets of different thicknesses or grades together before stamping. This places thicker, stronger metal only where needed (e.g., crash zones) and thinner metal elsewhere, reducing the overall blank weight and improving the vehicle's material utilization ratio.

Scrap Management & Sustainability

Despite the best nesting strategies, some scrap is inevitable. This "engineered scrap" typically consists of the window cutouts (holes inside the part) and the carrier web. However, modern efficiency standards treat this offal as a potential resource rather than pure waste.

- Scrap-in-Scrap Production: For larger body panels like doors or fenders, the large window cutouts can sometimes be large enough to stamp smaller brackets or washers. This "nesting inside the scrap" technique essentially entails free material for the smaller components.

- Sustainability Impact: Maximizing material utilization is directly linked to environmental stewardship. By reducing the gross weight of steel required for a vehicle, manufacturers lower their carbon footprint associated with steel production and logistics. High-yield stamping processes support ISO 14001 goals and OEM sustainability mandates by minimizing the energy consumed per usable kilogram of metal.

Conclusion: The Profit is in the Pitch

Automotive stamping material utilization is a definitive metric of manufacturing efficiency. With material costs comprising the majority of part expenses, the difference between a 58% yield and a 69% yield determines the profitability of a program. By adopting data-driven nesting strategies, utilizing simulation for addendum reduction, and partnering with capable manufacturers for execution, automotive engineers can significantly reduce waste. In an industry where margins are measured in pennies, maximizing every millimeter of the coil is not just good engineering—it is essential business strategy.

Frequently Asked Questions (FAQ)

1. What is the raw material utilization rate in stamping?

The raw material utilization rate is the ratio of the weight of the finished, usable part to the total weight of the raw material (coil or sheet) consumed to produce it. It is expressed as a percentage: (Net Weight / Gross Weight) * 100. A higher percentage indicates less waste and lower material costs.

2. Why is material utilization critical in the automotive industry?

Raw materials typically represent 60-70% of the total cost of a stamped automotive component. Because vehicle production volumes are high, even small improvements in utilization (reducing scrap) result in massive cumulative cost savings and reduced environmental impact.

3. What is the difference between One-Up and Two-Up nesting?

One-Up nesting stamps a single part with each press stroke, often resulting in lower material yield (e.g., ~58%) due to inefficient spacing. Two-Up nesting produces two parts per stroke, allowing for better interlocking of geometries (nesting), which can significantly increase yield percentages (often >60%) and production speed.

4. Which materials are commonly used for automotive stamping?

Carbon steel is the most widely used material due to its strength and affordability, available in various grades like mild steel and high-strength steel (HSS). Aluminum alloys are also increasingly used for lightweighting applications to improve fuel efficiency, despite being more challenging to form.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —