Fender Stamping Process: From Raw Coil to Aerodynamic Precision

TL;DR

The fender stamping process is a high-precision manufacturing sequence that transforms flat metal coils into the complex, aerodynamic body panels seen on vehicles. It begins with Blanking, where raw steel or aluminum is cut into rough 2D shapes, followed by the critical Deep Drawing phase, where high-tonnage presses force the metal into 3D dies to form compound curves. Subsequent operations like Trimming and Flanging refine the edges and add mounting points before the part undergoes surface finishing. This workflow balances material science with heavy industrial mechanics to ensure every fender meets strict "Class A" surface standards.

Phase 1: Material Selection & Blanking (The Foundation)

Every fender begins as a flat coil of raw material, and the choice of this material dictates the entire downstream process. Manufacturers typically choose between Cold-Rolled Steel and Aluminum Alloys. Cold-rolled steel is the industry standard for its balance of cost, formability, and strength. However, modern manufacturing—particularly for electric vehicles like Tesla—is shifting toward aluminum alloys to reduce weight and increase range. While aluminum offers significant mass reduction, it presents higher costs and increased difficulty in forming due to its lower elasticity compared to steel.

Once the material is selected, it enters the Blanking stage. Here, the continuous metal coil is unspooled and fed into a specialized press that cuts it into discrete, rough flat shapes known as "blanks." This is not merely chopping the coil into rectangles; advanced Oscillating Shear dies often cut trapezoidal or contoured shapes to minimize scrap waste. These blanks are then thoroughly cleaned and washed. Removing oil, dust, and microscopic debris at this stage is non-negotiable, as even a single particle trapped in the die later can cause surface pimples or rupture the metal during the high-pressure drawing phase.

Phase 2: Deep Drawing & Forming (The Critical Step)

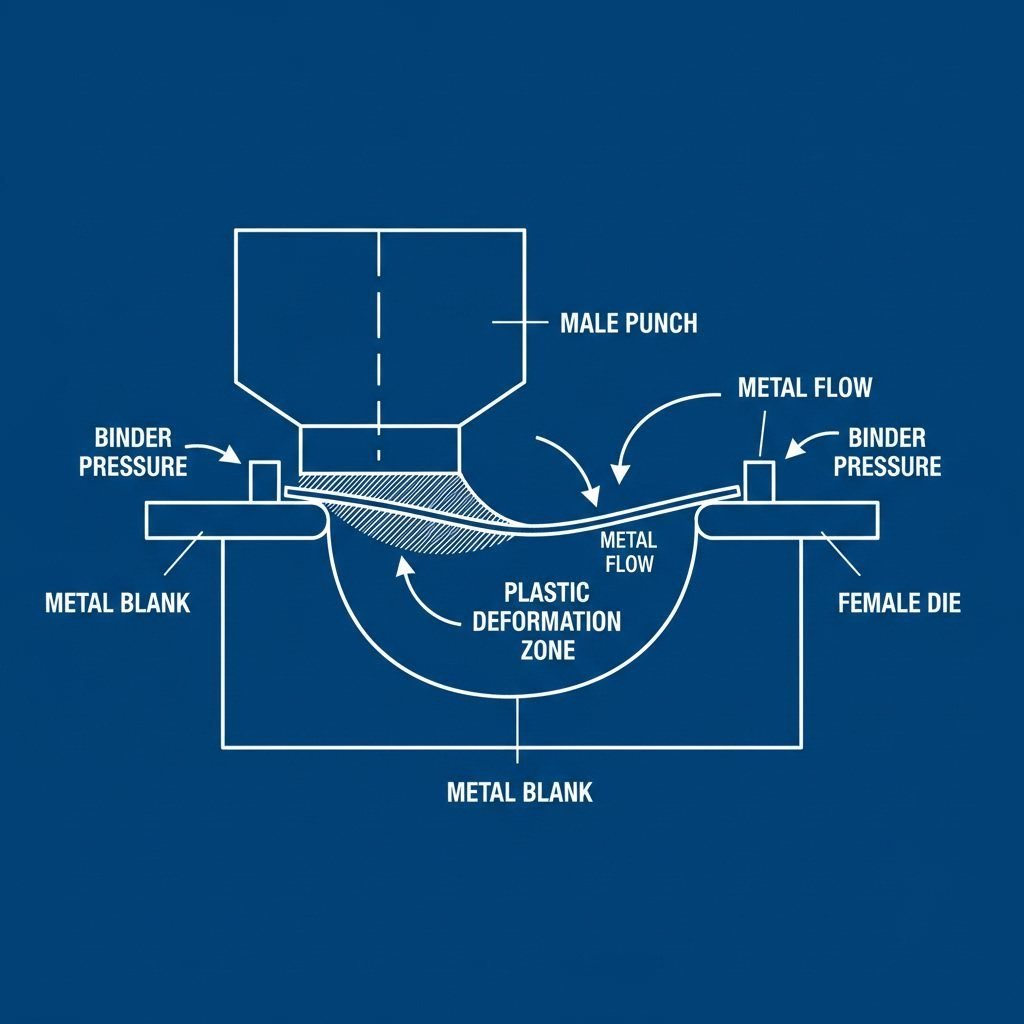

The heart of the fender stamping process is Deep Drawing. In this phase, the flat blank is transformed into a three-dimensional shape with complex compound curves. The blank is placed over a female die cavity, and a massive male punch descends to force the metal into the shape of the fender. A "binder" or "blank holder" ring clamps the edges of the metal to control the flow. If the metal flows too freely, it creates wrinkles; if it is held too tightly, it stretches until it splits.

Achieving these aerodynamic geometries requires immense force and precision control. The press must apply hundreds of tons of pressure evenly across the surface. This is where the capability of the manufacturing partner becomes critical. For instance, automotive supply chains often rely on specialized firms like Shaoyi Metal Technology, which leverages press capabilities up to 600 tons to bridge the gap from rapid prototyping to high-volume manufacturing. Their adherence to IATF 16949 standards ensures that the deep drawing process remains consistent, whether producing fifty prototype parts or five million production units.

The distinction between Single Action and Double Action presses is also vital here. In a double action press, the outer slide clamps the binder first, and the inner slide drives the punch separately. This allows for superior control over the metal flow, which is essential for the deep, dramatic wheel arches found on modern SUVs and sports cars.

Phase 3: Trimming, Flanging & Piercing (Refinement)

After deep drawing, the fender has its general shape, but it is surrounded by excess metal held by the binder. The Trimming operation removes this scrap, cutting the part to its final perimeter. This step requires hardened steel cutting steels that must be maintained to razor-sharpness to avoid leaving burrs on the edge of the panel.

Next comes Flanging and Piercing. Flanging involves bending specific edges of the fender—such as the wheel arch lip or the hood mating surface—typically to 90 degrees. These flanges provide structural rigidity and create surfaces for bonding or welding. Simultaneously, piercing dies punch the necessary holes for mounting bolts, side marker lights, and trim clips. In mass production, these operations are often combined into a single "Restrike" or "Calibration" die to ensure perfect alignment. For low-volume prototypes, manufacturers might use 5-axis laser trimmers instead of hard tooling to save on initial die costs.

Phase 4: Surface Finishing & E-Coating

Because fenders are "Class A" exterior surfaces, the finish must be flawless. The raw stamped metal is highly susceptible to rust, so it undergoes a rigorous chemical treatment immediately after assembly. The industry standard is E-Coating (Electro-deposition Coating), a process that acts as a primer and corrosion inhibitor.

The process begins with Phosphating, where the fender is dipped in a zinc phosphate solution that etches the metal surface slightly, creating a crystal matrix that allows paint to adhere. The part is then submerged in a tank of electrically charged paint emulsion. An electric current flows through the fender, attracting the paint particles to every crevice, ensuring 100% coverage even inside the hemmed edges. Finally, the fender is baked in an oven to cure the coating, creating a hard, durable shell that resists salt spray and road debris.

Phase 5: Common Defects & Quality Control

Stamping complex shapes often leads to specific defects that engineers must constantly mitigate. The most common issues include:

- Wrinkling: Occurs when the binder pressure is too low, causing the metal to bunch up in the die radius.

- Splitting/Tearing: The opposite of wrinkling; caused by excessive tension where the metal thins out until it fractures.

- Springback: The elastic tendency of metal to return to its original flat shape after forming. Die designers must compensate for this by "over-bending" the part slightly so it bounces back to the correct geometry.

- Surface Imperfections: Dings, scratches, or "orange peel" textures that ruin the mirror-like finish required for painting.

Quality control relies on both technology and trained eyes. Coordinate Measuring Machines (CMM) and "Blue Light Scanners" verify the dimensional accuracy of the fender to within fractions of a millimeter. For surface quality, parts are passed through a "Light Tunnel"—a highly illuminated inspection station where inspectors look for minute ripples or defects that would show up under glossy paint.

Conclusion

The journey from a steel coil to a finished fender is a masterclass in modern manufacturing efficiency. It combines the brute force of hydraulic presses with the microscopic precision of chemical engineering. Understanding this process highlights why vehicle body panels are not just simple sheets of metal, but highly engineered components designed for safety, aerodynamics, and longevity. As materials evolve toward lighter aluminum and composites, the stamping process continues to adapt, demanding even tighter tolerances and more advanced machinery.

Frequently Asked Questions

1. What is the difference between stamping and bending?

Bending is a simpler operation typically performed on a press brake to create straight-line angles in sheet metal. Stamping is a complex, high-speed process using custom dies to cut, draw, and form metal into 3D shapes in a single or progressive cycle. Stamping is ideal for mass production of complex parts like fenders, whereas bending is better for low-volume brackets or simple enclosures.

2. What is the typical cycle time for stamping a fender?

In a high-volume automotive stamping line, the cycle time is incredibly fast, often ranging from 10 to 15 seconds per part. Automated transfer press lines can move the part from blanking to drawing to trimming without manual intervention, allowing manufacturers to produce thousands of fenders per shift.

3. What is the "lancing" process in stamping?

Lancing is a specialized cutting operation used to create vents, tabs, or louvers without removing any material (scrap). The metal is sliced along three sides and bent simultaneously. While less common on the exterior skin of a fender, lancing is frequently used on the inner structural reinforcements to create attachment points or wire routing paths.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —