Automotive Cross Member Stamping: Precision Chassis Manufacturing

TL;DR

Automotive cross member stamping is a high-precision manufacturing process used to fabricate the structural "backbone" of a vehicle's chassis. These components, critical for supporting the engine, transmission, and suspension, are primarily manufactured using progressive die or transfer die technologies to ensure dimensional stability and crash safety. As the industry prioritizes lightweighting, manufacturers are increasingly shifting from traditional steel to Advanced High-Strength Steel (AHSS) and aluminum alloys, which introduce complex challenges like springback and heat distortion. Successful production requires sophisticated die design strategies, including over-bending and computer-aided engineering (CAE) simulation, to maintain tight tolerances in mass production.

The Anatomy and Function of Automotive Cross Members

In the hierarchy of automotive structural components, the cross member serves as a critical load-bearing element within the Body-in-White (BIW) assembly. Unlike cosmetic body panels, cross members are engineered to withstand immense mechanical stress, acting as the lateral braces that connect the longitudinal frame rails. Their primary function is to resist torsional forces (twisting) during cornering and to provide rigid mounting points for the vehicle's heaviest subsystems: the engine, transmission, and suspension control arms.

For automotive engineers, the design of a cross member is a balancing act between rigidity and crash energy management. In the event of a frontal or side impact, the cross member must deform in a controlled manner to absorb kinetic energy while preventing intrusion into the passenger cabin. Specific configurations, such as the front cross member with coupling jaw, are designed to integrate multiple functions—steering rack support, suspension geometry alignment, and radiator mounting—into a single stamped assembly.

The structural integrity of these parts is non-negotiable. A failure in a transmission cross member, for instance, can lead to drivetrain misalignment, excessive vibration, and catastrophic loss of vehicle control. Consequently, the stamping process must guarantee 100% repeatability, ensuring that every unit meets strict ISO and IATF dimensional standards.

Manufacturing Processes: Progressive vs. Transfer Die Stamping

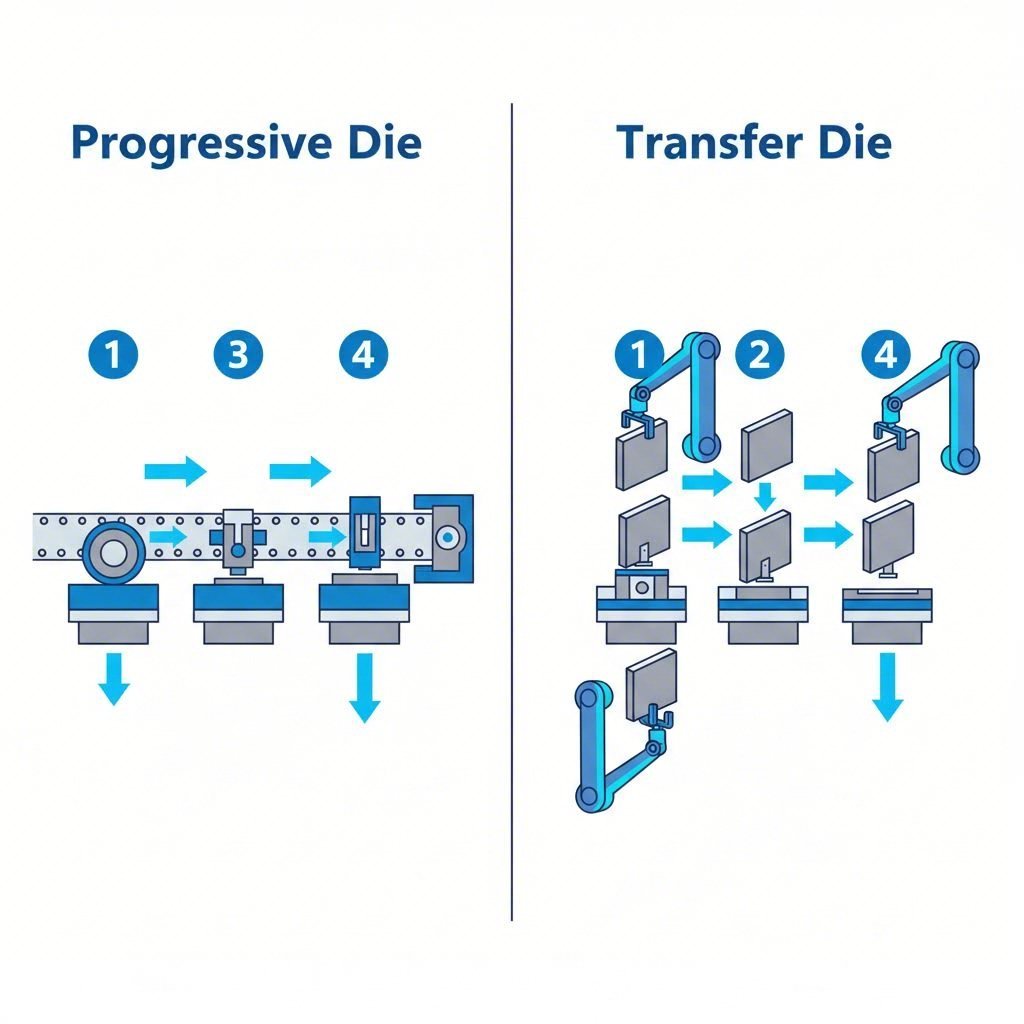

Selecting the correct stamping methodology is determined by the part's complexity, production volume, and material thickness. Two dominant technologies define the landscape of cross member manufacturing: progressive die stamping and transfer die stamping.

Progressive Die Stamping

Ideal for high-volume production of smaller to medium-sized cross members, progressive die stamping feeds a continuous coil of metal strip through a series of stations within a single die set. As the strip moves forward with each stroke of the press, specific operations—cutting, bending, punching, and coining—are performed sequentially. This method is highly efficient for parts requiring intricate features and tight tolerances at high speeds. However, it is generally limited by the maximum size of the die bed and the need for the part to remain attached to the carrier strip until the final station.

Transfer Die Stamping

For larger, deeper, or more geometrically complex cross members—such as those found in heavy trucks or SUVs—transfer die stamping is the superior choice. In this process, individual blanks are cut first and then mechanically transferred between separate die stations using robotic arms or transfer rails. This allows for free manipulation of the part, enabling deep drawing operations that would be impossible in a progressive die. Transfer stamping is essential for heavy-gauge components where material flow must be precisely controlled to prevent thinning or splitting.

Process Comparison

| Feature | Progressive Die | Transfer Die |

|---|---|---|

| Material Feed | Continuous coil strip | Pre-cut individual blanks |

| Part Complexity | Medium complexity, connected to strip | High complexity, deep draw capabilities |

| Production Speed | High (fast cycle times) | Medium (limited by transfer speed) |

| Ideal Application | Brackets, smaller structural supports | Large cross members, frame rails |

For manufacturers seeking a partner capable of handling these diverse requirements, Shaoyi Metal Technology offers comprehensive solutions ranging from rapid prototyping to mass production. With press capabilities up to 600 tons and IATF 16949 certification, they bridge the gap between engineering concept and high-volume delivery, accommodating both complex transfer operations and high-speed progressive runs.

Material Selection: The Shift to AHSS and Aluminum

The imperative for fuel efficiency and electric vehicle (EV) range extension has revolutionized material selection for stamped components. The traditional mild steel utilized in decades past has largely been replaced by advanced materials that offer superior strength-to-weight ratios.

Advanced High-Strength Steel (AHSS)

AHSS is now the industry standard for safety-critical cross members. Materials like dual-phase (DP) and martensitic steels allow engineers to use thinner gauges without sacrificing structural rigidity. While this reduces overall vehicle weight, it complicates the stamping process. AHSS has higher tensile strength, which increases the wear on stamping dies and requires significantly higher tonnage presses to form effectively. Furthermore, the material's limited ductility makes it prone to cracking if the bend radii are not calculated precisely.

Aluminum Alloys

For premium and electric vehicles, aluminum (specifically 5000 and 6000 series alloys) is increasingly favored. Aluminum components can weigh roughly one-third of their steel counterparts, offering massive lightweighting benefits. However, stamping aluminum presents unique challenges: it has lower formability than steel and is more susceptible to tearing. Advanced techniques such as superforming—using gas pressure to shape heated aluminum sheets—or specialized lubricants are often required to produce complex aluminum cross members successfully.

Engineering Challenges and Quality Control

Producing cross members to automotive standards involves overcoming significant metallurgical and mechanical hurdles. Two primary defects—springback and heat distortion—demand rigorous engineering solutions.

Springback Compensation

When metal is stamped, it has a natural tendency to return to its original shape after the forming force is removed; this is known as springback. With high-strength materials like AHSS, springback is more pronounced and difficult to predict. To counter this, die designers use simulation software to calculate the exact amount of elastic recovery and engineer the die to "over-bend" the part. By stamping the metal past the desired angle, it springs back into the correct tolerance.

Managing Heat Distortion

Cross members are rarely standalone parts; they are often welded to brackets, coupling jaws, or frame rails. The intense heat from robotic MIG welding creates thermal expansion and contraction, which can warp the stamped component. Leading manufacturers like Kirchhoff Automotive address this by designing the initial stamping with compensatory geometry. The part is intentionally stamped "out of spec" in a specific direction so that the subsequent weld heat pulls it into the correct final dimensions.

Note: Quality control for these components goes beyond visual inspection. It requires automated optical scanning and coordinate measuring machines (CMM) to verify that critical mounting points remain within sub-millimeter tolerances despite these physical stresses.

Conclusion

The manufacturing of automotive cross members is a discipline that merges brute force with microscopic precision. As vehicles evolve toward lighter architectures and electrified powertrains, the demand for sophisticated stamping—capable of forming AHSS and aluminum with zero defects—will only intensify. For buyers and engineers, success lies in selecting suppliers who not only possess heavy-tonnage capacity but also the engineering depth to master material behavior, ensuring the chassis backbone remains unyielding under pressure.

Frequently Asked Questions

1. What is the primary function of a cross member in a vehicle?

A cross member acts as a structural brace connecting the vehicle's frame rails. It supports critical components like the transmission, engine, and suspension while resisting torsional twisting forces to maintain chassis rigidity and handling stability.

2. Can a damaged cross member be repaired?

Generally, a bent or cracked cross member should be replaced rather than repaired. Since it is a safety-critical structural component, welding or straightening it can compromise its metal fatigue properties and crashworthiness. Driving with a damaged cross member can lead to transmission misalignment and severe vibration.

3. Why is heat distortion a concern in cross member manufacturing?

Cross members often require welding to attach mounting brackets. The heat from welding causes the metal to expand and contract, potentially warping the part. Manufacturers must design the stamping die to compensate for this anticipated distortion to ensure the final assembly fits perfectly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —