Aluminum Stamping Automotive Benefits: Engineering Guide

TL;DR

Aluminum stamping automotive benefits center on a critical "lightweighting" advantage: aluminum components weigh approximately one-third as much as their steel counterparts while maintaining structural integrity. This weight reduction directly correlates to performance; a 10% drop in vehicle mass typically yields a 6–8% improvement in fuel economy and significantly extends the range of electric vehicles (EVs). Beyond weight, stamped aluminum offers superior corrosion resistance through its natural oxide layer and actually gains strength in cryogenic temperatures, unlike steel which can become brittle.

However, the transition to aluminum requires specialized engineering to manage "springback"—the metal's tendency to return to its original shape after stamping. To fully leverage benefits like high strength-to-weight ratios and recyclability (saving 95% of energy vs. primary production), manufacturers must utilize advanced alloy selection (typically 5xxx and 6xxx series) and precision servo-press technologies.

The Lightweighting Imperative: Efficiency & Performance

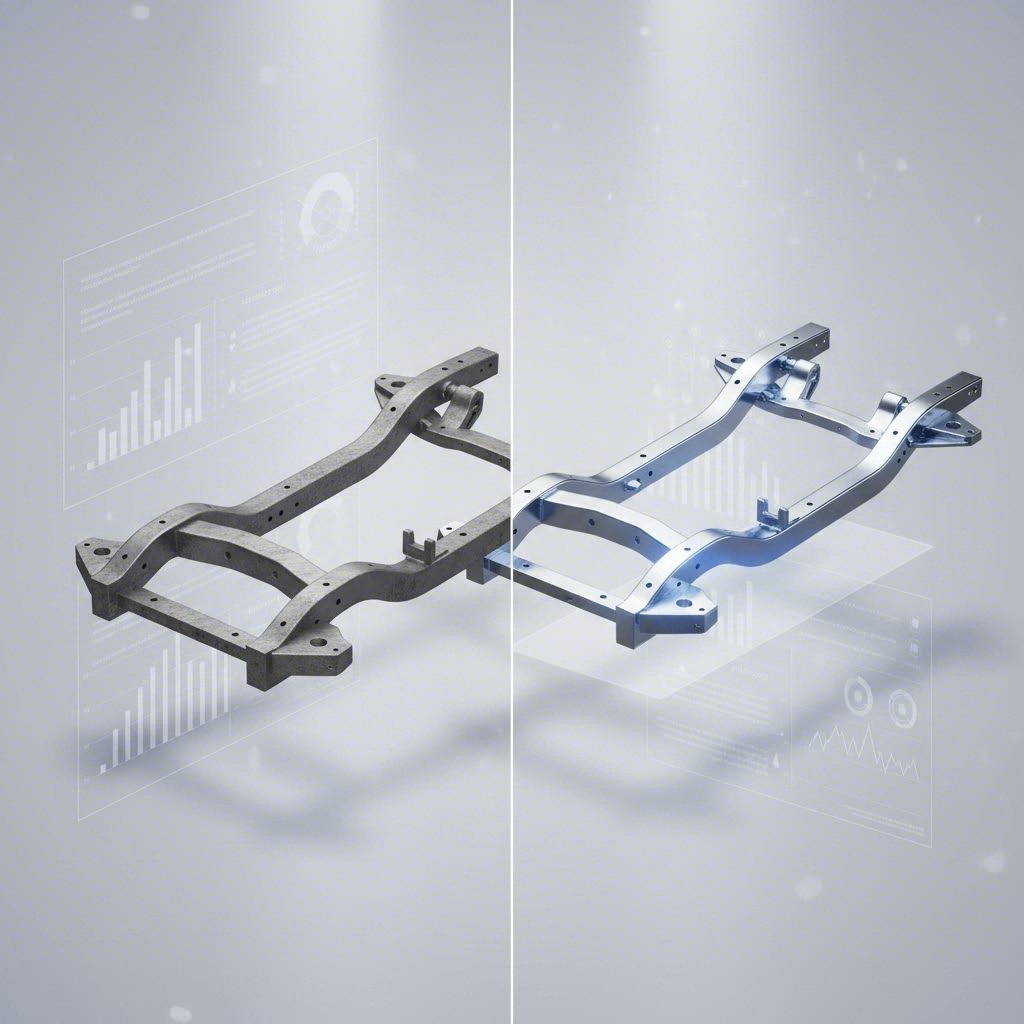

The automotive industry's drive toward aluminum stamping is fundamentally fueled by the physics of mass. With a density roughly one-third that of steel, aluminum offers the most immediate path to "lightweighting"—a strategic reduction in vehicle mass that triggers a virtuous cycle of efficiency. When a manufacturer replaces a heavy steel chassis component with a stamped aluminum alternative, the benefits cascade throughout the vehicle design: a lighter body requires less braking force, allowing for smaller brake systems, lighter suspension components, and reduced engine power to achieve the same acceleration figures.

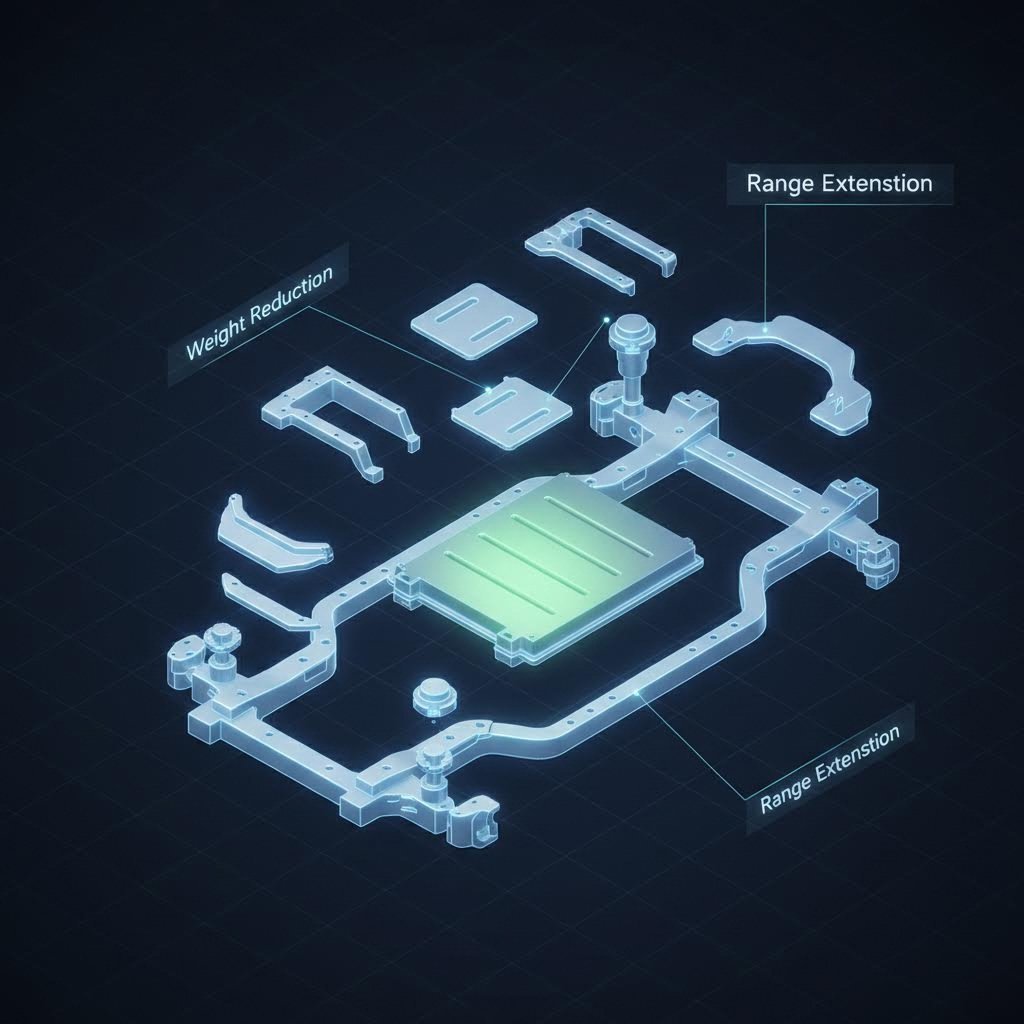

For internal combustion engines, the data is compelling. Industry analysis indicates that a 10% reduction in vehicle weight translates to a 6–8% improvement in fuel economy. In the context of Electric Vehicles (EVs), this math becomes even more critical. Battery weight remains a primary constraint for EV range; offsetting that mass with stamped aluminum body panels, battery enclosures, and structural nodes allows OEMs to maximize range without increasing battery size or cost.

This efficiency does not come at the cost of safety. Modern aluminum stamping techniques allow engineers to manipulate material thickness and geometry to create "crush zones" that absorb impact energy effectively. The result is a vehicle that is lighter, more agile, and equally safe, meeting increasingly stringent global emissions standards.

Technical Advantages: Beyond Just Weight

While weight reduction grabs the headlines, the technical properties of aluminum alloys provide distinct advantages in durability and manufacturing versatility. A primary benefit is the material's inherent corrosion resistance. Unlike steel, which requires heavy galvanization or coating to prevent rust, aluminum naturally forms a thin, hard oxide layer upon exposure to air. This self-repairing shield protects stamped components like underbody shields and wheel arches from road salts and moisture, significantly extending the vehicle's service life.

Another often-overlooked property is aluminum's performance in extreme temperatures. Traditional carbon steels can become brittle and prone to fracture in freezing conditions. In contrast, aluminum alloys demonstrate increased tensile strength and ductility as temperatures drop. This cryogenic stability makes stamped aluminum an ideal choice for vehicles operating in harsh northern climates or for components exposed to extreme cold, ensuring structural reliability where other materials might fail.

Furthermore, aluminum is non-magnetic and non-sparking. These properties are increasingly relevant in modern automotive electronics and EV battery housing, where magnetic interference must be minimized, and safety against spark generation is paramount during collisions or servicing.

Navigating Challenges: Springback & Formability

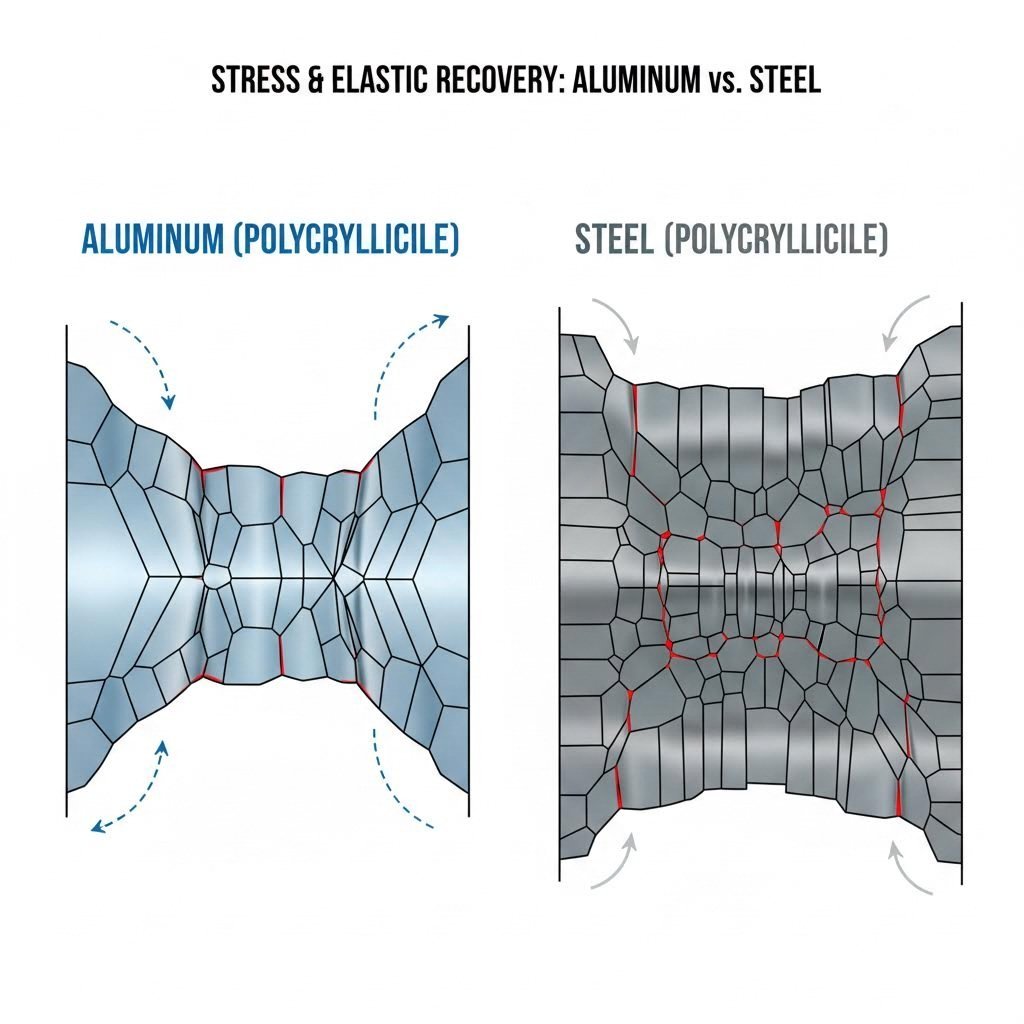

Despite its benefits, stamping aluminum presents unique engineering challenges, the most notorious being "springback." Aluminum has a lower modulus of elasticity compared to steel, meaning it has more "memory." After the stamping die hits the metal and retracts, aluminum tends to spring back toward its original flat shape more aggressively than steel. If not calculated precisely, this can result in parts that drift out of tolerance, affecting assembly alignment and panel gaps.

To overcome this, leading manufacturers employ advanced simulation software and servo-press technology. Servo presses allow for variable stroke profiles—slowing down the ram speed at the bottom of the stroke (bottom dead center) to reduce stress and set the shape more permanently. This precise control helps mitigate springback and allows for deeper draws without tearing the material.

Formability is another consideration. While aluminum is malleable, certain high-strength alloys can crack if pushed beyond their forming limits. Engineers must carefully design bend radii—typically adhering to a rule of at least 1.5 times the material thickness—to prevent fracturing. Utilizing lubricants specifically formulated for aluminum stamping also helps manage friction and heat generation, ensuring clean cuts and smooth surfaces.

Alloy Selection Guide for Automotive Stamping

Not all aluminum is created equal. The success of a stamped component relies heavily on selecting the correct alloy series, as each offers a different balance of formability, strength, and weldability. The automotive sector primarily relies on the 5xxx and 6xxx series.

| Alloy Series | Primary Element | Key Characteristics | Typical Automotive Application |

|---|---|---|---|

| 5xxx Series (e.g., 5052, 5754) | Magnesium | Excellent corrosion resistance (especially salt), good workability, high fatigue strength. Non-heat-treatable. | Fuel tanks, interior panels, sound dampening brackets, intricate non-structural parts. |

| 6xxx Series (e.g., 6061, 6082) | Magnesium & Silicon | Heat-treatable for high strength, versatile, good formability in T4 temper, high corrosion resistance. | Chassis frames, structural body-in-white components, suspension arms, crash management systems. |

| 1xxx Series (e.g., 1100) | Aluminum (99% Pure) | Superior thermal/electrical conductivity, highest corrosion resistance, lowest strength. | Heat shields, decorative trim, electrical connectors, nameplates. |

| 7xxx Series (e.g., 7075) | Zinc | Highest strength (comparable to some steels), more difficult to form, expensive. | Bumper beams, aerospace-grade structural reinforcements. |

For detailed sourcing and specifications on these grades, consulting resources like HLC Metal Parts' comprehensive guide can assist engineers in matching the specific alloy temper (e.g., T4 vs. T6) to the manufacturing process.

From Prototype to Production: Managing Volume & Precision

Moving from a digital CAD design to a physical stamped part involves distinct phases, each requiring specific capabilities. In the prototyping phase, speed and flexibility are key to validating designs and testing fitment. However, scaling to mass production introduces the need for consistency and raw power.

Handling the unique behaviors of automotive-grade aluminum—such as the need for higher tonnage to set complex shapes—requires robust machinery. Partners with engineering versatility are essential here. For instance, manufacturers like Shaoyi Metal Technology leverage 600-ton presses and IATF 16949-certified workflows to bridge the critical gap between rapid prototyping and high-volume automotive stamping. This capacity ensures that the precision achieved in a prototype is maintained across millions of production units, strictly adhering to OEM standards for control arms, subframes, and other critical safety components.

Cost-Benefit Analysis & Sustainability

While the raw material cost of aluminum is higher than that of mild steel, the total lifecycle analysis often favors aluminum. The upfront investment is offset by the long-term fuel savings for the consumer and the elimination of rust-proofing treatments during manufacturing. Additionally, manufacturing efficiency is improving; modern high-speed stamping lines can produce aluminum panels at rates comparable to steel, narrowing the production cost gap.

Sustainability is the final, decisive factor. Aluminum is infinitely recyclable without degradation of its properties. Recycling scrap aluminum requires only 5% of the energy needed to produce primary aluminum from bauxite ore. This massive energy saving aligns perfectly with the automotive industry's carbon neutrality goals, allowing OEMs to market vehicles that are not only efficient to drive but also responsible to produce.

Engineering Efficiency

The shift toward aluminum stamping is more than a trend; it is a fundamental re-engineering of the modern automobile. By balancing the trifecta of weight reduction, strength, and sustainability, aluminum stamping enables the next generation of high-efficiency internal combustion and electric vehicles. While challenges like springback and higher material costs exist, the solutions—ranging from advanced servo presses to strategic alloy selection—are well-established. For automotive engineers and procurement teams, the question is no longer if they should adopt aluminum stamping, but how to optimize the process for maximum value and performance.

Frequently Asked Questions

1. What are the primary advantages of using aluminum for car bodies?

The primary advantage is significant weight reduction, often up to 40-50% compared to traditional steel bodies. This lower mass directly improves fuel efficiency, acceleration, and braking performance. Additionally, aluminum offers excellent natural corrosion resistance and energy absorption capabilities during crashes, enhancing both longevity and safety.

2. Why is aluminum used in the automotive industry despite higher costs?

Although the raw material is more expensive, aluminum delivers lower lifecycle costs through fuel savings and reduced maintenance (due to no rust). Furthermore, it is critical for meeting strict government emissions regulations and extending the range of electric vehicles, which justifies the upfront premium for manufacturers.

3. How does metal stamping improve production efficiency?

Metal stamping is a high-speed manufacturing process capable of producing thousands of identical parts with tight tolerances in a short time. By using progressive dies or transfer presses, complex shapes can be formed, punched, and trimmed in a single automated pass, significantly reducing labor costs and cycle times compared to machining or casting.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —