Stamping Copper Busbars for EVs: Material, Process & Design Mastery

TL;DR

Stamping copper busbars for EVs is a critical manufacturing process that transforms conductive copper alloys into precision power distribution components essential for electric vehicle battery packs, inverters, and motor drives. Unlike standard wiring, stamped busbars offer superior current density, reduced inductance, and robust mechanical stability under vibration. Engineering teams typically select C11000 (ETP) or C10100 (Oxygen-Free) copper to maximize electrical conductivity (up to 101% IACS) while utilizing progressive die stamping to ensure tight tolerances and cost-efficiency at high volumes. Correctly stamped and insulated busbars are vital for managing the high-voltage thermal loads (400V–800V) inherent in modern electric powertrains.

Key Takeaways:

- Material: C11000 is standard; C10100 is preferred for brazing/welding applications.

- Process: Progressive die stamping offers the highest repeatability for mass production.

- Insulation: Epoxy powder coating provides critical dielectric strength for compact battery modules.

EV Busbar Material Selection: C11000 vs. C10100

Selecting the correct copper grade is the foundational decision in designing busbars for electric vehicles. While aluminum is gaining traction for weight reduction in structural components, copper remains the undisputed standard for high-voltage power distribution due to its superior electrical conductivity and thermal properties.

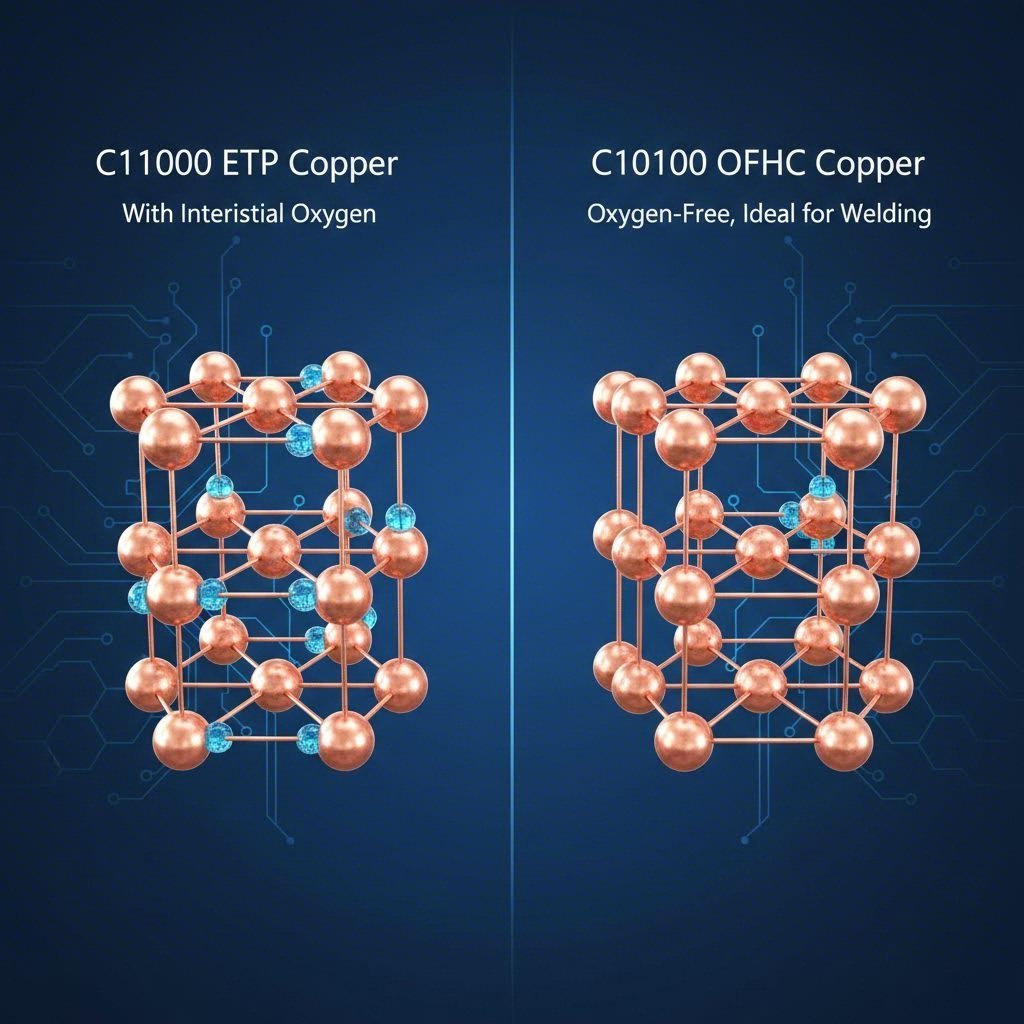

C11000 (Electrolytic Tough Pitch - ETP) is the industry standard for most stamped busbars. It offers a conductivity rating of 100-101% IACS (International Annealed Copper Standard), making it highly efficient for transmitting current with minimal resistance. However, C11000 contains a small amount of oxygen, which can cause embrittlement if the busbar undergoes hydrogen brazing or high-temperature welding.

C10100/C10200 (Oxygen-Free Copper - OFE/OF) is widely specified for complex EV battery interconnects that require extensive welding or brazing. By virtually eliminating oxygen content, these grades prevent the formation of steam within the metal structure during heating, ensuring the structural integrity of the joint. For engineers designing intricate battery modules where space is at a premium, the slight cost premium of Oxygen-Free copper is often justified by its superior formability and joint reliability.

| Feature | C11000 (ETP) | C10100 (Oxygen-Free) |

|---|---|---|

| Conductivity (IACS) | 100-101% | 101% |

| Oxygen Content | ~0.04% | <0.0005% |

| Best Application | General power distribution, bolted connections | Welded battery interconnects, vacuum applications |

| Cost | Standard | Premium |

The Stamping Process: Progressive Die vs. CNC Forming

Manufacturing busbars for electric vehicles requires a balance between precision, speed, and scalability. The choice between progressive die stamping and CNC forming is largely dictated by production volume and design complexity.

Progressive Die Stamping is the methodology of choice for high-volume EV production (typically 10,000+ units). In this process, a strip of copper feeds through a series of stations in a single die. Each station performs a specific operation—punching, coining, bending, or shaving—simultaneously. This ensures that a finished part exits the press with every stroke. Progressive stamping achieves exceptional tolerances (often +/- 0.05mm) and repeatability, which are non-negotiable for automated battery pack assembly lines.

Conversely, CNC Forming is ideal for prototyping and low-volume runs. It uses press brakes to bend precut strips. While flexible, it lacks the speed and unit-cost efficiency of hard tooling. Ideally, manufacturers leverage a partner capable of handling the entire lifecycle. For instance, Shaoyi Metal Technology provides comprehensive stamping solutions that bridge the gap from rapid prototyping to mass production. With press capabilities up to 600 tons and IATF 16949 certification, they enable automotive OEMs to validate designs quickly before scaling to millions of parts without compromising on precision.

Key advantages of stamping over machining include:

- Material Efficiency: Stamping minimizes scrap, a significant cost factor when working with copper.

- Work Hardening: The physical impact of stamping can work-harden the copper, increasing the mechanical strength of the final component.

- Speed: A progressive die can produce hundreds of parts per minute, matching the throughput requirements of gigafactories.

Insulation & Coating: The Powder Coating Advantage

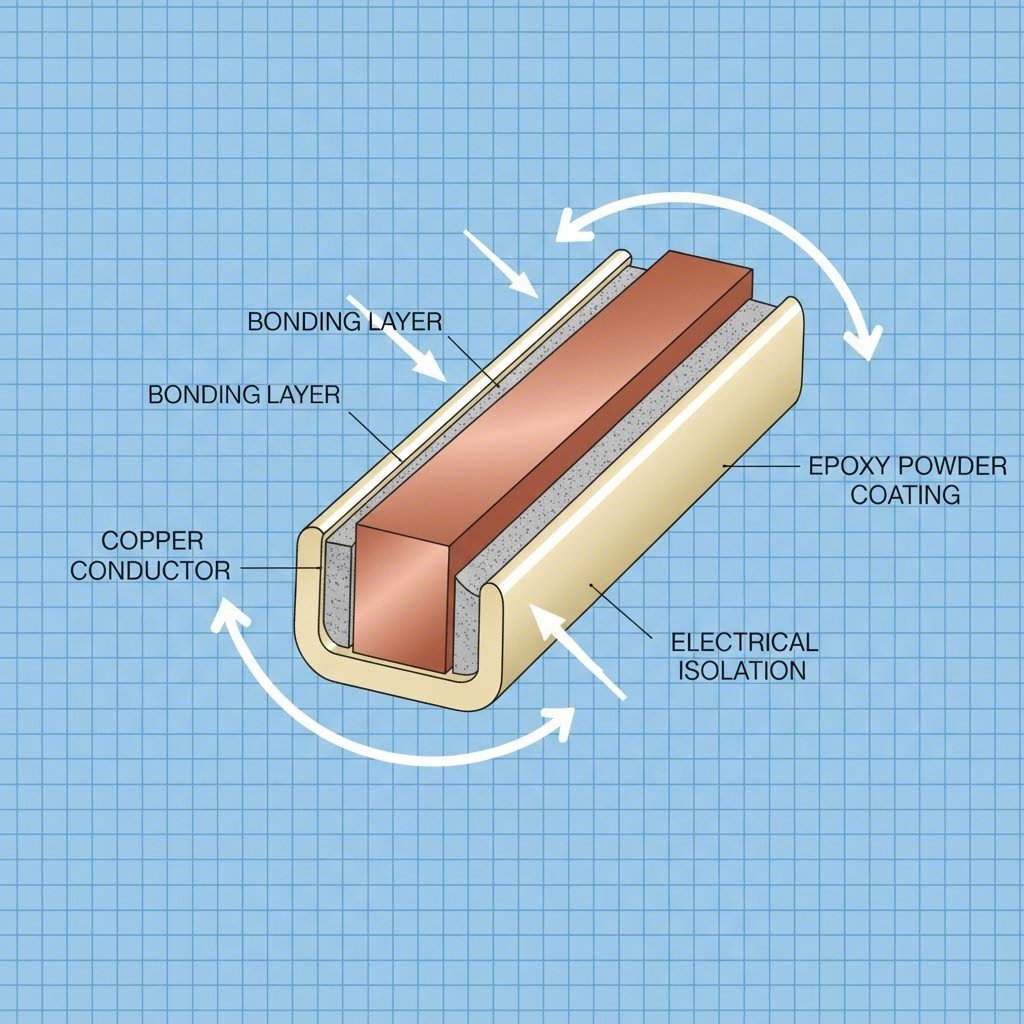

In high-voltage EV architectures (often 400V to 800V+), the insulation of stamped copper busbars is a critical safety feature. Uninsulated bars pose severe arcing risks, especially in the tight confines of a battery pack. While heat shrink tubing and PVC dipping are traditional methods, Epoxy Powder Coating has emerged as the superior solution for complex stamped geometries.

Powder coating involves applying a dry powder—usually epoxy or polyester—electrostatically and then curing it under heat to form a continuous, durable skin. Unlike heat shrink tubing, which can wrinkle or leave air gaps on sharp bends, powder coating bonds directly to the metal surface. This eliminates air voids where partial discharge (corona) could occur. Furthermore, powder coating allows for precise control over coating thickness (typically 0.1mm to 0.5mm), providing high dielectric strength (often >800V per mil) without adding unnecessary bulk.

Comparison of Insulation Methods:

- Epoxy Powder Coating: Best for complex shapes, high heat resistance, and consistent dielectric strength.

- Heat Shrink Tubing: Good for straight runs but difficult to apply to multi-axis bends; lower thermal dissipation.

- PVC Dip: Cost-effective but offers lower thermal ratings (typically 105°C limit) compared to epoxy (130°C+).

Design Challenges: Thermal, Vibration, and Inductance

Designing stamped copper busbars for EVs is not merely about connecting Point A to Point B. Engineers must solve complex physical challenges unique to the automotive environment.

Thermal Management & The Skin Effect: As current flows, it generates heat (I²R losses). In high-frequency switching applications like inverters, the "skin effect" causes current to crowd the surface of the conductor, increasing effective resistance. Stamped busbars with wide, flat profiles maximize surface area, aiding in both cooling and reducing high-frequency resistance compared to round cables.

Vibration Resistance: EVs subject components to constant road vibration. Rigid copper busbars can fatigue and fracture at connection points if not properly dampened. Solutions include designing flexible expansion loops (using laminated copper foils) or utilizing compliant pin press-fit connections that absorb stress.

Low Inductance Design: To improve the efficiency of the EV's power electronics, minimizing stray inductance is crucial. Laminating positive and negative busbars together with a thin dielectric layer (creating a "laminated busbar") cancels out magnetic fields, significantly reducing inductance and protecting sensitive IGBTs (Insulated-Gate Bipolar Transistors) from voltage spikes.

Quality Standards: IATF 16949 and Beyond

The automotive supply chain demands strict adherence to quality standards to ensure safety and reliability. For busbar manufacturers, IATF 16949 certification is the baseline requirement. This standard goes beyond general ISO 9001 quality management to address specific automotive needs, such as defect prevention and supply chain variation reduction.

Crucial quality checks for stamped busbars include:

- PPAP (Production Part Approval Process): A rigorous validation process ensuring the manufacturing process consistently produces parts meeting all engineering specifications.

- Hi-Pot Testing: High-potential testing checks the integrity of the insulation by applying a voltage significantly higher than the operating voltage to ensure no breakdown occurs.

- Burr-Free Finishes: Stamping can leave sharp edges (burrs). In high-voltage applications, a burr acts as a concentration point for electrical stress, potentially leading to arcing. Automated deburring and electropolishing are essential post-stamping steps.

Engineering the Future of EV Power

The transition to electric mobility relies heavily on the hidden backbone of power distribution: the stamped copper busbar. By moving beyond simple metal strips to engineered, insulated, and precision-stamped components, manufacturers ensure the safety, range, and longevity of electric vehicles. Whether utilizing C10100 copper for welded packs or implementing advanced powder coatings for dielectric safety, the choices made during the design and stamping phase ripple through the entire vehicle lifecycle.

For procurement officers and engineers, the goal is clear: partner with manufacturers who understand not just the geometry of stamping, but the physics of electrification. Securing a supply chain that guarantees IATF 16949 quality and offers scalability from prototype to production is the final step in bringing a high-performance EV to market.

Frequently Asked Questions

1. What is the best copper grade for EV busbars?

For most applications, C11000 (ETP) is the best choice due to its excellent conductivity (101% IACS) and cost-effectiveness. However, if the busbar design requires extensive welding or brazing, C10100 (Oxygen-Free) is recommended to prevent hydrogen embrittlement and ensure joint integrity.

2. Why is epoxy powder coating preferred over heat shrink for busbars?

Epoxy powder coating provides superior coverage on complex, stamped geometries where heat shrink tubing might wrinkle or tear. It bonds directly to the copper, eliminating air gaps that could lead to partial discharge, and offers excellent thermal dissipation and high dielectric strength in a thinner profile.

3. How does metal stamping reduce costs for busbar production?

Metal stamping, particularly using progressive dies, significantly reduces costs for high-volume production by combining multiple forming operations into a single machine pass. This reduces labor, increases throughput (hundreds of parts per minute), and minimizes material waste compared to machining or cutting individual bars.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —