Stamping Electric Vehicle Busbars: Engineering & Sourcing Guide

TL;DR

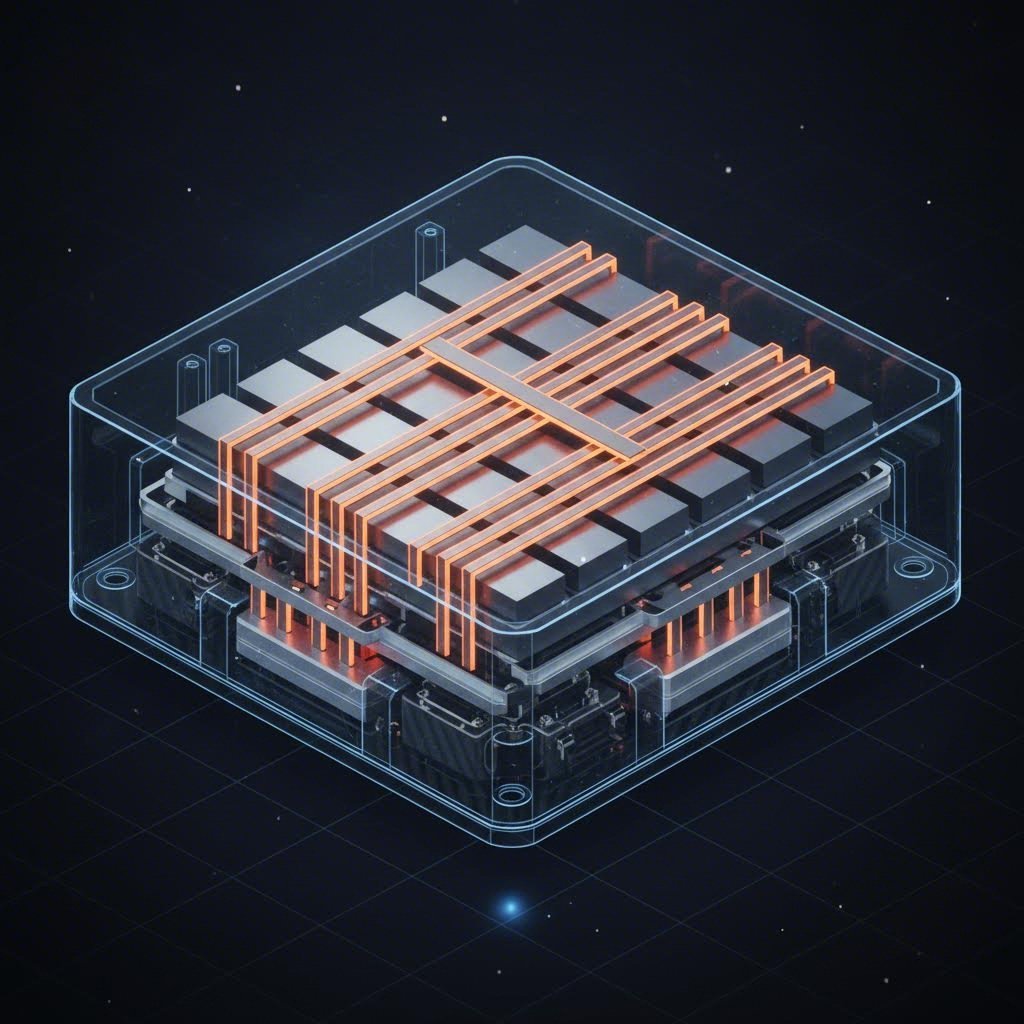

Stamping electric vehicle (EV) busbars has replaced traditional wiring harnesses as the industry standard for high-voltage power distribution, primarily due to superior thermal efficiency, reduced weight, and automated assembly capabilities. By utilizing progressive die stamping, manufacturers can mass-produce complex geometries with tight tolerances essential for battery packs and inverters.

Key advantages include optimized space utilization within compact EV platforms and the ability to integrate advanced features like in-die assembly of fasteners. For decision-makers, the shift to stamped busbars represents a move toward scalable, zero-defect manufacturing that directly supports the electrification goals of increased range and lower production costs.

The Strategic Shift: Why EVs Demand Stamped Busbars

The transition from flexible cabling to rigid stamped busbars is not merely a design preference; it is an engineering necessity driven by the unique constraints of modern electric vehicle architectures. As EV battery packs and power electronics become denser, the spatial volume required by traditional round cables becomes a liability. Stamped busbars, with their flat, rectangular cross-sections, offer a significantly better packing factor, allowing engineers to route high-voltage power through narrow channels that would be impossible for wire harnesses.

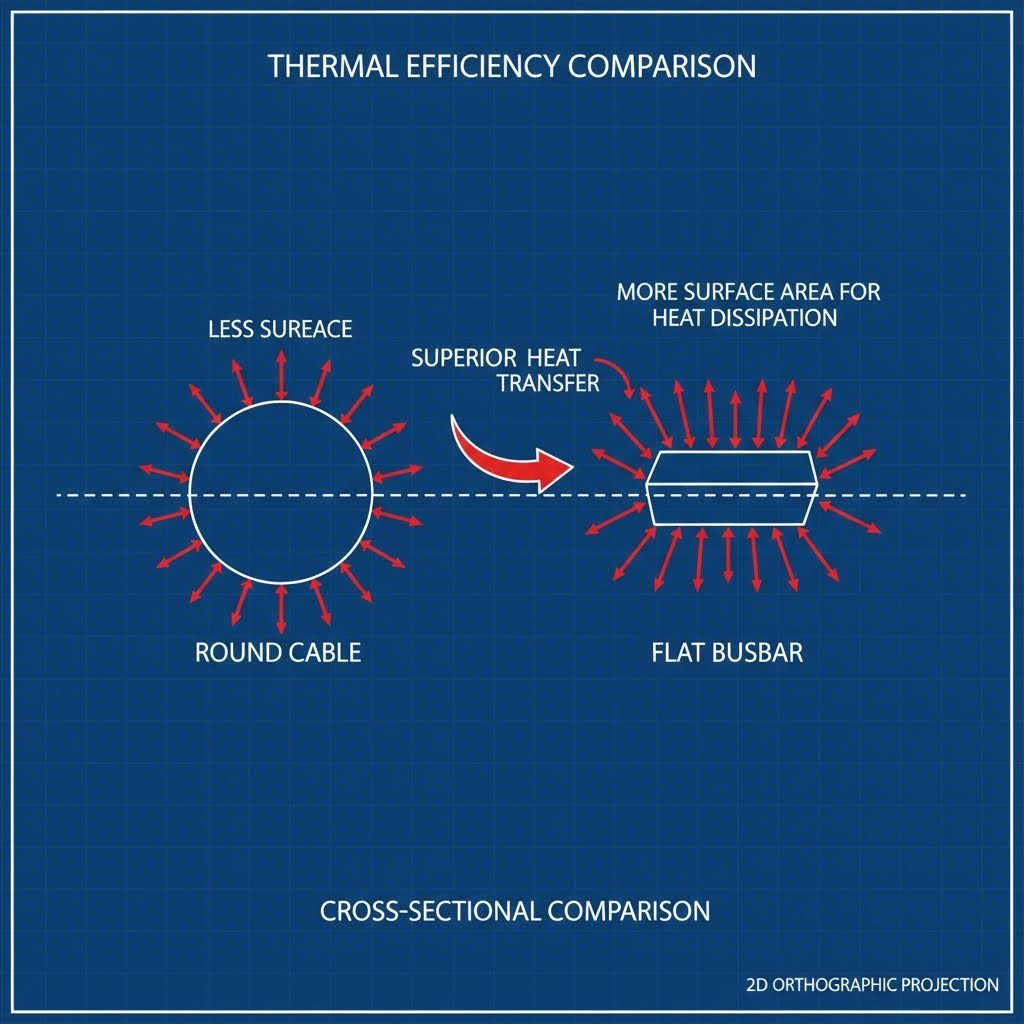

Thermal management acts as the second critical driver. The surface area-to-cross-section ratio of a flat busbar is superior to that of a round cable, facilitating more efficient heat dissipation. This physical property allows busbars to carry higher current densities—referred to as ampacity—without exceeding temperature limits. In high-performance EVs, where peak currents during rapid charging or acceleration can spike dramatically, this thermal headroom is vital for system safety and longevity.

Furthermore, stamped busbars enable automated assembly, a cornerstone of mass-production vehicle manufacturing. Unlike cables, which often require manual routing and connection, rigid busbars can be picked and placed by robotic systems. This rigidity also reduces the risk of connection errors and vibration-induced failures, contributing to the overall reliability of the high-voltage electrical system.

Manufacturing Processes: Stamping vs. Forming vs. Etching

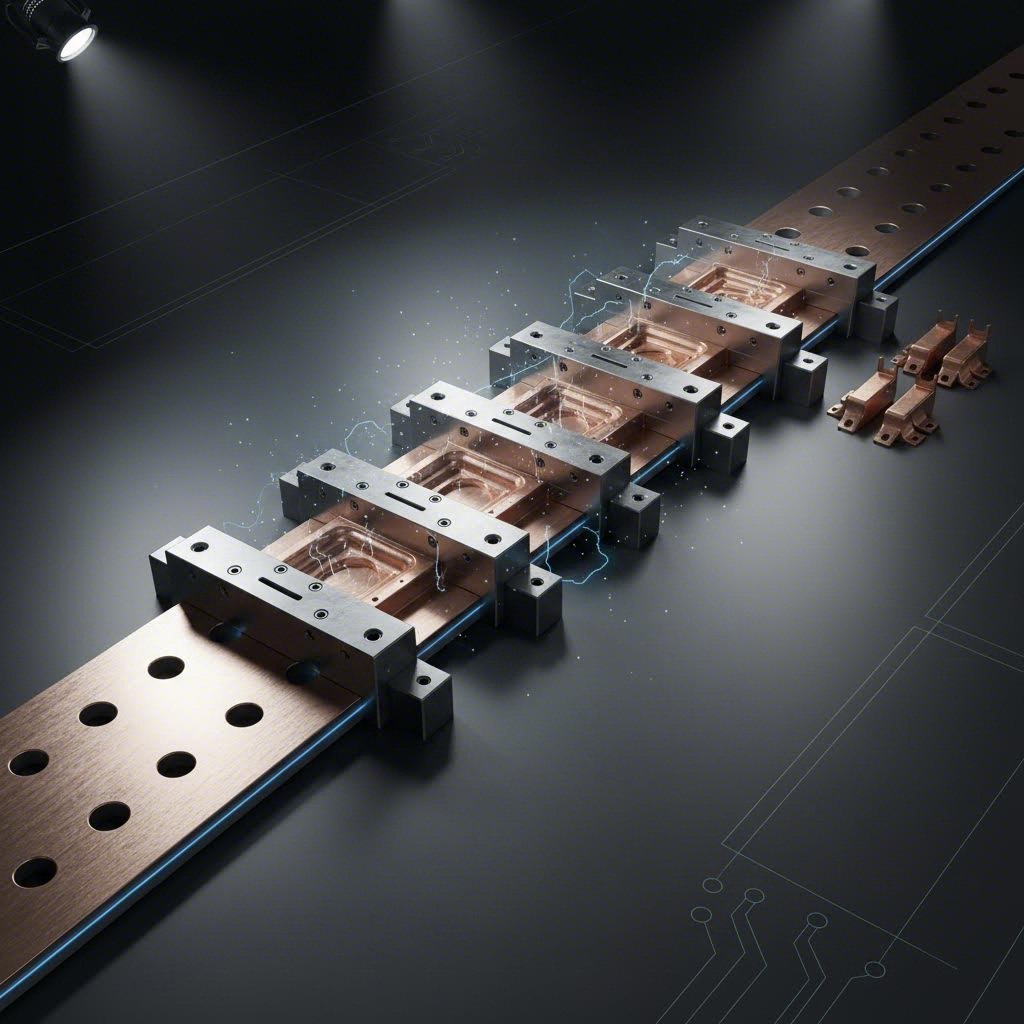

Selecting the correct manufacturing process depends heavily on production volume and part complexity. While several methods exist, progressive die stamping reigns supreme for high-volume EV production. In this process, a metal coil is fed through a series of stations in a single die set. Each station performs a specific operation—cutting, bending, punching, or coining—incrementally shaping the busbar. This method ensures consistent repeatability and supports high-speed output, making it the most cost-effective solution for annual volumes exceeding 20,000 units.

For lower volumes or highly complex 3D shapes that cannot be easily stamped, CNC bar forming is utilized. This process bends and twists metal bars into intricate configurations without expensive hard tooling. It is ideal for prototyping or low-volume performance vehicles but lacks the cycle speed of stamping. Chemical etching or laser cutting serves as a third option, primarily for extremely thin, intricate busbars used in battery module interconnects where mechanical stress from stamping could deform the delicate material.

Advanced progressive die setups now incorporate in-die assembly capabilities. Leading manufacturers utilize systems that can insert fasteners, stake nuts, or even assemble multi-layer laminated busbars directly within the stamping press. This integration eliminates secondary operations, reducing handling costs and improving the positional accuracy of connection points.

Material Science: Copper, Aluminum, and Bi-Metals

The choice between copper and aluminum is the central trade-off in busbar engineering. Copper (C11000) remains the gold standard for conductivity, offering the highest ampacity per unit of volume. It is indispensable for space-constrained areas like inverters and traction motors where maximizing power density is paramount. However, copper is heavy and expensive, posing challenges for lightweighting initiatives.

Aluminum (AA6000 series) has emerged as the preferred alternative for long runs, such as the main battery-to-motor connections. While aluminum has only about 60% of the conductivity of copper, it is approximately 70% lighter. By increasing the cross-sectional area to compensate for lower conductivity, engineers can achieve the same electrical performance at half the weight of a copper equivalent. This mass reduction directly translates to increased vehicle range.

To bridge the gap, the industry increasingly relies on bi-metal solutions. Technologies such as friction stir welding or ultrasonic welding join copper contact points (for reliable, oxidation-resistant connections) with aluminum main bodies (for weight savings). These hybrid busbars offer the best of both worlds but require specialized manufacturing partners capable of managing the galvanic corrosion risks inherent in dissimilar metal interfaces.

Design for Manufacturing (DFM) for Stamped Busbars

Successful busbar production begins on the drawing board. Adhering to Design for Manufacturing (DFM) principles ensures that a part can be stamped reliably without excessive tool wear or failure. A critical factor is the minimum bend radius. For most copper and aluminum alloys, the inside bend radius should be at least equal to the material thickness (1T) to prevent cracking on the outer edge of the bend. Tighter radii are possible but may require specialized material tempers or coining operations that add cost.

Engineers must also account for springback—the tendency of metal to return partially to its original shape after bending. High-tensile alloys exhibit more springback, requiring the stamping die to over-bend the material slightly to achieve the final desired angle. Accurate prediction of this behavior via simulation software is a hallmark of a capable stamping partner.

Insulation and isolation are equally critical DFM considerations. High-voltage EV busbars require robust dielectric protection. Options range from epoxy powder coating (which offers high temperature resistance and uniform coverage) to heat-shrink tubing and laminated films. The choice of insulation affects the stamping process, as allowance must be made for the thickness of the coating, and sharp edges must be deburred or coined to prevent the insulation from being punctured.

Sourcing Strategy: Evaluating Busbar Manufacturers

Sourcing busbars for automotive applications requires vetting suppliers against stringent quality standards. IATF 16949 certification is non-negotiable; it verifies that the manufacturer’s quality management system meets the rigorous demands of the automotive supply chain. Beyond basic certification, evaluate a supplier’s vertical integration. Ideally, a partner should handle tooling design, stamping, plating, and assembly in-house. This control reduces lead times and centralizes accountability for quality.

When moving from development to mass production, the ability to scale is crucial. Some manufacturers specialize only in prototypes, while others require massive minimum order quantities. Finding a partner that can bridge this gap is essential for a smooth launch. Accelerate your automotive production with Shaoyi Metal Technology’s comprehensive stamping solutions, bridging the gap from rapid prototyping to high-volume manufacturing. Leveraging IATF 16949-certified precision and press capabilities up to 600 tons, they deliver critical components like control arms and subframes with strict adherence to global OEM standards.

Finally, look for "design assist" capabilities. The best suppliers act as extensions of your engineering team, offering DFM feedback early in the design phase to reduce tooling costs and improve part performance. They should use simulation tools to validate designs before steel is cut, ensuring that the transition from CAD to physical part is seamless and error-free.

Conclusion

As electric vehicles continue to dominate the automotive landscape, the role of stamped busbars will only grow in significance. These components are the arteries of the EV powertrain, balancing the competing demands of power density, weight reduction, and manufacturing scalability. For engineers and sourcing professionals, success lies in understanding the interplay between material properties, stamping mechanics, and strategic partner selection. By prioritizing early DFM collaboration and selecting manufacturers with proven automotive pedigrees, OEMs can ensure their power distribution systems are as robust and efficient as the vehicles they drive.

Frequently Asked Questions

1. Why are stamped busbars preferred over cables in EVs?

Stamped busbars offer superior space efficiency, better thermal management, and are rigid enough to support automated robotic assembly. They allow for higher current density (ampacity) in a smaller footprint compared to traditional round wiring harnesses, which is critical for dense EV battery packs.

2. What is the difference between progressive die stamping and CNC forming?

Progressive die stamping is a high-speed manufacturing process ideal for mass production (20,000+ units), using a custom tool to perform multiple operations in a single pass. CNC forming is a slower, tool-less process better suited for low-volume prototypes or complex 3D shapes that are difficult to stamp.

3. Can aluminum busbars replace copper entirely?

Not entirely. While aluminum is lighter and cheaper, it has lower conductivity than copper. It is excellent for main power transmission where space allows for a larger cross-section, but copper is still preferred for compact areas requiring maximum power density, such as inside inverters.

4. What is the IATF 16949 certification?

IATF 16949 is the global technical standard for quality management systems in the automotive industry. It ensures that a manufacturer has robust processes for defect prevention, supply chain variability reduction, and continuous improvement, which is mandatory for Tier 1 and OEM suppliers.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —