Heat Treatment for Stamped Car Parts: Hot Stamping vs. Post-Process Hardening

TL;DR

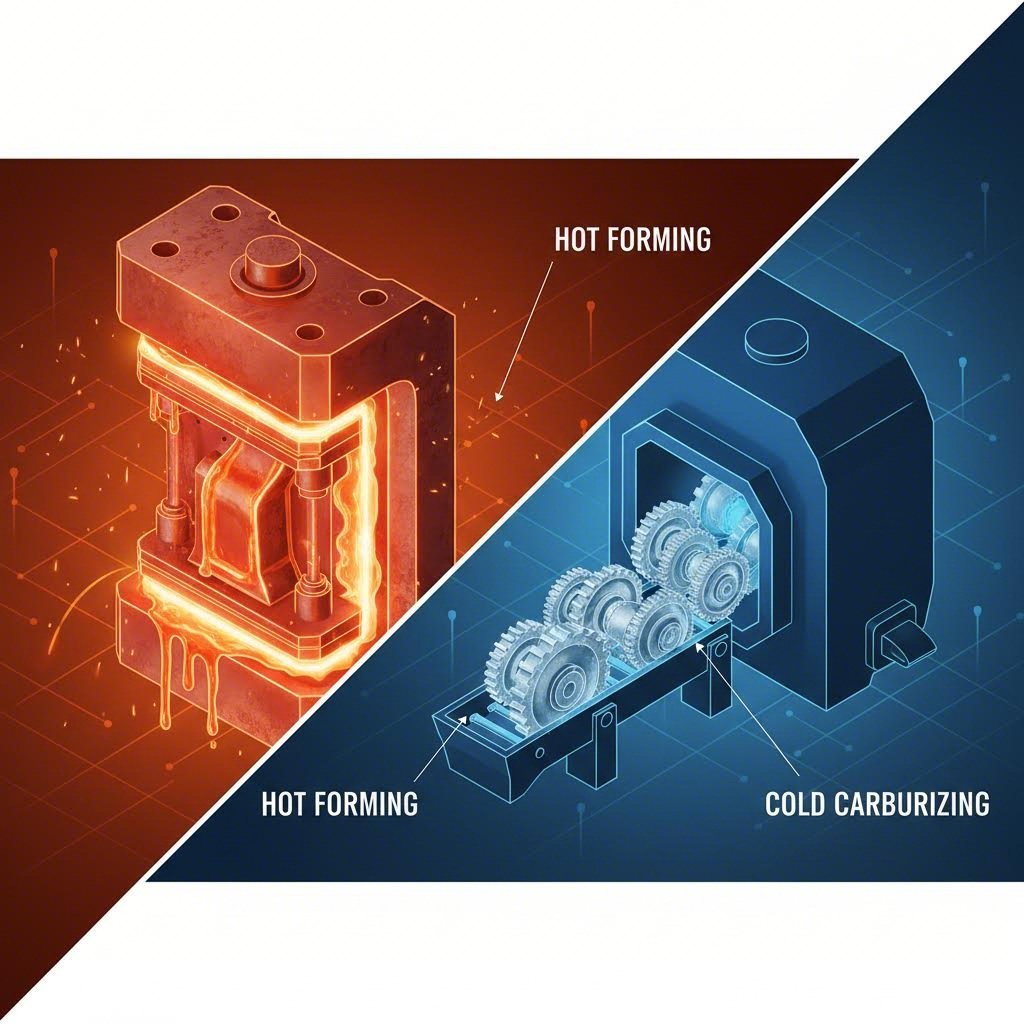

Heat treatment for stamped car parts generally falls into two distinct categories based on when the heat is applied: Hot Stamping (Press Hardening) and Post-Stamping Heat Treatment.

Hot Stamping involves heating boron steel blanks (typically 22MnB5) to over 900°C before forming and quenching them simultaneously in the die. This creates ultra-high-strength structural components like B-pillars and bumpers with tensile strengths up to 1,500 MPa. Post-Stamping Heat Treatment applies secondary processes—such as Carburizing, Ferritic Nitrocarburizing (FNC), or Induction Hardening—to parts that have already been cold stamped. This route is ideal for functional mechanisms like seat recliners and brake ratchets that require wear resistance without altering the core geometry.

The Two Primary Pathways: Hot Stamping vs. Post-Treatment

When engineering stamped automotive components, the choice of heat treatment is not merely a finishing step; it dictates the entire manufacturing strategy. The industry divides these processes into two primary workflows: Press Hardening (Hot Stamping) and Secondary Heat Treatment (Cold Stamping + Post-Process).

Understanding the fundamental differences between these pathways is critical for procurement managers and design engineers:

- Integration vs. Separation: Hot stamping integrates forming and hardening into a single die stroke. The material enters the press soft and leaves hardened. In contrast, post-treatment separates these stages; parts are formed cold (soft) and then sent to a furnace for hardening.

- Material Specificity: Hot stamping almost exclusively uses manganese-boron steels (like 22MnB5) designed to transform microstructure during quenching. Post-treatment works with a wider range of low-to-medium carbon steels and alloys (like 1020, 4140, or 8620).

- Primary Goal: The goal of hot stamping is usually structural integrity and crash safety (anti-intrusion). The goal of post-treatment is often wear resistance, fatigue life, or corrosion protection for moving parts.

Hot Stamping (Press Hardening): For Safety-Critical Structure

Hot Stamping, also known as Press Hardening, has revolutionized automotive safety. It allows manufacturers to produce complex, lightweight structural components that can withstand immense crash forces without fracturing. This process is standard for the "safety cage" of modern vehicles, including A-pillars, B-pillars, roof rails, and door intrusion beams.

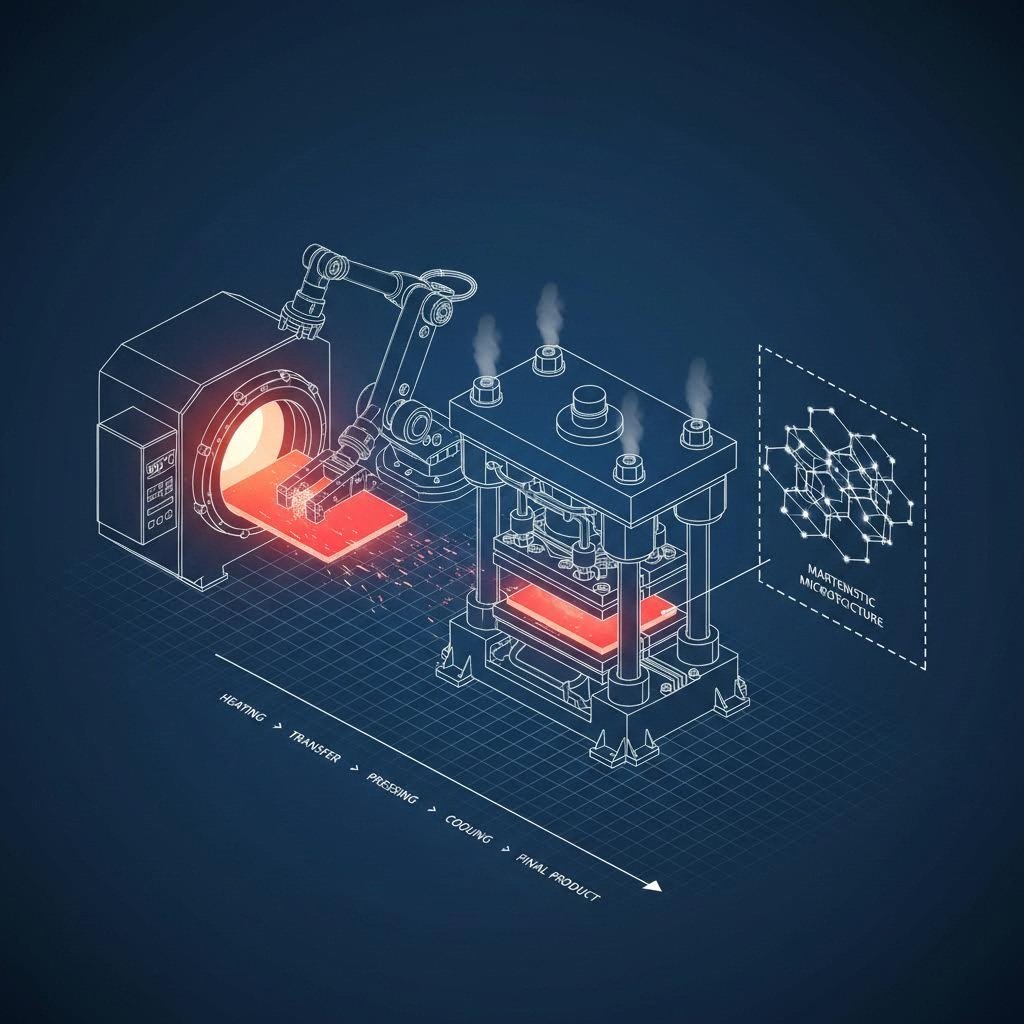

The Process: From Austenite to Martensite

The science behind hot stamping relies on a precise metallurgical transformation. The process begins by heating a steel blank in a furnace to approximately 900°C–950°C. At this temperature, the steel's internal structure changes from ferrite-pearlite to austenite, making it extremely malleable.

The red-hot blank is then quickly transferred to a water-cooled die. As the press closes to form the part, the cold die surfaces simultaneously quench the steel. This rapid cooling (at rates often exceeding 27°C per second) traps the carbon atoms in a distorted lattice, transforming the austenite into martensite. The result is a part with a yield strength that jumps from roughly 400 MPa (in its initial state) to over 1,500 MPa.

Advantages and Constraints

The primary advantage of hot stamping is the ability to form complex shapes without "springback" (the tendency of metal to return to its original shape), ensuring exceptional dimensional accuracy. However, the process requires specialized laser trimming for holes and edges, as the hardened steel is too tough for traditional mechanical cutting tools.

Post-Stamping Hardening: For Wear and Moving Parts

While hot stamping builds the car's skeleton, Post-Stamping Heat Treatment ensures the durability of its moving organs. Components like seat recliners, transmission plates, parking brake ratchets, and door latches are typically cold stamped from softer steel and then hardened to prevent wear.

For manufacturers navigating the transition from prototype to mass production of these complex functional parts, partnering with a capable supplier is essential. Shaoyi Metal Technology specializes in bridging this gap, offering comprehensive stamping solutions that align with rigorous global OEM standards, from initial engineering to final heat-treated delivery.

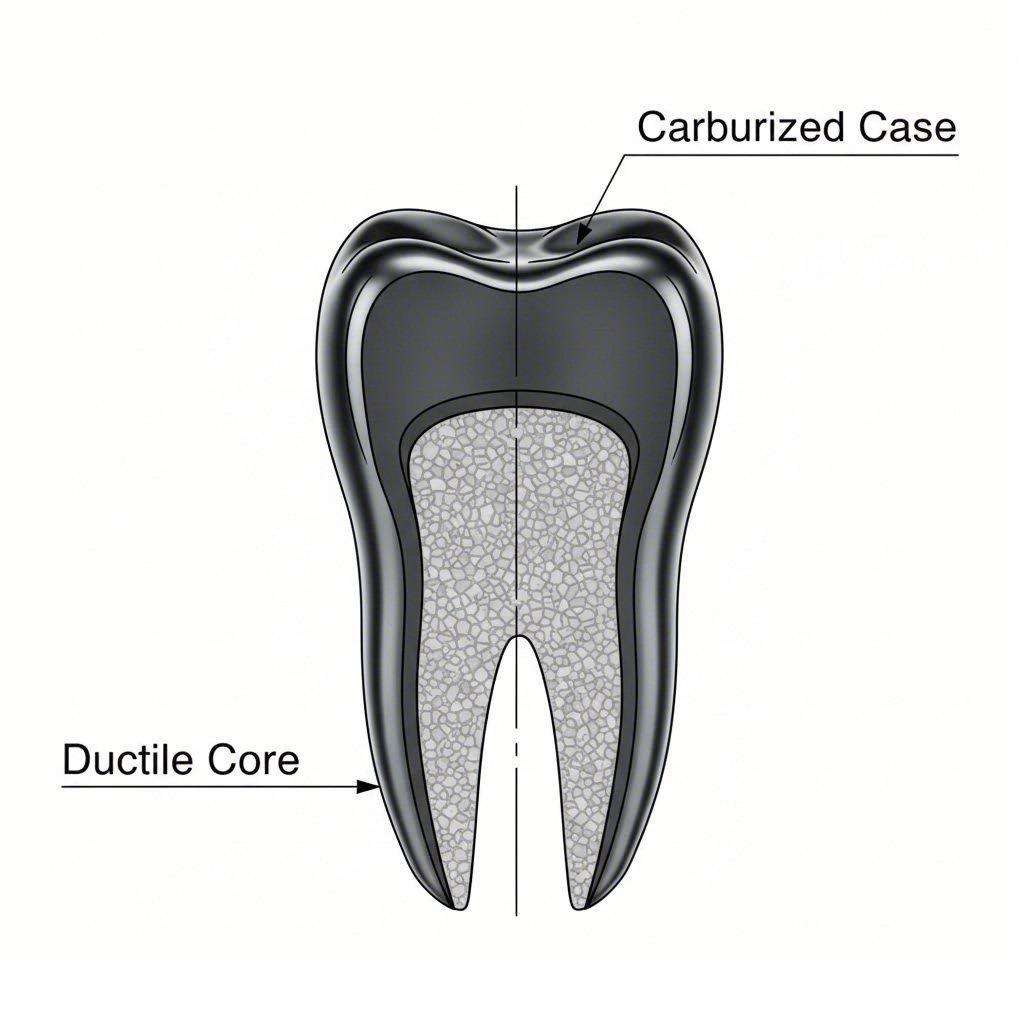

Carburizing (Case Hardening)

Carburizing is the go-to process for parts that endure heavy friction and load, such as gears and ratchets. In this process, low-carbon steel parts are heated in a carbon-rich atmosphere. The carbon diffuses into the surface, creating a hard "case" while leaving the core soft and ductile. This hard-case/tough-core combination prevents the part from snapping under sudden impact while ensuring the surface resists wear from mating components.

Induction Hardening

When only a specific area of a stamped part needs hardening—such as the teeth of a seat gear or the tip of a pawl—induction hardening is the preferred method. An electromagnetic coil heats only the target zone, which is then immediately quenched. This localized treatment minimizes distortion across the rest of the part.

Through Hardening (Neutral Hardening)

For structural brackets, clips, and seat belt tongues that require uniform strength throughout the entire cross-section, through hardening is used. This process involves heating the entire part to its austenitizing temperature and quenching it, producing a consistent hardness from surface to core. It is typically used with medium-to-high carbon steels.

Corrosion and Stability: FNC and Nitriding

For underbody parts or brake components exposed to road salt and moisture, hardness alone is insufficient. Ferritic Nitrocarburizing (FNC) and Nitriding provide a dual benefit: surface hardness and superior corrosion resistance.

Unlike carburizing, which occurs at high temperatures (often >850°C) and can cause parts to warp, FNC is performed at lower temperatures (around 575°C). This "sub-critical" temperature prevents phase transformation in the steel's core, resulting in virtually zero dimensional distortion. This makes FNC ideal for precision stamped parts like brake caliper brackets, transmission clutch plates, and thin-gauge washers that must remain perfectly flat.

Annealing and Stress Relief: The Helper Processes

Not all heat treatments are designed to harden metal. Annealing and Stress Relieving are "softening" processes essential for the manufacturing journey itself.

During deep drawing (e.g., forming an oil pan or engine cover), cold working builds up internal stress that can cause the metal to crack or tear. Intermediate annealing heats the metal to recrystallize its grain structure, restoring ductility and allowing for further forming steps. Similarly, stress relief is often applied after heavy stamping or welding to prevent the part from warping over time due to residual tension.

Conclusion

Selecting the correct heat treatment for stamped car parts is a balance of function, geometry, and material science. Hot stamping remains the uncontested champion for the safety cage, offering lightweight strength that defines modern vehicle architecture. Conversely, post-stamping treatments like Carburizing and FNC are indispensable for the intricate moving mechanisms that drivers interact with daily. By aligning the component's performance requirements—whether it's crash resistance, wear life, or corrosion protection—with the appropriate thermal cycle, engineers ensure both safety and longevity in automotive design.

Frequently Asked Questions

1. What is the difference between hot stamping and cold stamping heat treatment?

Hot stamping heats the metal before and during the forming process, transforming the steel's microstructure to create ultra-high-strength parts in one step. Cold stamping forms the metal at room temperature, and heat treatment (like carburizing or annealing) is applied as a separate secondary operation afterward to adjust hardness or relieve stress.

2. Why is boron steel used for hot stamped parts?

Boron steel, specifically grades like 22MnB5, is used because adding boron significantly improves hardenability. It allows the steel to fully transform into a hard martensitic structure during the rapid cooling phase within the water-cooled die, achieving tensile strengths up to 1,500 MPa.

3. Can you heat treat a stamped part after welding?

Yes, but it requires caution. Welding introduces heat that can alter the properties of previously heat-treated areas. Stress relief is commonly performed after welding to relax thermal tensions. However, if a part requires high hardness, it is often welded first and then heat-treated as a final assembly, provided the design allows for it.

4. What heat treatment is best for corrosion resistance in car parts?

Ferritic Nitrocarburizing (FNC) is widely regarded as the best heat treatment for combining hardness with corrosion resistance. It creates a hard, wear-resistant surface layer (the "compound zone") that also protects against oxidation, making it popular for brake components and underbody clips.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —