Mastering Stamping Die Maintenance for Peak Performance

TL;DR

Effective stamping die maintenance relies on a proactive, systematic approach. Best practices involve a regular schedule of cleaning, inspection, sharpening, and proper lubrication to prevent production failures before they start. This strategy not only ensures consistent part quality but also significantly reduces costly downtime and extends the operational lifespan of your tooling.

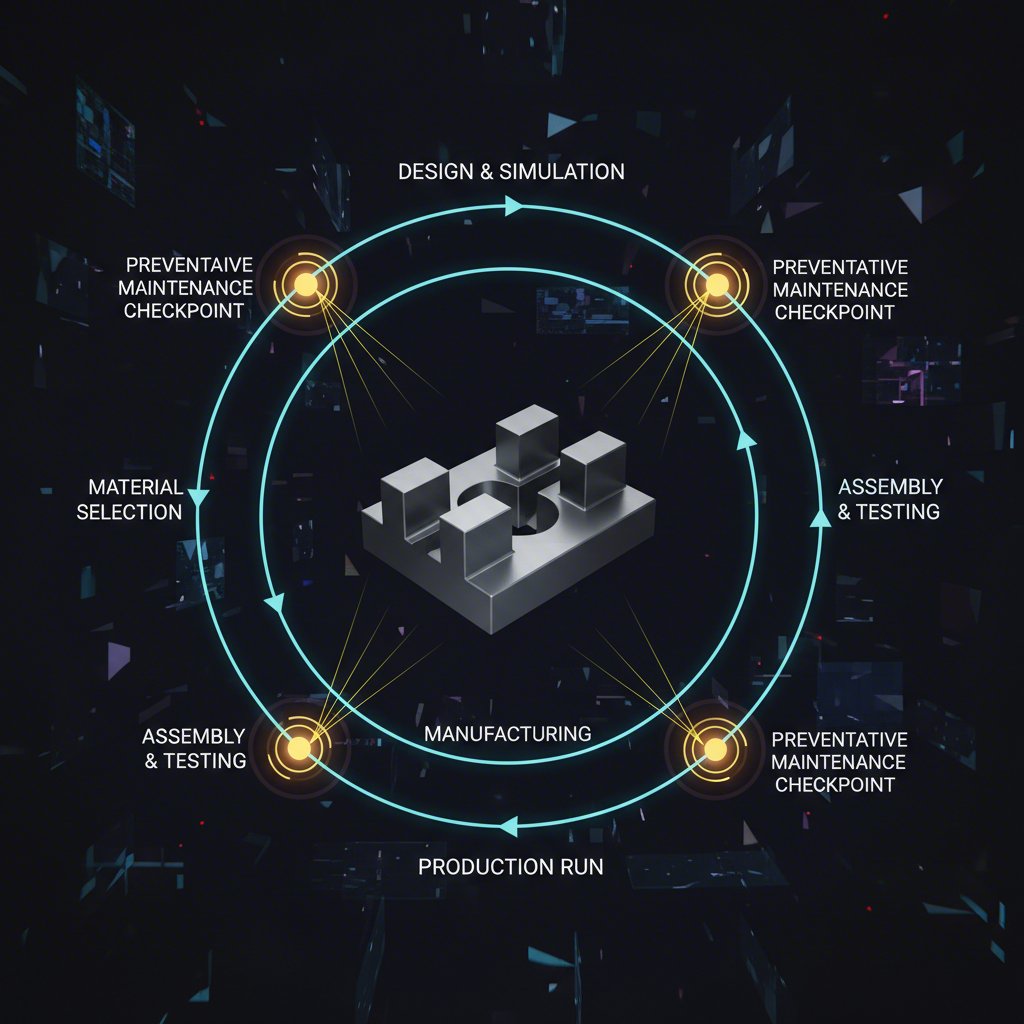

The Core Principle: Proactive vs. Reactive Maintenance

The foundation of any successful stamping die maintenance program is the shift from a reactive to a proactive mindset. Reactive maintenance—addressing problems only after they occur—is a recipe for operational inefficiency. It leads to unexpected breakdowns, emergency repairs, increased scrap rates, and costly production halts that disrupt schedules and harm profitability. A poorly defined maintenance process can dramatically decrease press line productivity and introduce significant hidden costs.

In contrast, proactive, or preventative, maintenance is a strategic approach focused on routine inspections and scheduled servicing to identify and correct minor issues before they escalate. As detailed by experts at JV Manufacturing Co., this method ensures tools remain in top condition, enhancing their durability and extending their lifespan. By addressing wear and tear during planned downtime, manufacturers can maintain a continuous workflow, achieve more stable and predictable maintenance budgets, and avoid the financial burden of emergency fixes.

The operational and financial differences between these two strategies are stark. A proactive approach improves equipment reliability, reduces the need for expensive part replacements, and ensures a safer manufacturing environment by mitigating the risk of equipment malfunctions. Adopting a proactive stance is not just about fixing parts; it's about controlling the entire manufacturing process to guarantee consistency and quality.

Proactive vs. Reactive Maintenance: A Comparison

| Factor | Proactive Maintenance | Reactive Maintenance |

|---|---|---|

| Cost | Predictable, budgeted costs for scheduled servicing. | High, unpredictable costs for emergency repairs and overtime. |

| Press Uptime | Maximized, with maintenance scheduled during planned downtime. | Frequent, unplanned downtime that halts production. |

| Part Quality | Consistent and high, meeting quality standards. | Inconsistent, with higher defect and scrap rates. |

| Tool Lifespan | Significantly extended through regular care. | Shortened due to excessive wear and unexpected failures. |

Essential Die Maintenance Procedures: A Detailed Checklist

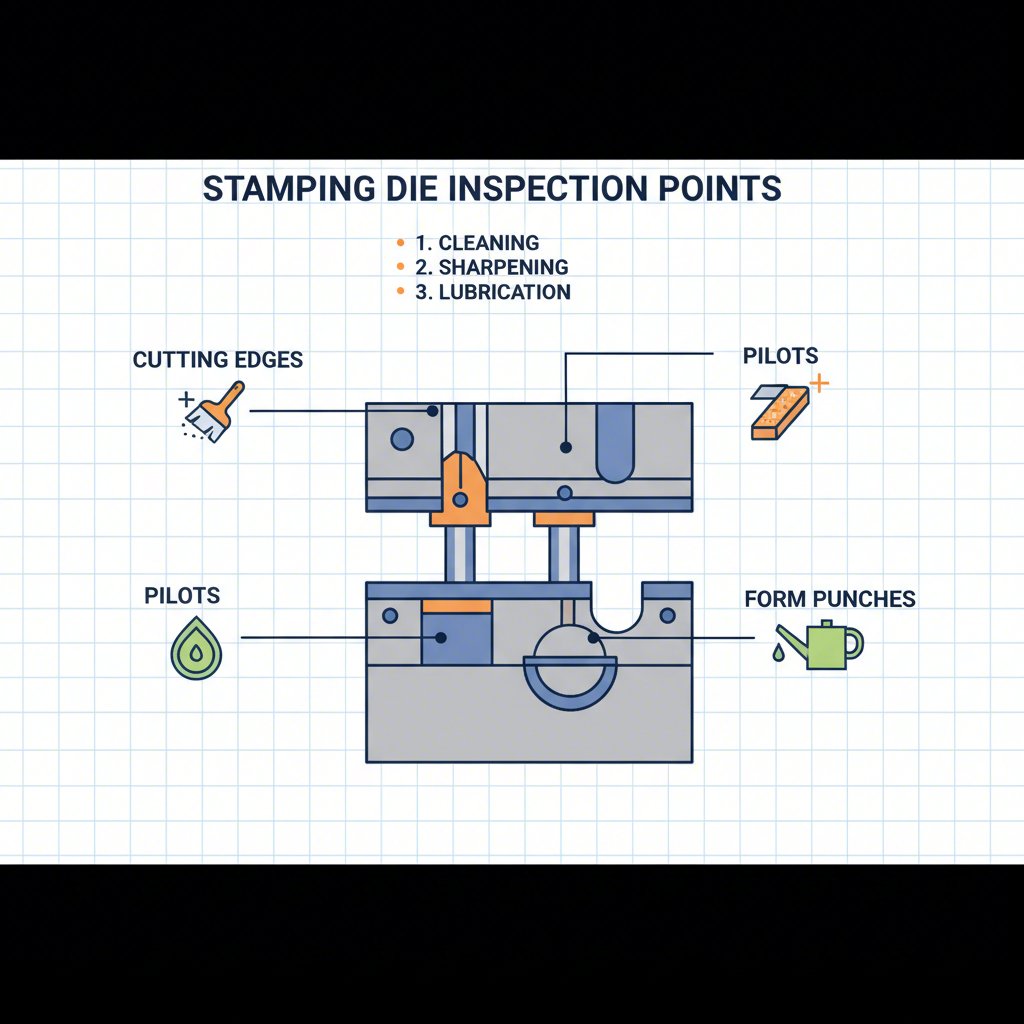

A comprehensive maintenance routine is built on a foundation of specific, repeatable tasks. The most common types of die maintenance include cleaning, sharpening, shimming, and component inspection or replacement. Mastering these procedures is essential for preserving the die's integrity and ensuring the quality of every part produced. A well-maintained die facilitates a consistent outcome, which is a cornerstone of quality workmanship.

Regular cleaning and inspection are the first lines of defense. During these checks, technicians should look for tell-tale signs of trouble, such as loose fasteners, missing components, excessive debris like metal slivers, or insufficient lubrication indicated by black grease. These visual cues can prevent minor issues from evolving into full-blown production problems. For complex tooling, such as those used in the automotive sector, partnering with specialists can ensure maintenance aligns with the original design intent. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd., which specialize in custom automotive stamping dies, bring a level of expertise that helps maintain the precision required for high-stakes manufacturing.

Sharpening is another critical task. The cutting sections and punch edges of a die naturally wear down over time, which can lead to burrs and inaccuracies in stamped parts. Periodic sharpening using a grinding wheel restores the original geometry and precision, preventing these defects from impacting the production run. Similarly, shimming may be necessary to ensure each station in a progressive die maintains proper timing and alignment, which is crucial for complex operations.

Comprehensive Die Inspection Checklist

- Cleaning: Remove all debris, metal shavings, sludge, and built-up lubricants from die surfaces. Ensure all components are free of contaminants before and after maintenance.

-

Inspection:

- Check for loose or broken fasteners, worn springs, and degraded lifters.

- Examine die shoe guideposts for galling or uneven wear.

- Inspect pilots for wear and proper length.

- Review all form punches and die sections for measurable wear, chips, or side galling.

- Verify punch lengths and heights to ensure proper timing and configuration.

-

Sharpening:

- Review all cutting sections for wear and sharpen as needed to maintain crisp, clean cuts.

- Ensure the grinding process restores the original geometry without removing excessive material.

-

Lubrication:

- Confirm that all moving parts are adequately lubricated according to manufacturer specifications.

- Check for signs of insufficient lubrication, such as excessive heat generation or corrosion.

Implementing a Robust Maintenance Schedule and Documentation

Beyond the physical tasks, best-in-class die maintenance relies on a systematic process of scheduling and documentation. Establishing a structured program is the foundation of effective upkeep, ensuring that all equipment is regularly attended to. The frequency of maintenance should be based on usage levels, production volume, and the complexity of the die. A die used daily in a high-volume run will naturally require a more rigorous schedule than one used infrequently.

A critical component of this system is the work order. As Phoenix Group explains, a work order system allows an organization to document, track, prioritize, and schedule all die repair and maintenance activities. It serves as a vital communication tool that identifies the root problem, outlines corrective steps, and records the work performed. This documentation is invaluable for tracking recurring issues and preventing future failures.

Creating and maintaining a detailed maintenance log is another essential practice. This log should capture the date of service, the work performed, any parts that were replaced, and observations about the die's condition. Over time, this data helps identify wear patterns and allows for more accurate predictive maintenance, enabling teams to address potential failures before they happen. Consistency in documentation ensures that every service technician performs tasks the same way, leading to predictable and reliable results.

Sample Maintenance Log

| Date | Die ID | Work Performed | Parts Replaced | Technician | Observations/Notes |

|---|---|---|---|---|---|

| YYYY-MM-DD | DIE-123-A | Cleaned, sharpened cutting edges, checked pilots. | Pilot #4 (worn) | J. Doe | Minor wear on form punch; monitor in next cycle. |

| YYYY-MM-DD | DIE-456-B | Full inspection, lubrication, and timing adjustment. | None | S. Smith | Die operating within specifications. |

Advanced Topics: Lubrication, Storage, and Continuous Improvement

A holistic approach to die care extends beyond the press and the toolroom. Proper lubrication, storage, and a commitment to continuous improvement are advanced practices that separate good maintenance programs from great ones. Lubrication is critical for reducing friction between moving surfaces, which prevents the excessive heat generation that leads to material fatigue and failure. It also protects against corrosion and contamination.

The choice of lubricant is not trivial; different types are suited for different operational conditions. For example, oils are versatile for machinery, while greases are better for bearings and joints where liquid lubricants are impractical. Dry lubricants like PTFE are ideal for applications where oil or grease could cause contamination.

Proper storage is equally important for preserving a die's condition when it is not in use. Dies should always be cleaned and lubricated before being stored in a controlled environment where temperature and humidity are regulated. As highlighted by Lijian Stamping Mold, using protective racks or cases can prevent physical damage and contamination during storage, ensuring the die is in optimal condition for its next production run.

Finally, the ultimate goal of a maintenance program should be continuous improvement. As Thomas Vacca notes in The Fabricator, once you achieve consistent, measurable results, you can begin to improve the tool's robustness, extend its life, and increase stamping speed. This involves setting SMART goals (specific, measurable, attainable, relevant, time-bound) to track improvements and stay ahead of the competition.

Best Practices for Lubrication and Storage

-

Lubrication Best Practices

- Select the correct lubricant type (oil, grease, dry) based on the application and material.

- Apply lubricants according to manufacturer specifications to avoid over- or under-lubrication.

- Regularly check lubrication systems to ensure they are functioning correctly.

-

Best Practices for Die Storage

- Thoroughly clean and apply a protective lubricant to the die before storage.

- Store dies in a climate-controlled area to prevent rust and corrosion from humidity.

- Use sturdy racks or cases to protect dies from accidental damage.

- Clearly label all stored dies for easy identification and tracking.

Frequently Asked Questions

1. How often should a stamping die be maintained?

The frequency of stamping die maintenance depends on several factors, including the production volume, the material being stamped, and the complexity of the die. For high-volume runs, dies may require inspection and cleaning after every run. A general best practice is to establish a scheduled maintenance program based on the number of hits or production hours and adjust it based on performance data and inspection findings.

2. What are the first signs that a die needs maintenance?

Early warning signs include a decline in part quality, such as burrs on cut edges, dimensional inaccuracies, or surface defects. You might also notice changes in the sound of the press during operation. Visual cues on the die itself, like metal slivers, black or sludgy grease, or visible wear on cutting edges and pilots, are clear indicators that maintenance is required.

3. Can improper maintenance damage a stamping die?

Absolutely. Neglecting maintenance leads to excessive wear, component failure, and potentially catastrophic damage to the die. Likewise, improper maintenance, such as removing too much material during sharpening, using the wrong lubricant, or incorrect shimming, can also degrade performance, reduce the die's lifespan, and lead to poor quality parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —