Lubrication Types for Metal Stamping: The 4 Critical Categories Explained

TL;DR

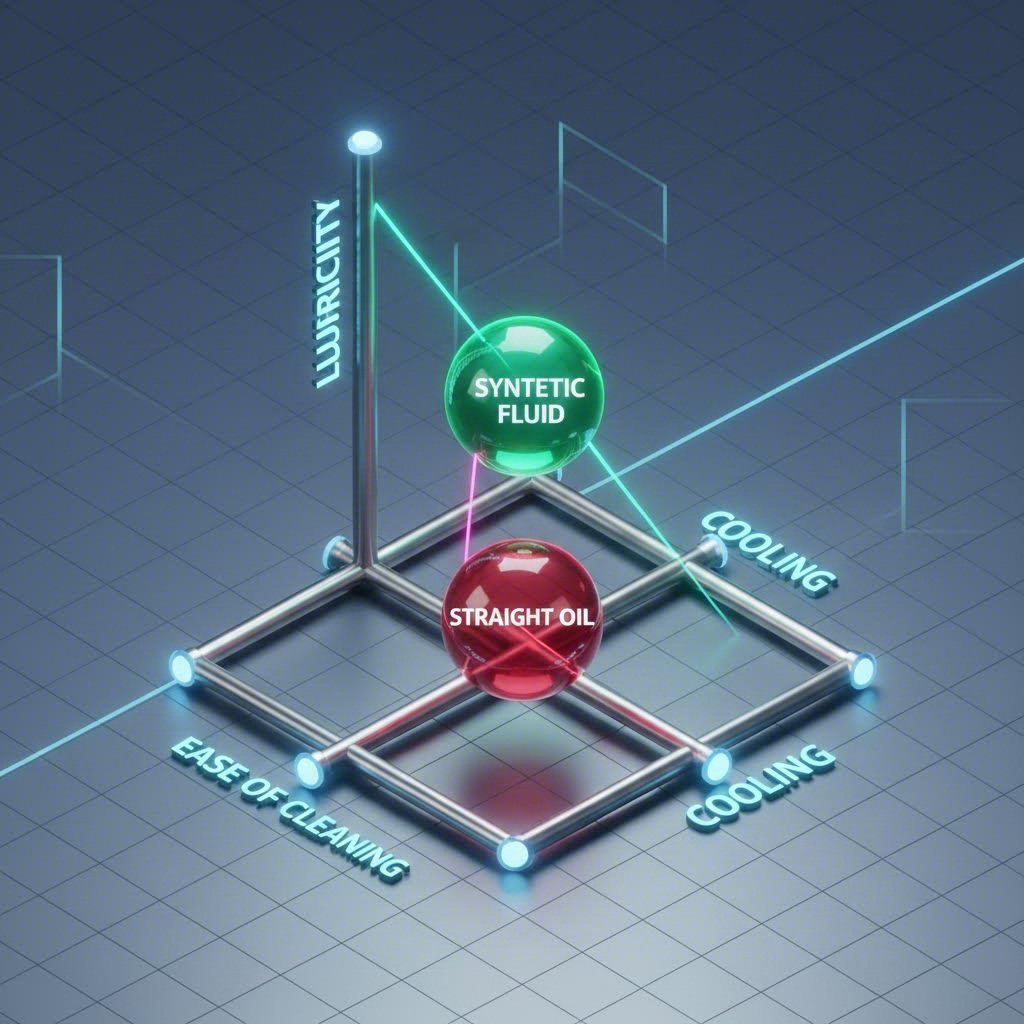

Lubrication for metal stamping generally falls into four primary categories: Straight Oils (for heavy-duty, high-lubricity needs), Soluble Oils (versatile emulsions for cooling and general use), Synthetics (for maximum cleanliness and cooling), and Vanishing Oils (evaporative fluids for light-duty, residue-free applications). The choice depends heavily on the severity of the operation (e.g., deep draw vs. blanking), the metal type, and post-stamping requirements like welding or painting. Selecting the right type balances the trade-off between protecting the die (lubricity) and protecting the part quality (cooling and washability).

Critical Selection Factors: How to Choose

Selecting the optimal lubrication type is not merely about buying a drum of oil; it is an engineering decision that impacts tool life, part quality, and downstream costs. The decision matrix typically revolves around three core variables: the severity of the deformation, the material being stamped, and the post-process requirements.

First, analyze the severity of the operation. Simple operations like blanking or piercing generate heat but require less hydrodynamic cushioning, making water-based synthetics or soluble oils ideal. In contrast, deep drawing or heavy-gauge stamping generates extreme pressure that can weld the part to the die (galling). These applications demand the high viscosity and Extreme Pressure (EP) additives found in straight oils. For manufacturers bridging the gap from rapid prototyping to mass production, partnering with specialists who understand these tribological nuances is essential. For instance, Shaoyi Metal Technology offers comprehensive stamping solutions that leverage precise lubrication strategies to deliver critical automotive components like control arms and subframes, ensuring consistency from the first 50 prototypes to millions of mass-produced units.

Second, consider the material compatibility. Ferrous metals (steels) often require corrosion inhibitors and can tolerate active sulfur or chlorine additives for extreme performance. Non-ferrous metals like aluminum or copper, however, are susceptible to staining from these same additives. For these softer metals, a polymer-fortified synthetic or a specialized soluble oil is often preferred to prevent chemical discoloration.

Finally, evaluating post-process requirements is critical for cost control. If a part must be welded, painted, or plated immediately after stamping, a heavy straight oil will require an expensive, multi-stage wash process. In such cases, a "vanishing" oil or a clean-running synthetic can eliminate the wash stage entirely, significantly reducing the total cost per part.

Type 1: Straight Oils (Heavy-Duty & Deep Draw)

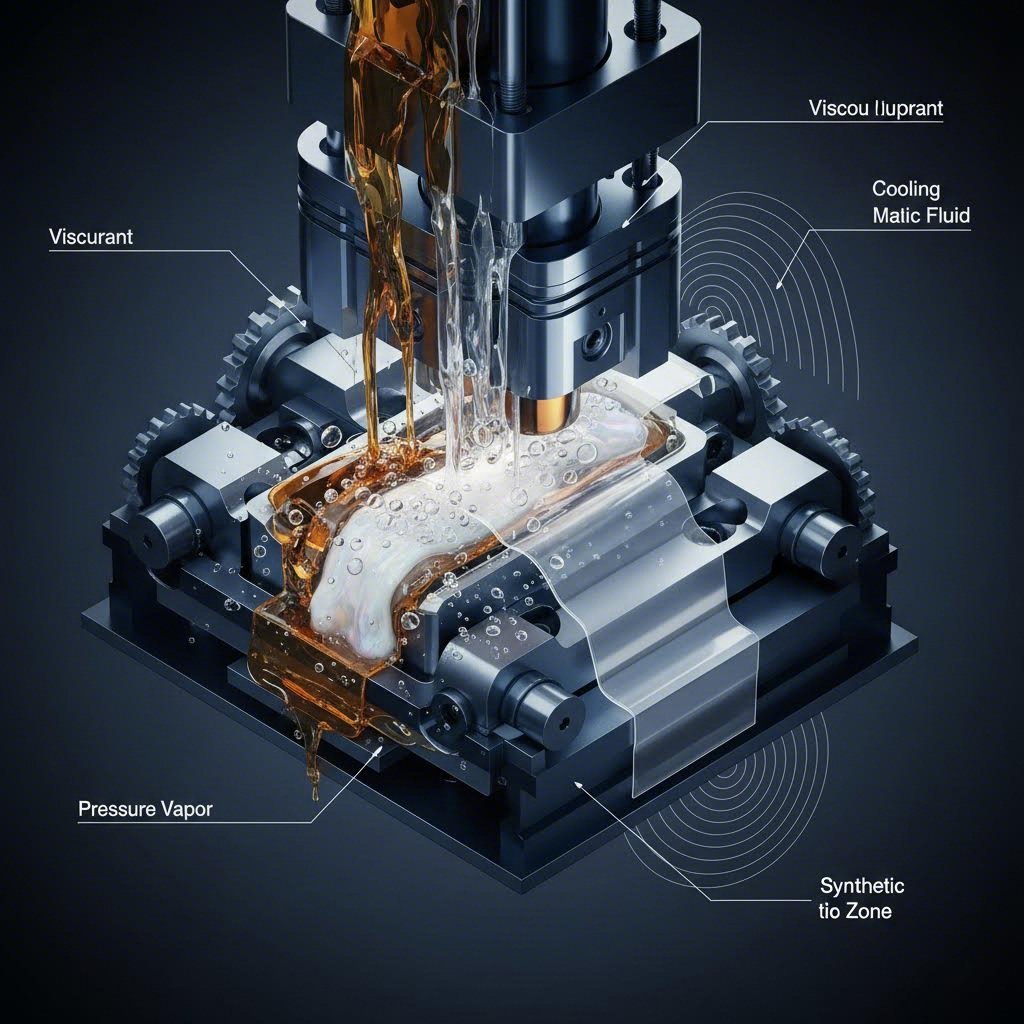

Straight oils, often called "neat" oils, are undiluted petroleum or mineral-based fluids that contain no water. They are the traditional workhorses of the metal stamping industry, prized for their superior lubricity and hydrodynamic cushioning capabilities. Because they do not rely on water, they provide excellent rust protection for the machine and the finished parts.

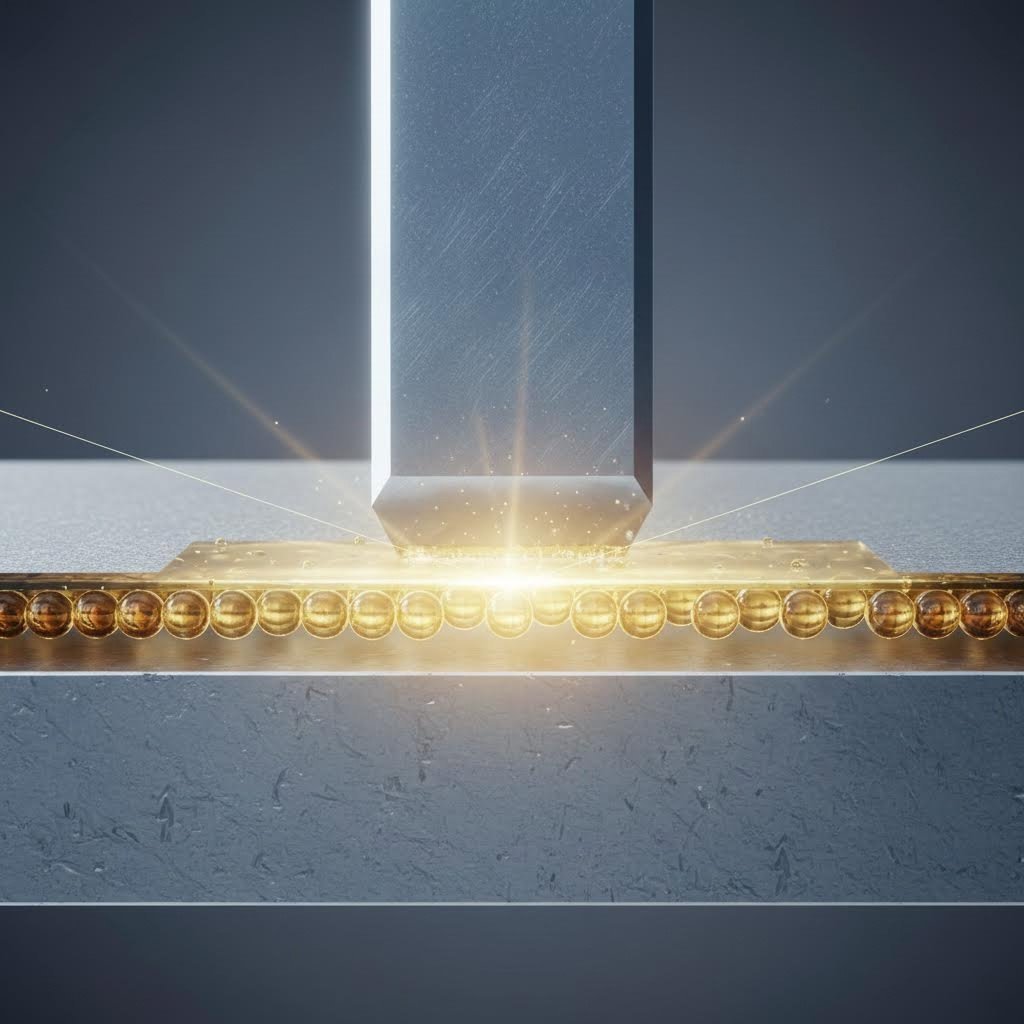

The primary mechanism of straight oils is their high viscosity, which creates a thick, physical barrier between the die and the workpiece. To enhance performance, manufacturers often blend these oils with Extreme Pressure (EP) additives such as chlorine, sulfur, or fat. These additives react with the metal surface under heat and pressure to form a sacrificial chemical film, preventing metal-to-metal contact even when the oil film is thinned by extreme force. This makes straight oils the gold standard for difficult operations like deep drawing stainless steel or forming thick-gauge high-strength alloys.

However, the performance of straight oils comes with significant trade-offs. They are poor coolants, meaning they can trap heat in the die during high-speed operations. They also leave a heavy, oily residue that acts like a magnet for shop dust and requires aggressive degreasing before painting or welding. Environmentally, they pose higher disposal costs and potential slip hazards on the shop floor. Application is typically achieved via roller coaters or drip systems rather than sprayers, due to their thickness.

Type 2: Water-Based Solubles (Cooling & Versatility)

Soluble oils, or emulsified oils, are the most common general-purpose lubricants in modern stamping shops. These fluids consist of mineral oil dispersed in water using emulsifiers and surfactants. The result is a milky-white fluid that attempts to offer the best of both worlds: the lubricity of oil and the superior cooling properties of water.

The high water content (often diluted at ratios from 5:1 to 20:1) allows soluble oils to dissipate heat rapidly, making them ideal for high-speed progressive die stamping where thermal expansion could otherwise ruin tight tolerances. The oil phase provides boundary lubrication to protect the tooling from wear. This versatility allows a single facility to use one concentrate at different dilution ratios for various jobs—richer mixtures for forming, leaner mixtures for light cutting.

While versatile, soluble oils require careful maintenance. Because they contain water and organic matter, they are prone to bacterial growth, which can lead to foul odors (often called "Monday morning smell") and skin dermatitis for operators. They also require biocides and regular pH monitoring to maintain stability. Clean-up is easier than with straight oils, but a wash stage is still typically required to remove the oily film before secondary operations.

Type 3: Synthetic Fluids (Cleanliness & Cooling)

True synthetic lubricants contain no mineral oil. Instead, they are chemical solutions composed of alkaline organic and inorganic compounds, often including polymers and detergents. They form a transparent solution when mixed with water, providing excellent visibility of the workpiece during production.

Synthetics are engineered primarily for cooling and cleanliness. They are the cleanest running option among fluids that still offer some lubricity, often rejecting "tramp oil" (leaked hydraulic fluid) to the surface for easy skimming. This keeps the bath clean and extends fluid life significantly compared to emulsions. Their rapid heat dissipation makes them perfect for very high-speed stamping of light-gauge metals, such as electrical laminations or beverage cans.

The limitation of synthetics has historically been lubricity. Without the oil content, they rely on chemical barriers that may not withstand the extreme pressures of deep drawing hard metals. However, modern "semi-synthetic" hybrids or heavy-duty polymer synthetics are bridging this gap. A major advantage is washability; many synthetics can be welded over without cleaning or wash off easily with plain water, streamlining the production line.

Type 4: Vanishing Oils (Evaporative)

Vanishing oils, also known as evaporative lubricants, are specialized fluids designed to eliminate the cleaning process entirely. They are formulated with a high percentage of fast-evaporating solvents (like mineral spirits) carrying a small amount of lubricity additives. After the stamping hit, the carrier solvent evaporates into the air, leaving behind an imperceptible, dry film that typically does not interfere with painting or packaging.

These lubricants are the preferred choice for light-duty stamping of parts where aesthetics are critical, such as appliance panels, architectural trim, or electronic connectors. They solve the "bottleneck" problem of wash stations, allowing parts to move directly from the press to assembly or shipping.

The trade-off is performance and safety. Vanishing oils offer very low lubricity and are unsuitable for anything beyond light forming or blanking. Furthermore, the evaporation process releases Volatile Organic Compounds (VOCs), which may require specialized ventilation systems to meet environmental regulations and protect worker health. Flammability is also a concern, requiring strict safety protocols around the press.

Conclusion

Optimizing your metal stamping process requires matching the lubricant not just to the press, but to the entire production lifecycle. While straight oils offer unmatched tool protection for heavy-duty forming, their cleaning costs can kill profitability on lighter jobs. Conversely, vanishing oils offer process speed but fail under high pressure. The most efficient manufacturers often utilize a mix of these four types—Straight, Soluble, Synthetic, and Vanishing—across different lines to maximize both tool life and process flow. Always test new lubricants on a small scale to verify washability and material compatibility before full implementation.

Frequently Asked Questions

1. What are the 4 main types of stamping lubricants?

The four primary categories are Straight Oils (petroleum-based, no water), Soluble Oils (emulsions of oil in water), Synthetics (chemical solutions with no oil), and Vanishing Oils (solvent-based evaporative fluids). Each serves a specific niche ranging from heavy-duty drawing to light-duty, no-clean blanking.

2. Can I use WD-40 for metal stamping?

While WD-40 is a popular general-purpose penetrant and light lubricant, it is generally not recommended for industrial metal stamping. It lacks the extreme pressure (EP) additives and viscosity required to protect tooling during high-tonnage deformation. Using it can lead to premature die wear, galling, and inconsistent part quality in a production environment.

3. What is the difference between drawing and stamping lubricants?

"Stamping" is a general term that includes cutting, blanking, and forming, while "drawing" specifically refers to stretching metal into a die. Drawing lubricants (often straight oils or heavy pastes) require much higher lubricity and barrier protection to prevent the metal from tearing or welding to the die as it stretches. General stamping lubricants may prioritize cooling and chip flushing over extreme pressure performance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —